Weaving process for Zhuanghua woolen product and weaving equipment thereof

A kind of technology for decorative velvet and products, which is applied in the direction of digging fabrics, textiles, papermaking, fabrics, etc., and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

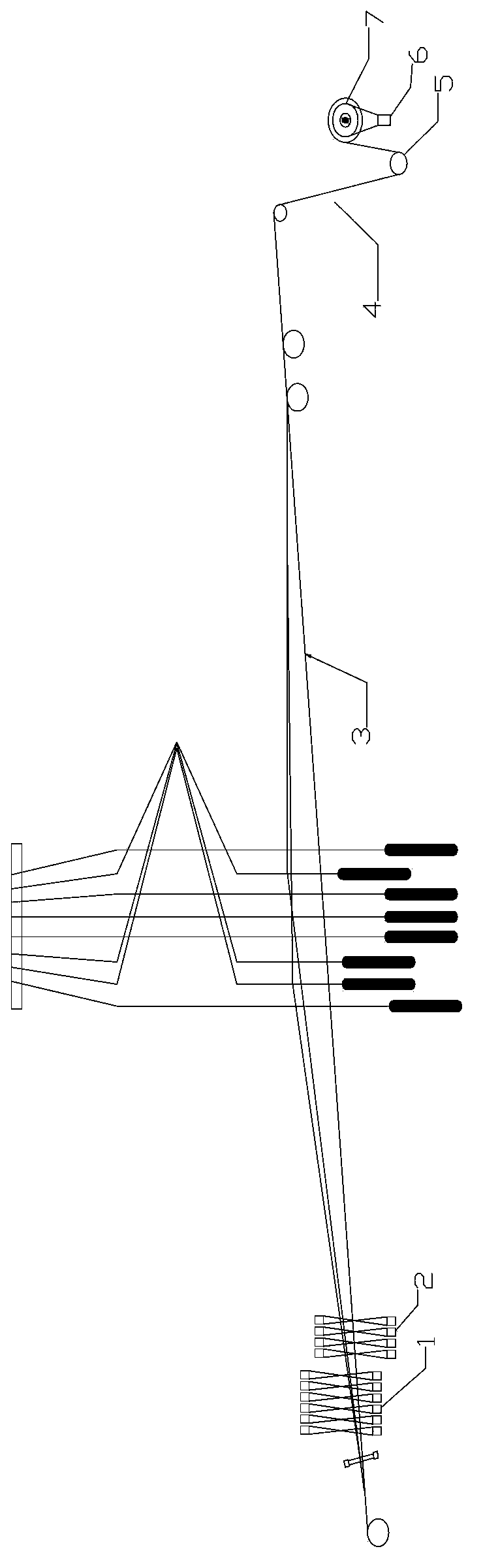

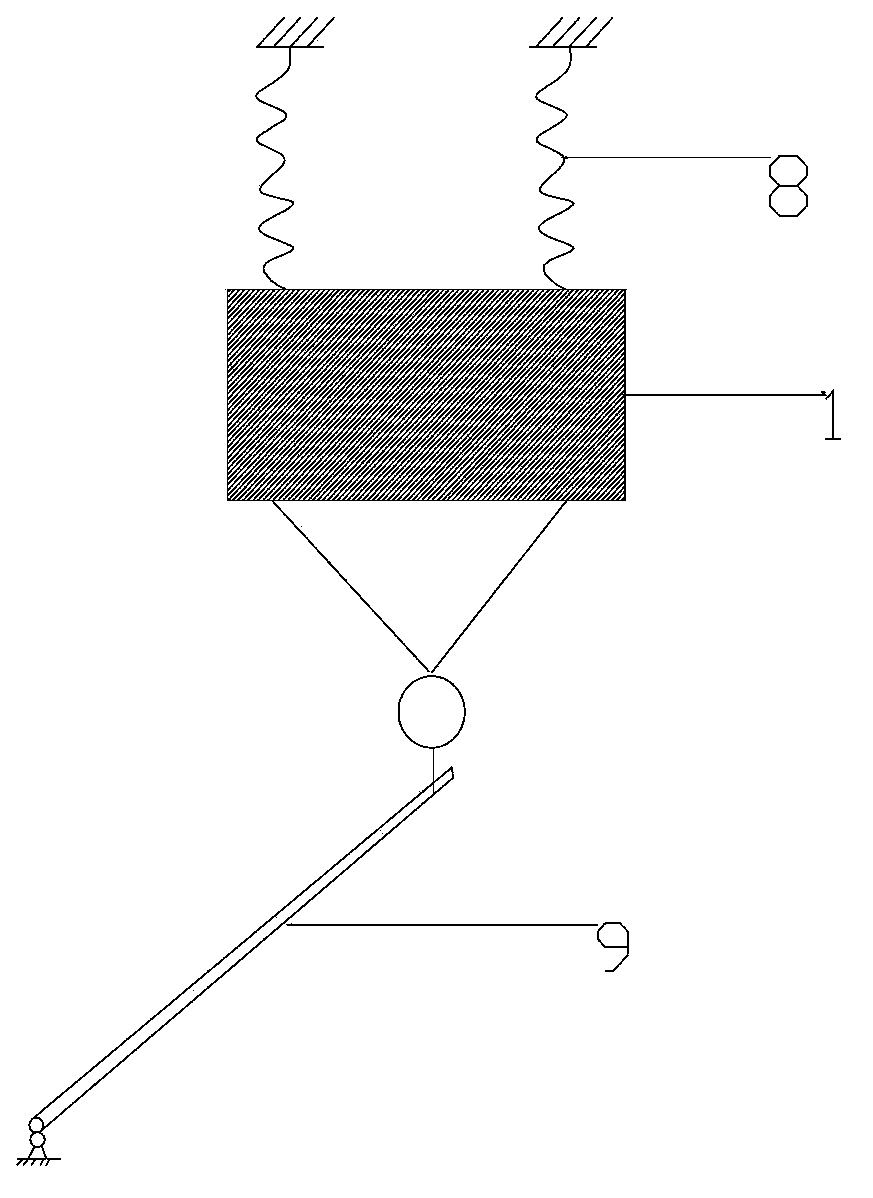

[0024] like figure 1 As shown in a method for weaving cosmetic velvet products according to the present invention, the front side of the fabric must be downward when weaving on the machine (reversed weaving method), comprising the following steps:

[0025] A) First, design the patterns and weaves of the pattern, draw the intentional drawing according to the designed pattern and organization, and then pick out the weft pattern according to the color position of the intentional drawing, and then pick out the flowering position of the pile rod in the same shuttle;

[0026] B) Divide the prepared warps into three layers, the first layer is the cashmere warp group, the second layer is the ground warp group, and the third layer is the joint warp group, in which the ground warp and the joint warp are wound on On the warp beam, the velvet warp is introduced into the jacquard fiber thread; the ground warp is threaded into the heald piece, and the plain weave is regularly threaded into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com