A alternating rear beam and its assembly and usage how to use

A technology of backrest and turning frame, which is applied in textiles, papermaking, looms, embossing, etc. It can solve the problems of fabric damage, etc., and achieve the effect of balanced yarn damage, obvious foaming effect, and uniform foaming distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

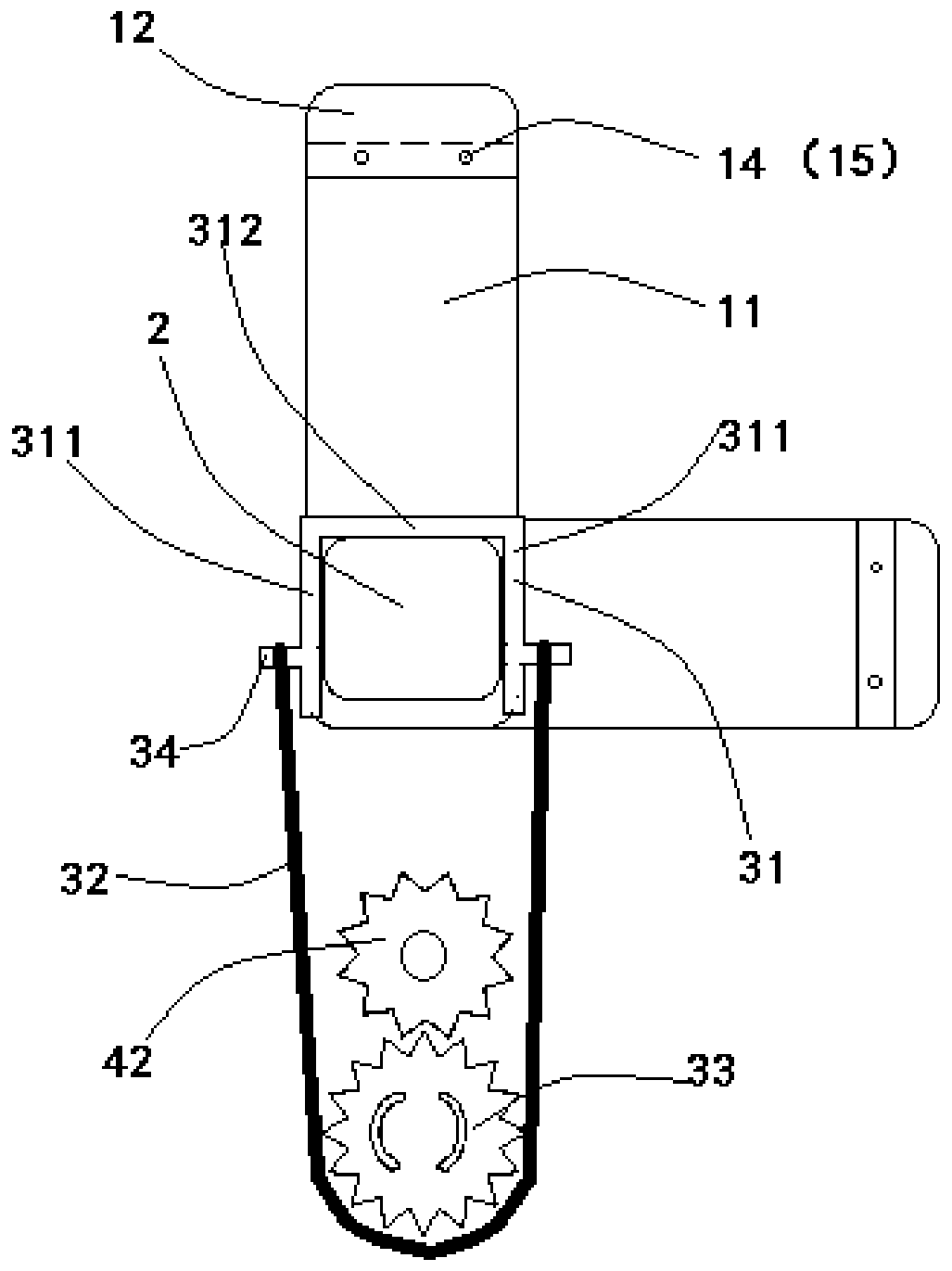

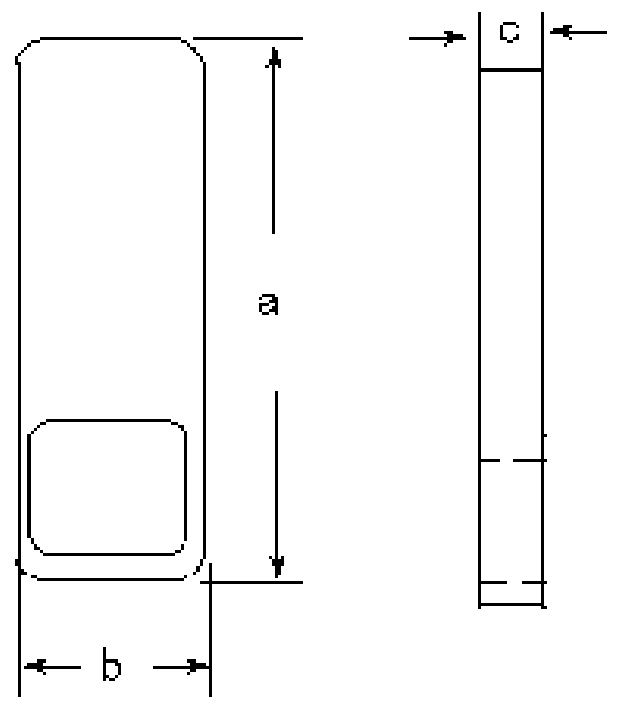

[0034] The invention proposes a 90° misplaced warp bracket and a reversible special back beam, which alternately flips the back beam by means of the mechanical transmission of the weaving movement, so that the warp yarns of adjacent supported sections alternately have a large tension difference, forming an alternating cloth surface. Areas appear embossed with a fancy seersucker effect.

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. But the present invention is not limited to the listed embodiments, but also includes any other known changes within the claimed scope of the present invention.

[0036] Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com