Lace fabric and method of attaching lace fabric to an adherend

A technology of adherend and lace, applied in the direction of fabric, knitting, loom, etc., can solve the problems of uneconomical, inconvenient cutting pattern, inability to separate adhesive film, etc., and achieve the effect of easy to complete the manufacture and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

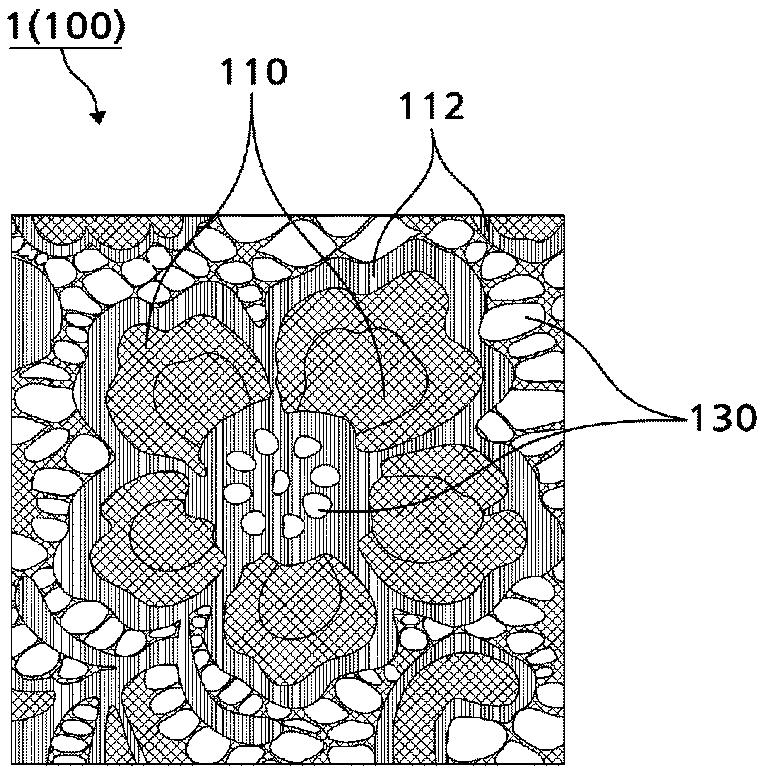

[0038] figure 1An exemplary surface 100 configuration of the lace fabric 1 of the present invention is schematically illustrated. The surface 100 of the lace fabric 1 comprises: a bottom thread layer 110, which is a coverage area (coverage factor) in which the threads of the knitted structure form a surface; and an open area (opening factor) 130, in which no said Knit construction. A lace design pattern is formed on the bottom thread layer 110, and the lace design pattern is provided in a plurality of layers according to the design. In order to express both the density of the knitted structure and the thickness of the threads, as well as the lace pattern and texture, the plurality of layers may include a pattern layer 112 configured to be represented by re-weaving on the surface of the bottom thread layer 110 Floral silk pattern. In other words, the lace design pattern is formed by weaving the pattern layer 112 on the bottom thread layer 110 . According to the pattern laye...

example 2

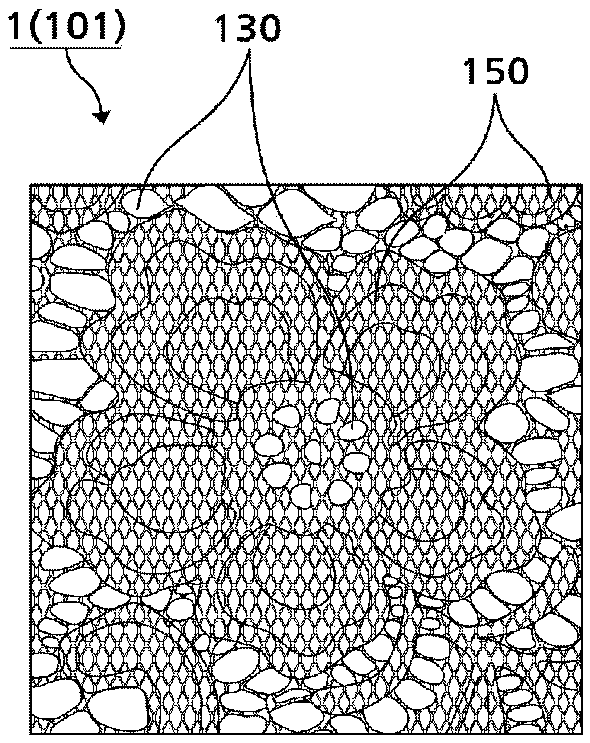

[0054] In the above example 1, the hot-melt coating layer 150 is formed on the rear surface of the lace fabric 1, but the following preferred example 2 of the present invention can be different from the example 1 in the following way: the hot-melt coating is performed on the thread itself of the lace fabric . Other configurations are essentially the same.

[0055] Such as Figure 5A to Figure 5C Shown in, lace fabric of the present invention is to be woven by two kinds of different silk threads. Furthermore, the lace fabric is formed by two different weaving layers. as in Figure 5A Among them, the bottom thread 11 includes a core body 11a and a coating layer 11b. A yarn can be generally used as the core 11a. In the present invention, the hot-melt coating layer 11b is formed on the entire surface of the core body 11a of the bottom wire 11 . Instead, as in Figure 5B As shown in , unlike the bottom thread 11, the surface of the effect thread 12 does not include said hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com