Intelligent float weaving control system

A control system and embossing technology, which is applied in embossing, textiles, papermaking, textiles, etc., can solve the problems of high investment cost, low weaving precision, slow replacement of varieties, etc., and achieve cost-saving transformation, high weaving control accuracy, and structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

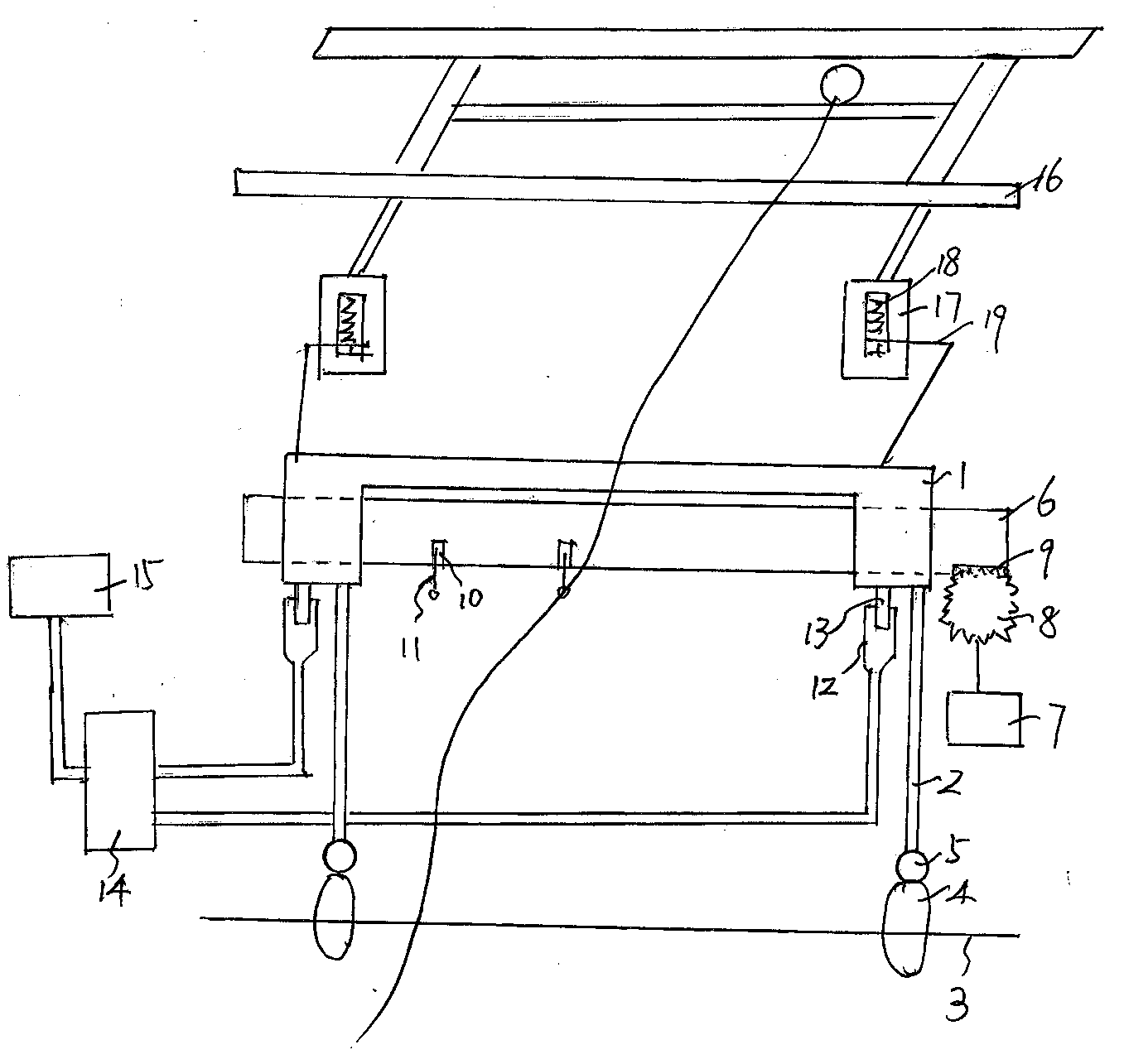

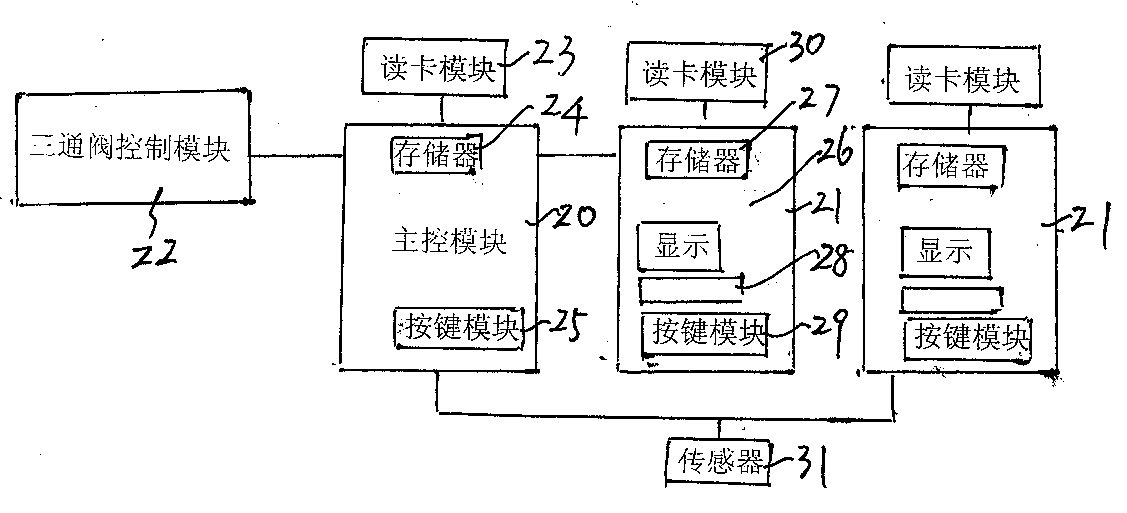

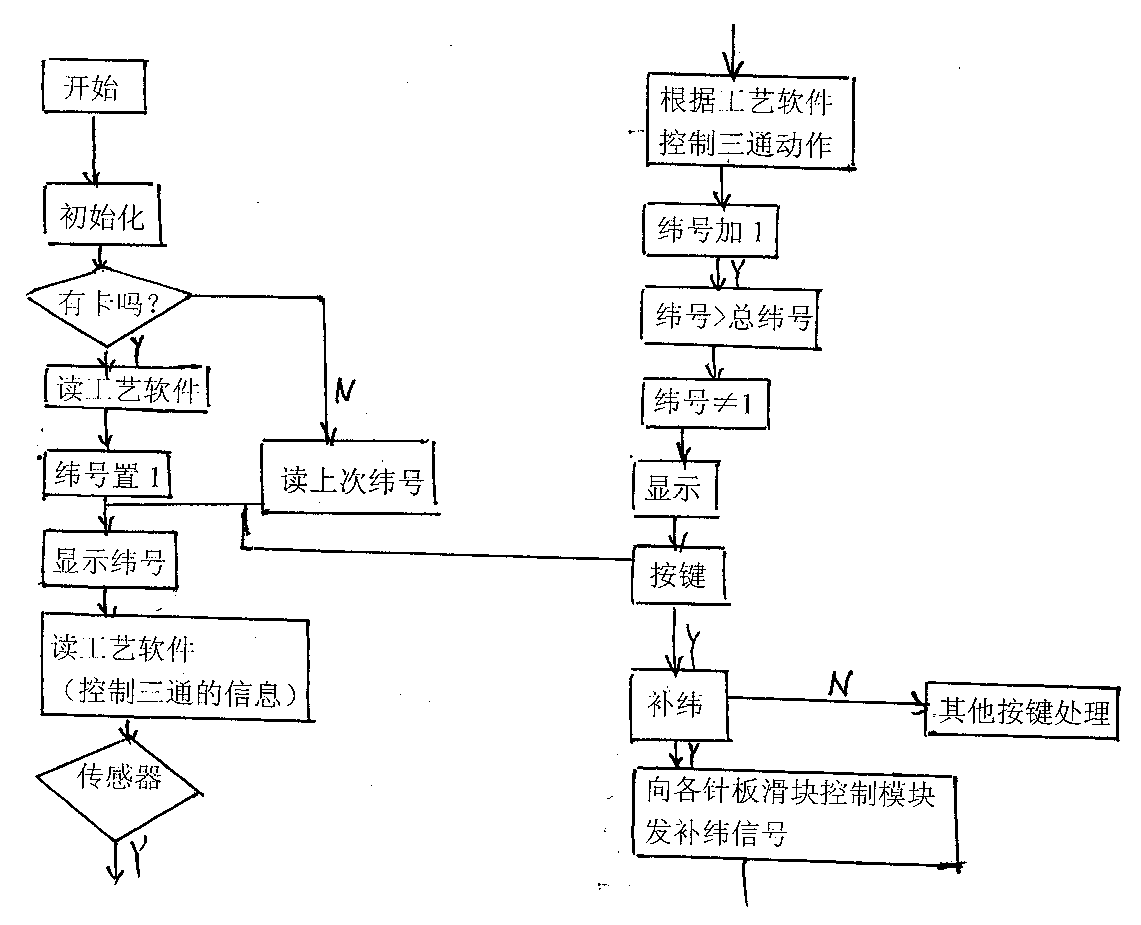

[0015] An intelligent embossed weaving control system, including a mechanical device and a control device; the mechanical device includes a needle plate seat 1, the needle plate seat is connected to a needle plate elevating rod 2, and the lower end of the needle plate elevating rod is mounted on the main shaft 3 of the loom The rotor 5 contacted by the cam 4 drives the lifting action of the needle plate elevating rod through the rotation of the cam, and the upper part of the needle plate seat is connected with the spring return mechanism that resets the needle plate seat; The needle plate slider is equipped with a rack 9 meshed with the gear 8 driven by the stepping motor 7, and the needle plate slider is driven by the gear to slide left and right. There is a knitting needle installation hole 10 at the lower end of the needle plate slider, and the knitting needle installation hole is installed The knitting needle 11 for relief weaving; the left and right cylinder piston rods 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com