Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

145results about "Flanged connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

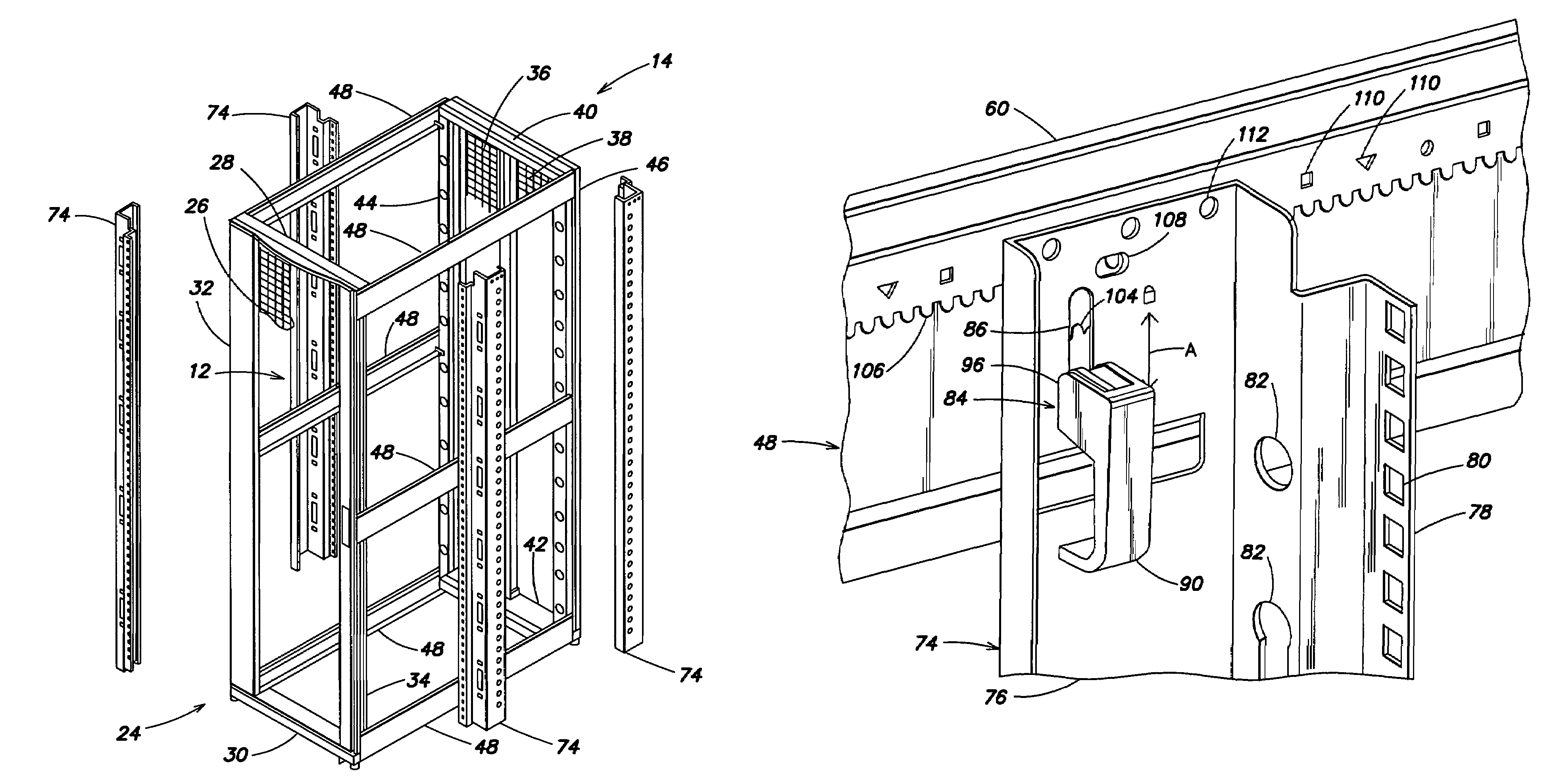

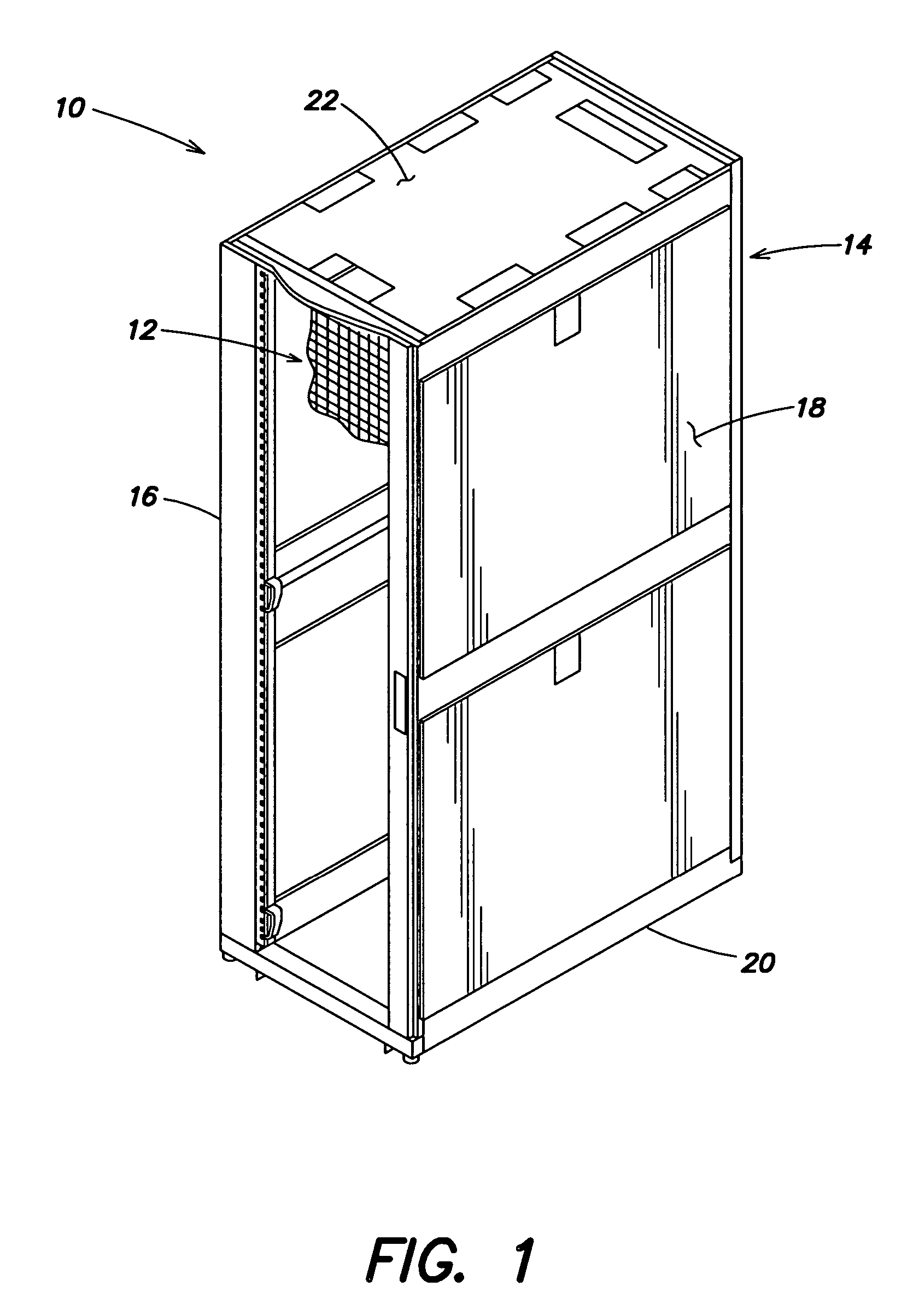

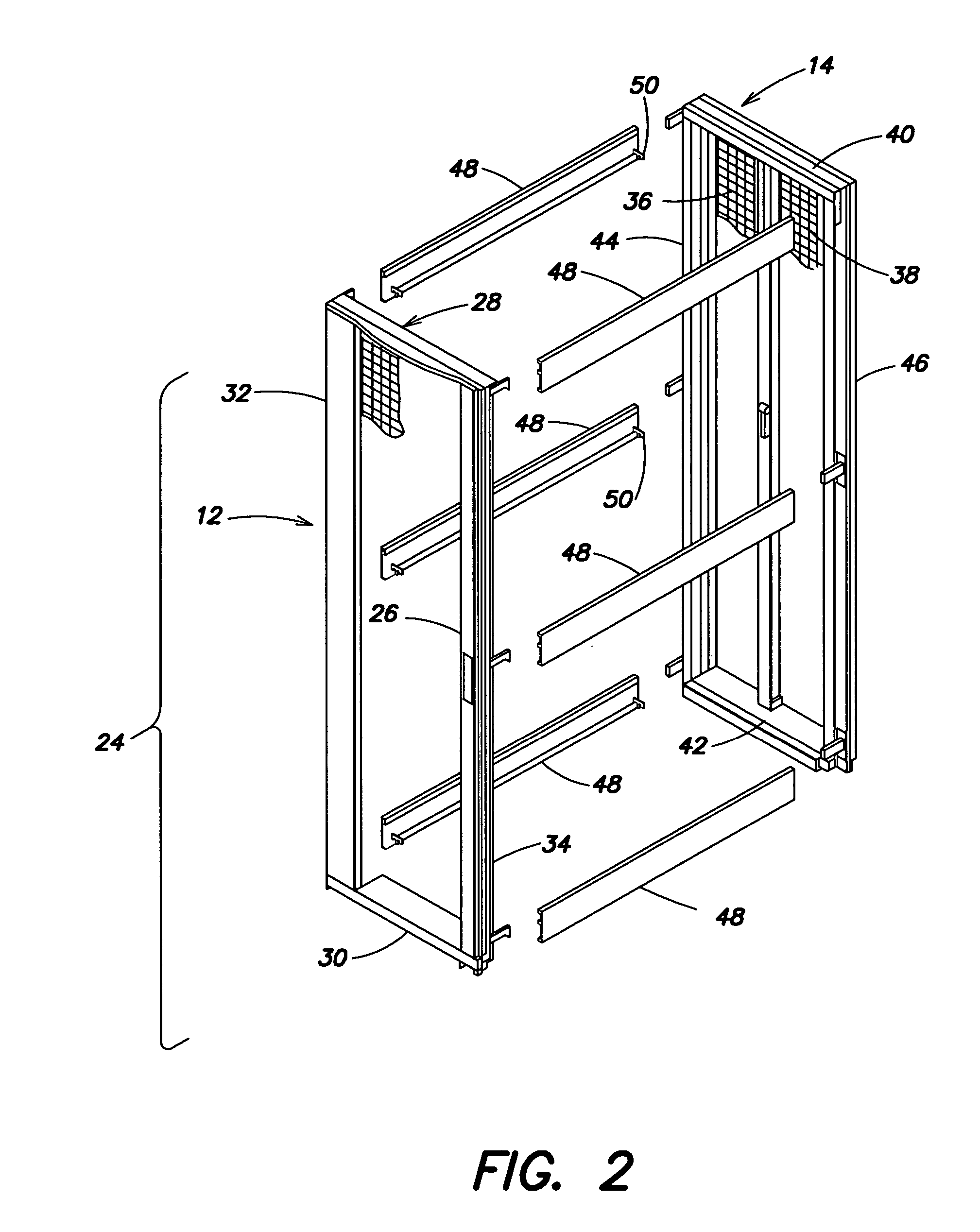

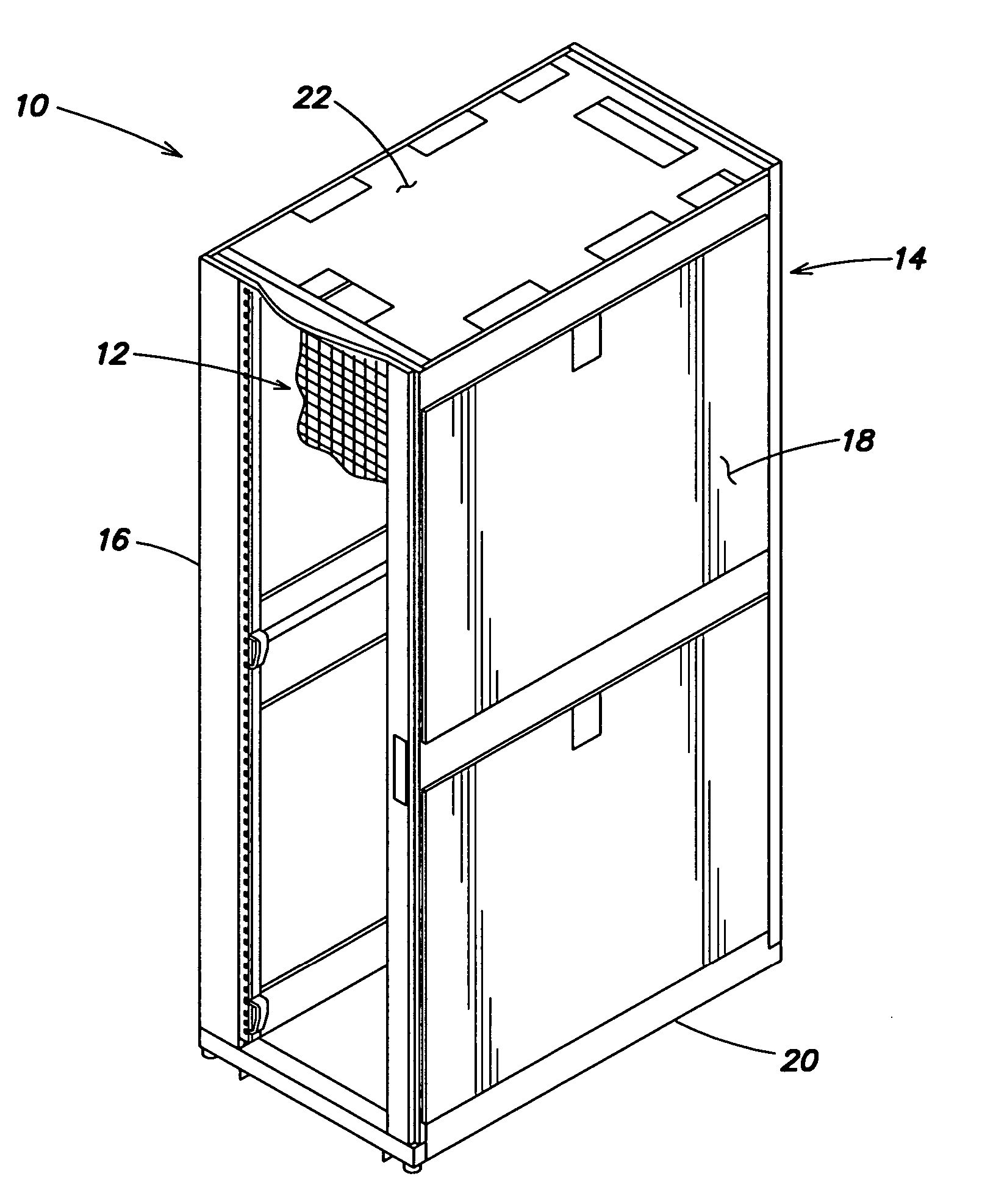

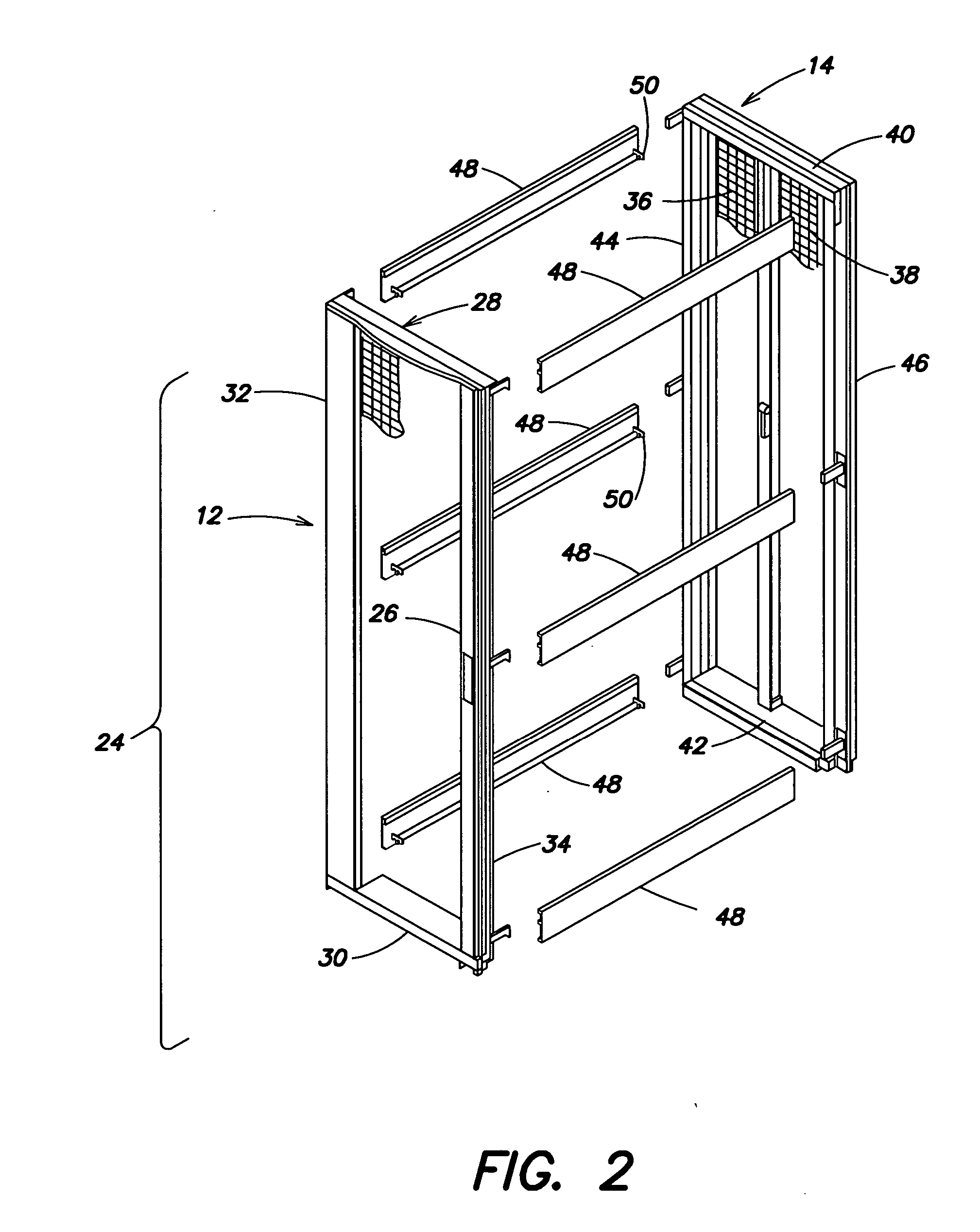

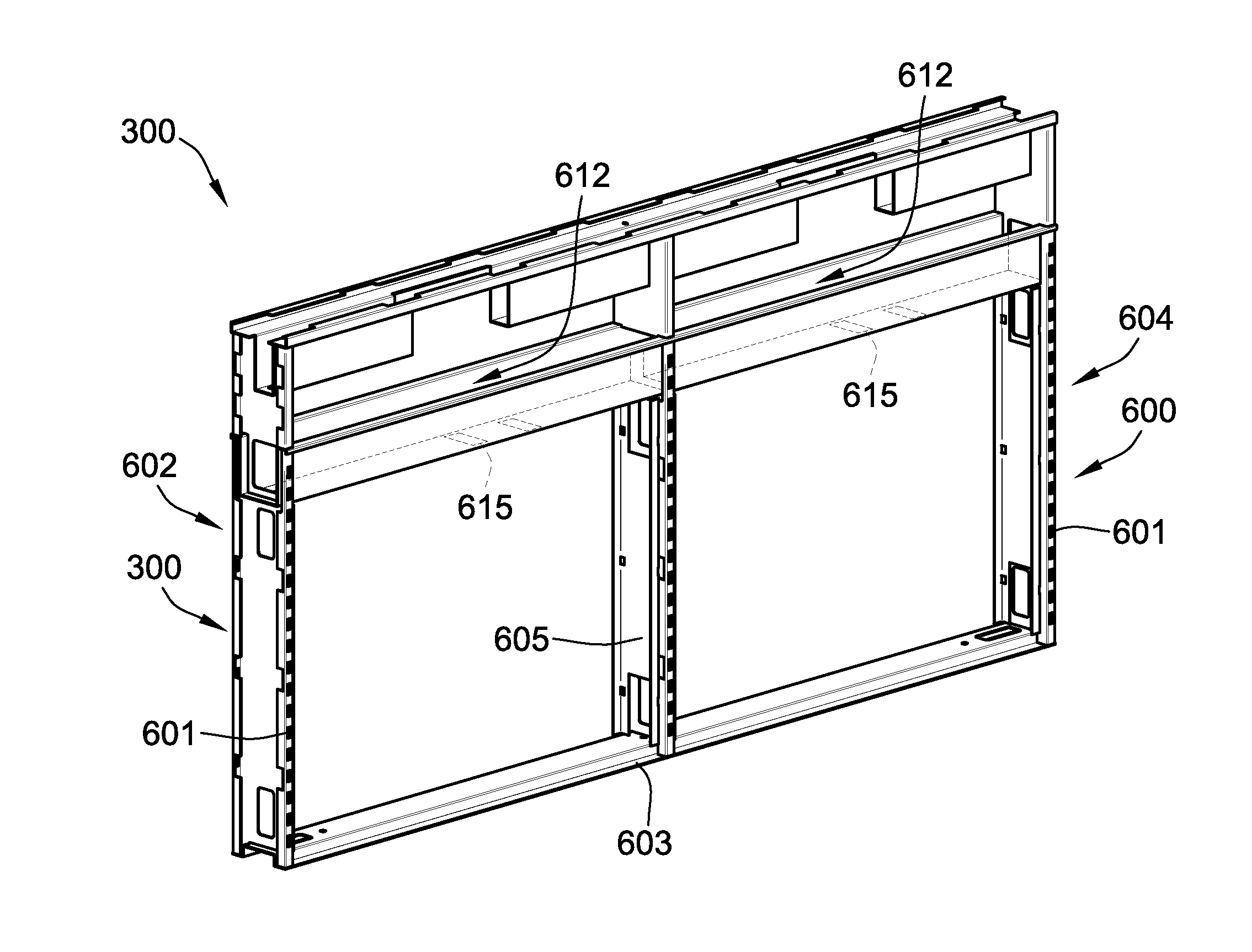

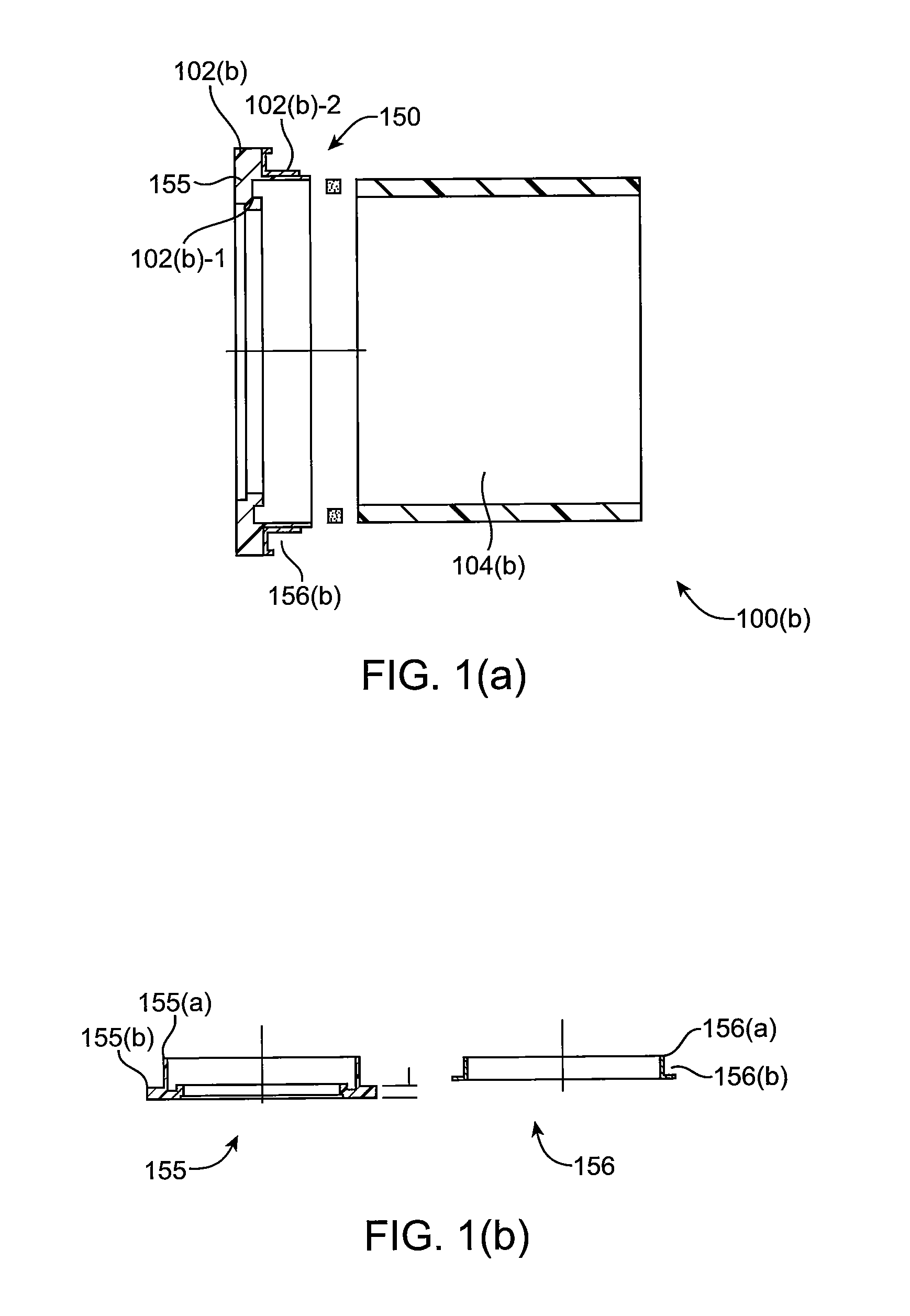

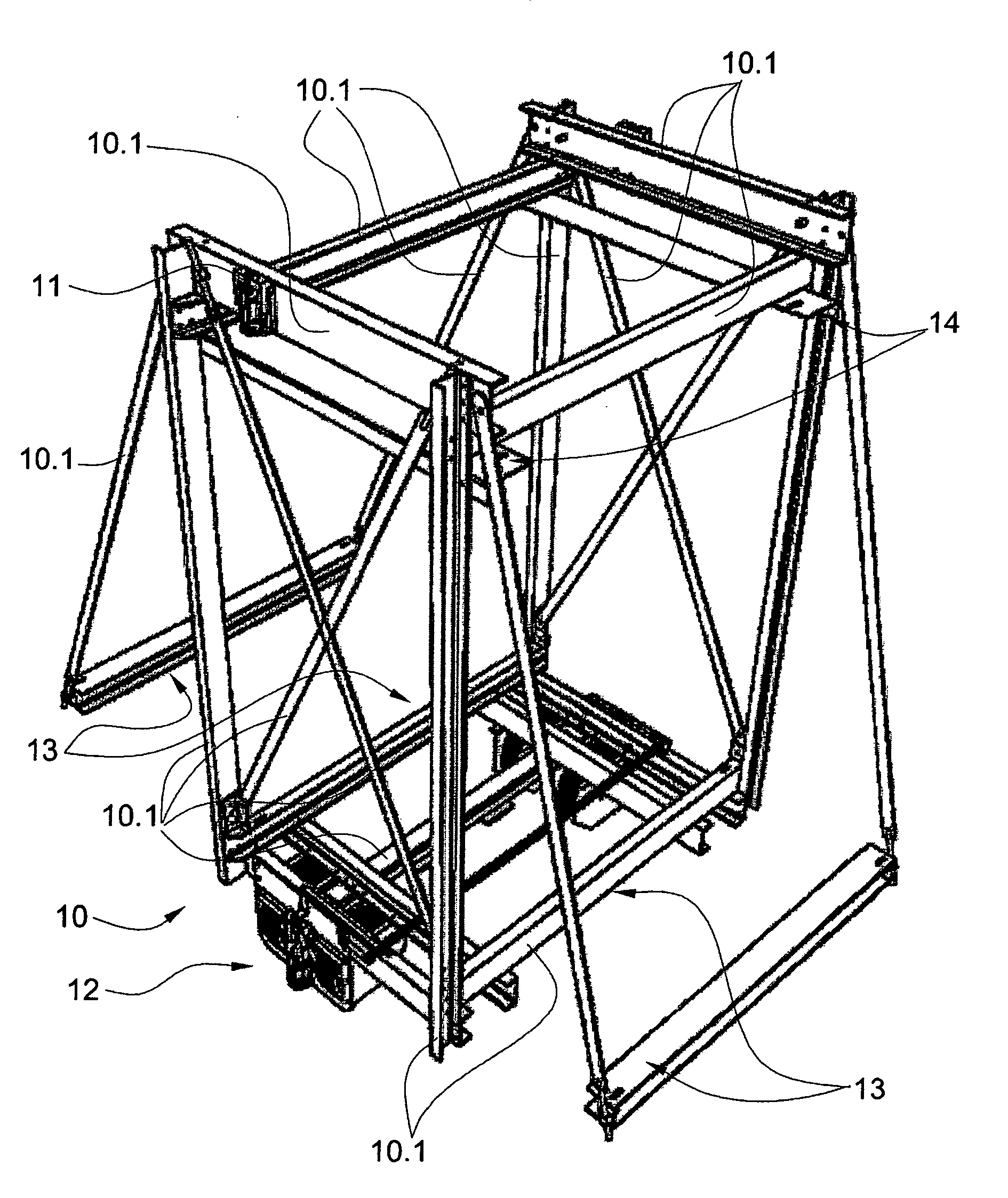

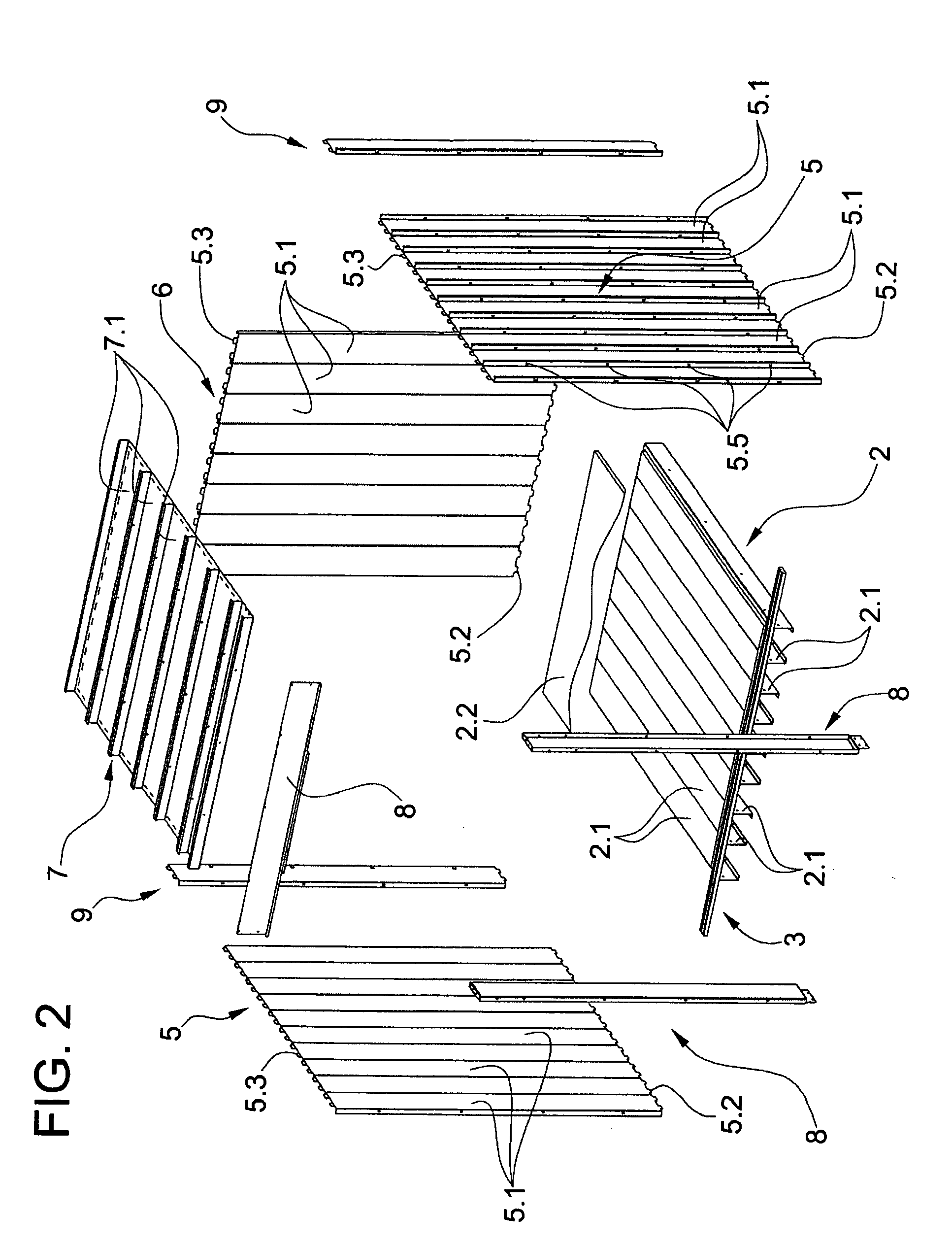

Equipment enclosure kit and assembly method

An equipment enclosure for housing electronic components includes a front assembly having a front frame, the front assembly defining a front of the enclosure, and a rear assembly having a rear frame. The enclosure further includes at least two side brace members, each side brace member having a first end and a second, opposite end. A first connector is configured to releasably connect the first end of one of the side brace members to the front frame. A second connector is configured to releasably connect the second end of the one of the side brace members to the rear frame. Other embodiments and methods are further disclosed.

Owner:SCHNEIDER ELECTRIC IT CORP

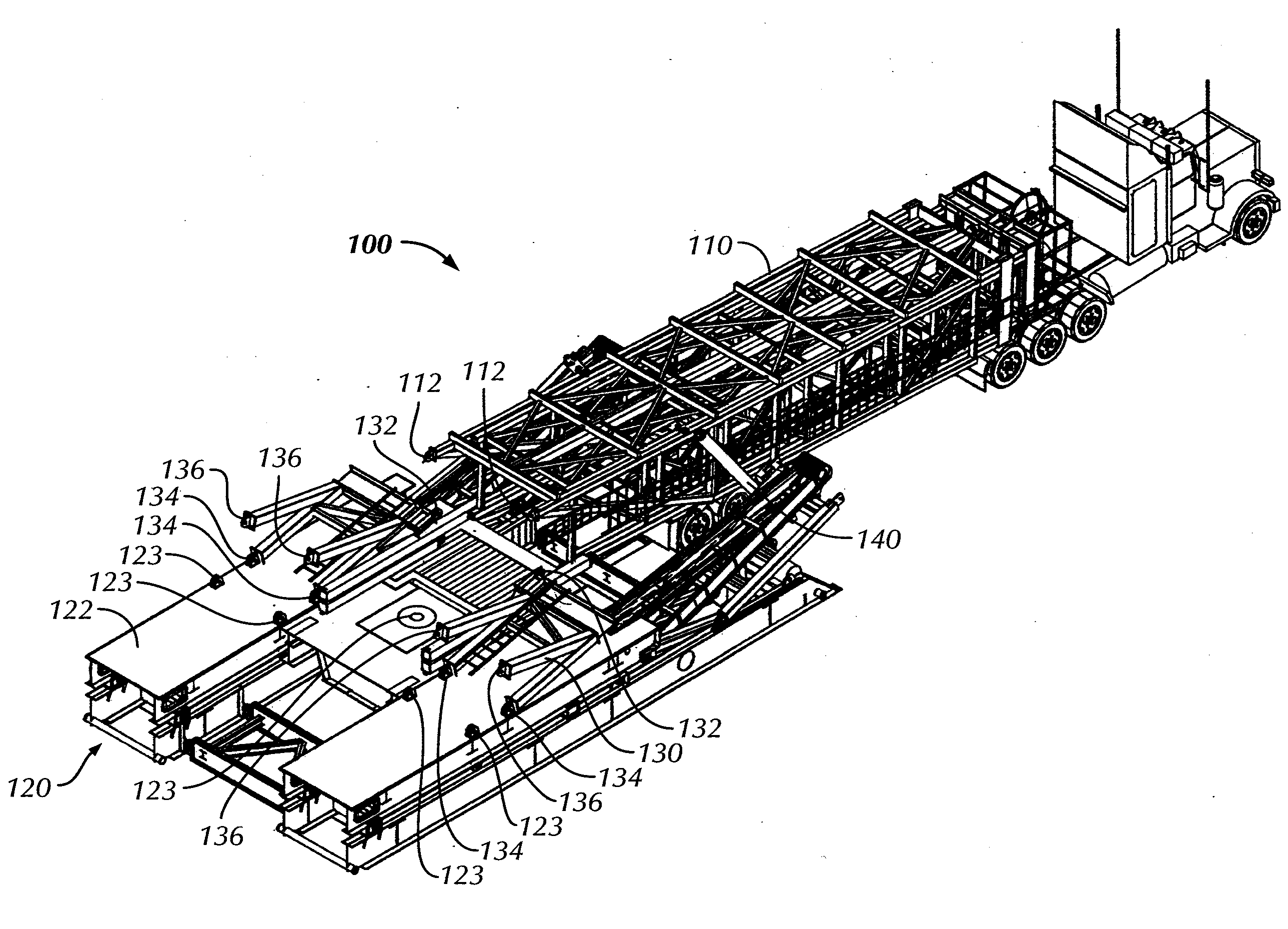

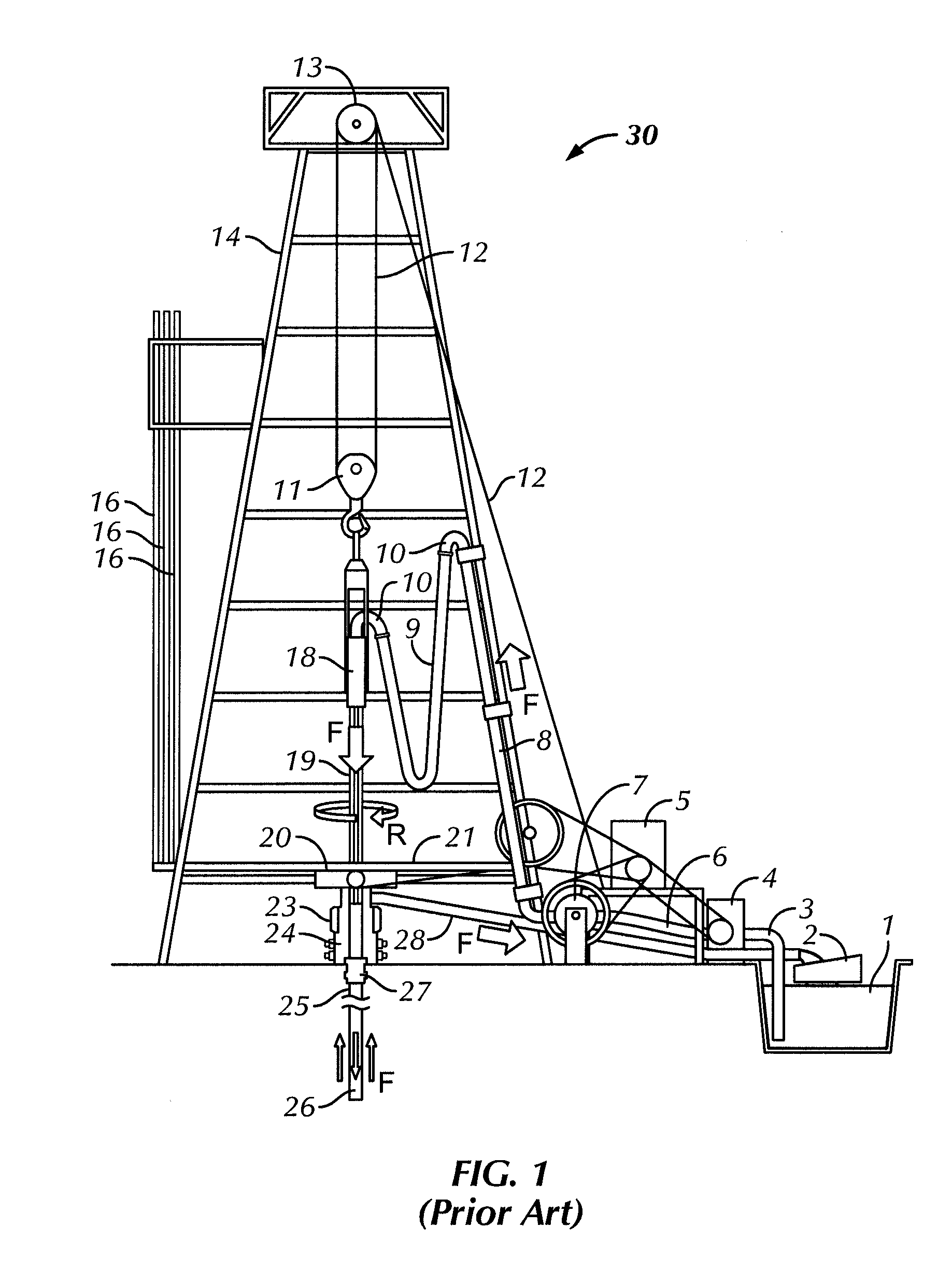

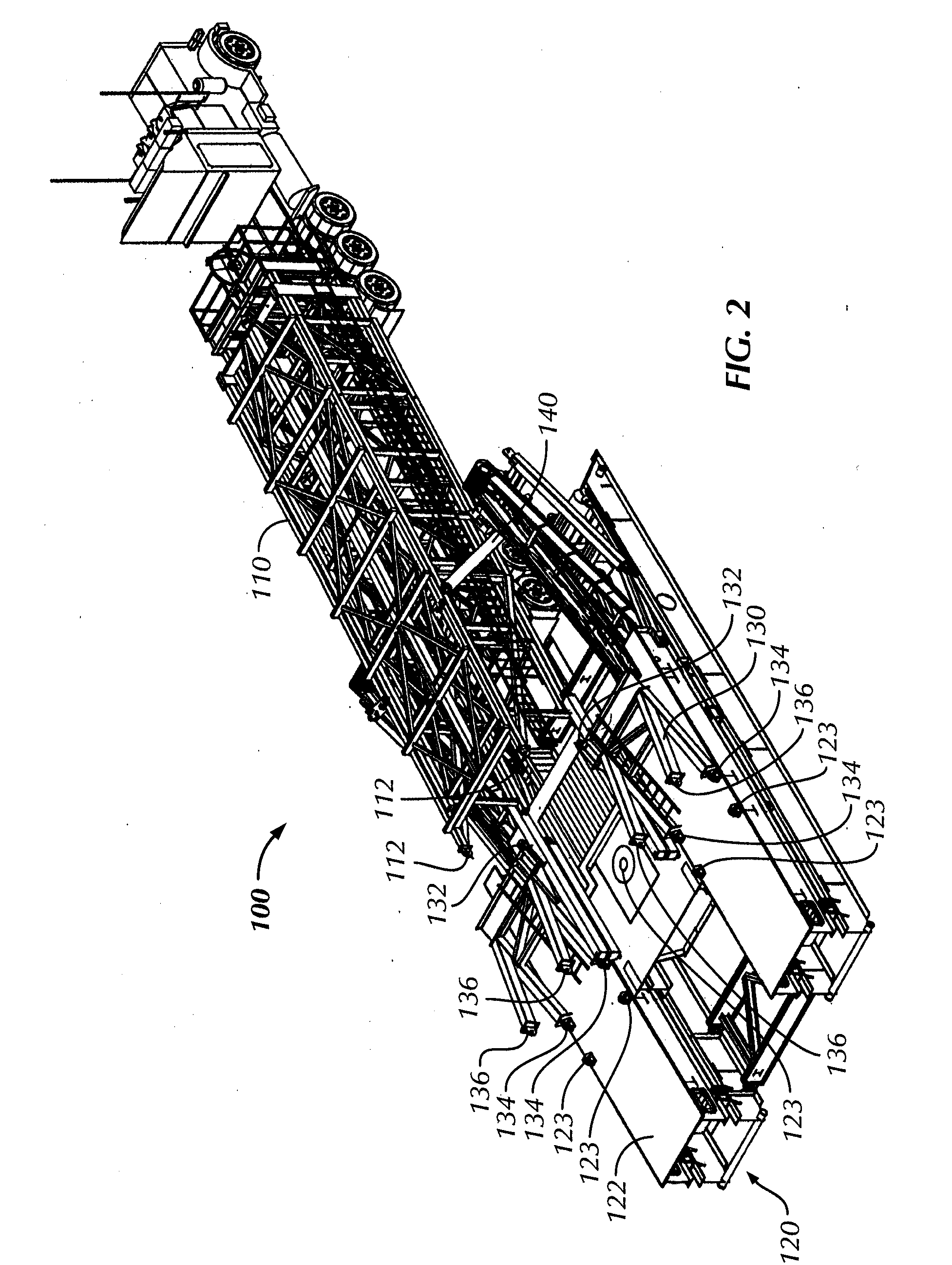

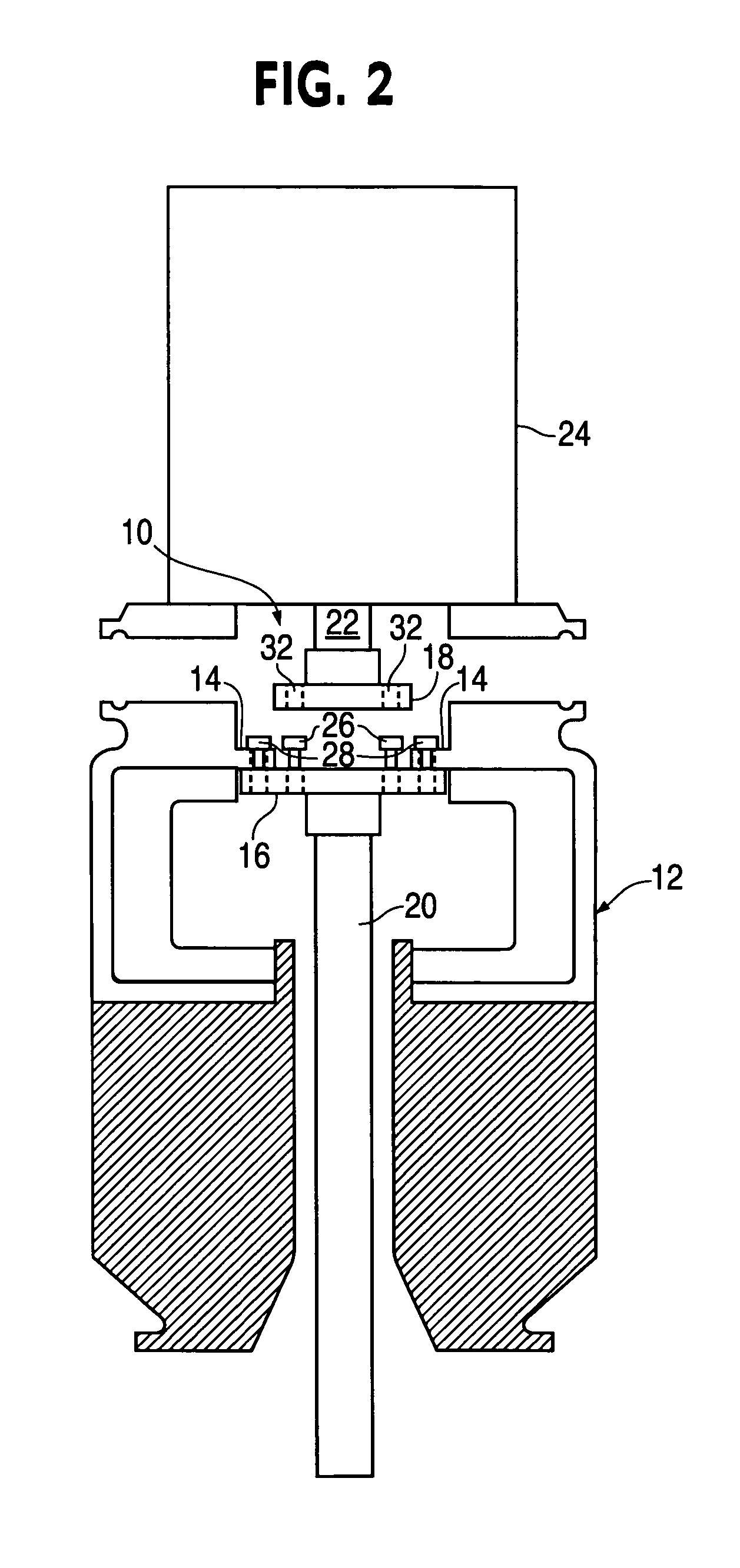

Portable drilling rig apparatus and assembly method

Owner:INTEGRATED DRILLING EQUIP

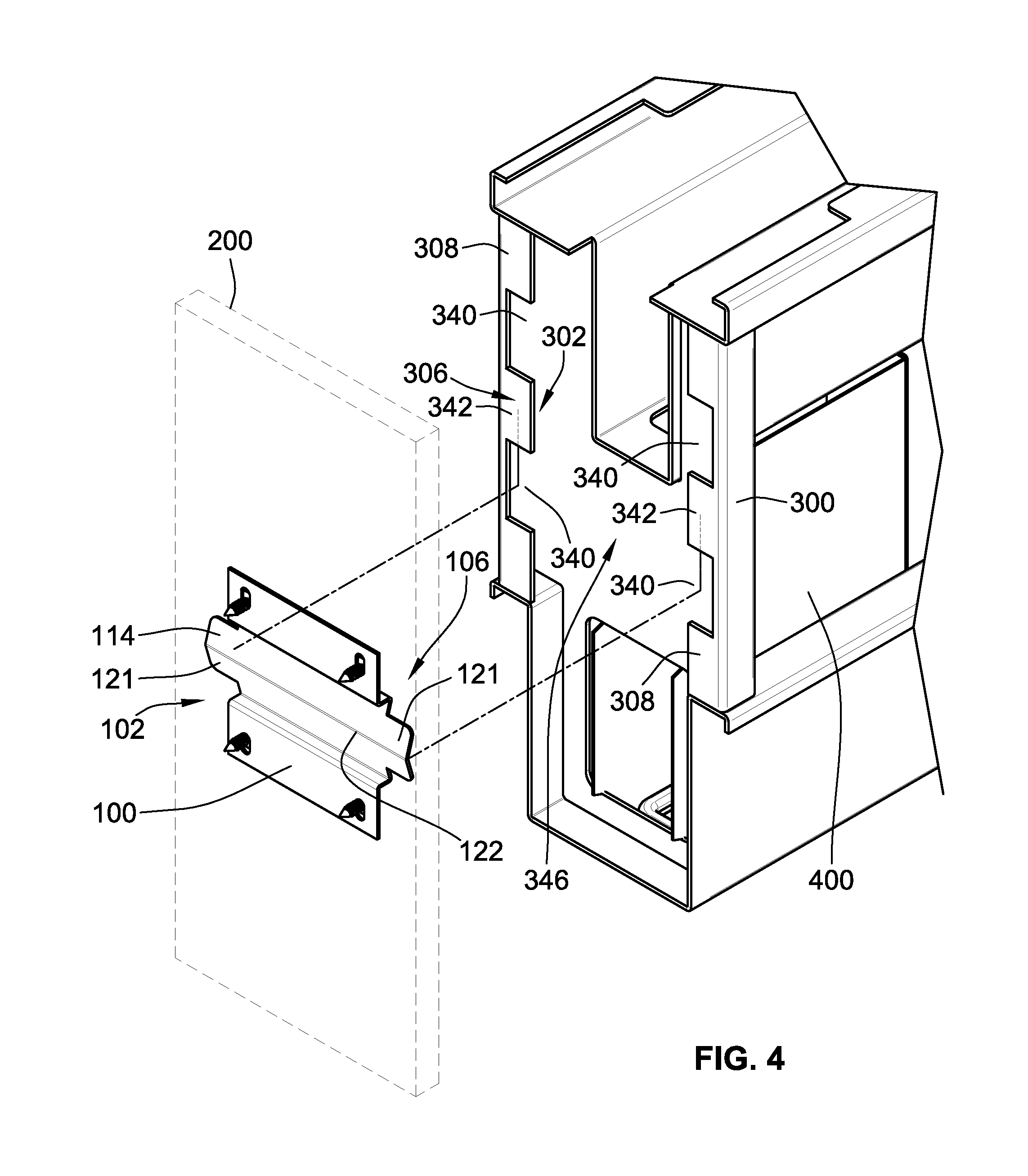

Equipment enclosure kit and assembly method

ActiveUS20060102575A1Protect normal useDigital data processing detailsStands/trestlesEngineeringElectronic component

An equipment enclosure for housing electronic components includes a front assembly having a front frame, the front assembly defining a front of the enclosure, and a rear assembly having a rear frame. The enclosure further includes at least two side brace members, each side brace member having a first end and a second, opposite end. A first connector is configured to releasably connect the first end of one of the side brace members to the front frame. A second connector is configured to releasably connect the second end of the one of the side brace members to the rear frame. Other embodiments and methods are further disclosed.

Owner:SCHNEIDER ELECTRIC IT CORP

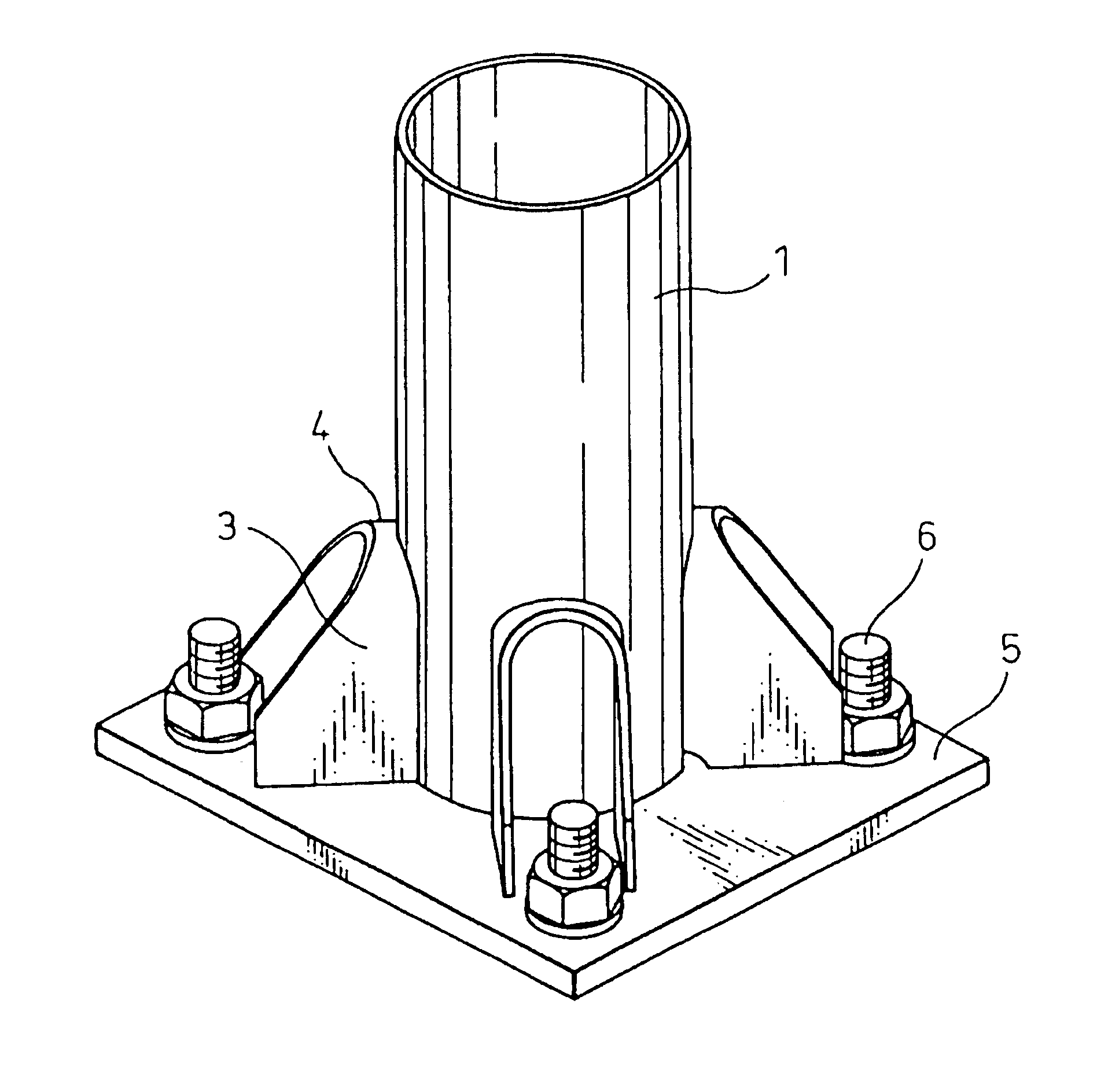

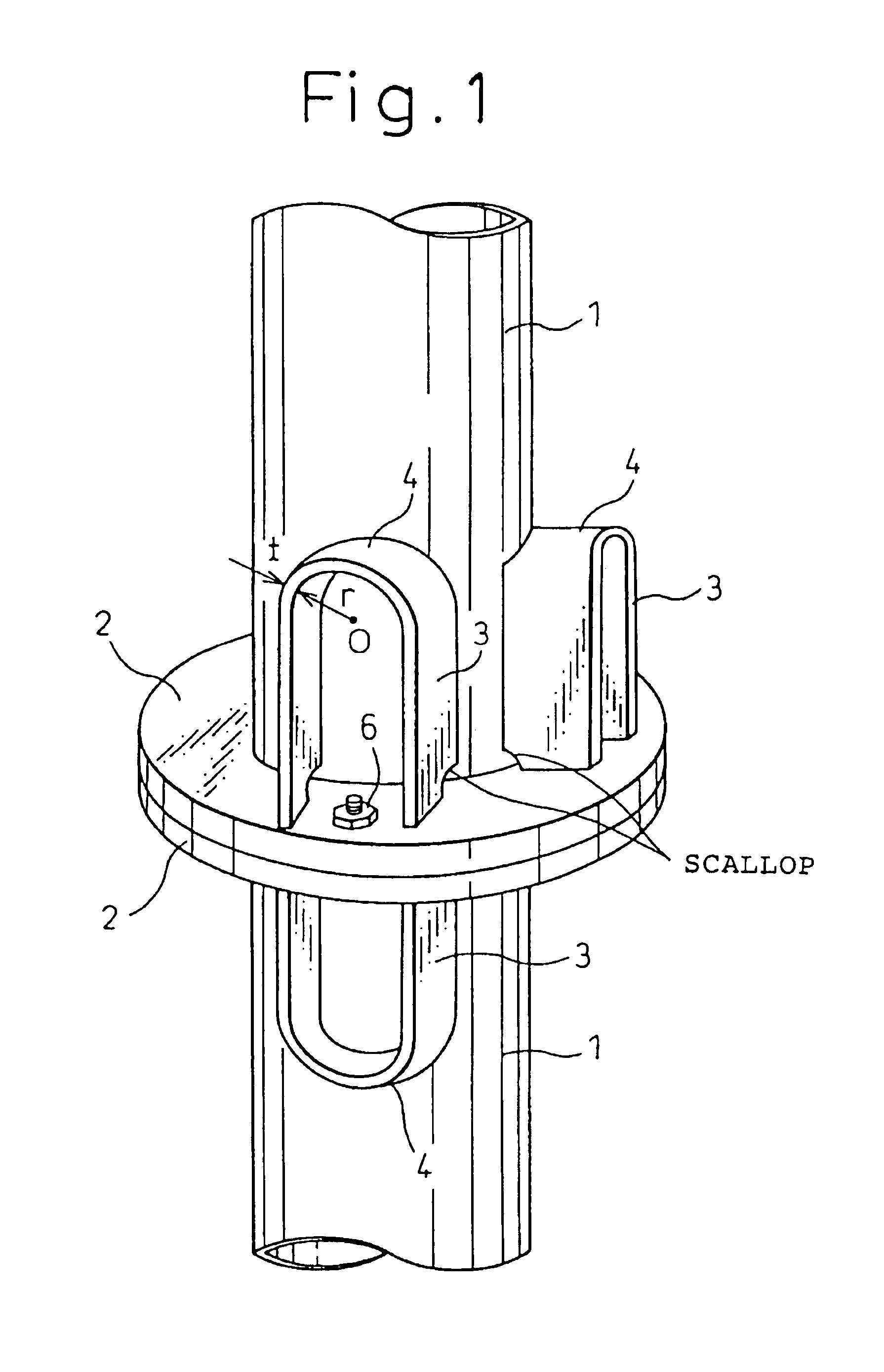

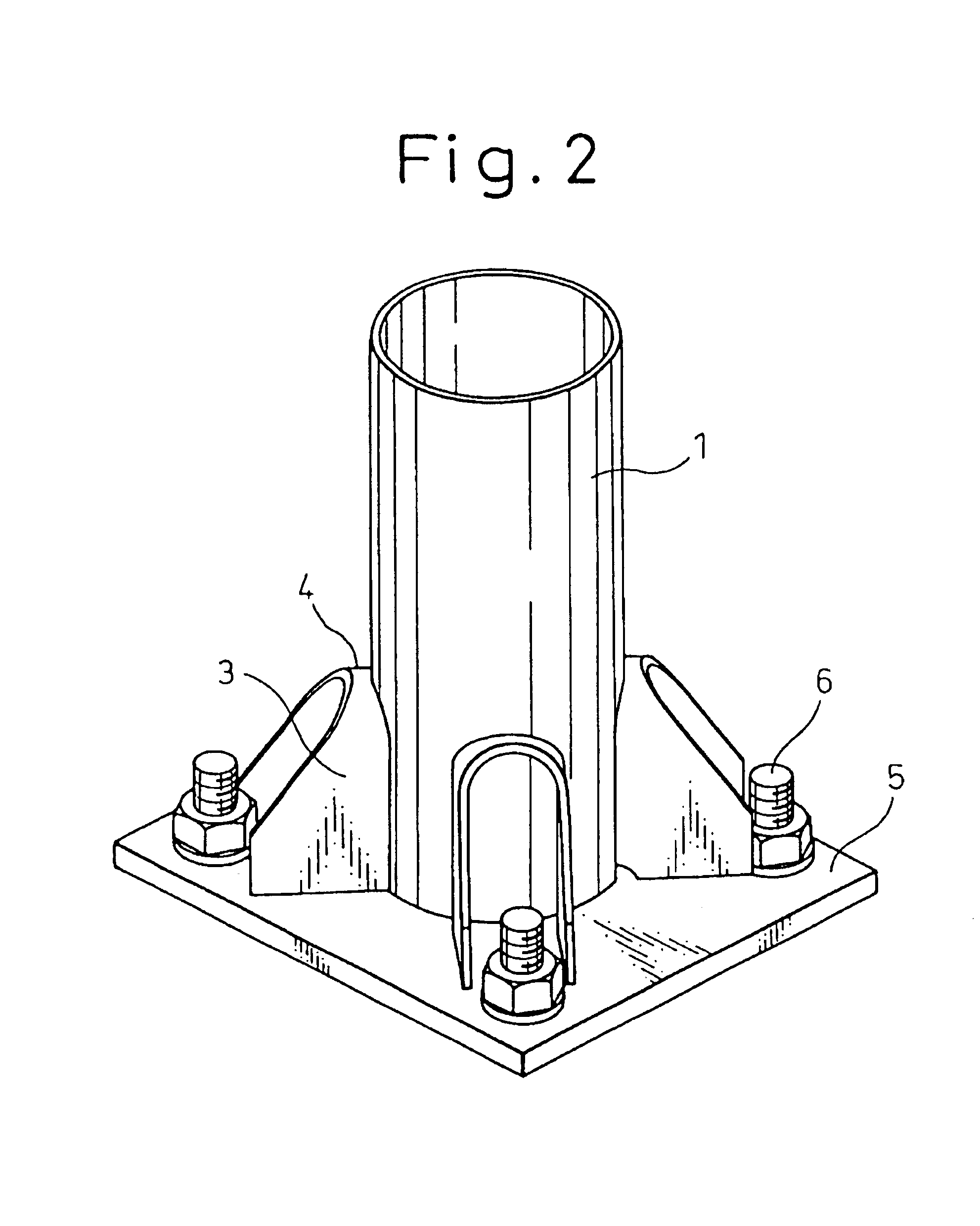

Joining structure

InactiveUS6857808B1Reduce stiffnessReduce stress concentrationMachine supportsFoundation engineeringStress concentrationPrincipal stress

The present invention provides a joining structure capable of greatly improving the proof stress and the fatigue property by alleviating the stress concentration and residual stress caused by welding heat at one or both ends of a tabular member.In the present invention, one or both ends 4 of a tabular member 3 such as a reinforcing rib, fixed to the surface of a structural member 1 in the direction of the principal stress of the structural member 1 so as to protrude in the shape of T, is / are bent in a direction deviating from the direction of the principal stress and, by this, the rigidity at the end(s) 4 of the tabular member 3 decreases and the stress concentration is alleviated. It is preferable to bend one or both ends of a tabular member 3 in the shape of an gradual curve and to the extent that each bent end is formed at a right angle to the direction of the principal stress. The tabular member may have the shape of a flat plate, or it may be bent so that it has the shape of U or V as a whole. Further, the tabular member may be welded to a structural member or formed as an integral part of a structural member.

Owner:NIPPON STEEL CORP +2

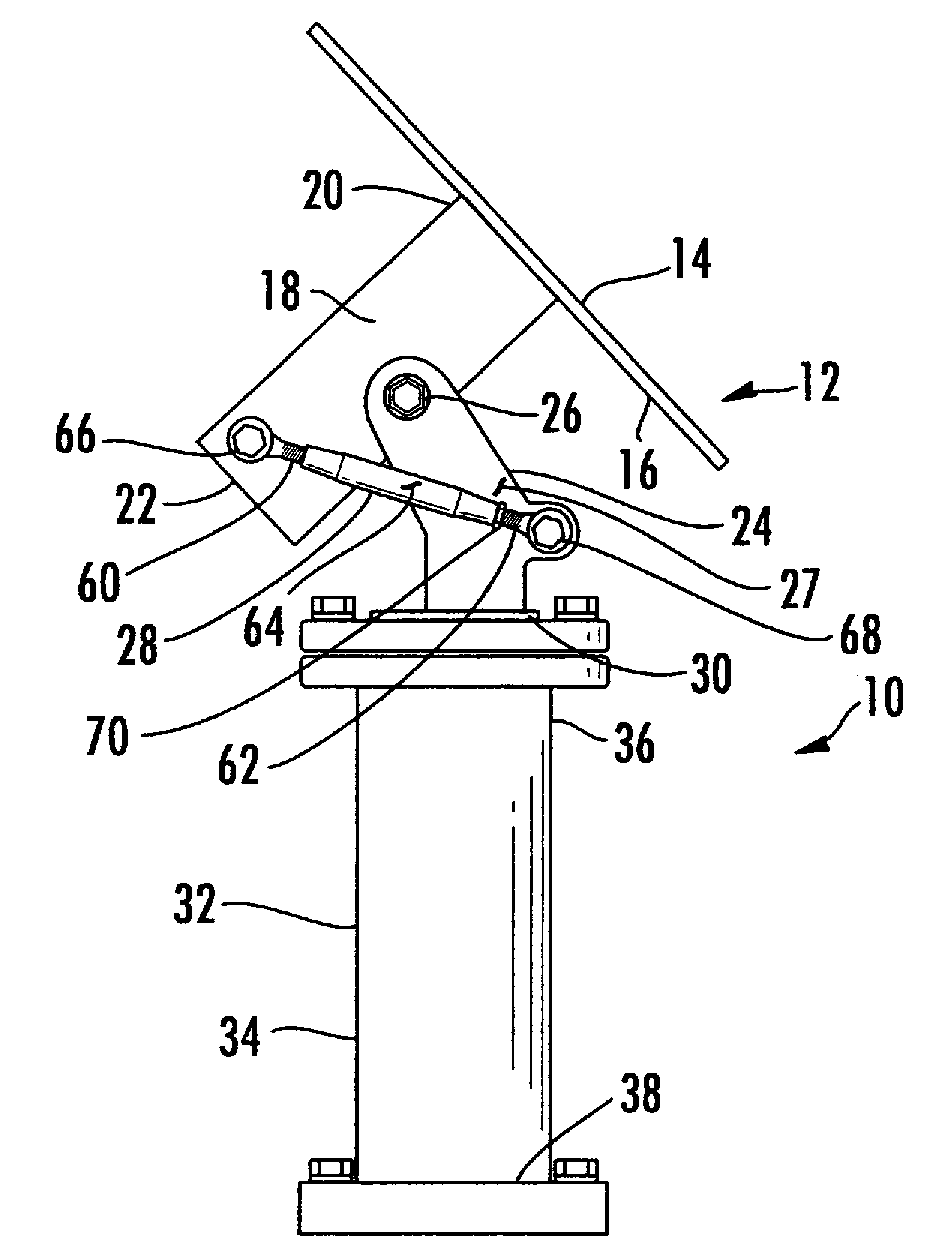

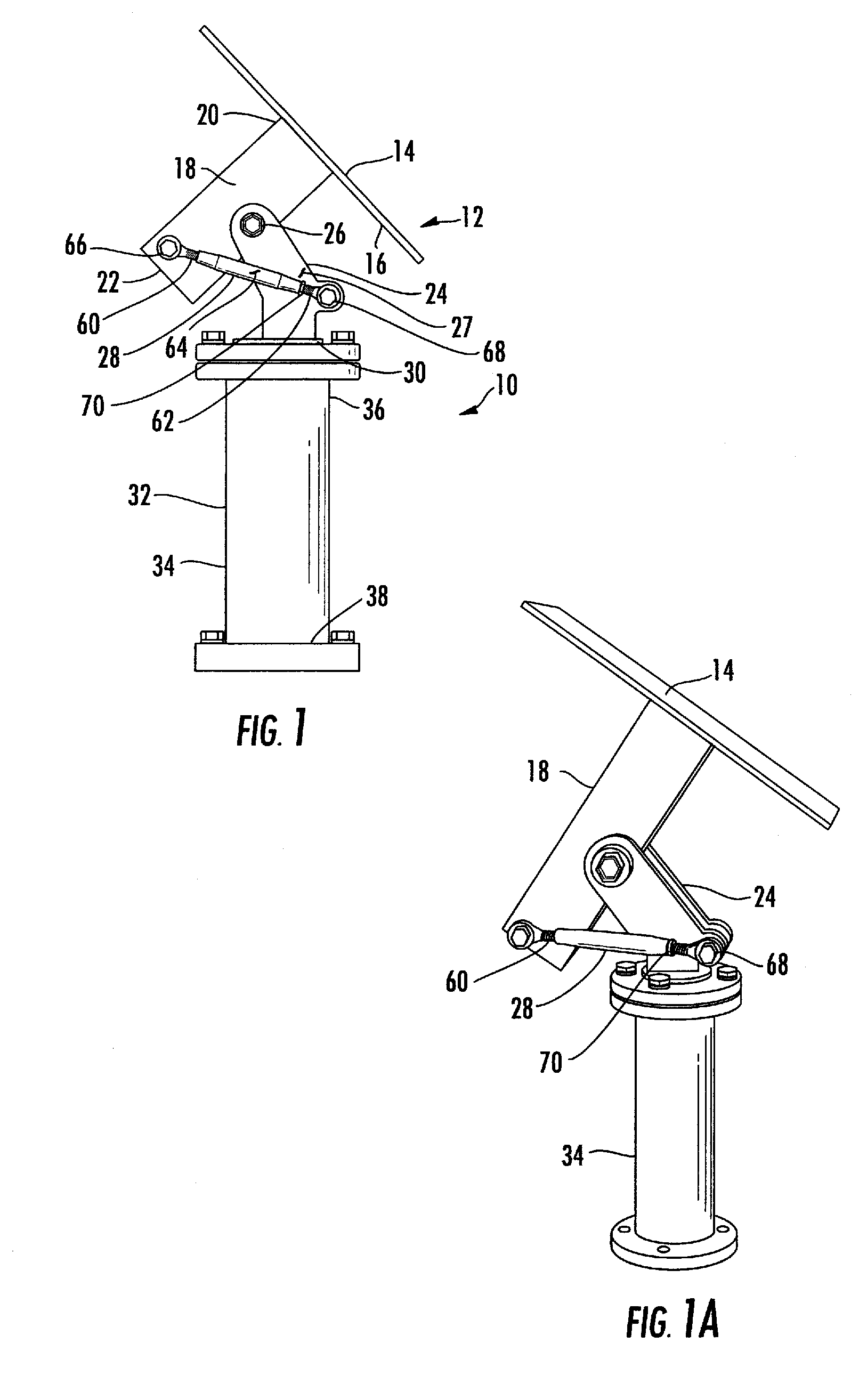

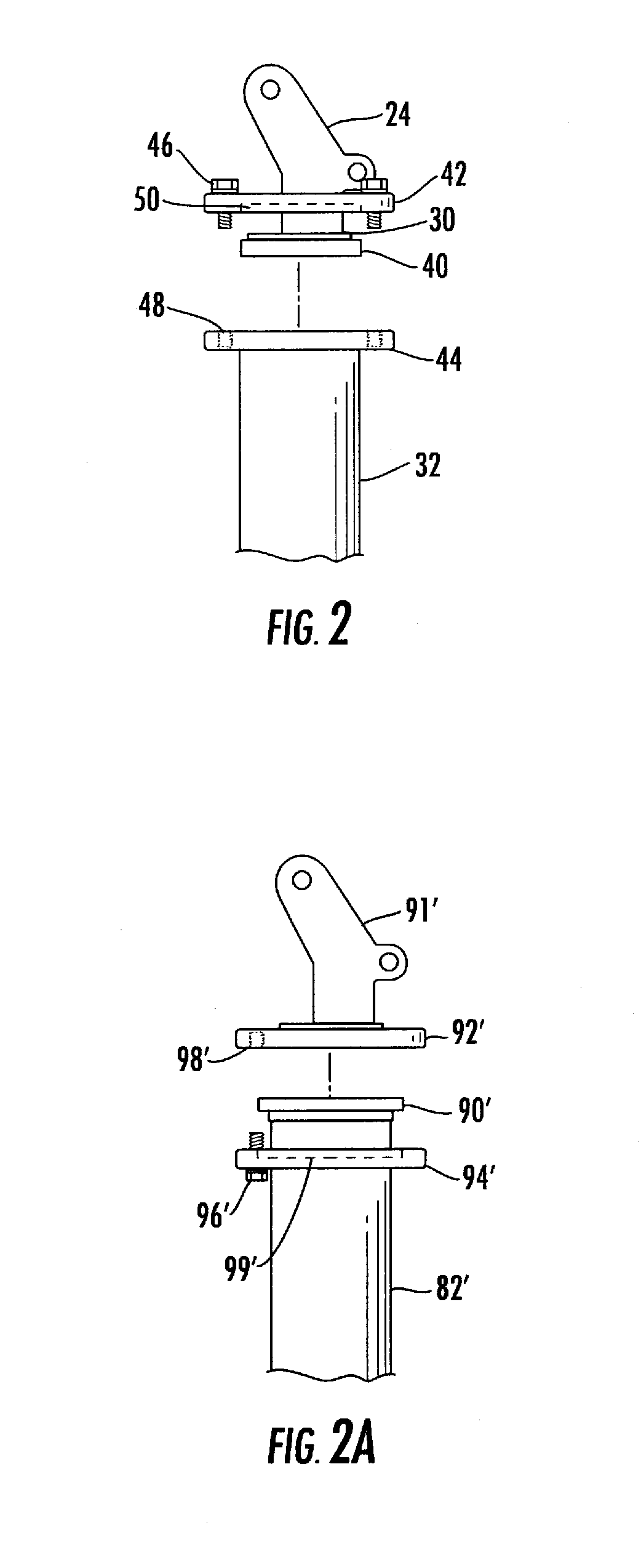

Directional support structure

InactiveUS7374137B2Eliminating disengagement of the directional devicesPrevent movementSolar heating energySolar heat devicesSatellite antennasFlange

A directional support structure for use with solar panels, flat satellite antennas, and the like items that are directed toward a point in space. The support structure includes a mounting plate with an extension tube extending outwardly therefrom, pivotally secured to a mounting bracket permitting rotational azimuth alignment of the mounting plate. At least one locking turnbuckle is attached between the extension tube and the mounting bracket to provide locking and vertical adjustable alignment of the mounting plate. The base member includes an attached first flange positioned along an upper end of the base member, an attached flaring positioned on the lower end of the mounting bracket, and an unattached second flange positioned over the flaring, securable to the first flange with fasteners.

Owner:STANEY WAYNE

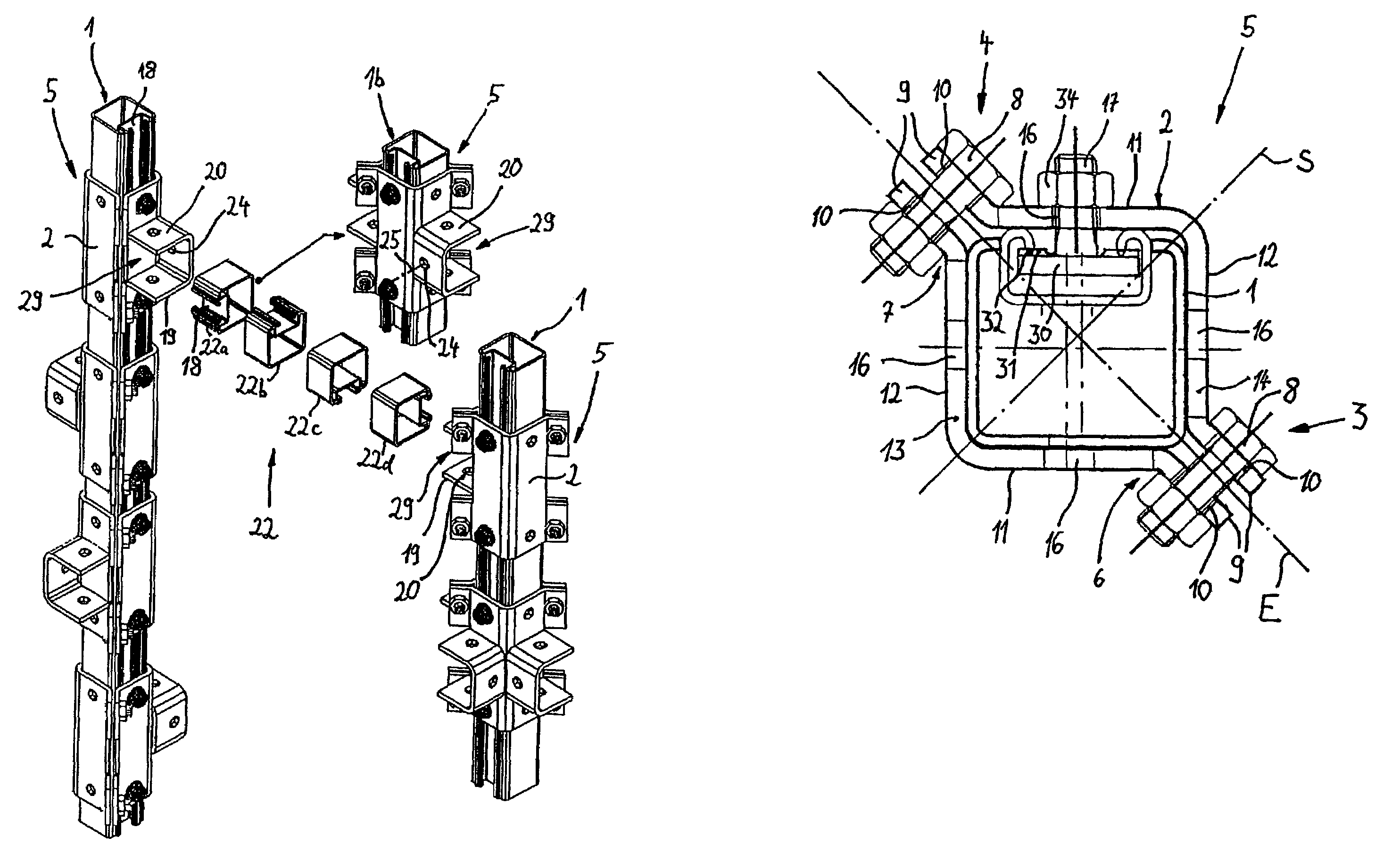

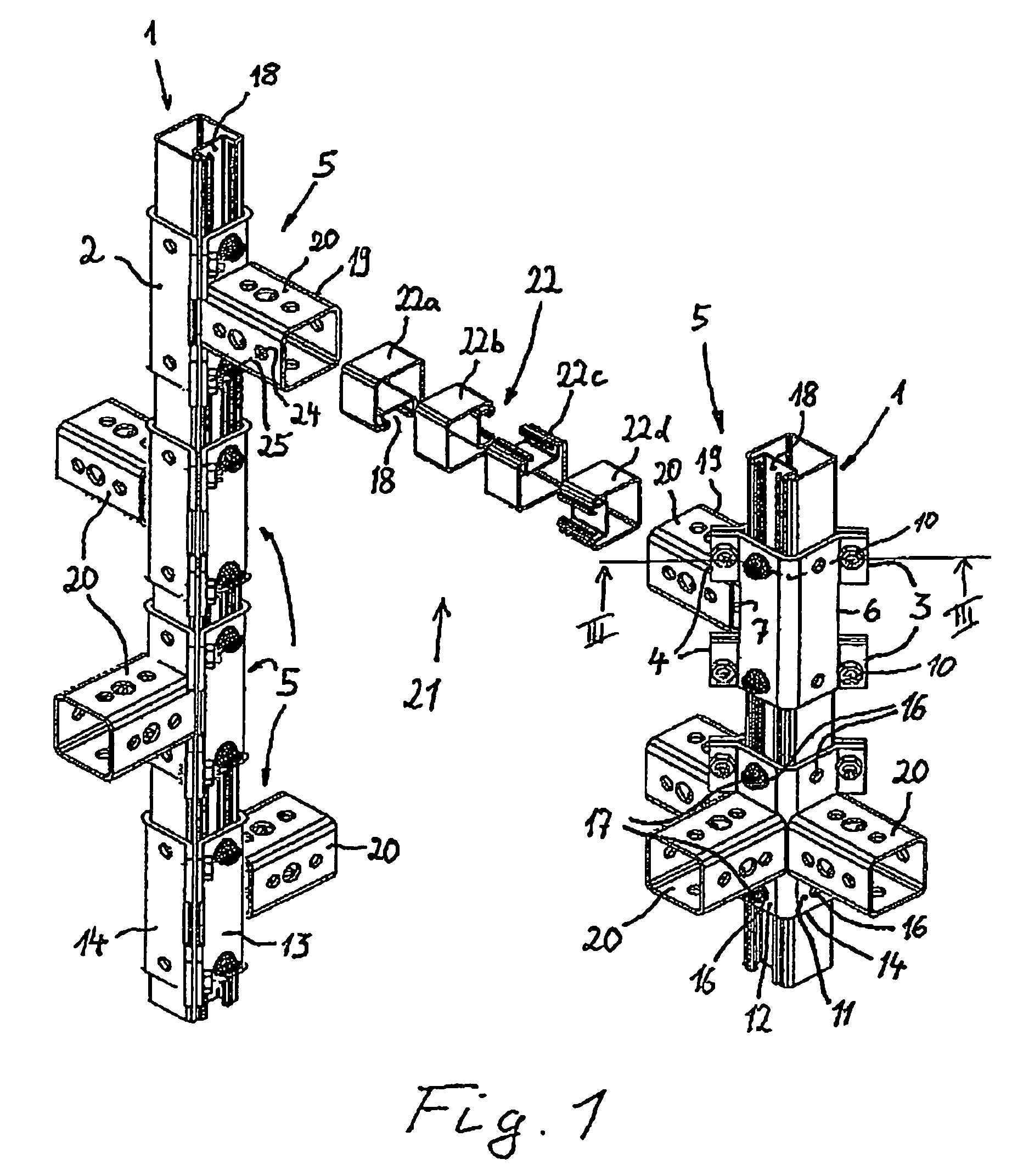

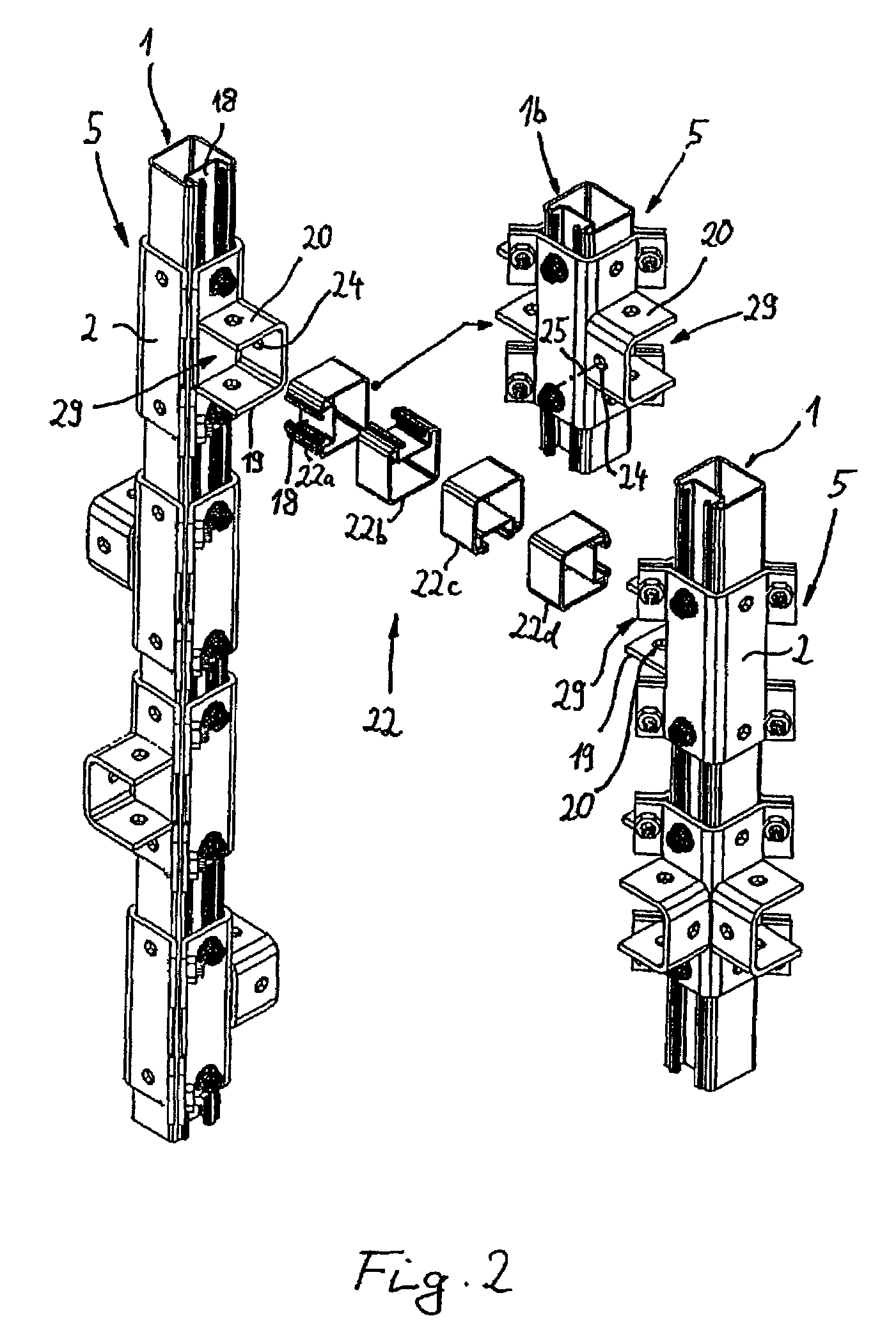

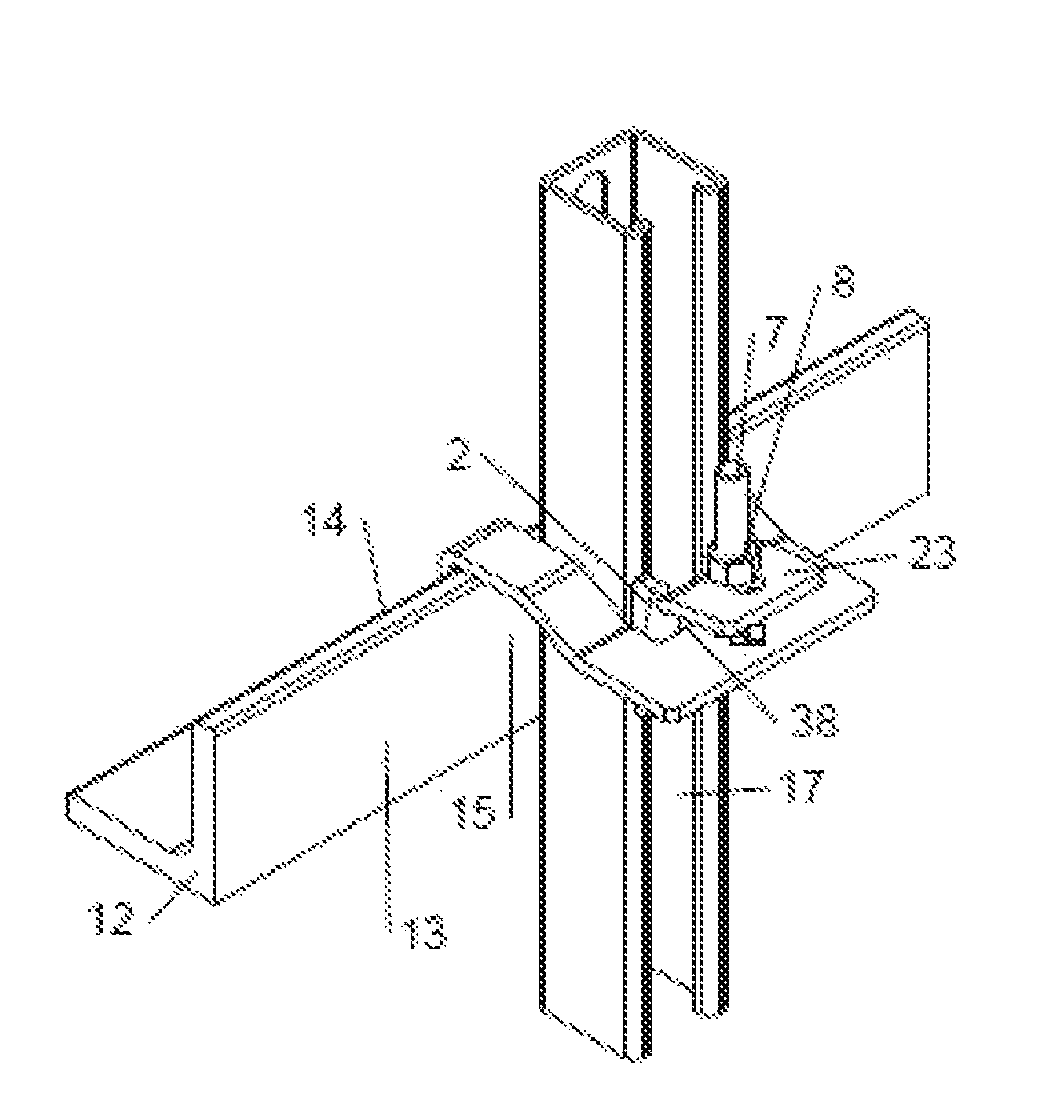

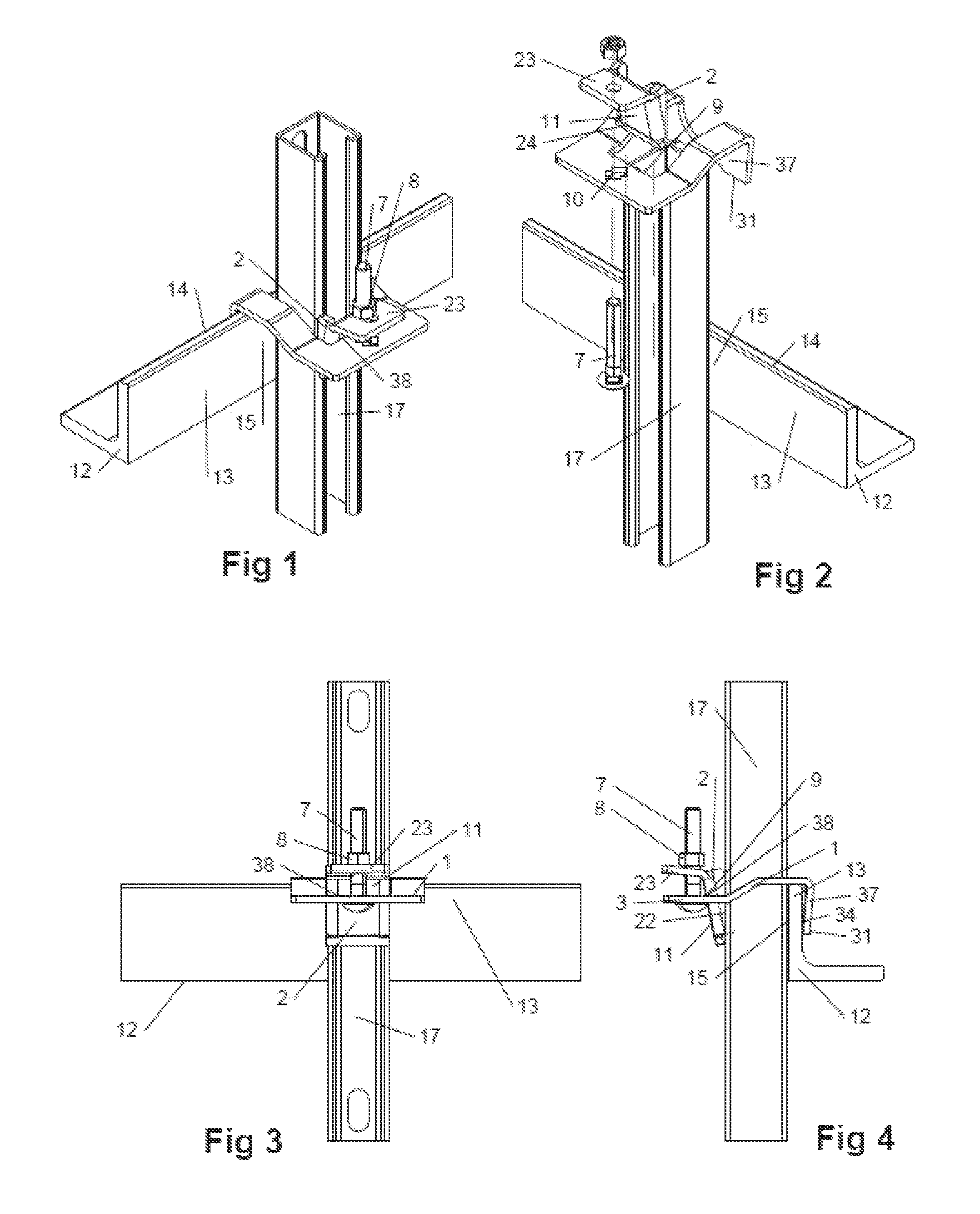

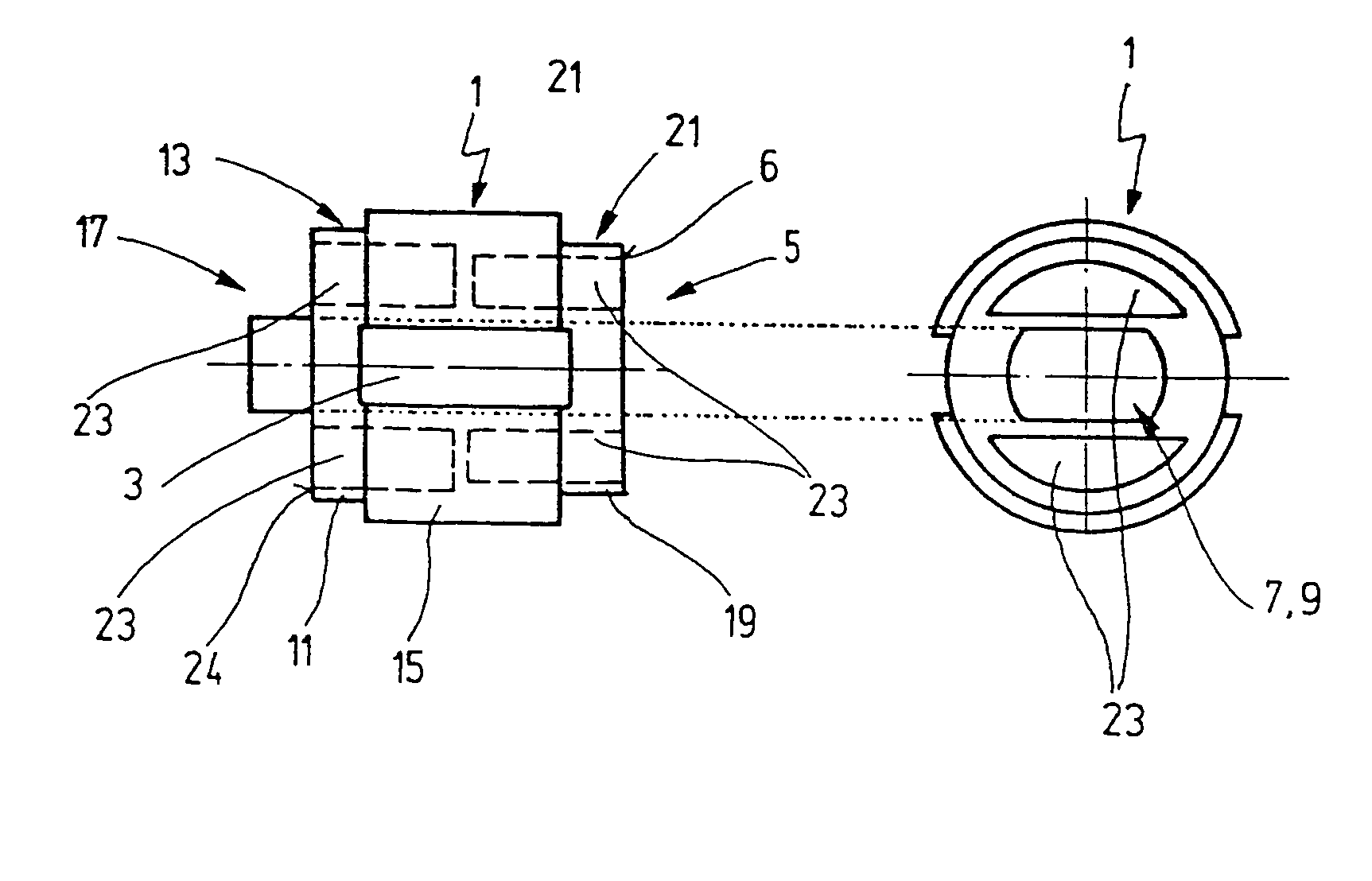

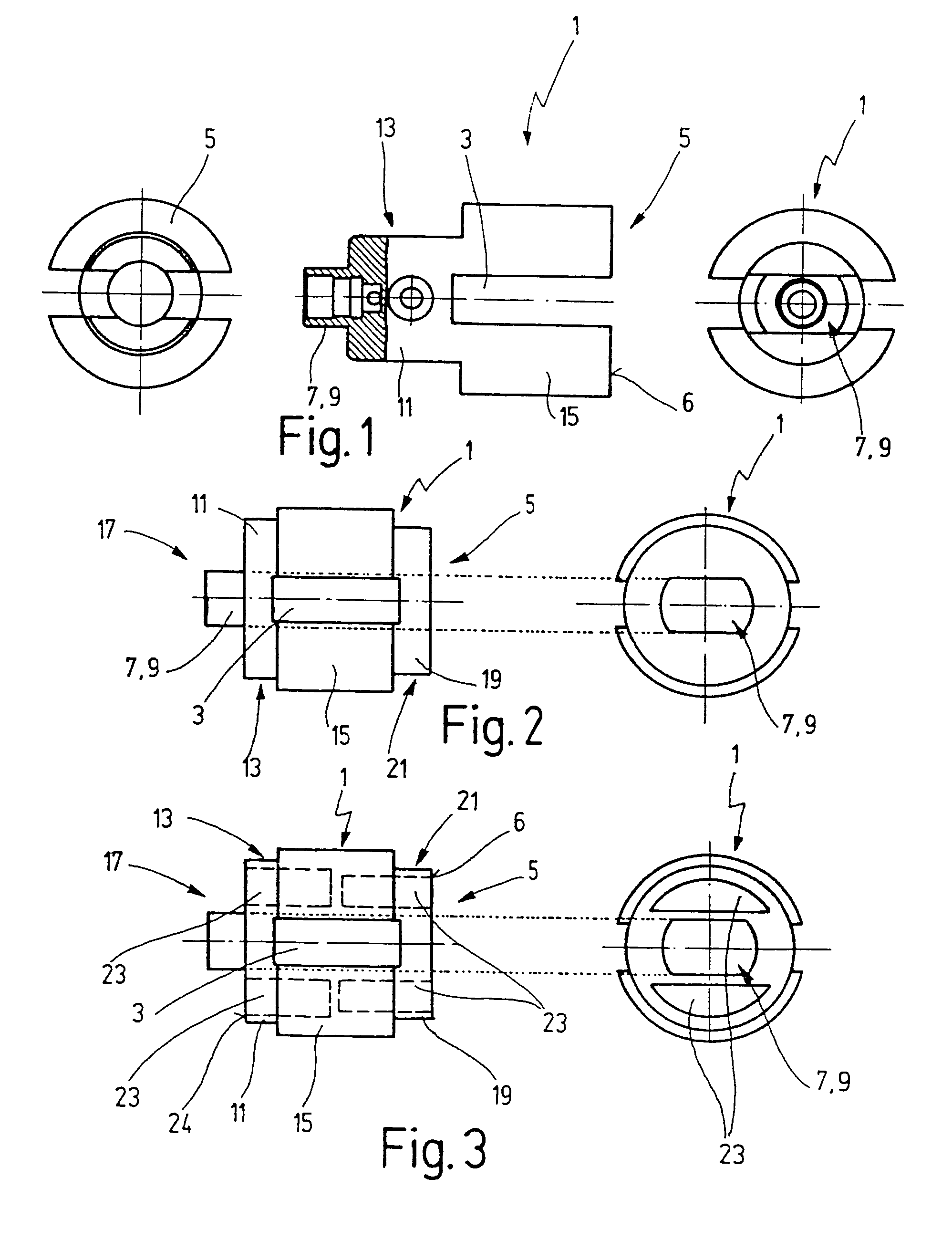

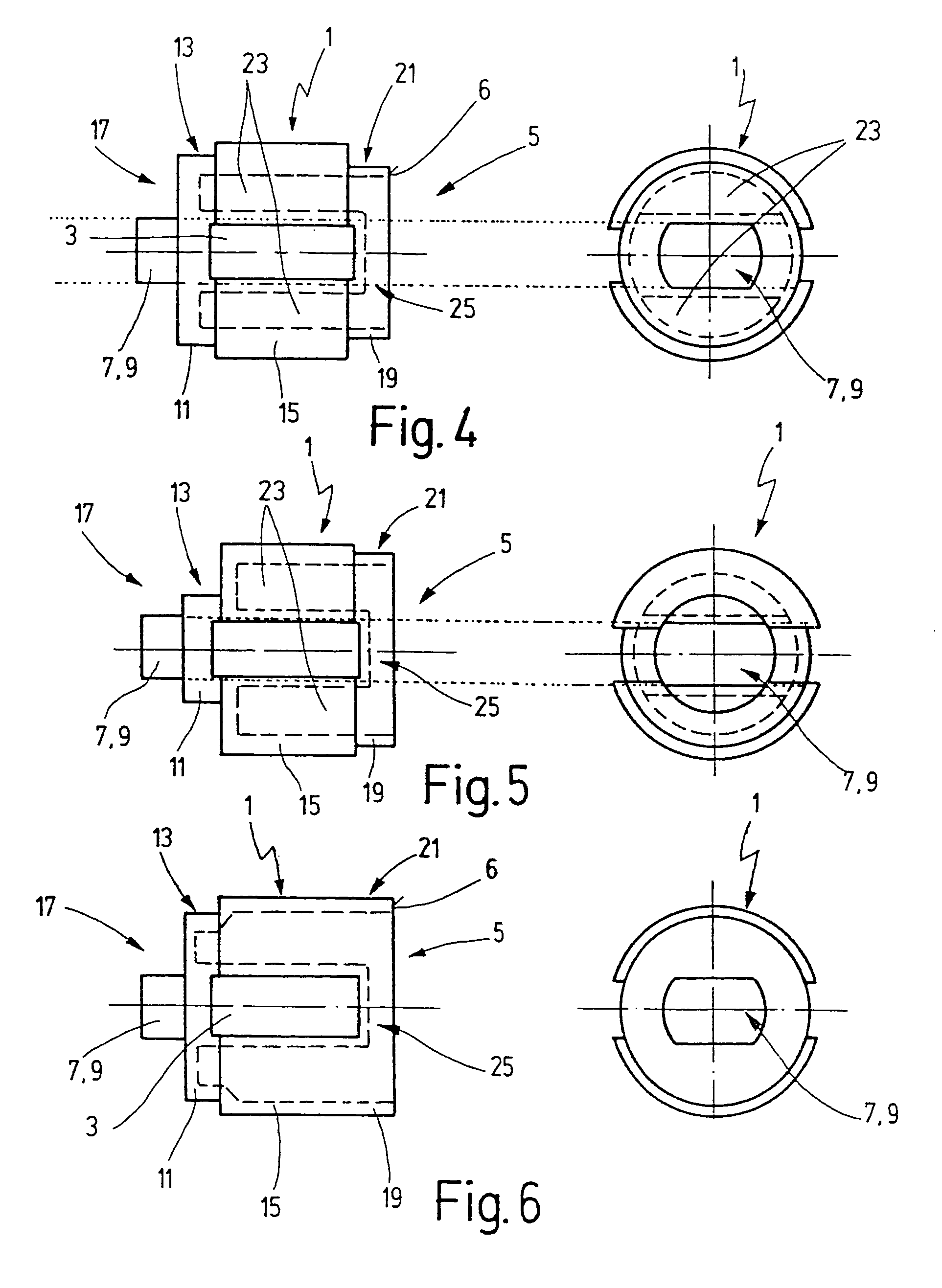

Connecting part for mounting rails

InactiveUS6974276B2Low production costImprove toleranceDerricks/mastsDoors/windowsMechanical engineeringSectional plane

A connecting part for attachment on a mounting rail has a fastening part with an at least approximately rectangular cross-section. The fastening part has legs and surrounds when mounted a mounting rail on all sides by having a matching cross-section formed by the legs. The fastening part has clamping devices for effecting a clamping fixation of the connecting part on the mounting rail. A cross-sectional plane of the fastening part has two diagonally opposed corners and the clamping devices are arranged on the two diagonally opposed corners, respectively.

Owner:HALFEN GMBH & CO KG

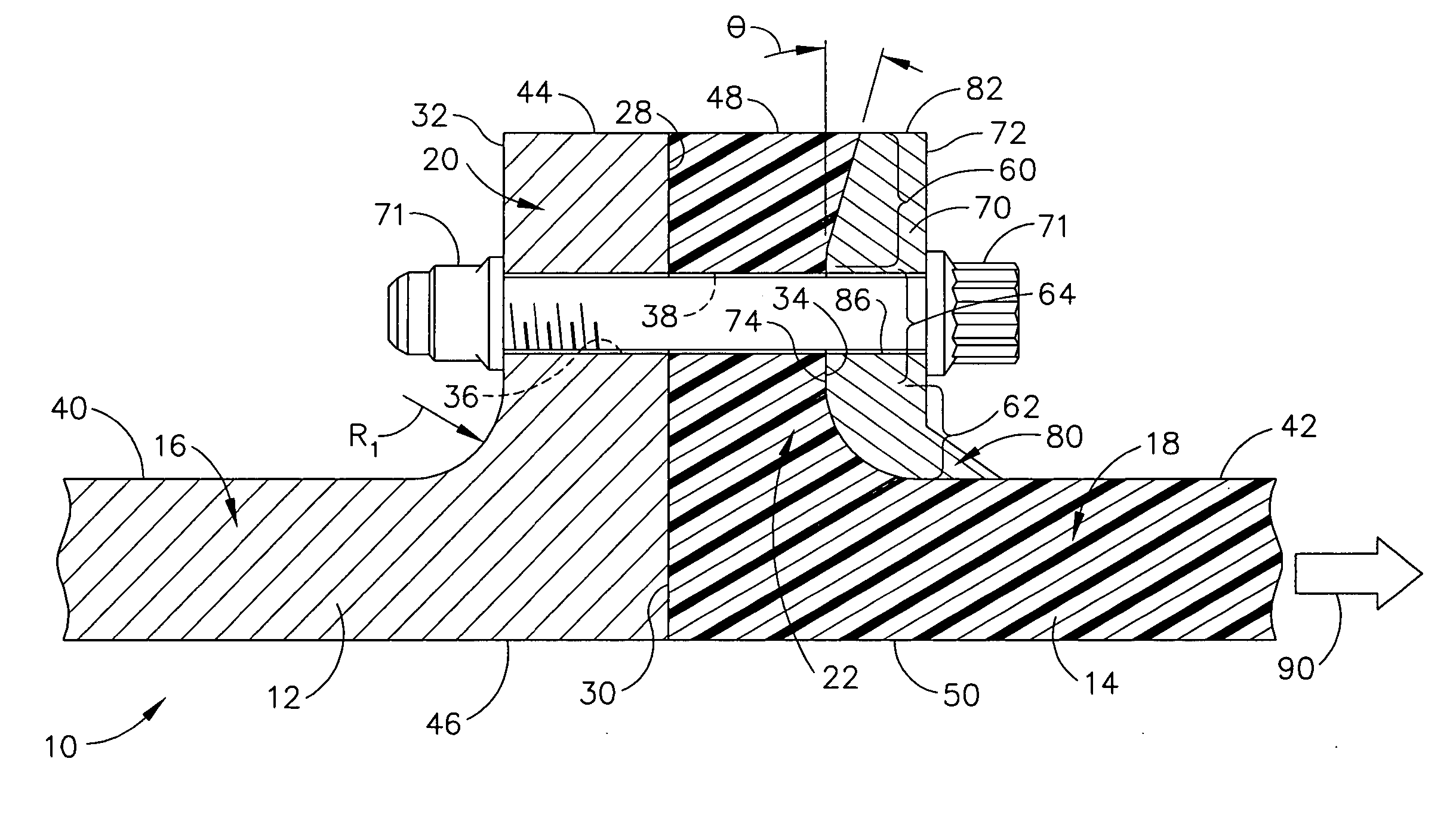

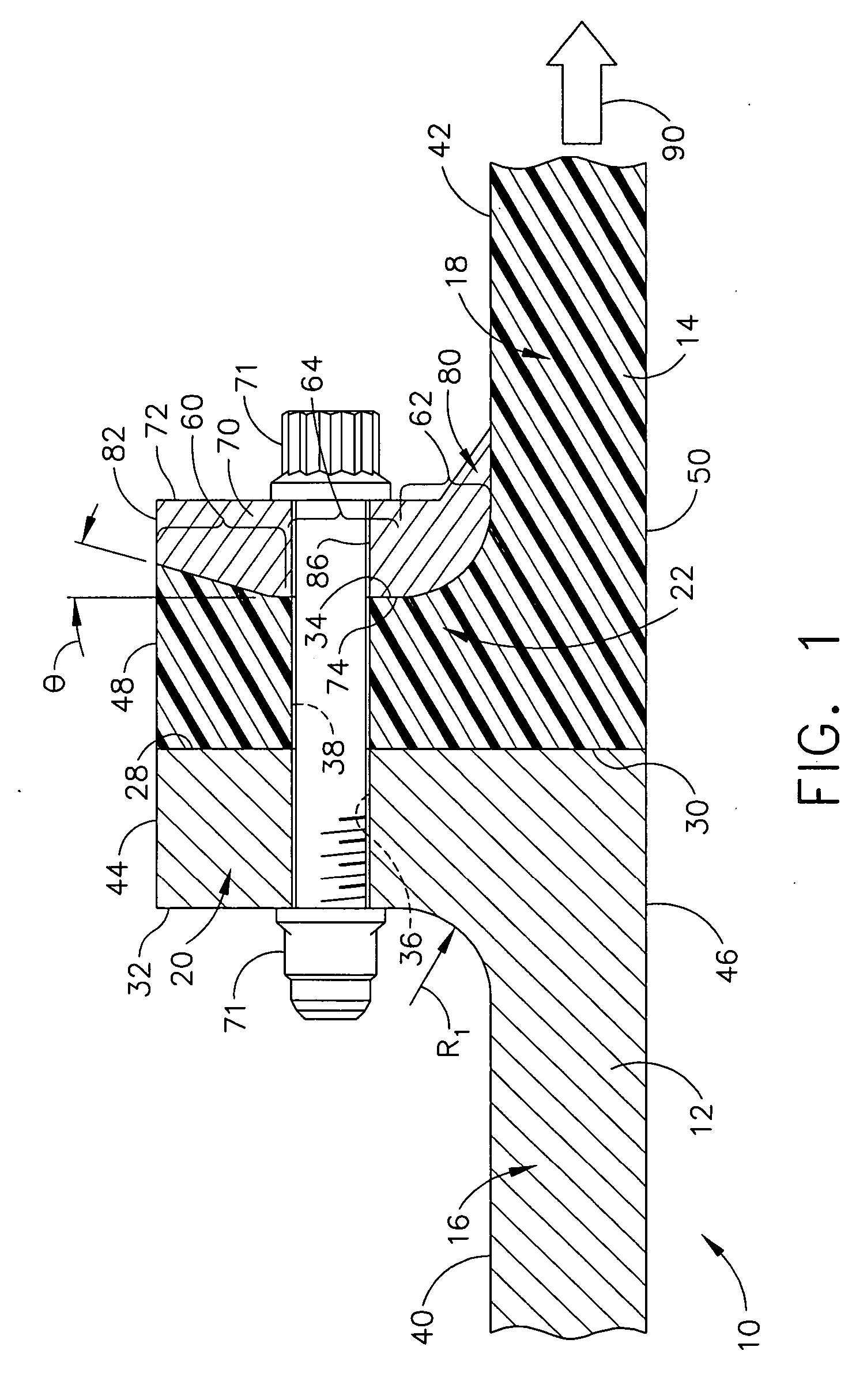

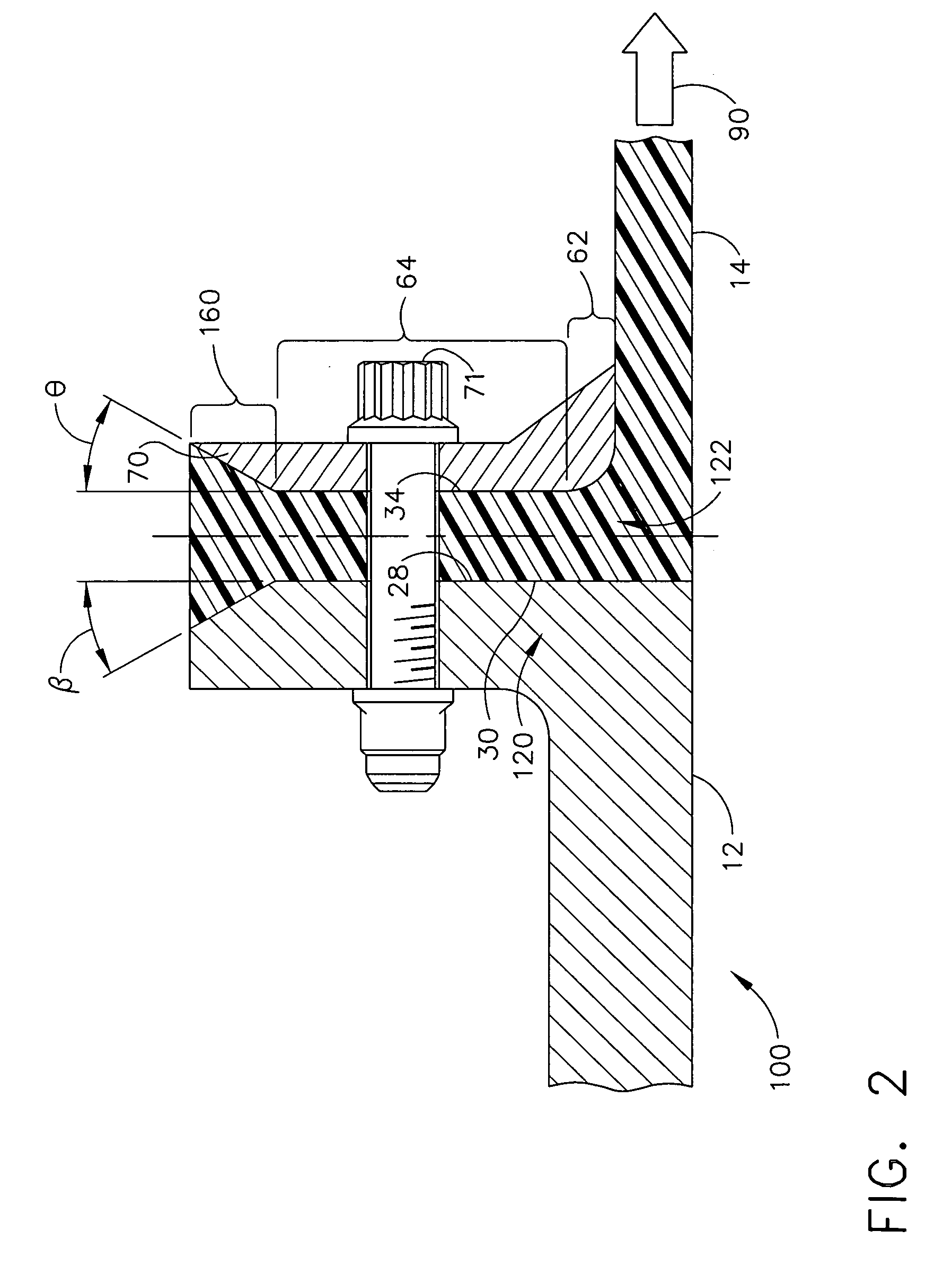

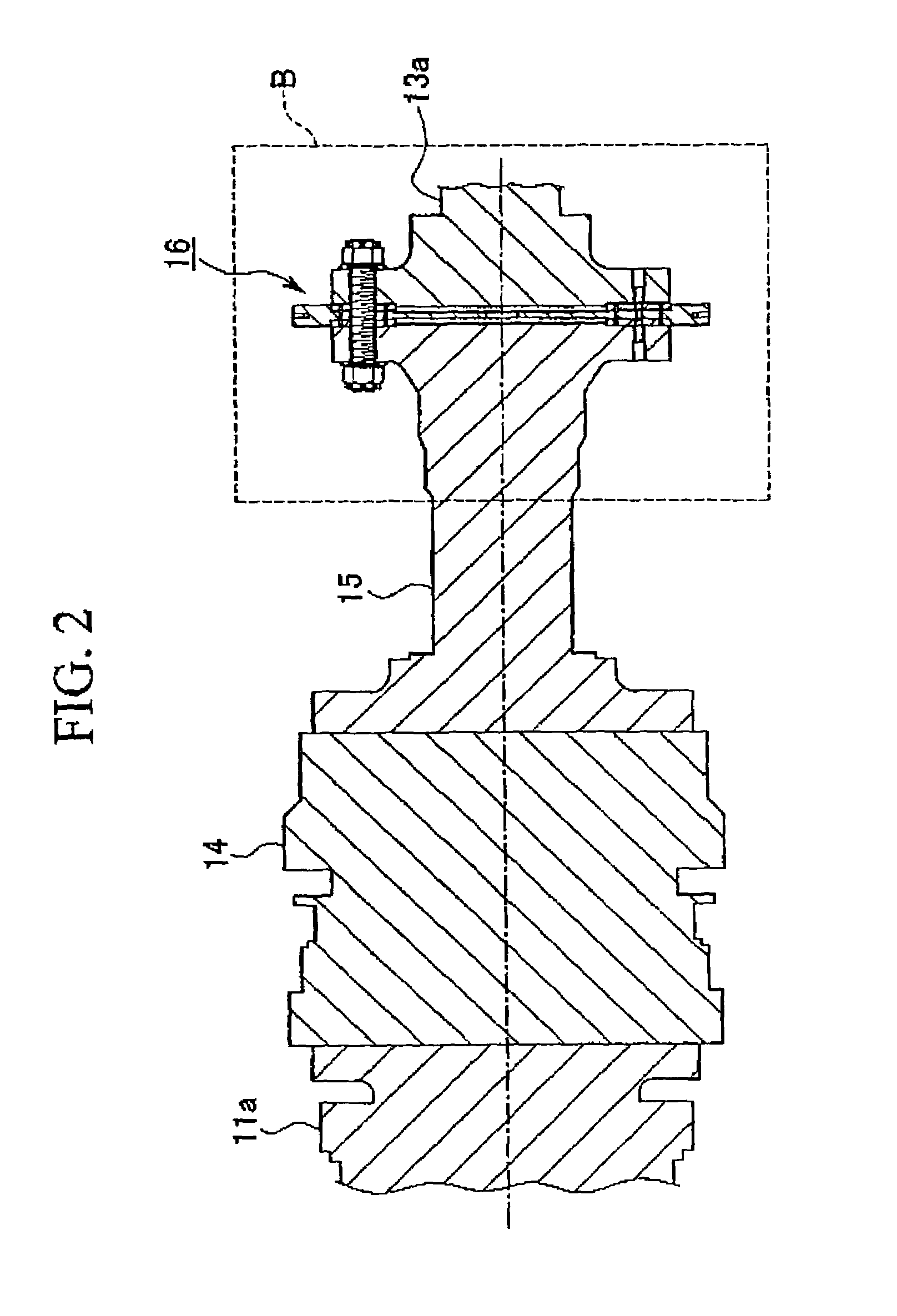

Methods and apparatus for assembling composite structures

ActiveUS20070086854A1Facilitates distributing loadingConducive to loadPump componentsMetal-working apparatusEngineeringTurbine

A method facilitates assembling a turbine engine casing. A first casing section is positioned radially outward from a turbine engine. The first casing includes a first flange having an outer end portion, an inner end portion, and a body therebetween. At least a portion of the outer end portion has a partial frusto-conical cross-sectional profile. A second casing section including a second flange is positioned adjacent the first casing section such that a mating surface of the second flange is positioned substantially flush against a first flange mating surface. Each respective mating surface is opposite a respective load-bearing surface. A fastener is inserted through an opening in the first and second flanges to couple casing sections together such that a portion of a load-bearing surface extending over the first flange outer end portion facilitates distributing loading induced therein substantially equally across the load bearing surface.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for assembling composite structures

Owner:GENERAL ELECTRIC CO

Joint arrangement

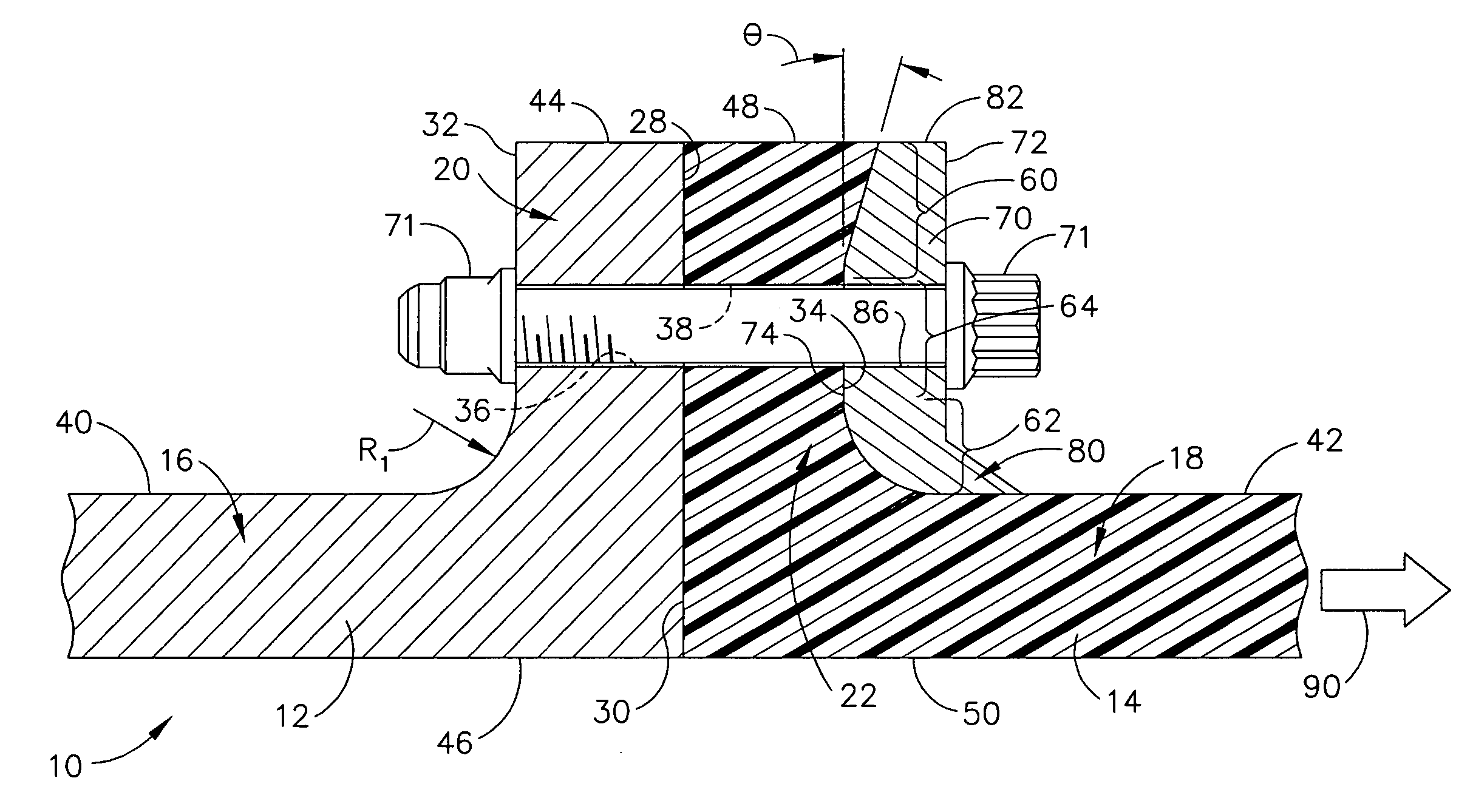

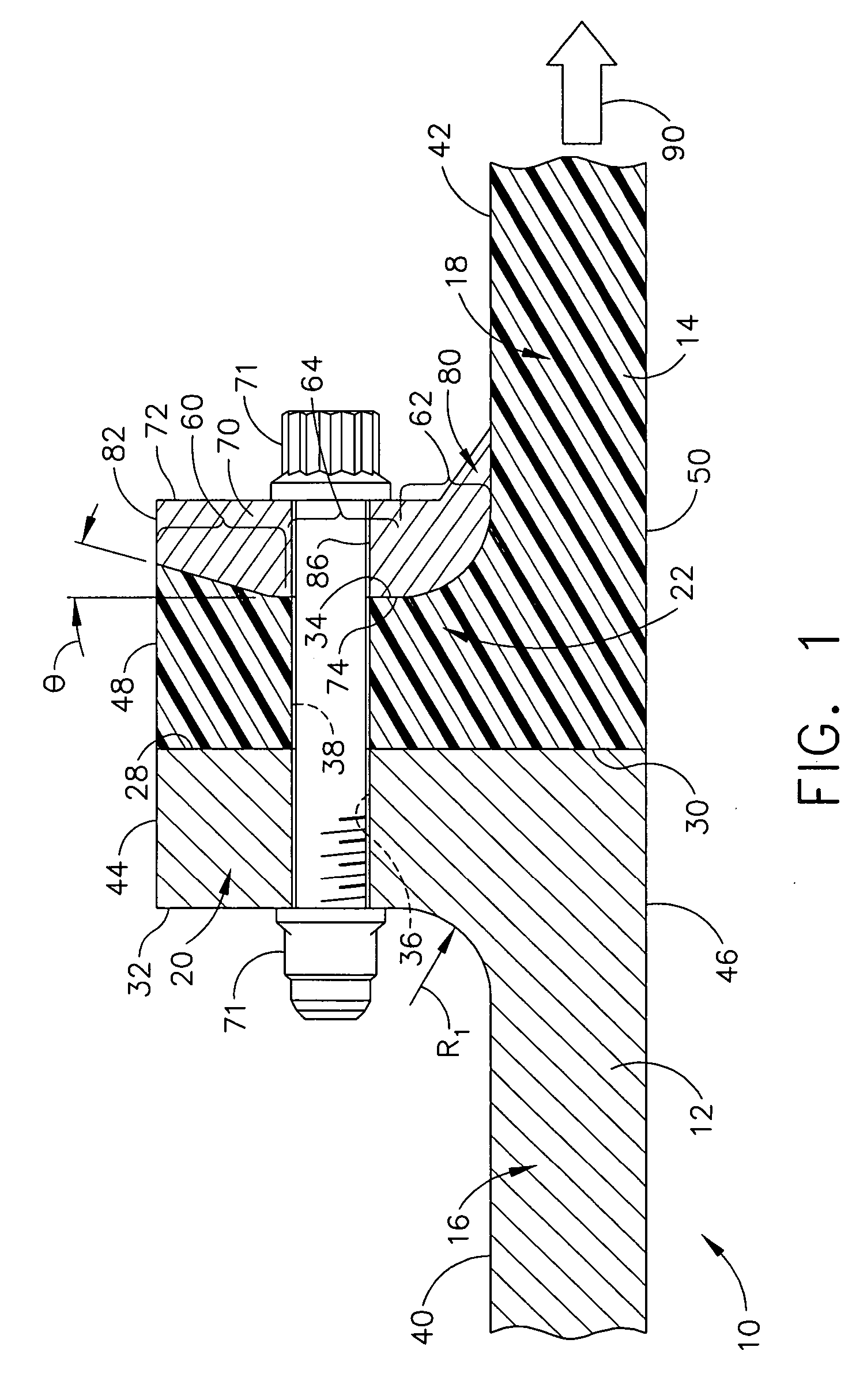

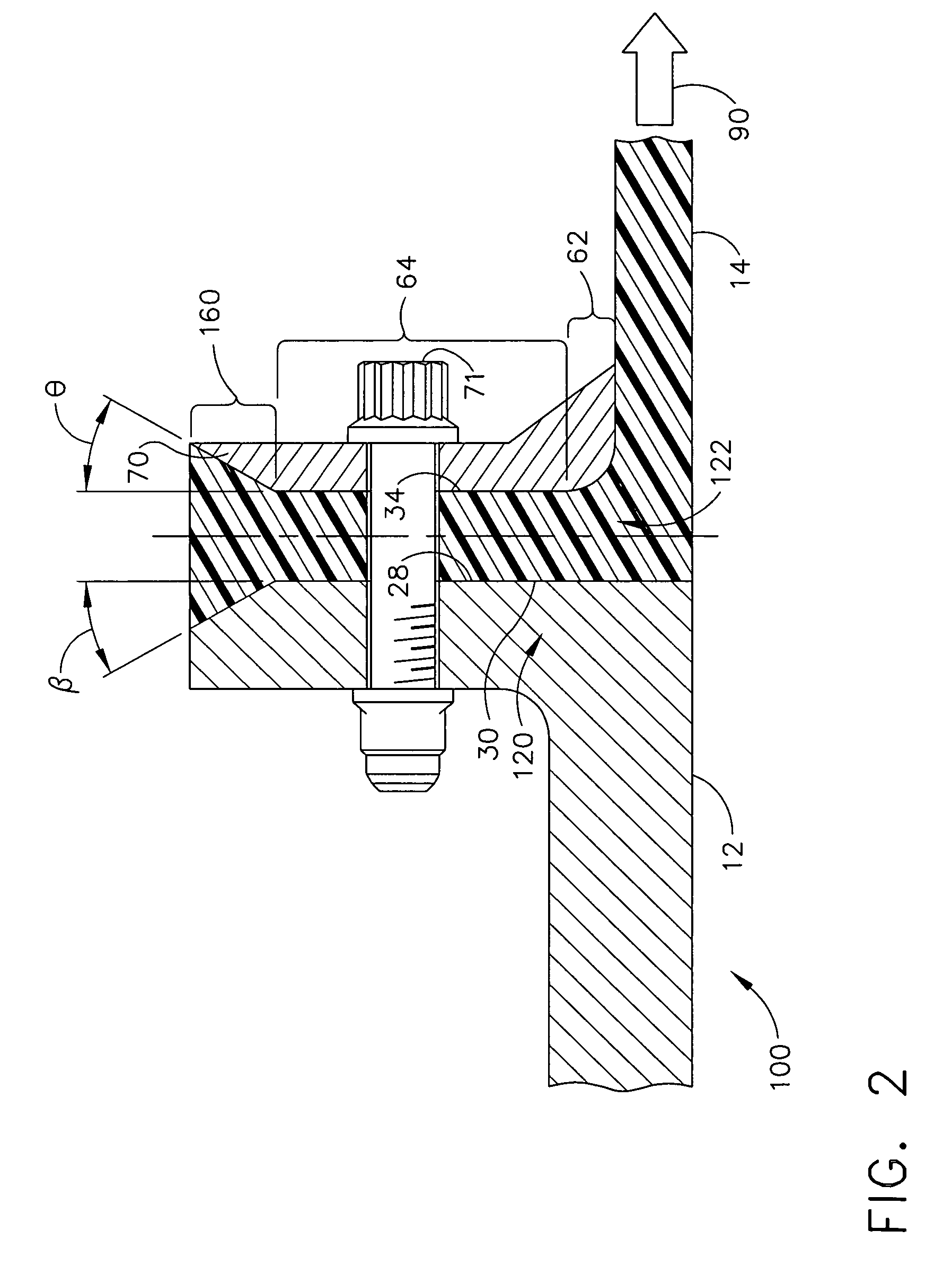

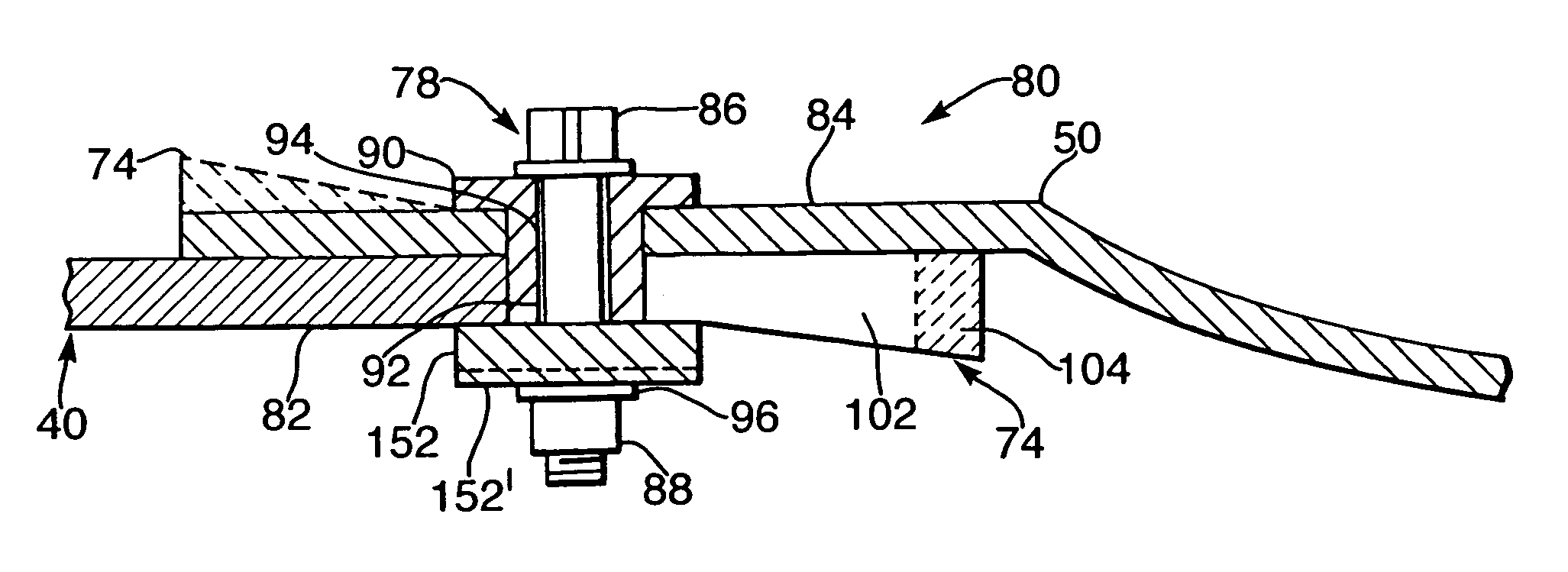

ActiveUS7121758B2Lose weightMore compliantEngineering emergency devicesTraffic signalsMechanical engineeringWedge shape

A joint assembly 80 is provided for limiting an extension of the joint 80 in the direction of a load path derived from an impact comprising. In its simplest form, the joint 80 comprises a first member 40 having a portion 82 and a second member 50 having a portion 84, the portions 82, 84 overlapping one another and arranged generally parallel to one another and secured together via securing means 78. The securing means 78 is disposed through corresponding holes 92, 94 defined by portions 82 and 84. At least one of the overlapping portions 82 or 84 further defines, sequentially in the direction of extension a pocket 102. The securing means 78 comprises a deformable member 152, 178 and at least one of the overlapping portions 82, 84 comprises a wedge-shaped portion 74. In the event of a worst-case impact load the securing means 78 is forced through the pocket 106 while the wedge-shaped portion 74 causes the deformable member 152 to deform and thereby increase the clamping force, in a progressive manner, to limit the extension of the joint assembly 80 and retain an integral joint assembly 80.

Owner:ROLLS ROYCE PLC

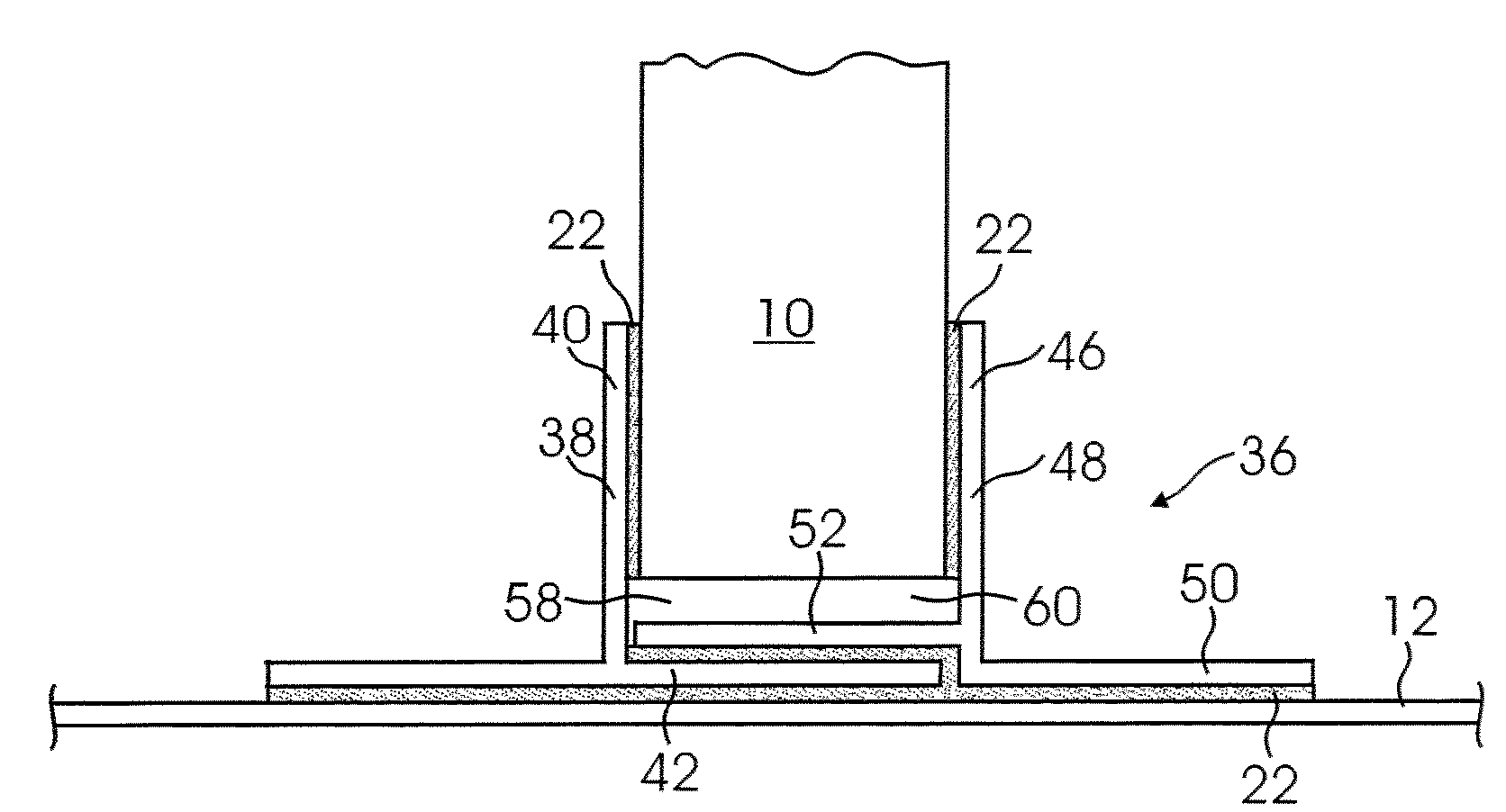

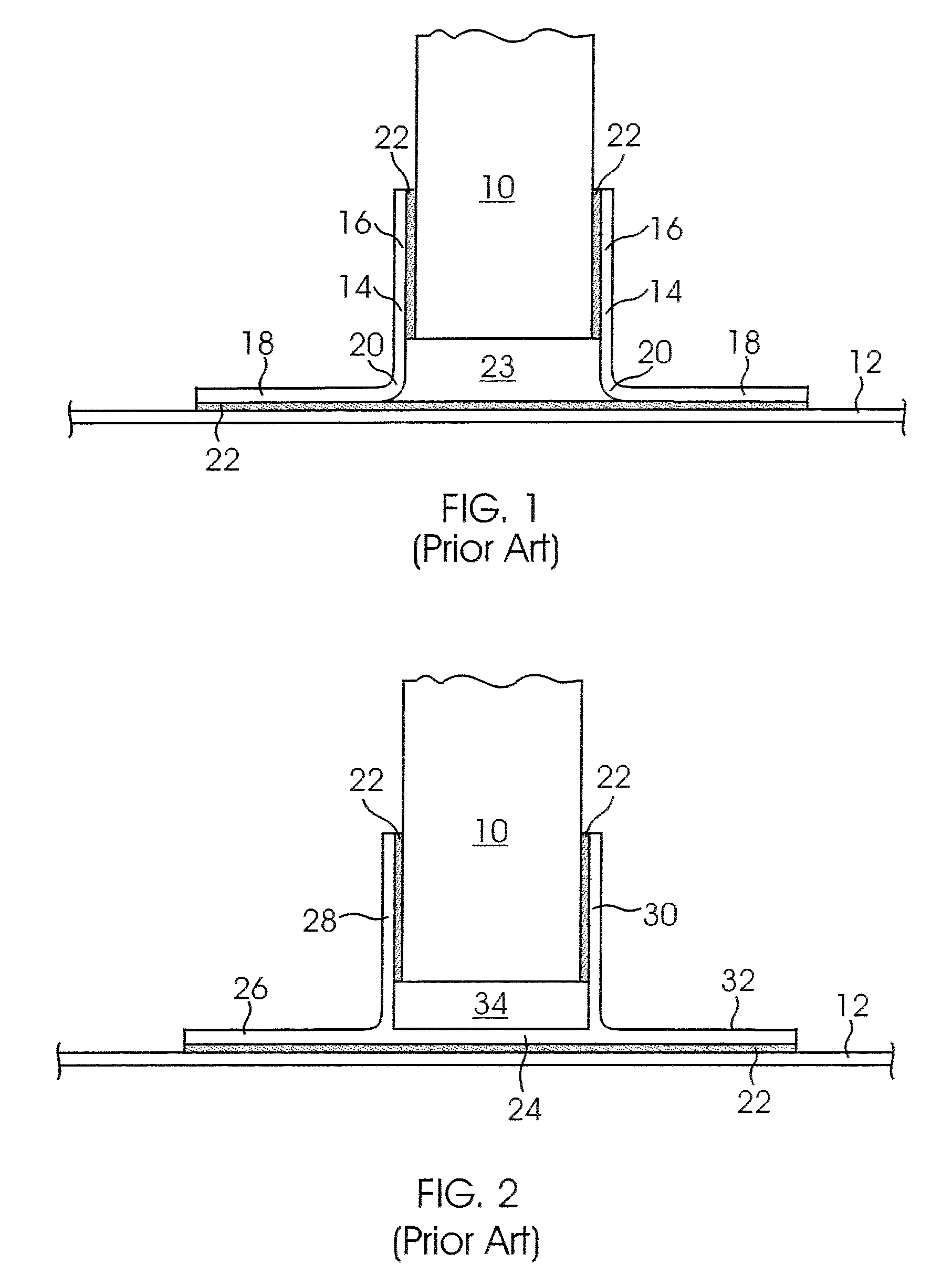

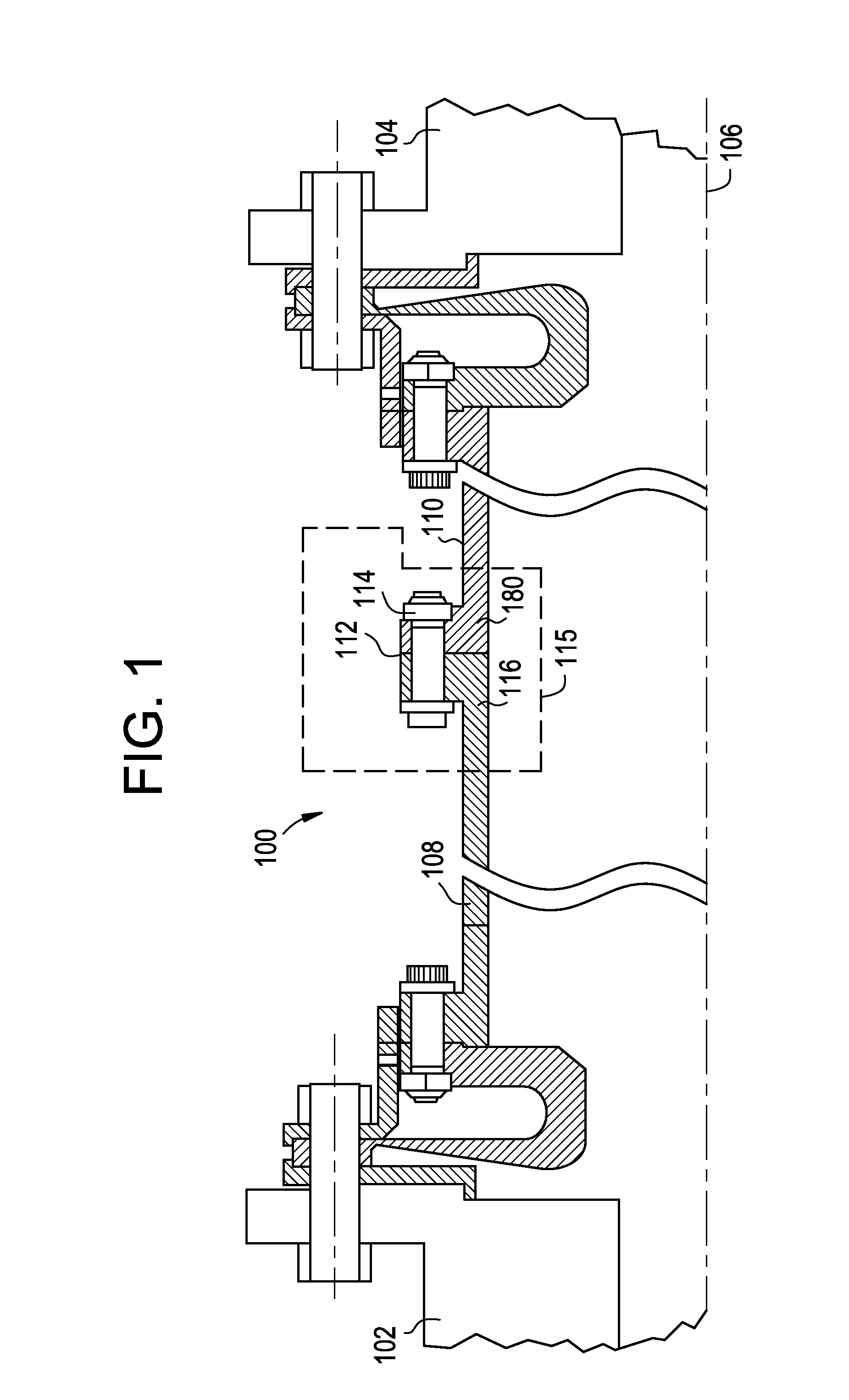

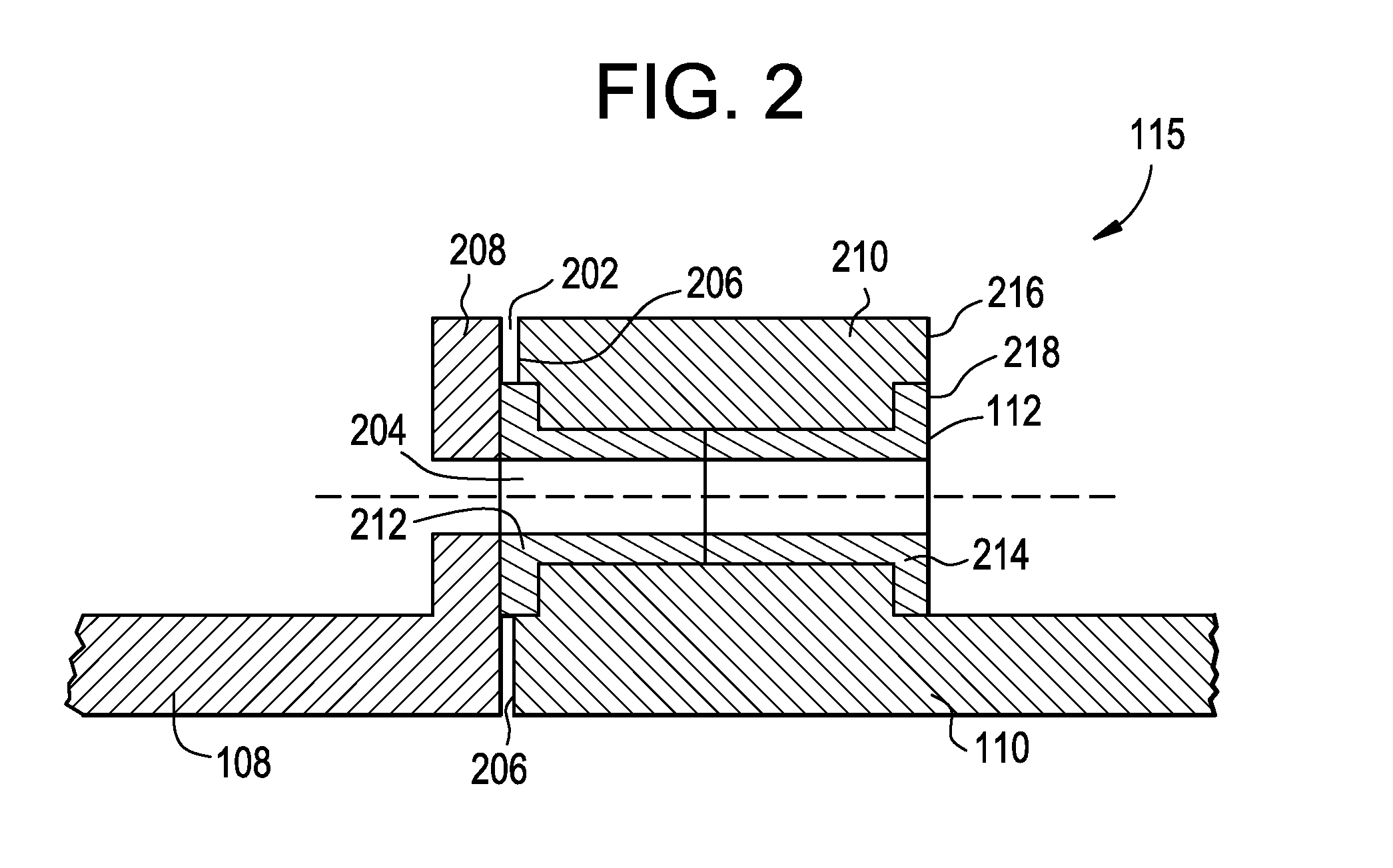

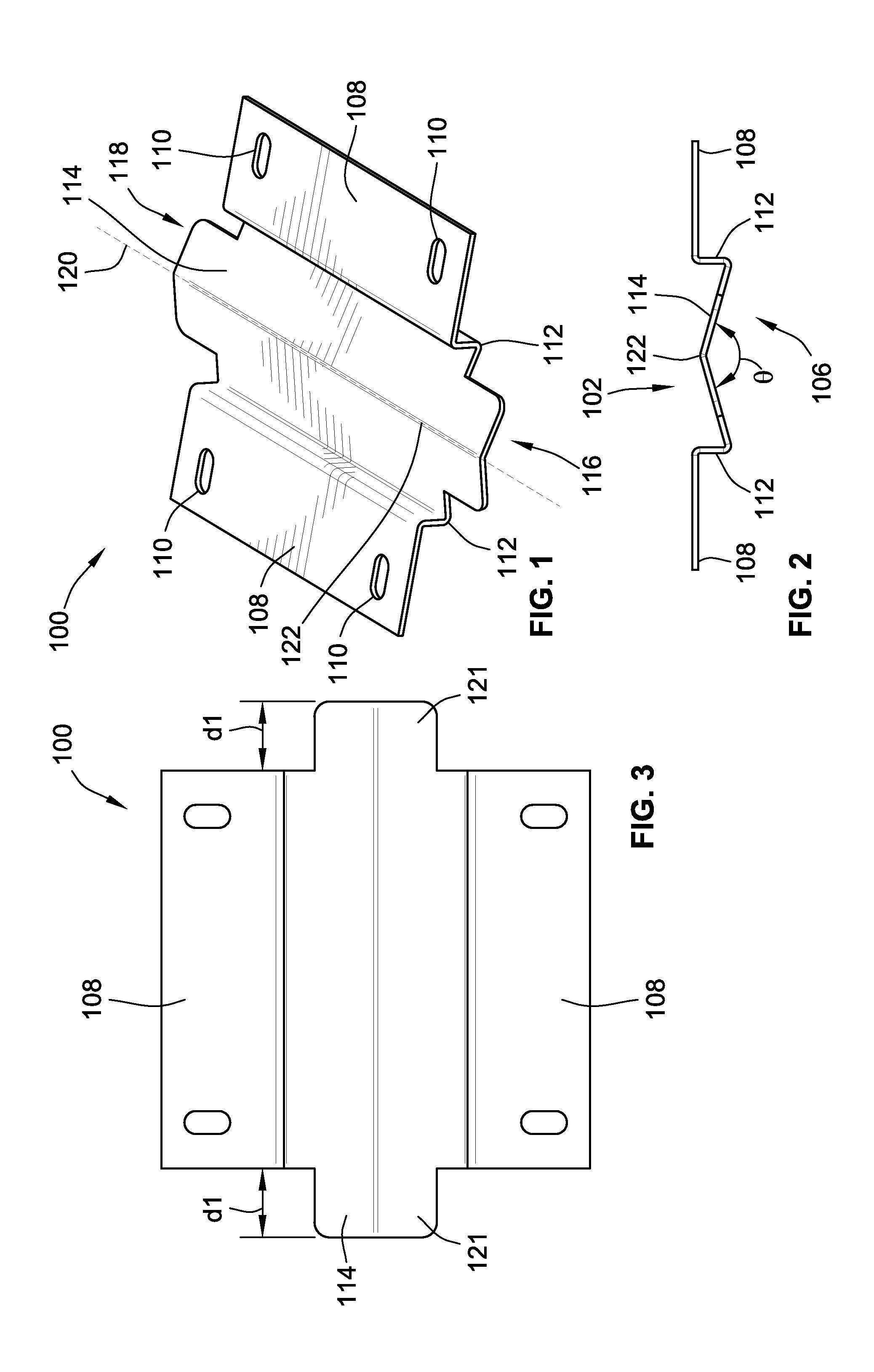

Apparatus and methods for securing a first structural member and a second structural member to one another

ActiveUS20080295334A1Improve the immunityAllowance for thickness variationFuselage framesFuselage bulkheadsVariable thicknessAdhesive

Apparatus and methods for securing a first structural member and a second structural member to one another. In one embodiment a two-piece fitting is provided. The fitting includes a variable gap between attachment surfaces, enabling the fitting to accommodate structural members of variable thickness. The fitting also includes overlapping sections that provide increased resistance to pull-off loads and impact loads. The configuration of the fitting advantageously simplifies the assembly process and preserves the integrity of the adhesive to form a strong joint.

Owner:THE BOEING CO

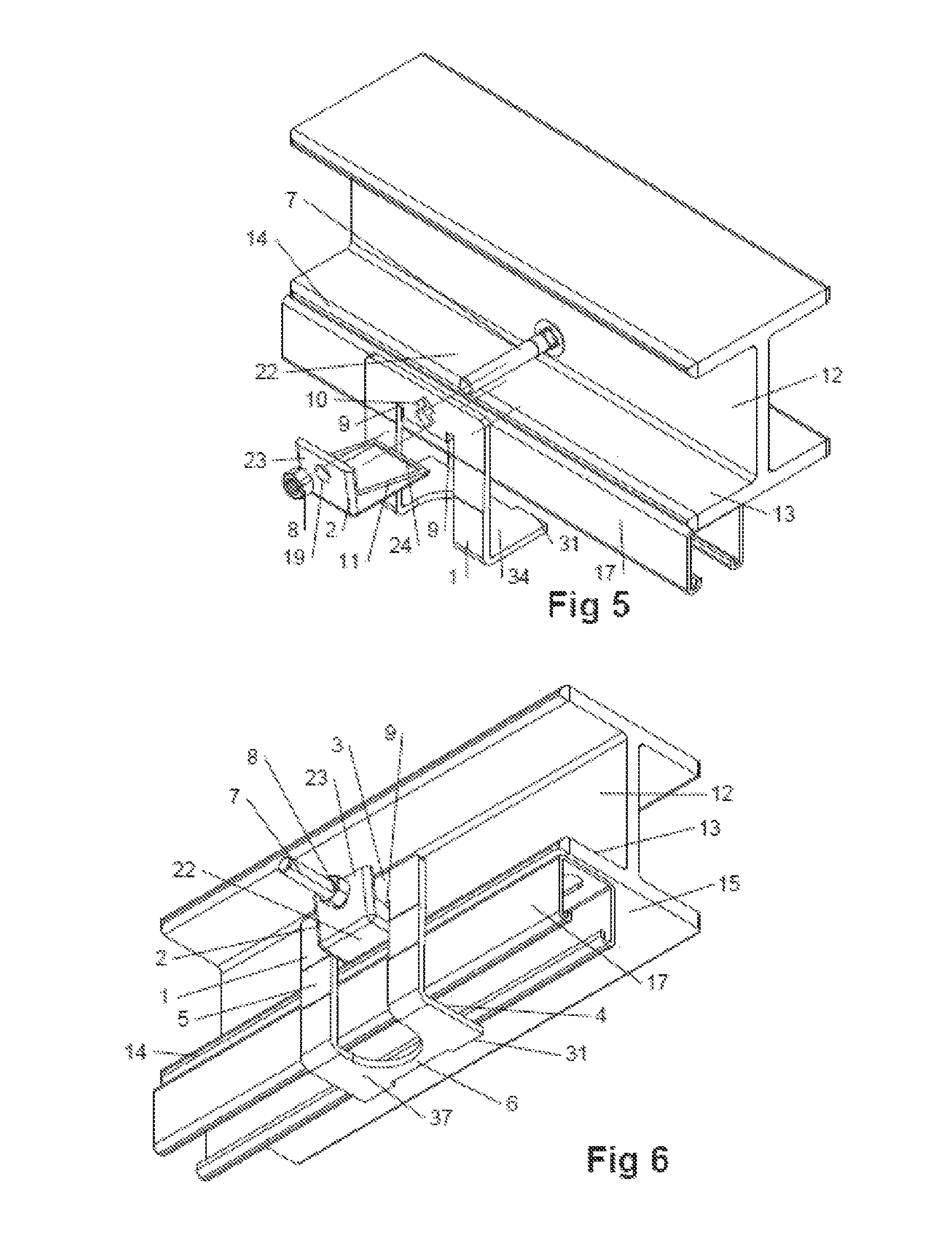

Beam clamp

A beam clamp providing for a positive attachment to I-beams, H-beams, T-bars, pairs of conventional angles, bulb angles, channels, plates and other similar structural shapes wherein the beam clamp includes a pair of clamping hooks incorporated into opposing clamp bodies that capture an attached elongated rectangular, round or other shape. The shapes are secured against the structure using one or more bolt with nut assemblies to pull the halves together towards each other and the attached member and towards the structure.

Owner:MYERS MELVIN L

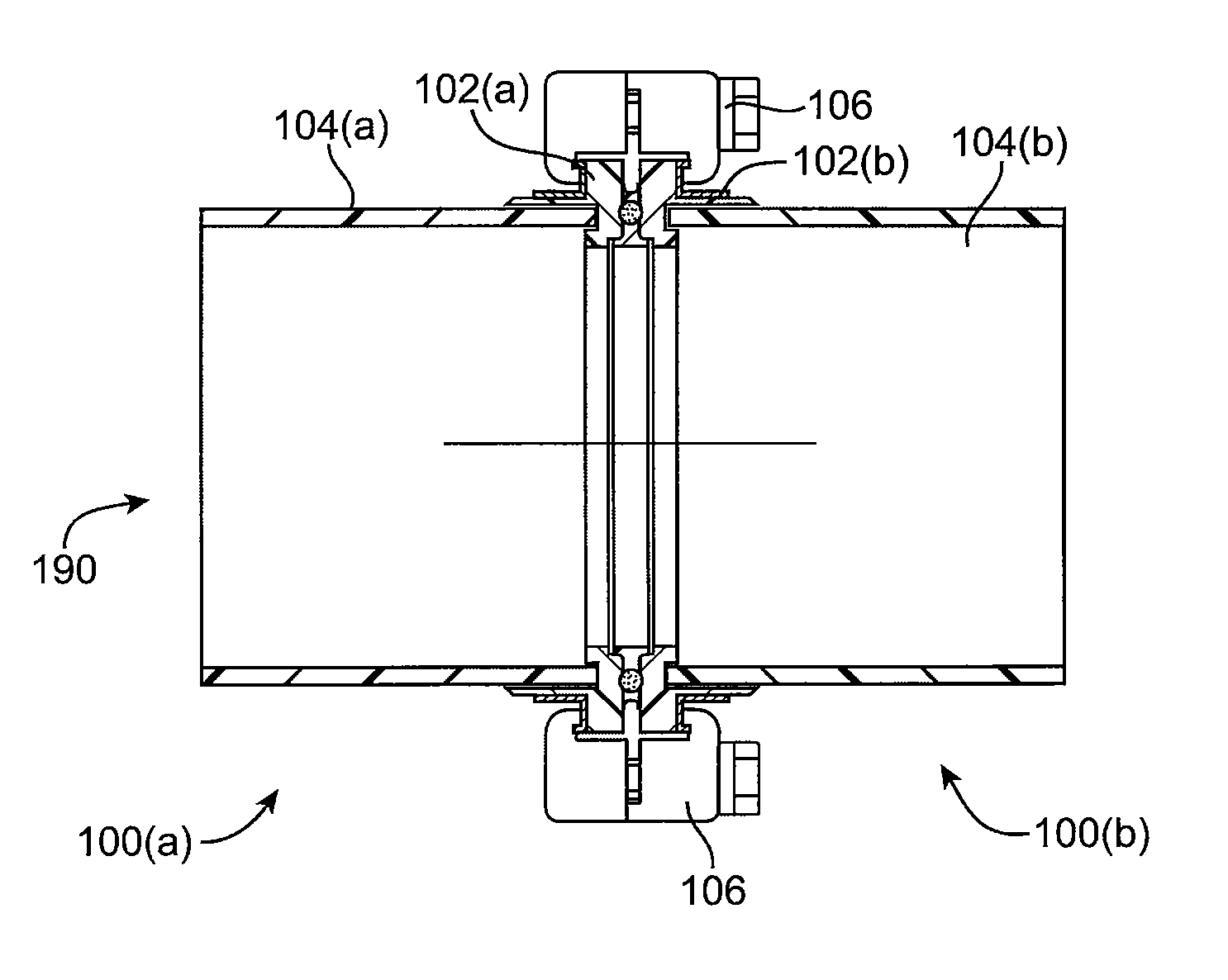

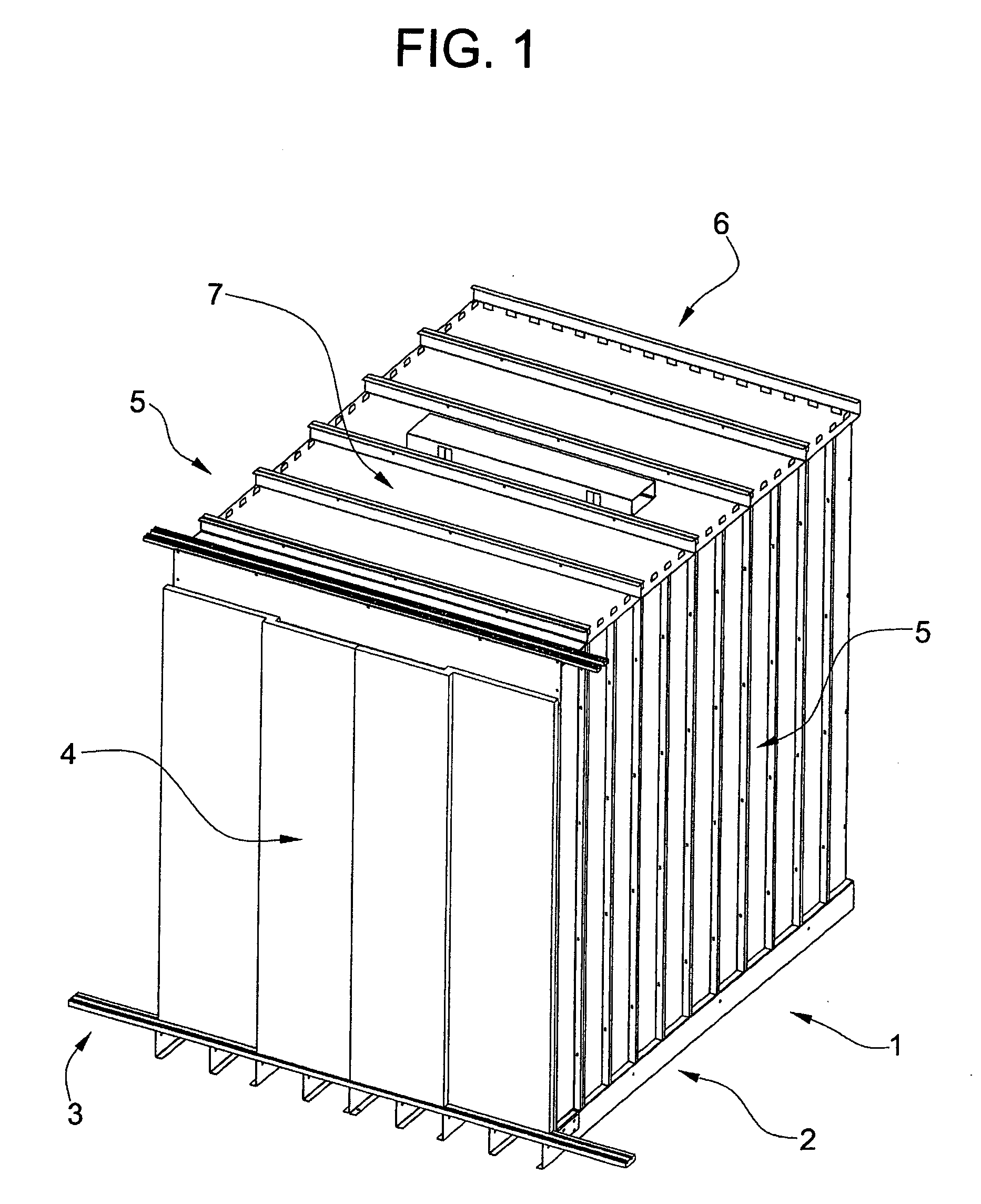

Integrated torque coupling and mount

ActiveUS20140090637A1Reduce gapHigh energyPhotovoltaic supportsSolar heating energyCouplingCollection system

A sun tracking solar energy collection system can include torque tubes formed with a plurality of rotatable shafts connected to each other in an end to end fashion. The ends of the shafts can be connected with coupling devices in the form of an integrated coupling flange and mounting devices. The coupling flange can include a mounting surface that extends generally parallel to the axis of rotation of the shaft. Additionally, the coupling flange can include a coupling face that extends generally perpendicular to the axis of rotation, so as to provide a mating face for an adjacent coupling flange to transmit torque from one shaft to another. The mounting flanges can be used to support devices such as solar energy collection devices including photovoltaic modules or other devices.

Owner:SUNPOWER CORPORATION

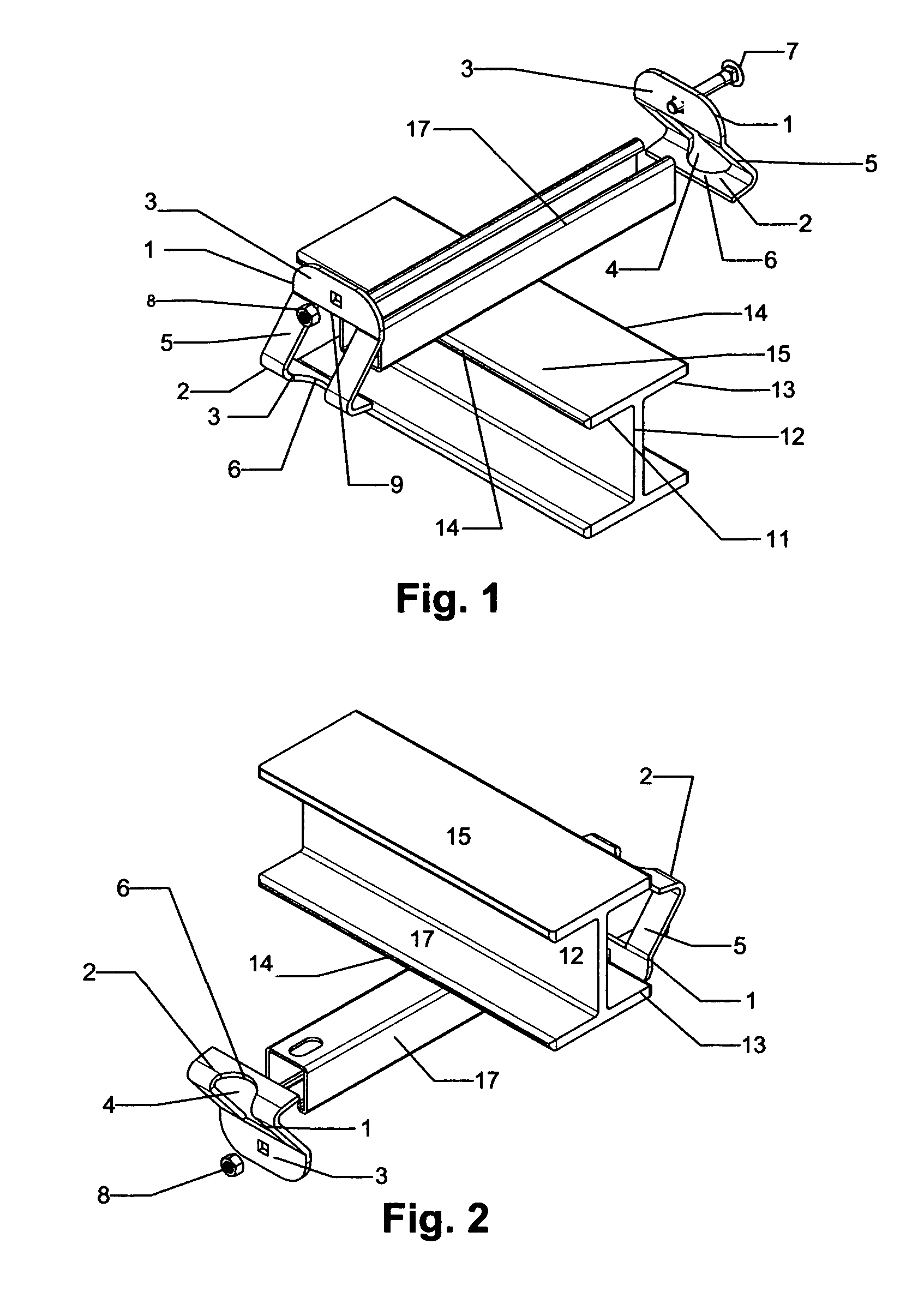

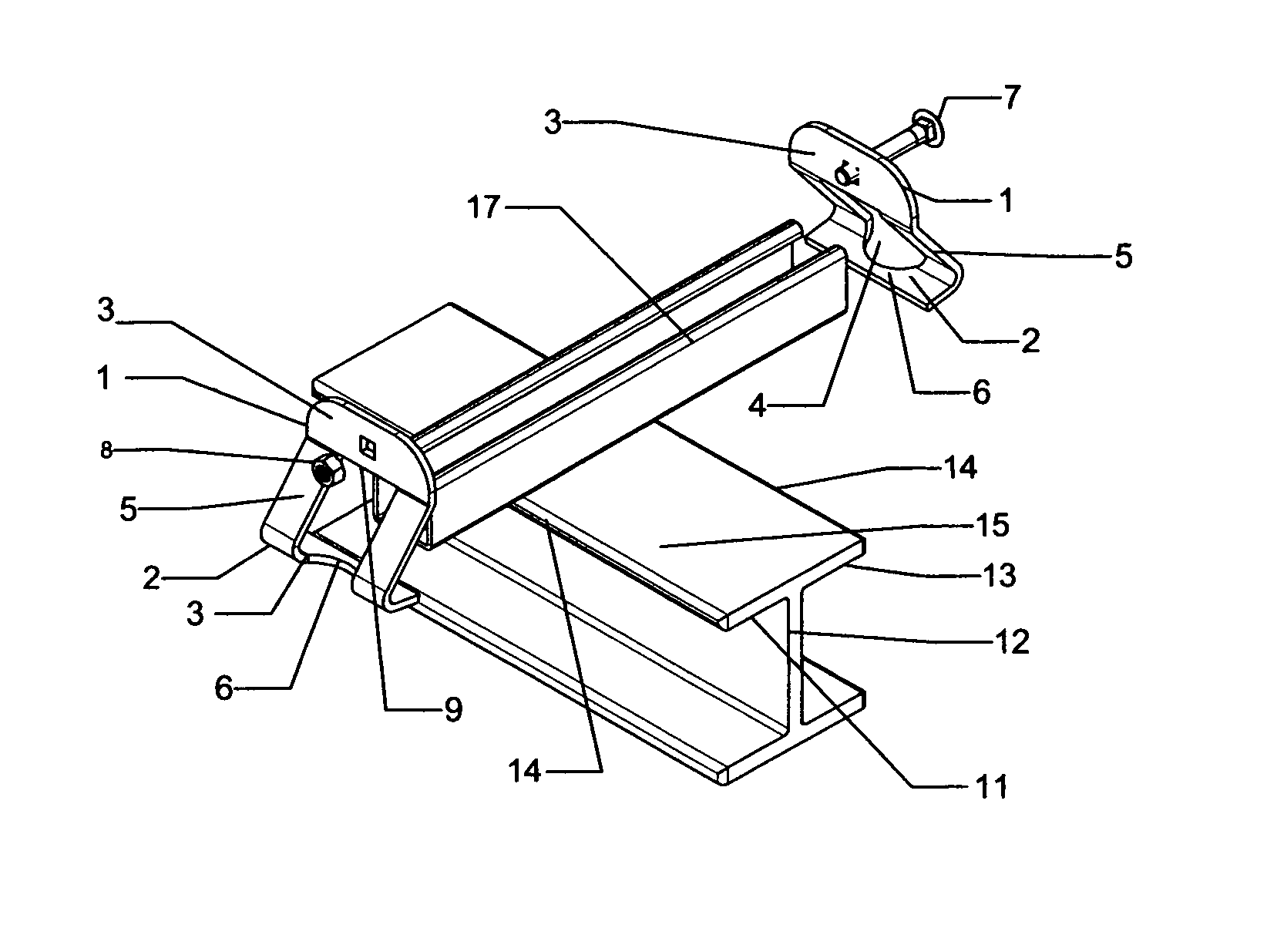

Wedge clamp

A wedge clamp providing for a positive attachment to structural angles, I-beams, H-beams, T-bars, plates, boards, conventional angles, bulb angles, channels, plates and other similar structural shapes comprises a clamp wedge and body that capture objects with two opposing surfaces securing the objects against each other using a fastener or other means to engage both parts of the clamp to pull the wedge through the body and causing the objects being attached together to be squeezed together. The wedge clamp is also used to support other members using a bolt or threaded rod attached to the wedge clamp which in this case normally attaches to a single flange of the structure.

Owner:MYERS MELVIN L

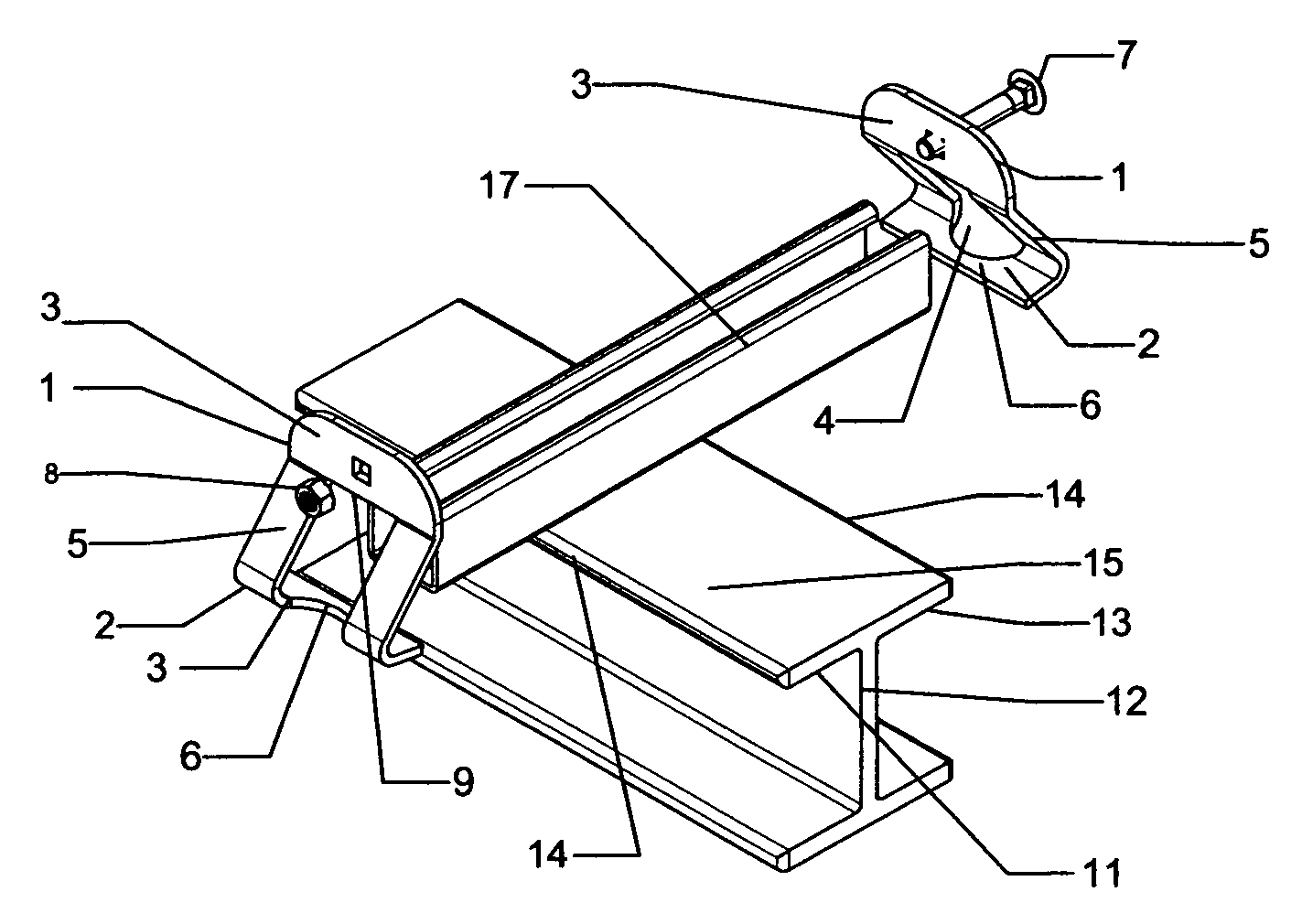

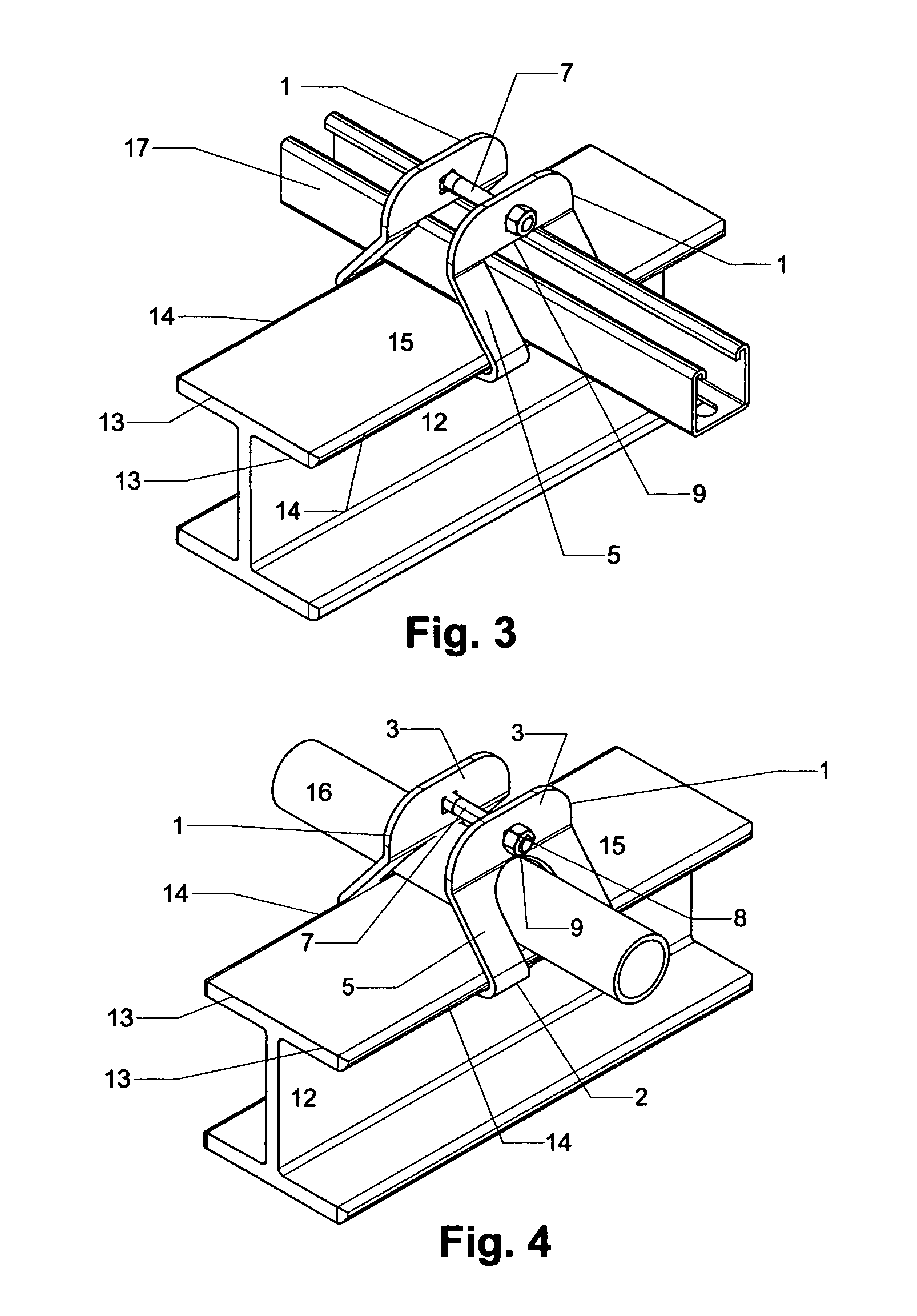

Beam clamp

A Beam Clamp comprised of a pair of similar opposing clamp bodies (1) that preferably has a cross section on the interior surface of each clamp body shaped generally like a “question mark” (?) and is arranged in an assembly where the opposing clamp bodies (1) generally mirror each other where the open portion of each faces each other. The two clamp bodies (1) are connected and pulled toward each other with a fastener such as a bolt (7). The clamp bodies (1) capture a member (16) or (17) such as a pipe or channel and a portion of a structure member (12). A structure flange (13) of a structure member (12) such as an I-Beam is captured with the clamp bodies (1) hooking over opposite edges of the structure flange (13) to leverage and secure the structure member (12), the round member (16) or rectangular members (17) and the 2 clamp bodies (1) together.

Owner:MYERS MELVIN L

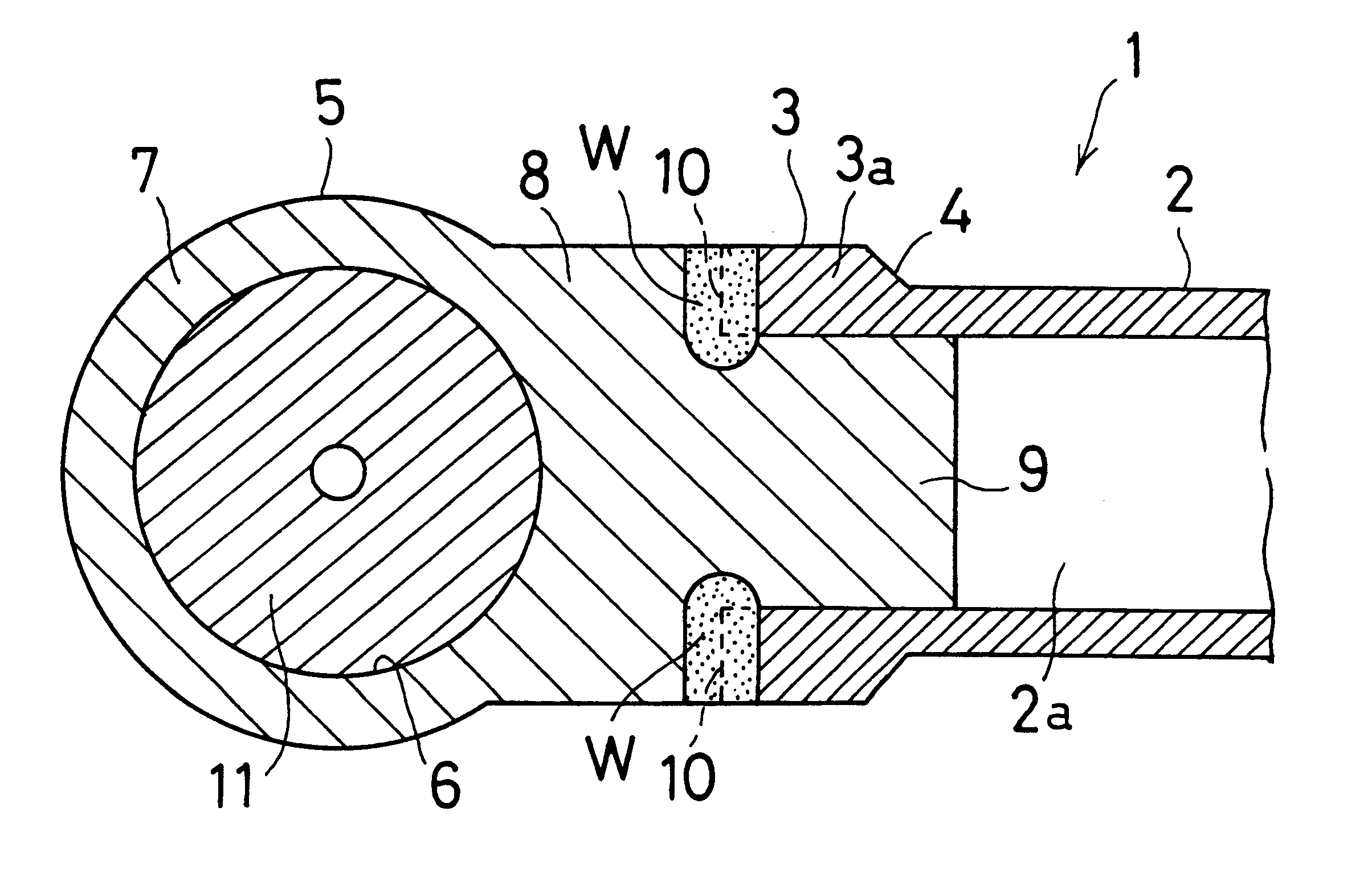

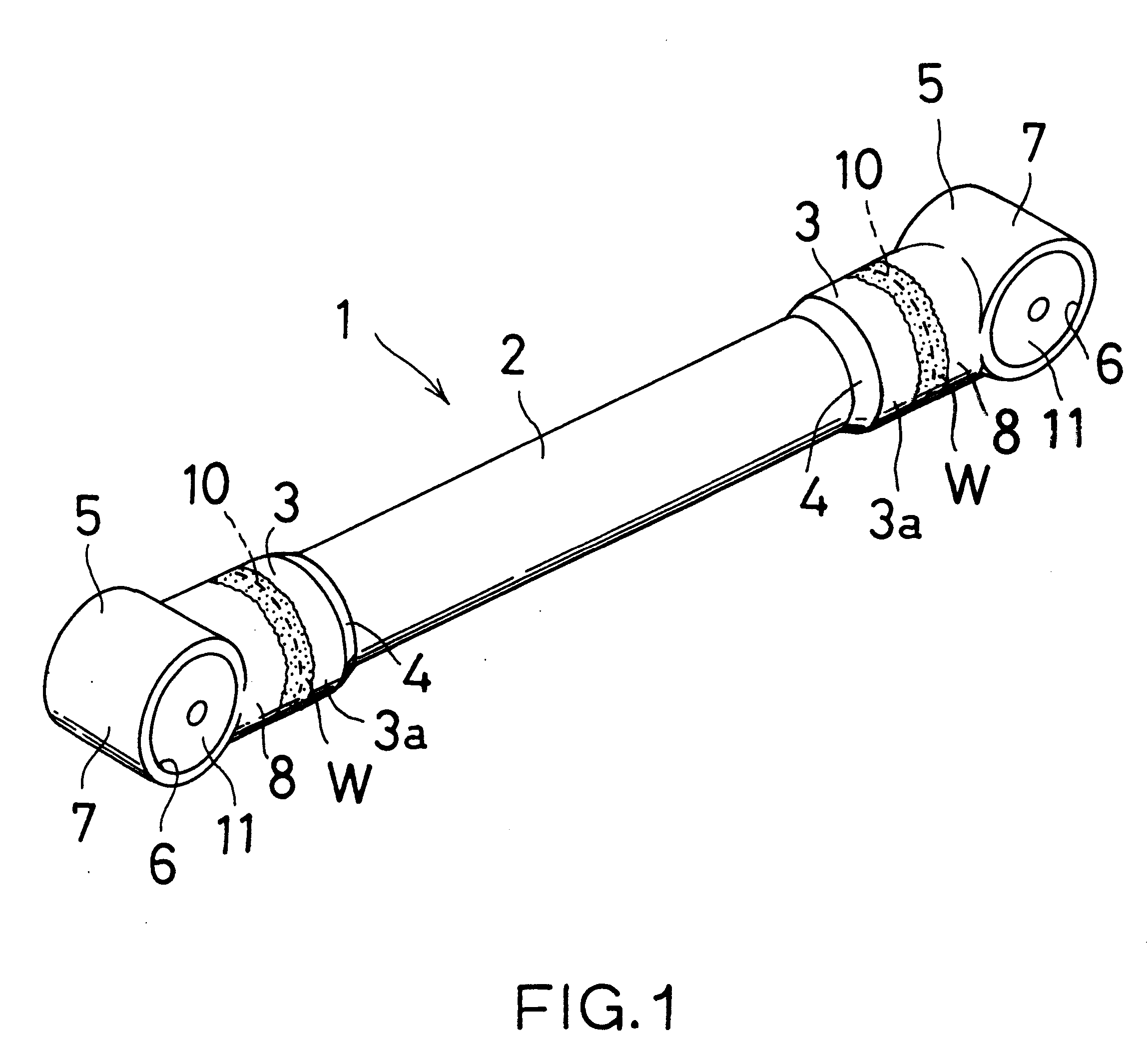

Arm member

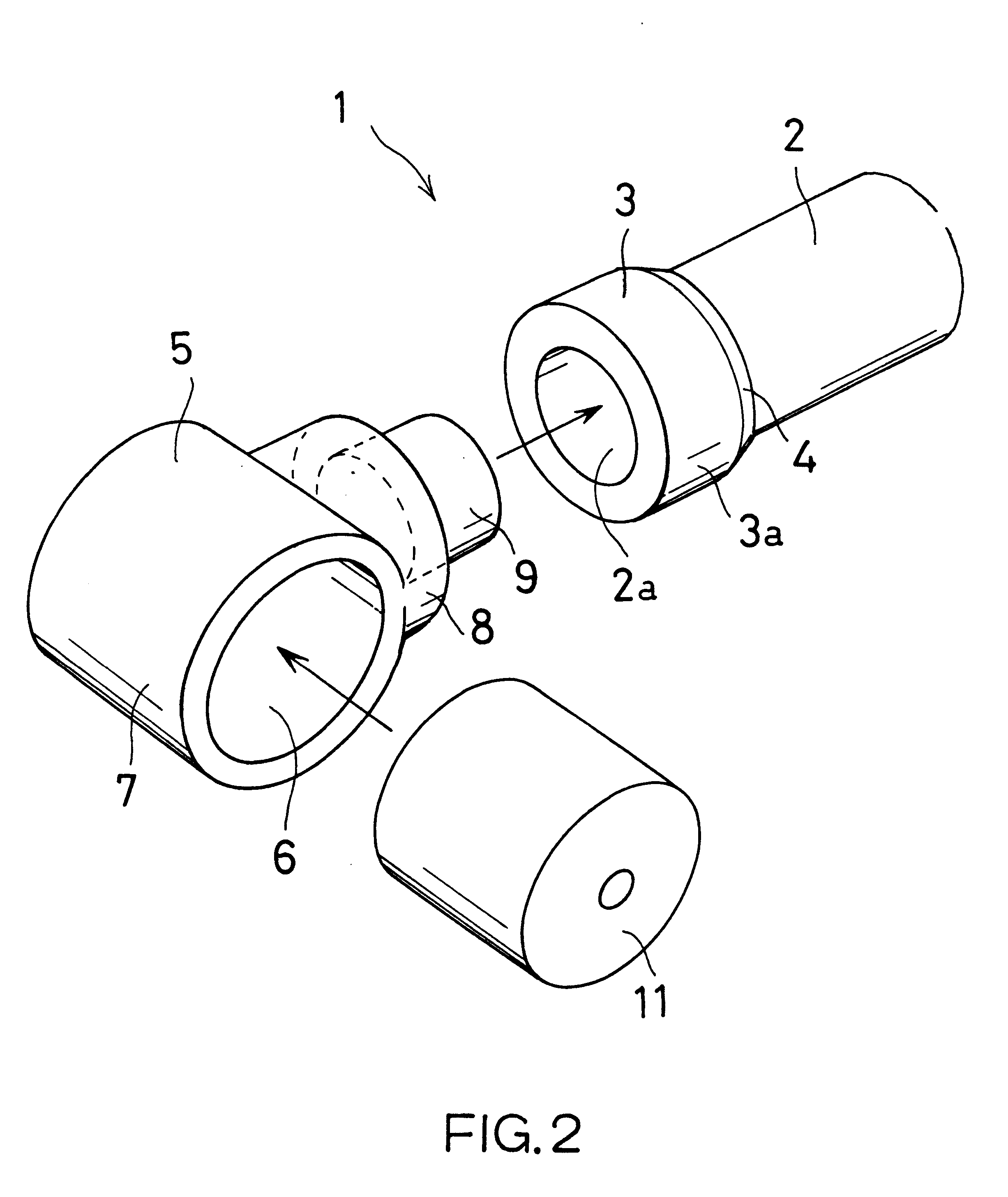

InactiveUS6325567B1Light weightAvoid crackingConnecting rodsMetal-working hand toolsAlloyMechanical engineering

An arm member is used as, for example, a suspension arm of an automobile. The arm member comprises a main body made of a pipe member and a coupling member having a connecting portion. The pipe member is made of aluminum or its alloy. The coupling member is made of aluminum and includes a bushing mounting portion for mounting a vibroisolating bushing. The thickness of the peripheral wall of the end portion of the main body is increased in thickness to have a thickness thicker than that of the other portion of the main body. The connecting portion is abutted to the peripheral wall of the end portion to form an abutted portion, and connected thereto at the abutted portion. Thus, the coupling member is coupled to the main body.

Owner:SHOWA DENKO KK +1

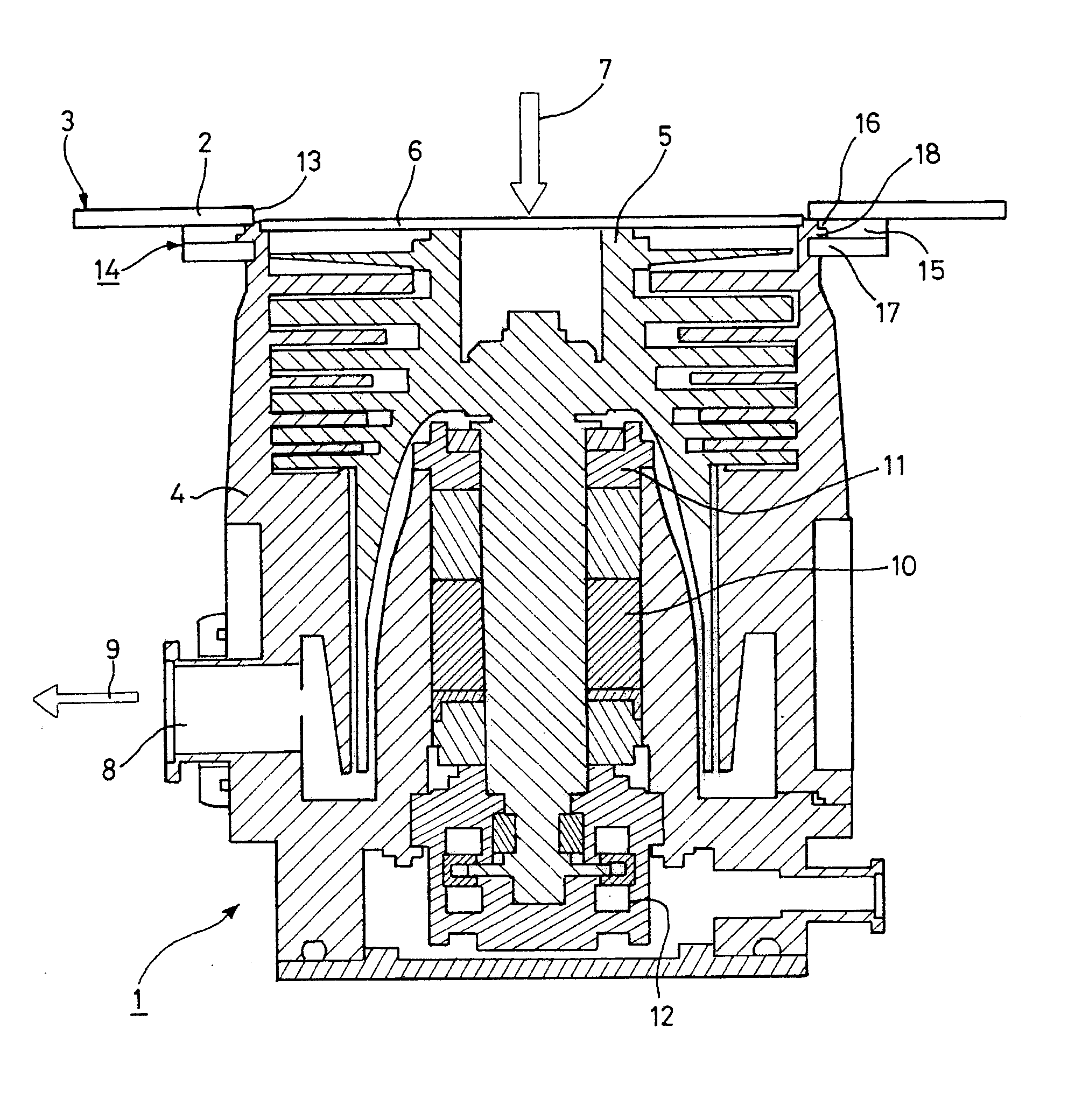

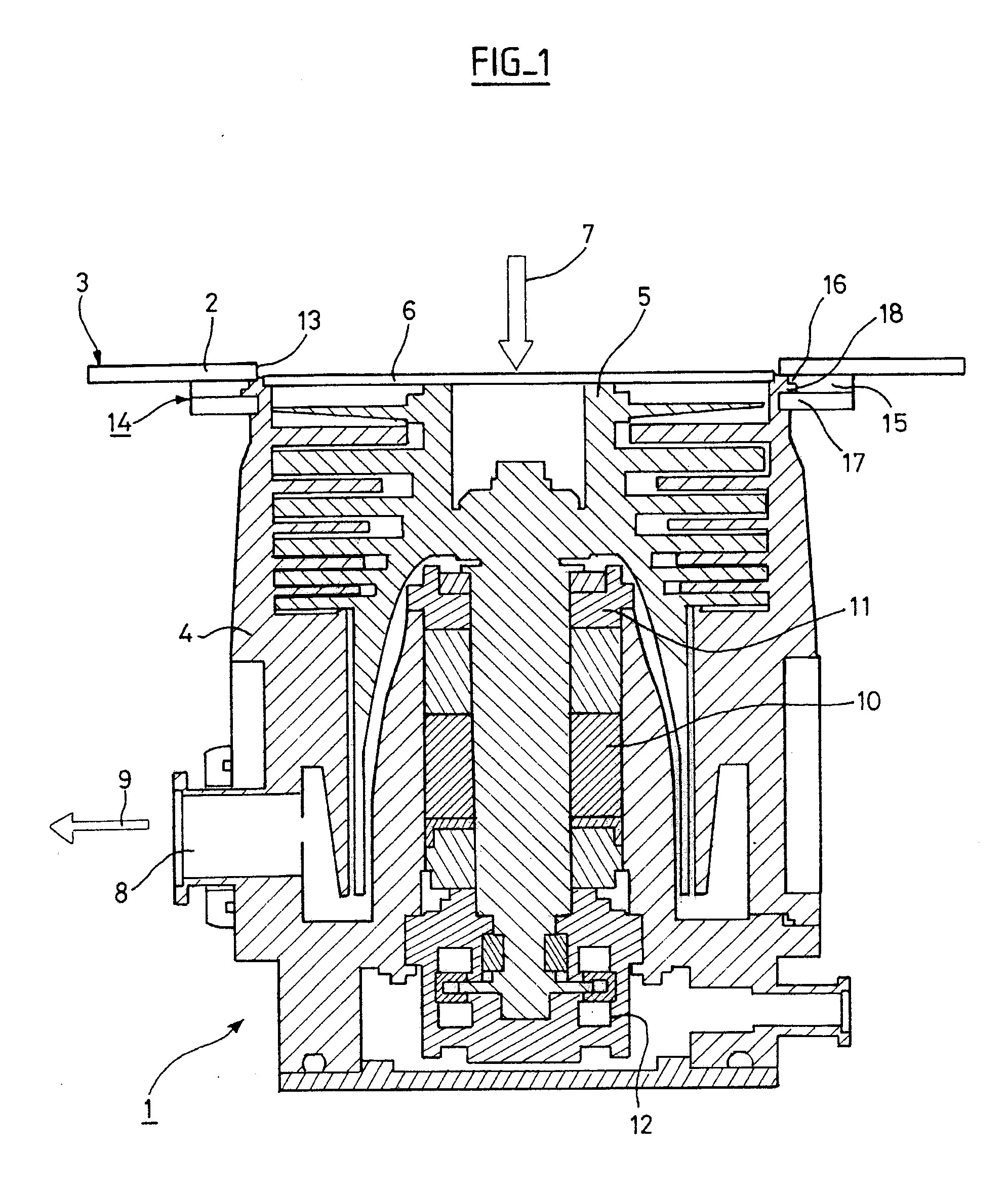

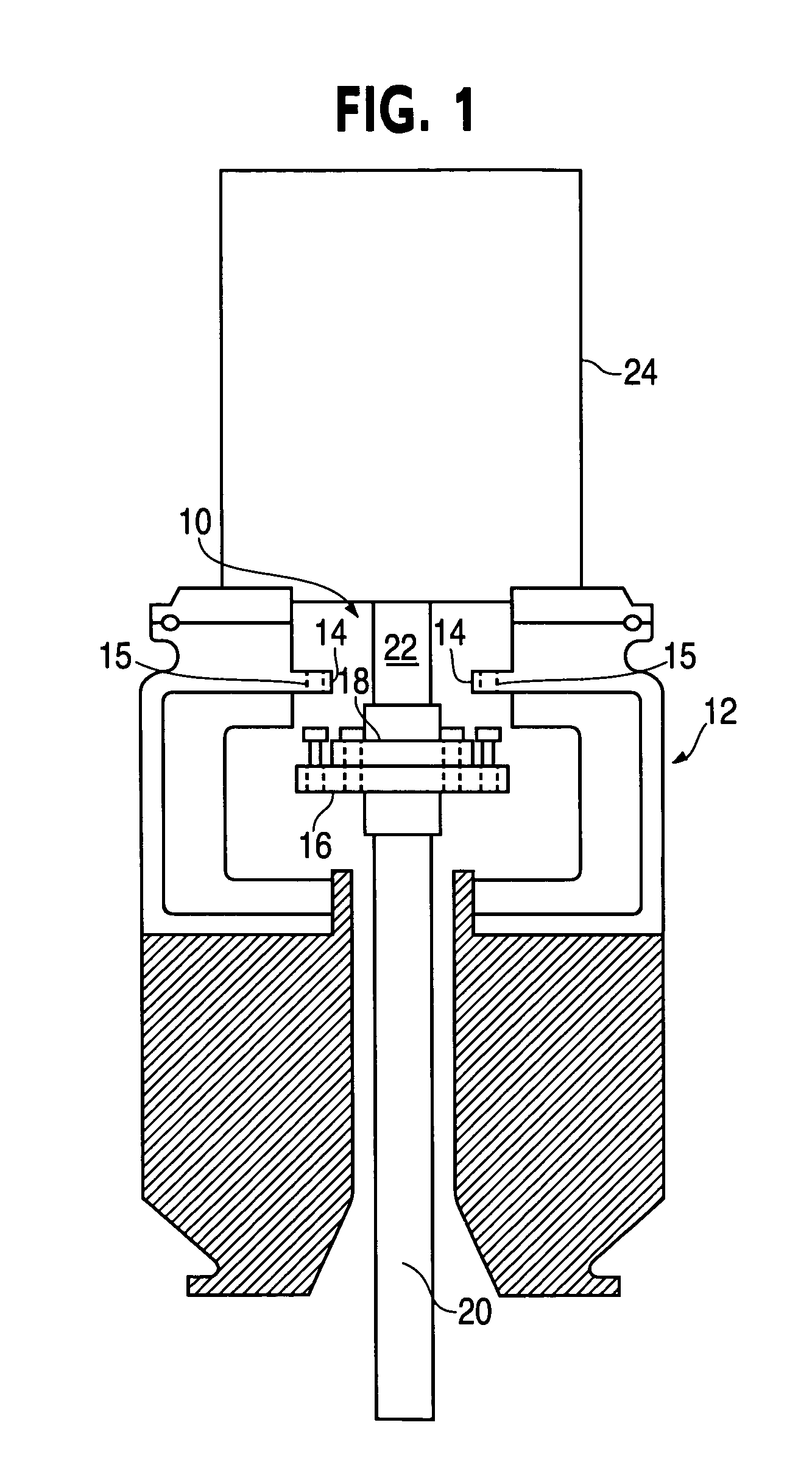

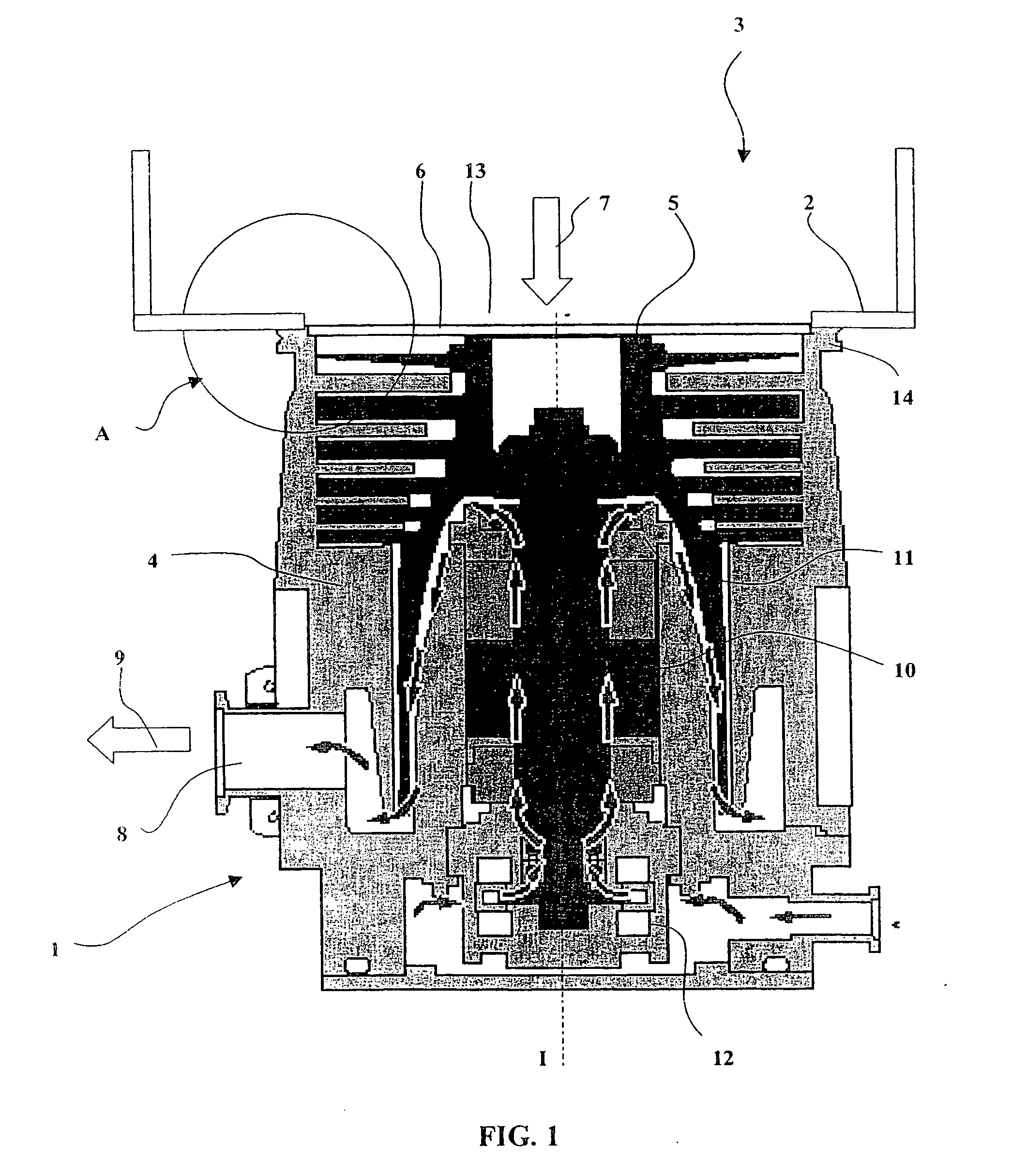

Vacuum pump

InactiveUS6923628B1Light weightSimple and cost-effectiveYielding couplingOscillating piston enginesMobile vehicleEngineering

A vacuum pump, in particular for brake booster systems in motor vehicles, with a drivable rotor via which a blade in a housing can be set in rotation is proposed. The vacuum pump is distinguished by the fact that the rotor consists of plastic and is formed as one piece.

Owner:HANON SYST EFP DEUT GMBH

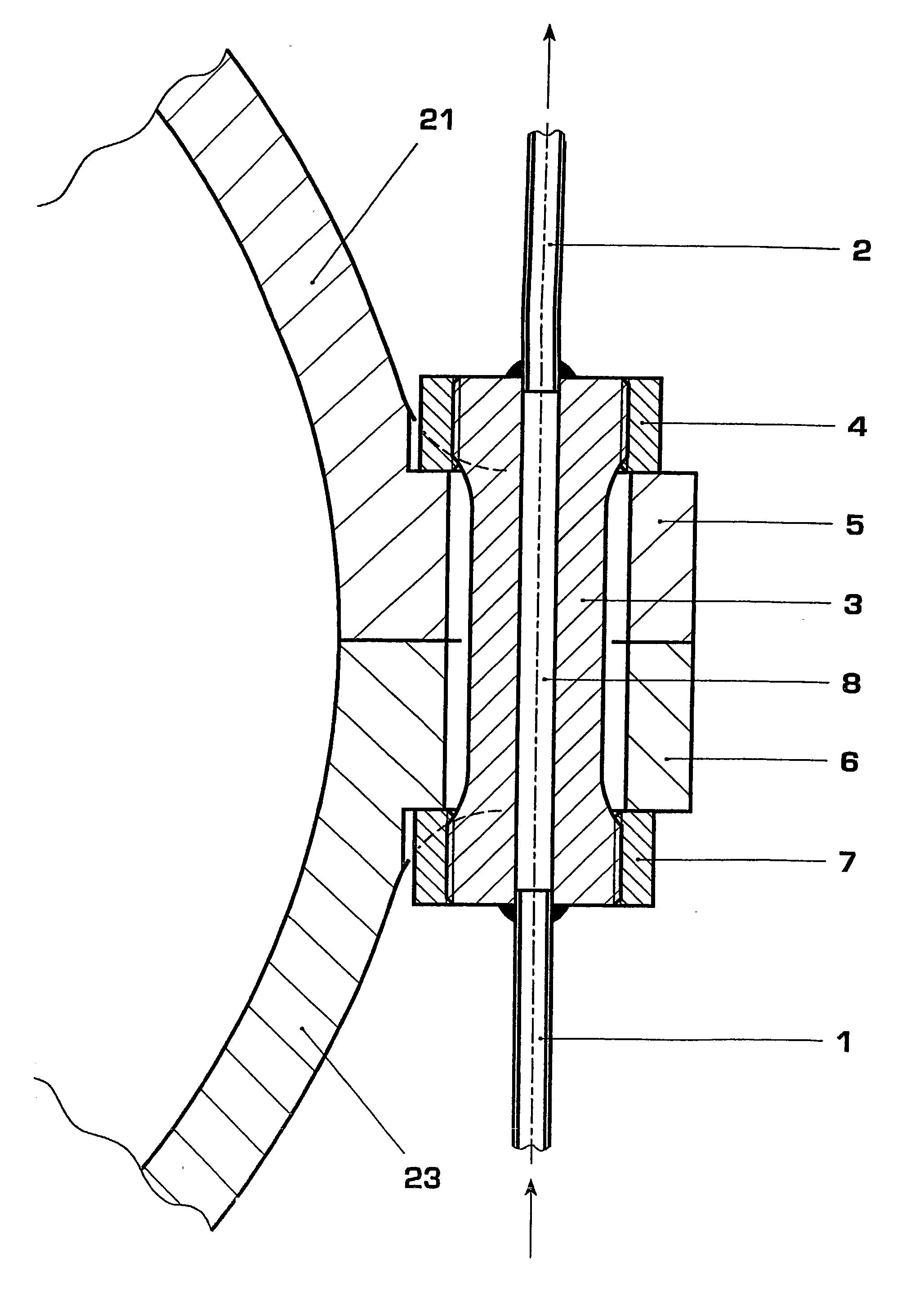

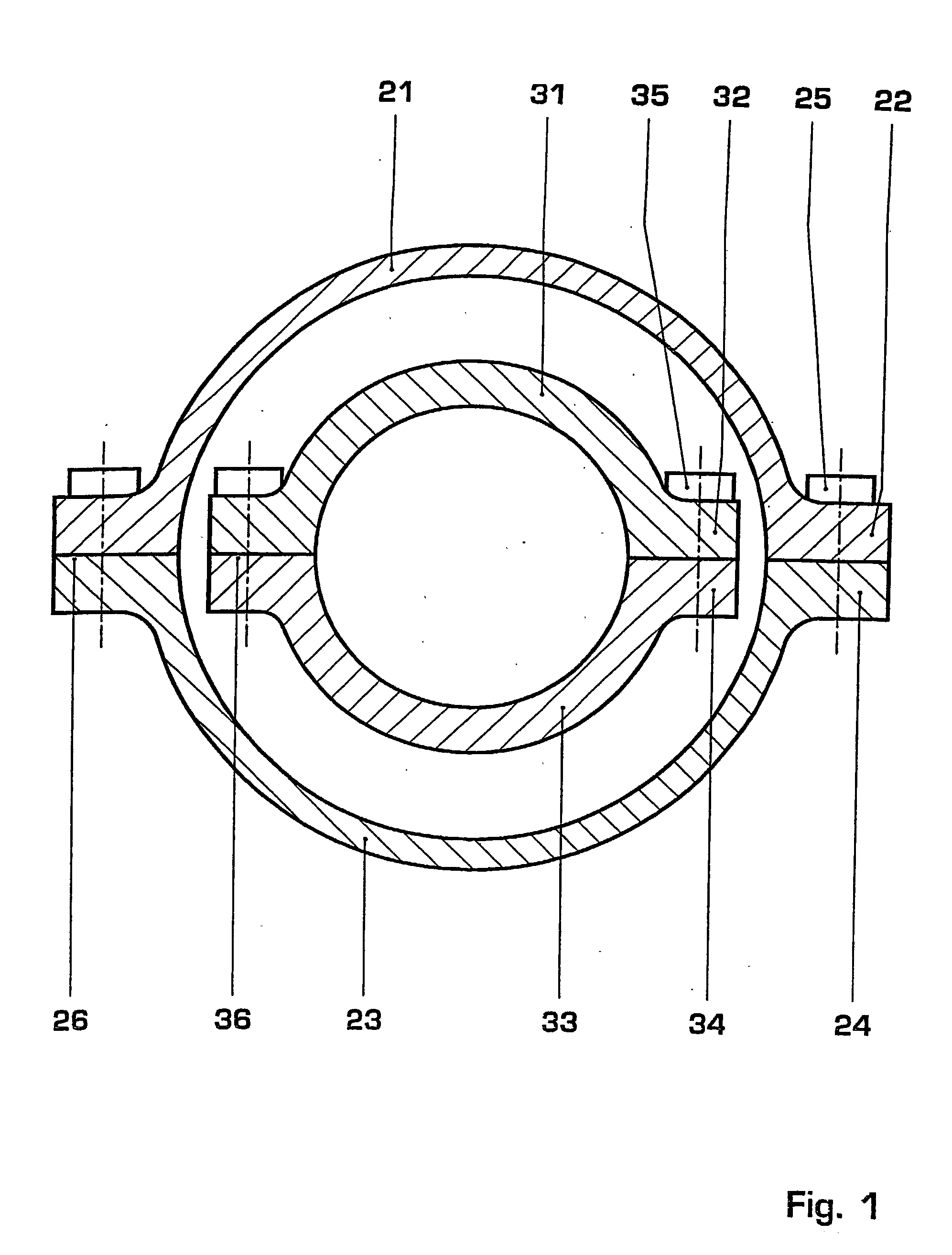

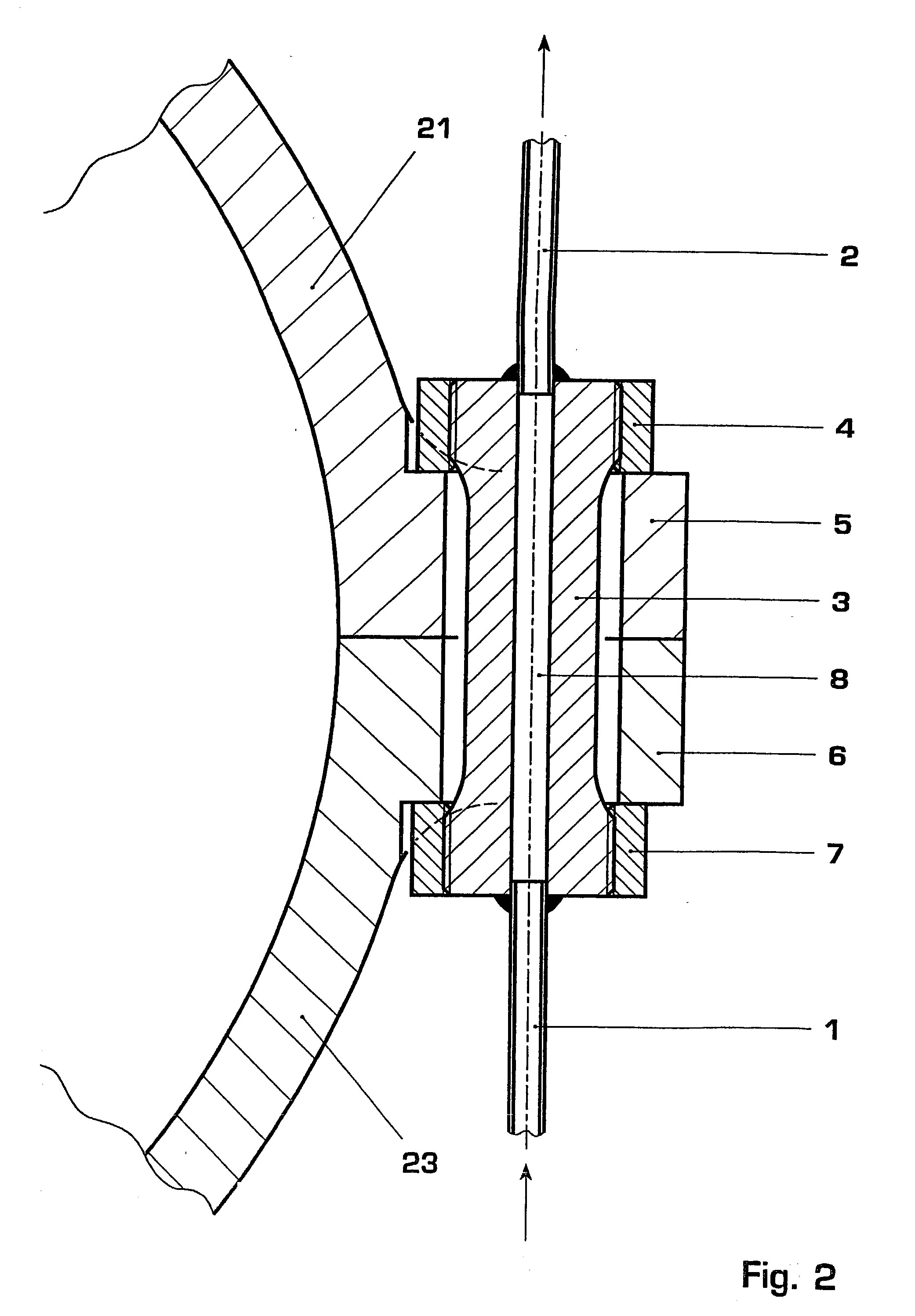

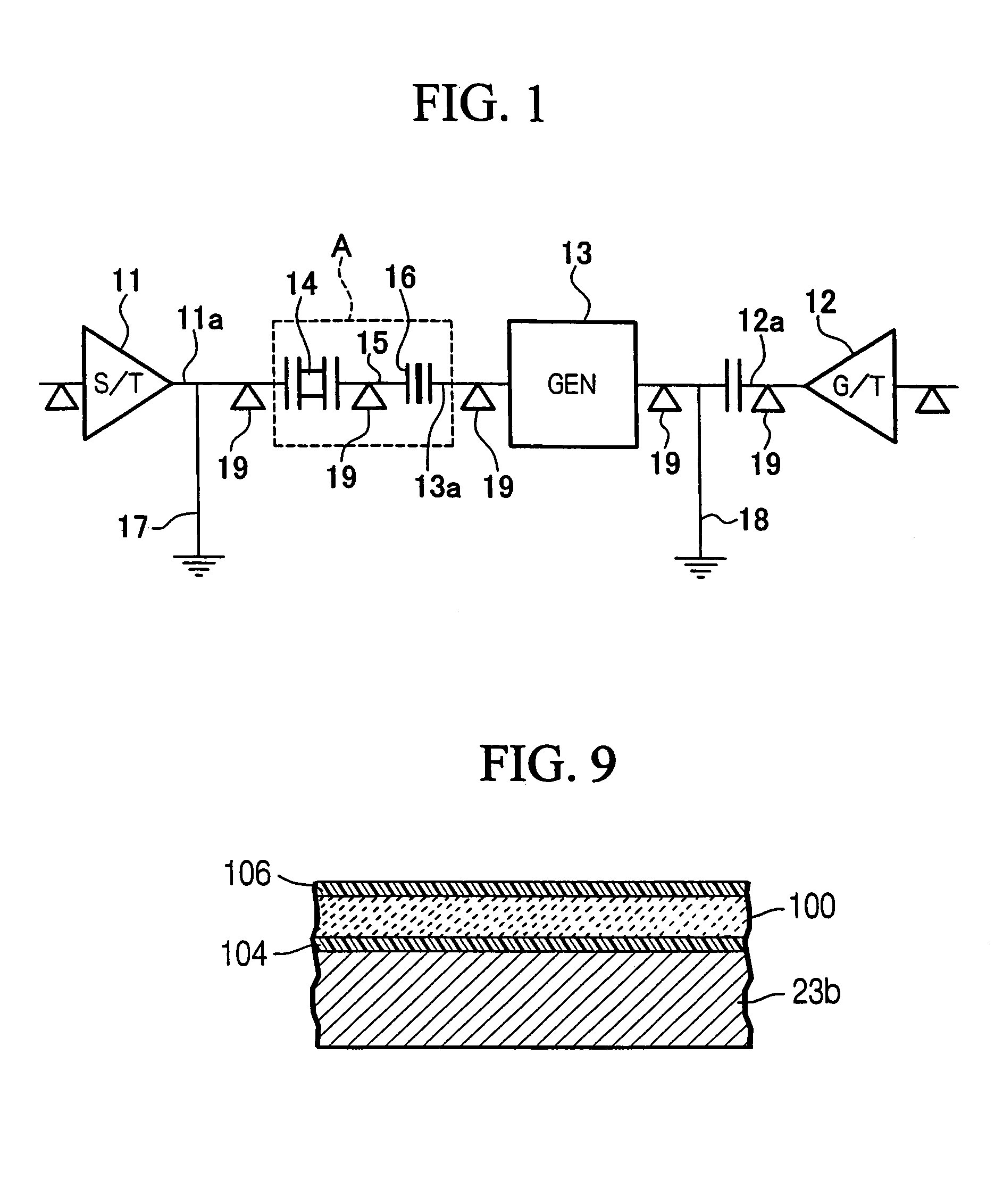

Flange bolt for turbines

InactiveUS20030180140A1Improve stabilityControl changesWind motor controlPipe elementsEngineeringTurbine

According to the invention an arrangement for cooling or heating of a flange bolt for turbines comprises one or more boreholes, that extend through the bolt, and inlet and outlet pipes that are connected to each end of the borehole. A cooling or heating medium such as air, steam or any other fluid flows through an inlet pipe into and through the borehole thereby cooling or heating the bolt, and exits from the borehole via an outlet pipe. The cooling or heating arrangement enables direct cooling or heating of the bolt itself and ensures stable bolting forces throughout the operation of the turbine. The flange bolts with this arrangement may be applied to gas turbines or steam turbines operated at elevated steam temperatures and pressures.

Owner:GENERAL ELECTRIC TECH GMBH

Electric isolators for couplings

A transfer device includes a first portion having a first portion flange and a second portion having a second portion flange. The device also includes one or more isolating members disposed at least partially within the second portion flange and at least partially between the first portion flange and the second portion flange, the one or more isolating members electrically isolating the first portion from the second portion. The device also includes a fastener passing through one of the one or more isolating members, the first portion flange and the second portion flange and holding the first portion flange and the second portion flange in a fixed relationship to one another.

Owner:GENERAL ELECTRIC CO

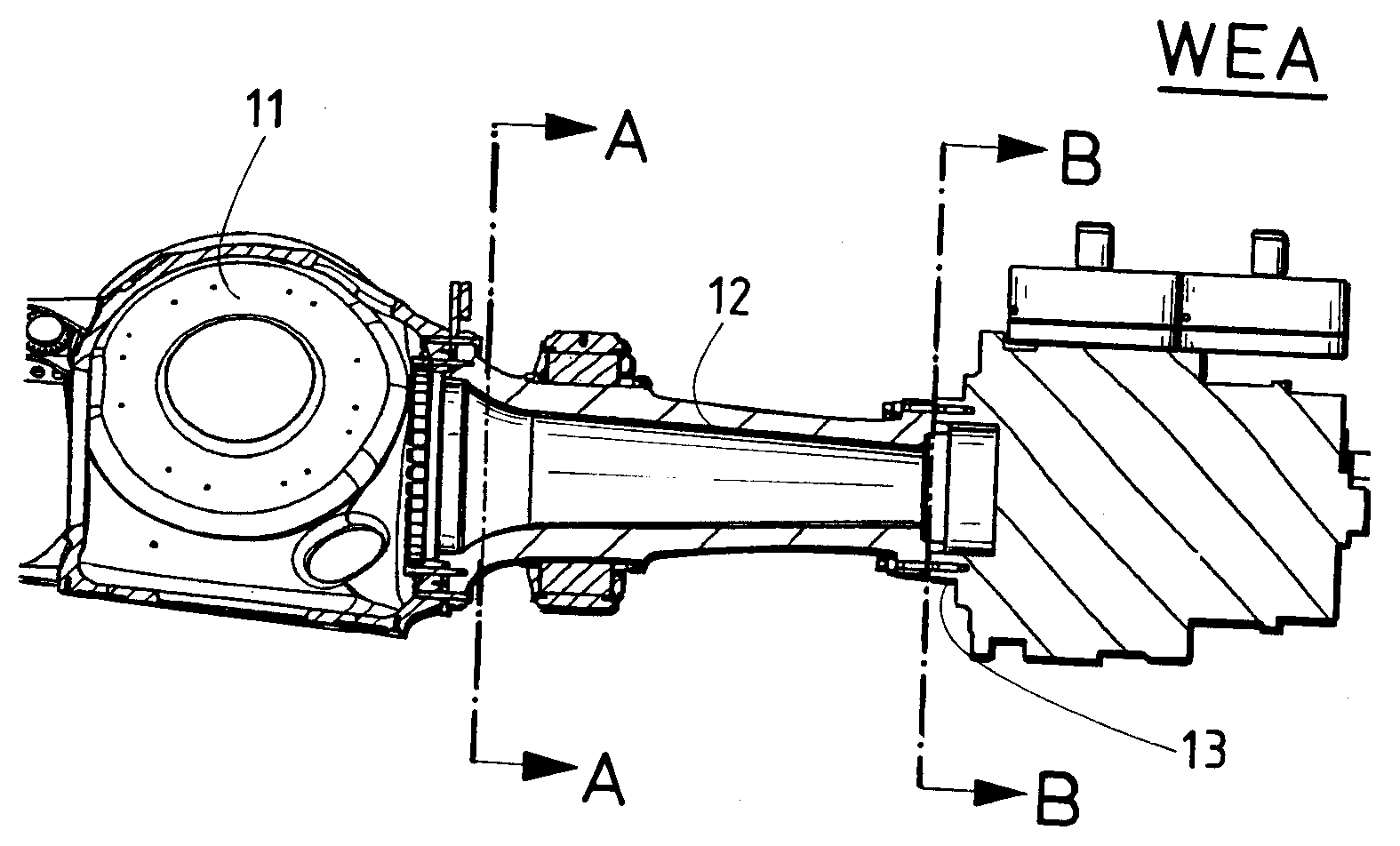

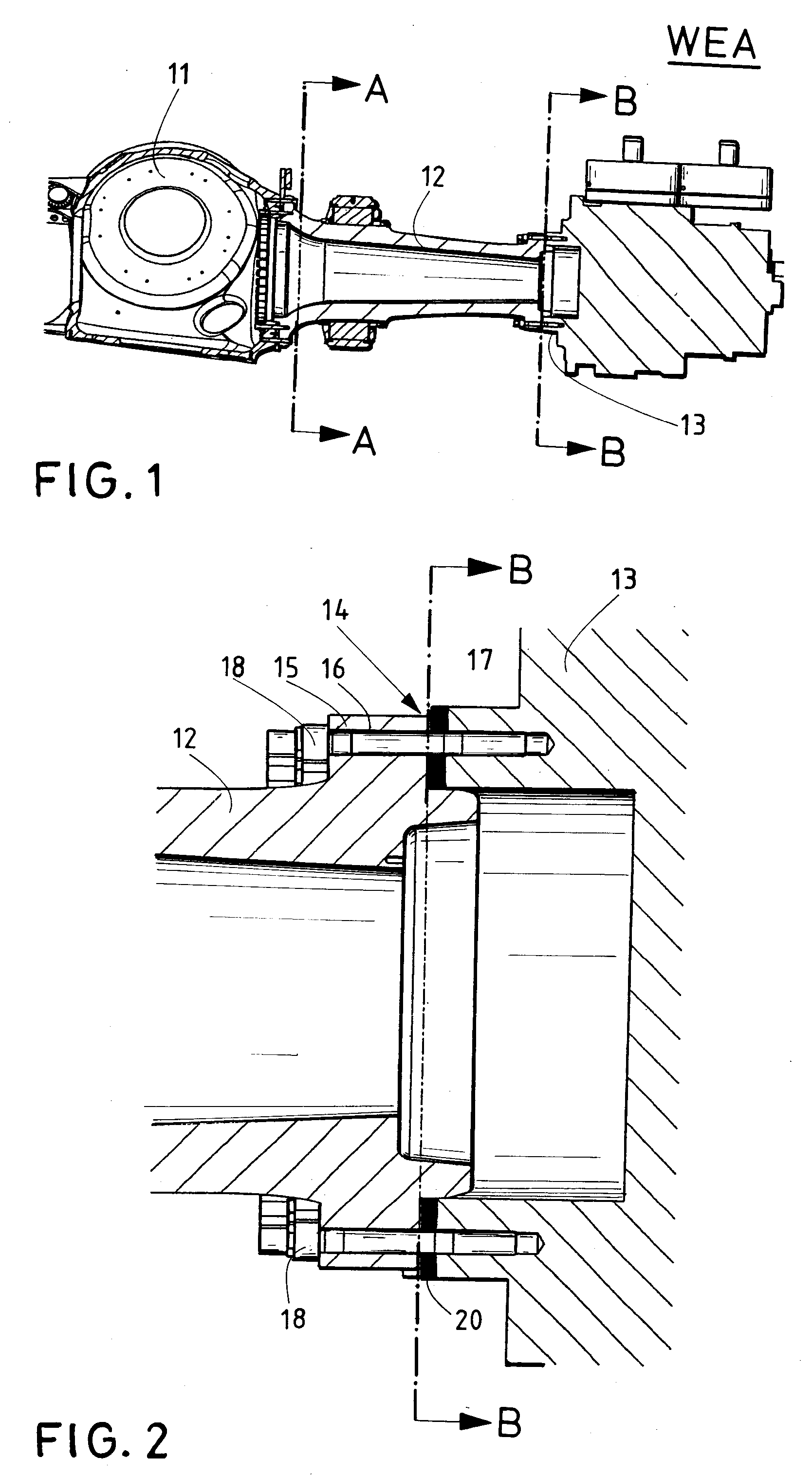

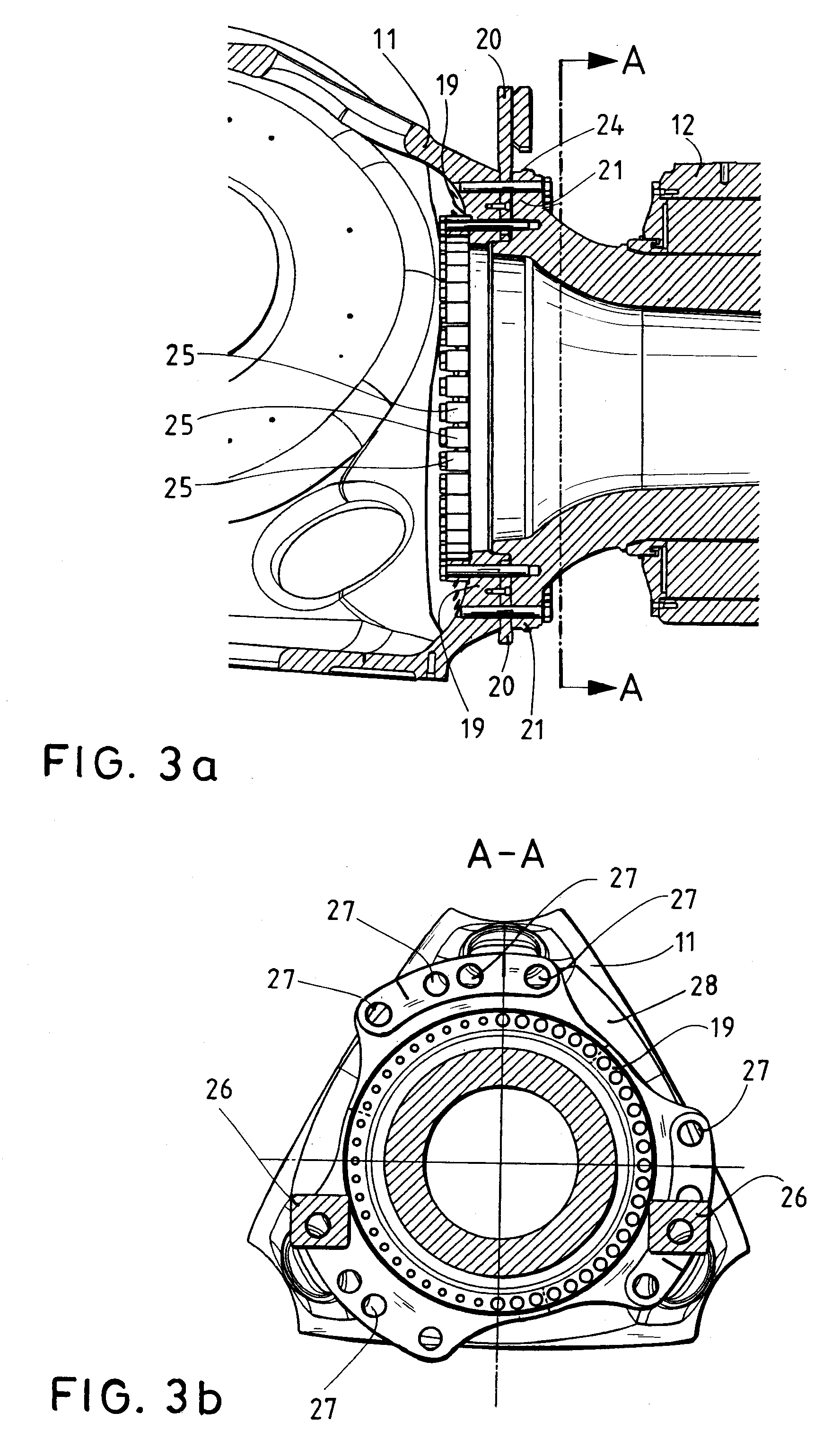

Connection of components of a wind turbine

ActiveUS20080240922A1Increase coefficient of frictionIncrease roughnessPropellersFinal product manufactureEngineeringTurbine

The invention relates to a connection between components of a wind turbine. More specifically, the present invention relates to components for a wind turbine having a diameter of more than 0.5 m, preferably more than 1.0 m, and more preferably more than 1.5 m. The wind turbine includes two components that are connected together, whereby each component has a contact surface. The surface of the contact surface of a first component is softer than the surface of the contact surface of a second component. Further, the surface of the contact surface of the second component is annealed.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

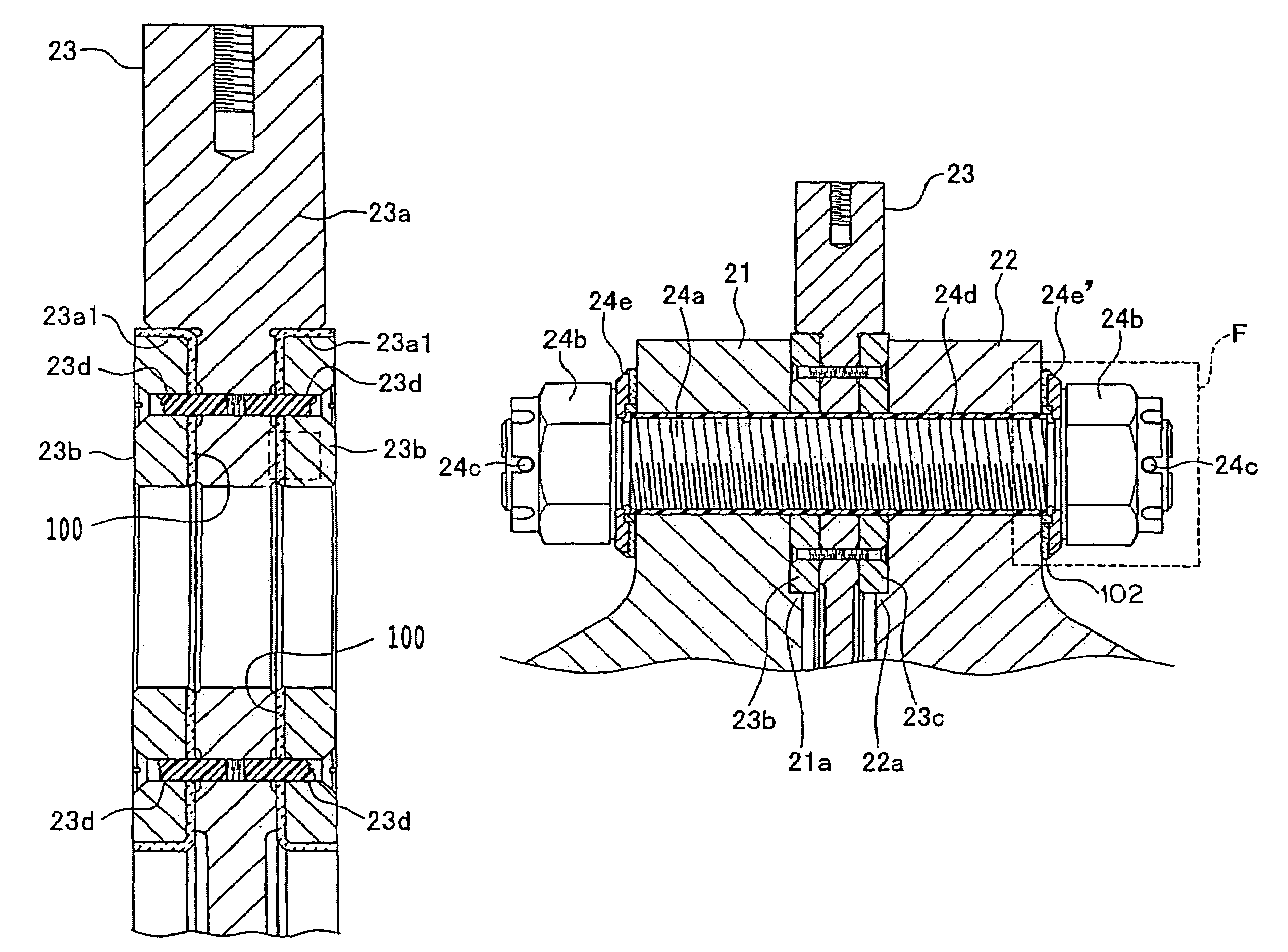

Rotor coupling having insulated structure

InactiveUS7530757B2Prevent galvanic corrosionPotential of each rotor can be reducedMolten spray coatingCombination enginesElectricityCoupling

A rotor coupling having insulated structure which can assuredly prevent galvanic corrosion of beating members, rotors and the like which is caused by shaft voltage, is provided in a shaft system that requires insulation. A generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine. The rotor coupling having insulated structure is employed in power generating equipment in which a generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine, a generator rotor and a rotating machinery rotor are connected, a first grounding electrode is provided to the steam turbine rotor, and a second grounding electrode is provided to the generator rotor, wherein both the rotors between the generator and the steam turbine are connected in an electrically insulated state.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Beltway system for a modular furniture assembly

A beltway system for modular furniture assembly is configured to connect to two or more workstations. The beltway system includes a main body including a first end and a second end opposing the first end and a first side and a second side opposite the first side. The first side faces a first of the two or more workstations and the second side faces a second of the two or more workstations. The beltway system includes a data trough configured to provide data connection to the two or more workstations. The data trough extends between the first end and the second end. The beltway system also includes at least one power block spatially separated a distance above the data trough. The power block includes a first power receptacle facing the first side and a second power receptacle facing the second side.

Owner:MAYLINE

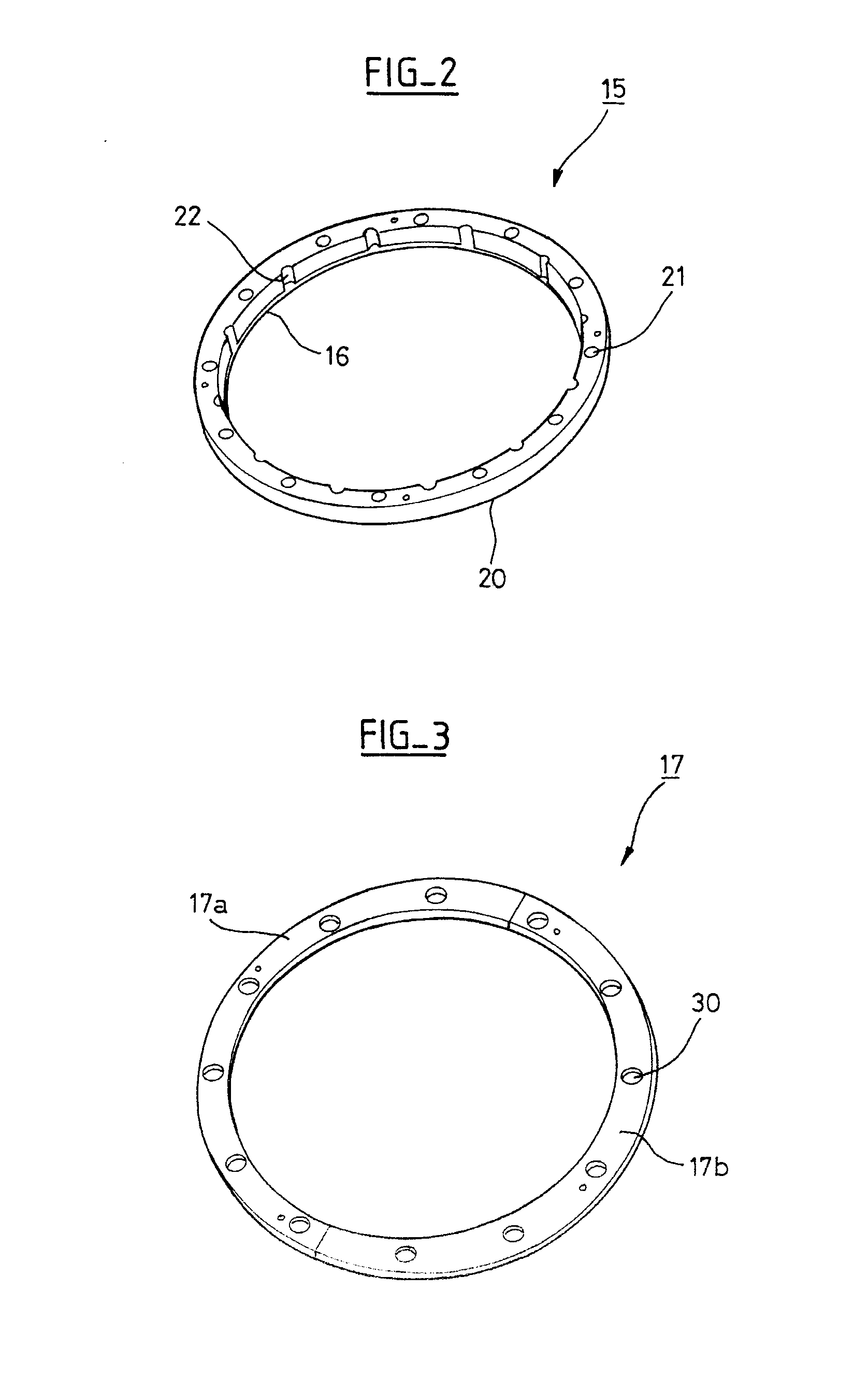

Flange assembly

ActiveUS7488010B2Easy disconnectionEasy to useSleeve/socket jointsFlanged jointsPlastic materialsEngineering

Owner:ATS PRODS

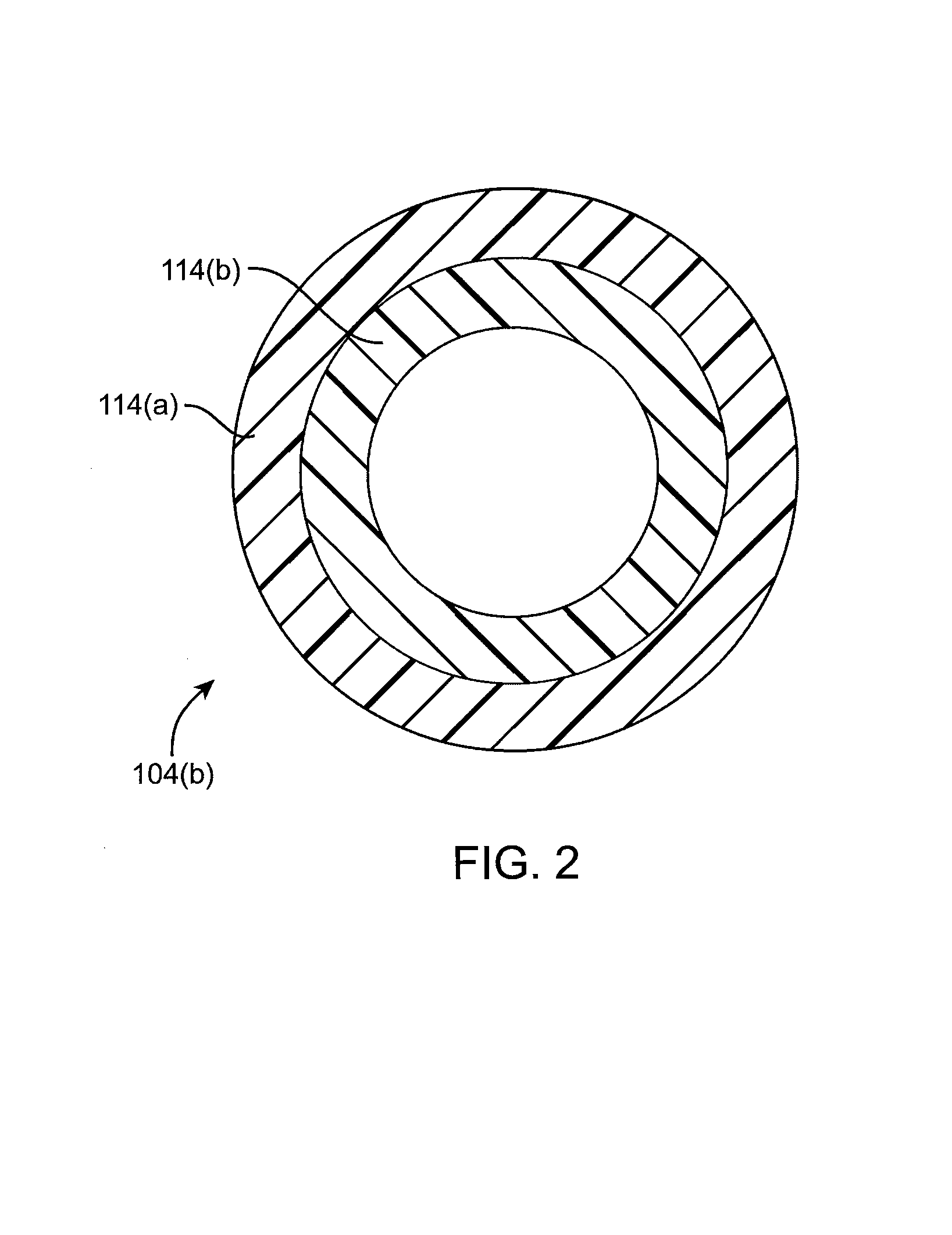

Fixing device for a vacuum pump

InactiveUS20070104598A1Increase volumeImprove damping performancePump componentsWorking fluid for enginesVacuum pumpFlange

The present invention relates to the field of high rotation speed vacuum pumps, which are fastened to and connected to a structure such as a vacuum enclosure or a pipe to generate a hard vacuum. It consists in an annular fixing flange including holes cooperating with headed bolts to fasten a vacuum pump to a structure. The flange comprises an upper ring and a lower ring cooperating to clamp the end of the pump body between the upper ring and the lower ring, and at least one first cavity in a face of the upper ring that is in a plane perpendicular to that of the face of the upper ring intended to come into contact with the wall of the structure. The invention also consists in a fixing system comprising an annular flange disposed coaxially with the pump body around the inlet orifice of the pump. At least one second cavity in the face of the end of the pump body in contact with a face of the upper ring is coupled with the first cavity to form a housing, and at least one flexible material stud inserted into the housing.

Owner:ALCATEL LUCENT SAS

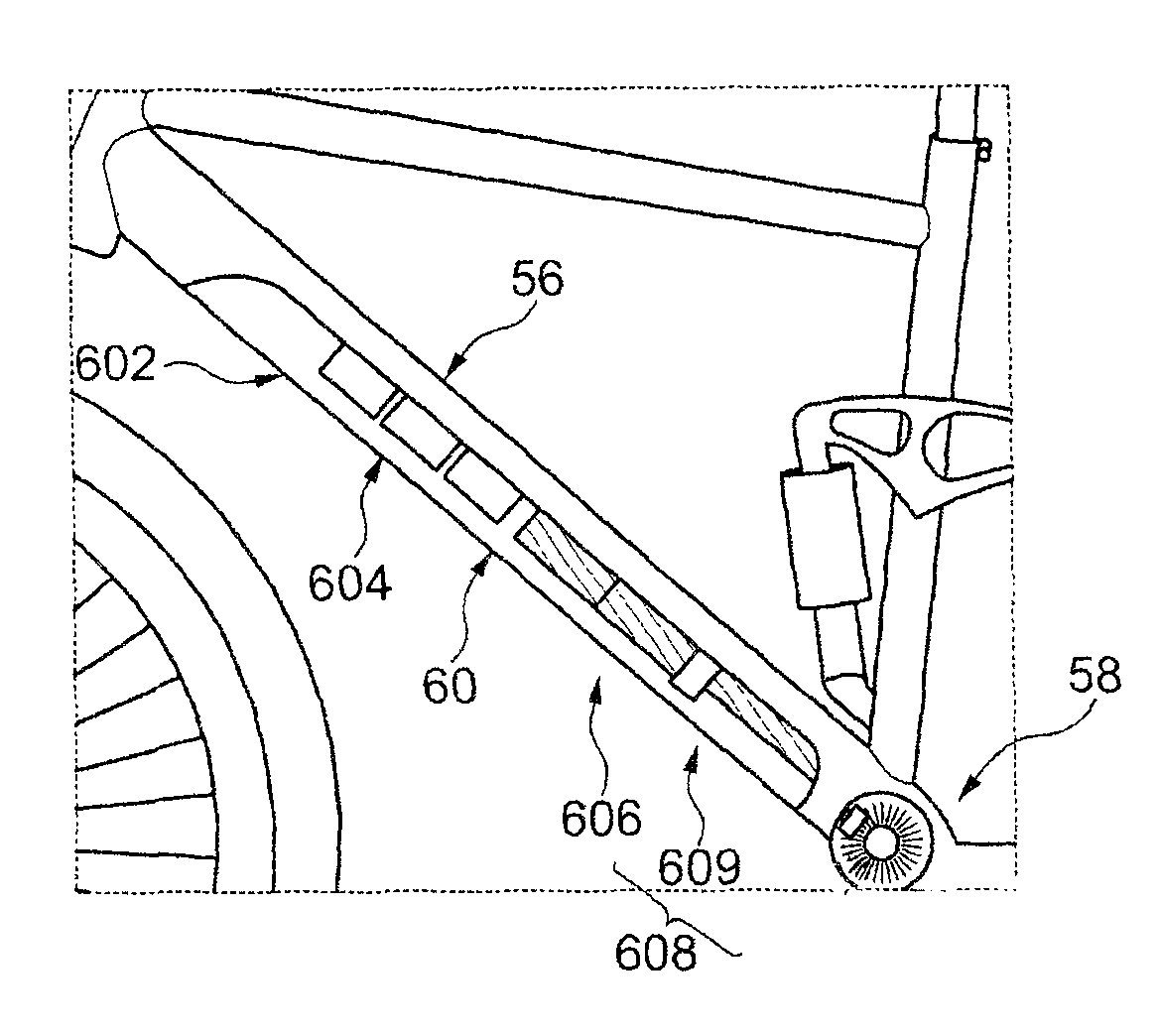

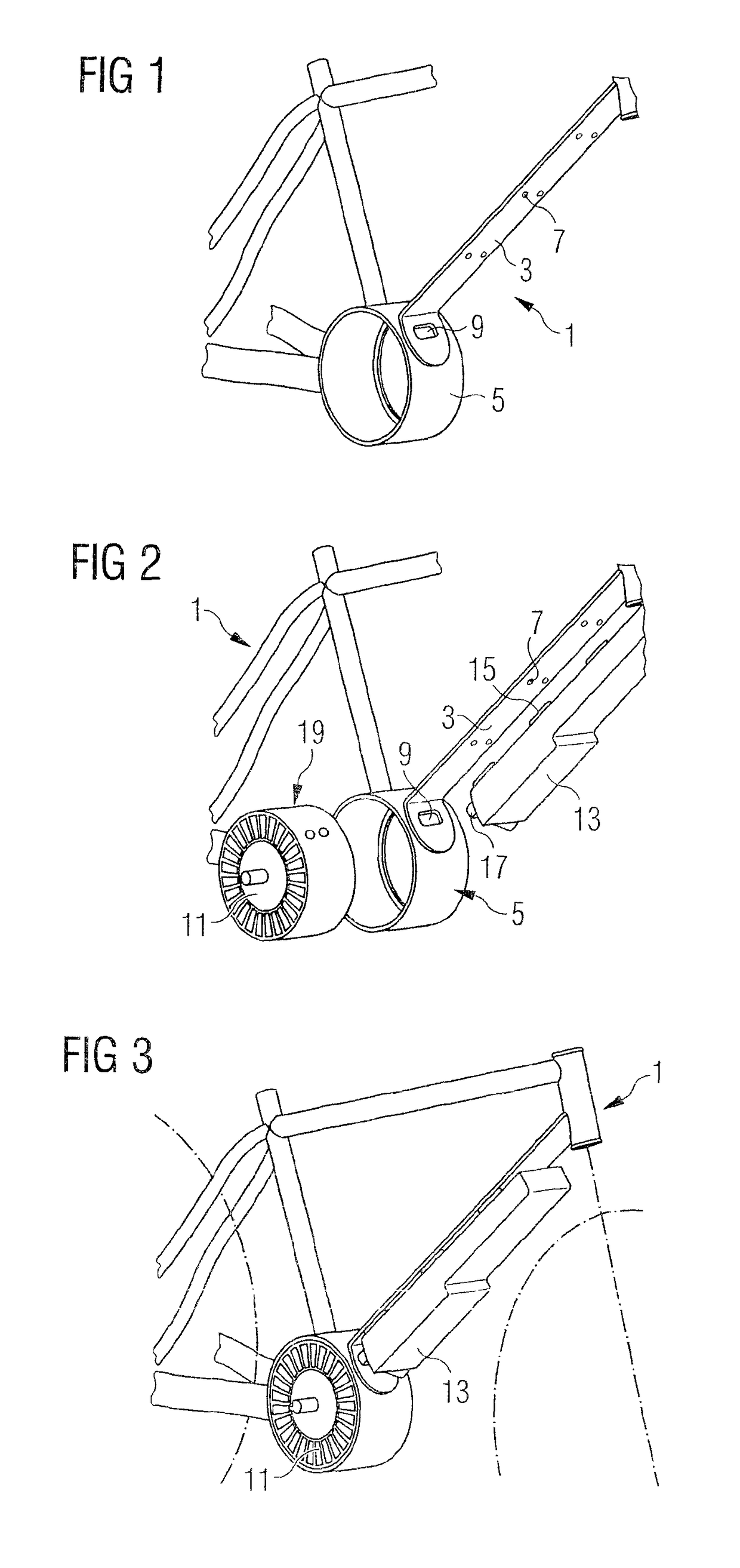

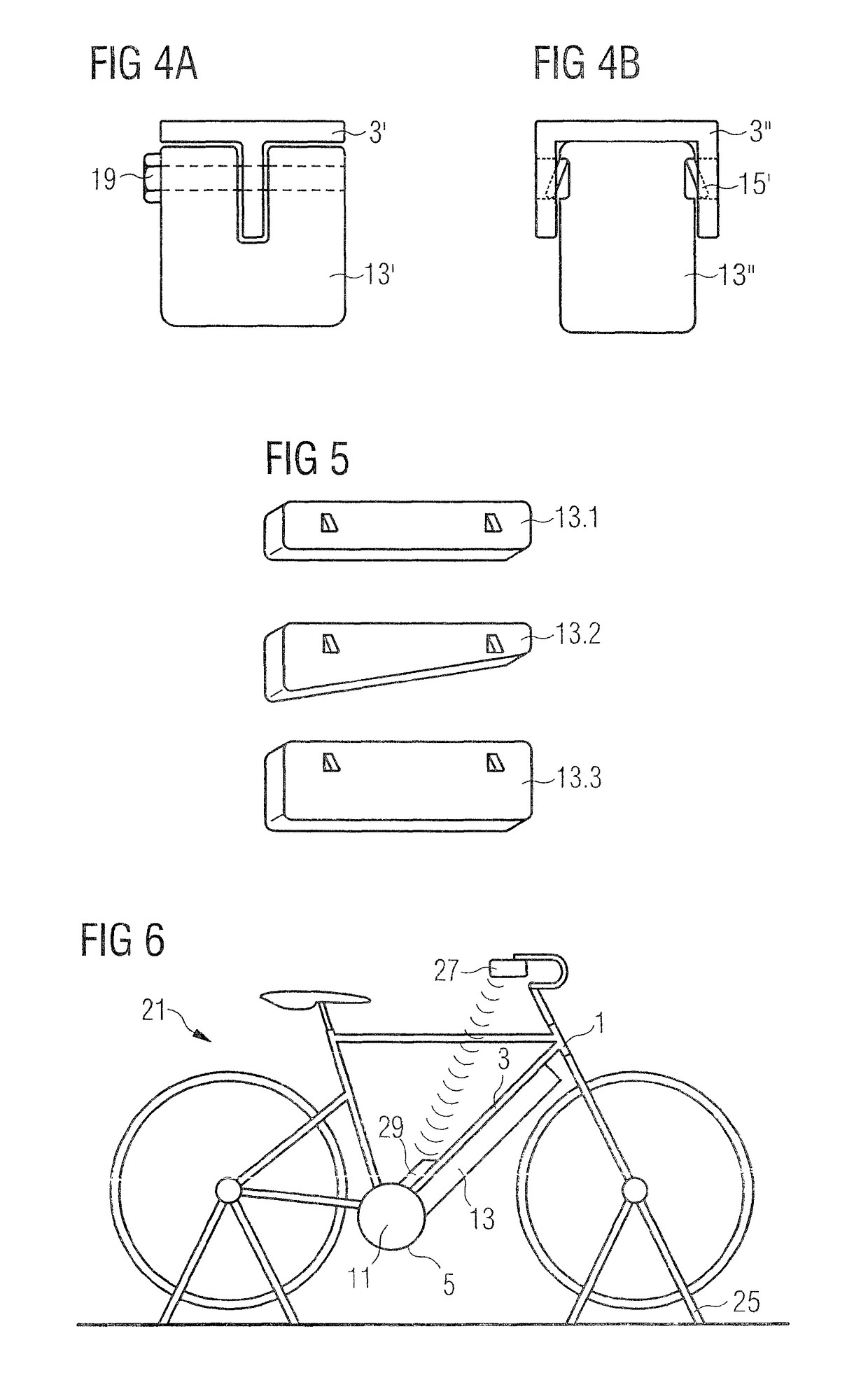

Bicycle frame, battery pack, and bicycle

ActiveUS9777774B2Improve aerodynamicImprove aesthetic characteristicCouplings for rigid shaftsFlanged connectionsEnergy storageBattery pack

An auxiliary motor, for a bicycle, includes an energy storage device for storing energy, a drive device for converting the energy stored in the energy storage device into kinetic energy and a transmission device for transmitting the kinetic energy onto a pedal crank spindle. The auxiliary motor is designed to be attached to a down tube of a bicycle at least parallel to the down tube and to power a pedal crank of the bicycle.

Owner:PORSCHE EBIKE PERFOMANCE GMBH

Coupling assembly and method for connecting and disconnecting a shaft assembly

ActiveUS20060099028A1Fast disconnectionQuick connectionFlanged jointsRotary stirring mixersImpellerCoupling

A coupling assembly that can be used to quickly connect and disconnect an impeller shaft to and from a drive output shaft. A portion of the coupling assembly can be used to secure the impeller shaft inside a mixing vessel so that the impeller shaft can remain secure inside the mixing vessel when the drive is disconnected. The coupling assembly has a first and a second coupling half, a first group of locking pens that extend from the first coupling half and can pass through openings formed in the second coupling half, and second group of locking pins that extend from the first coupling half and can pass through openings formed in the top region of the mixing vessel.

Owner:SPX FLOW INC

Elevator car

InactiveUS20060175148A1Easy constructionEasy to transportBuilding roofsFlanged jointsPunchingEngineering

An elevator car consists of a floor, side walls, a back wall and a roof which are each constructed in a modular manner from a plurality of panels and which can be held together by means of connecting elements. The floor is formed from, in total, eight floor panels. The threshold is connected with the floor panels. The side walls each consist of ten wall panels. The back wall consists of eight wall panels and the roof consists of six roof panels. On site, the elevator car can be constructed in a short assembly time by means of plug connections and with a few screw connections. The panel mode of construction enables a low-volume transport of the elevator car to the construction site directly from the punching and changing machine.

Owner:INVENTIO AG

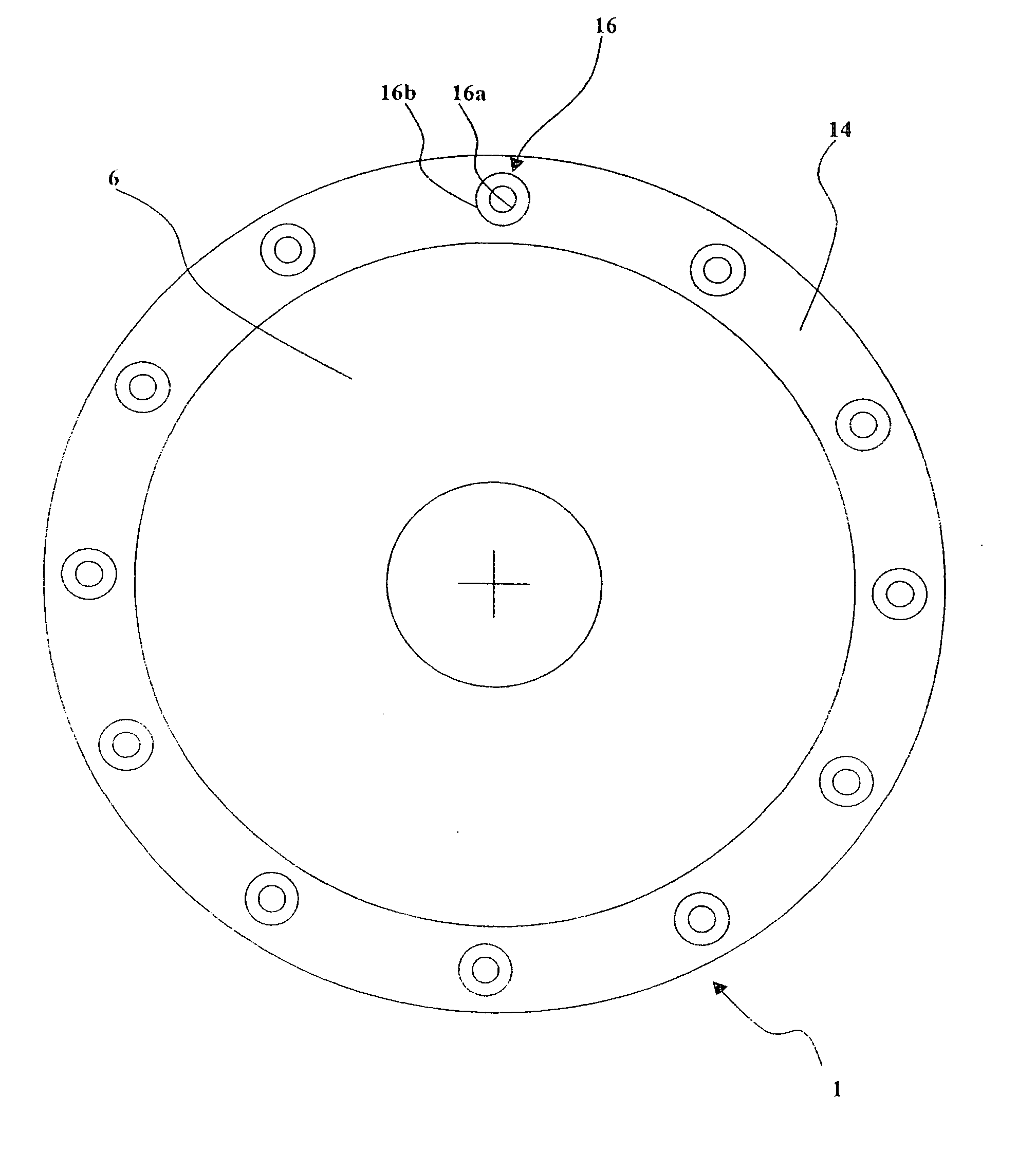

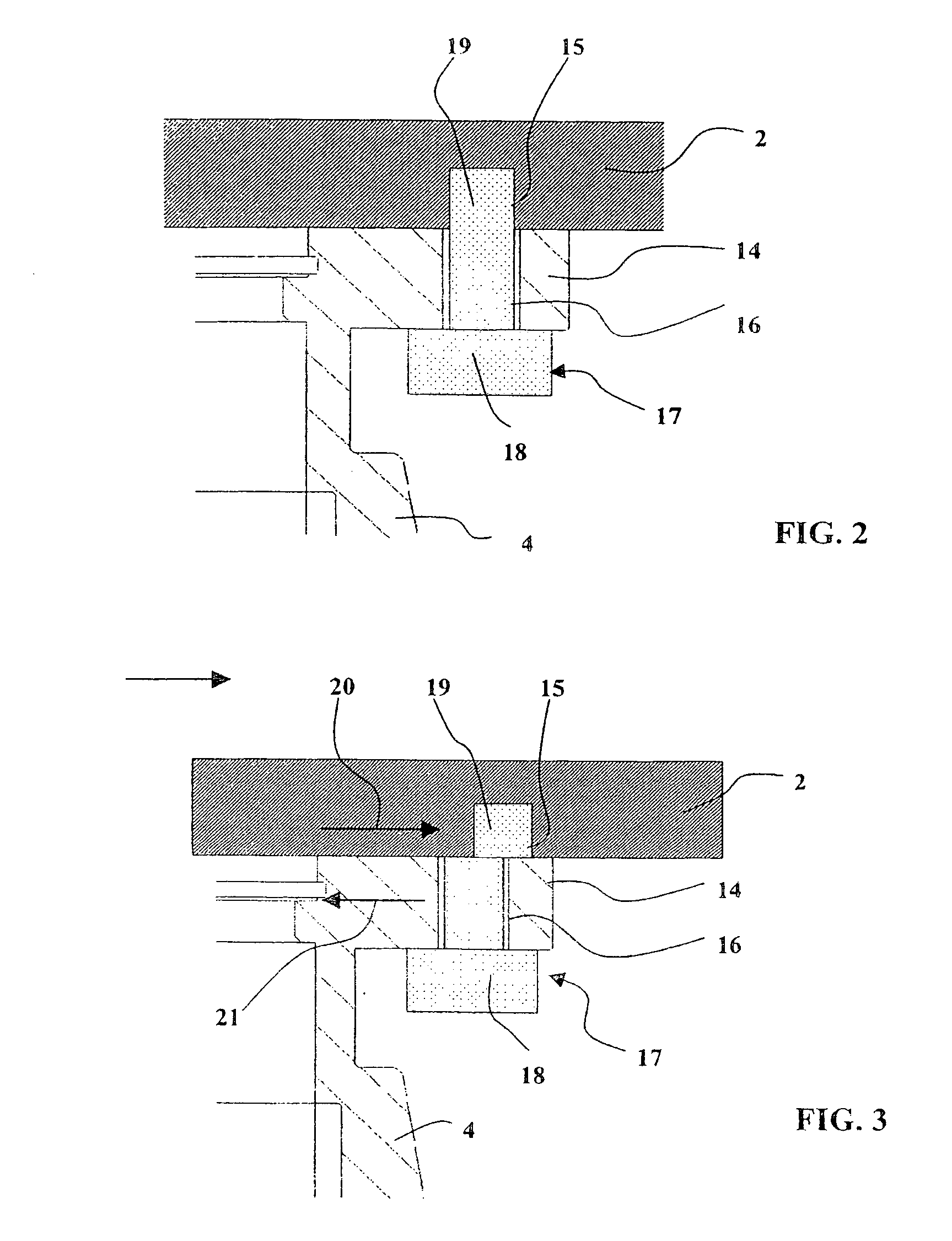

Device for fixing a vacuum pump

InactiveUS20050244219A1Improve mechanical strength propertiesRelievingPump componentsSecuring devicesEngineeringDistal segment

The fastener system of the invention comprises a coaxial annular flange (14) having through holes (16) provided therein, each serving to pass a screw (17) for screwing into an associated tapped hole (16) in the wall (2) of a stationary structure. Each through hole (16) comprises a circularly cylindrical distal segment (16a) followed by an enlarged proximal segment (16b) adjacent to the wall (2) of the stationary structure, and allowing the shank (19) of the screw to bend and enabling a corresponding lateral offset (D). This prevents the screw (17) rupturing under high shear forces due to accidental destruction of a vacuum pump rotor while rotating at full speed.

Owner:ALCATEL LUCENT SAS

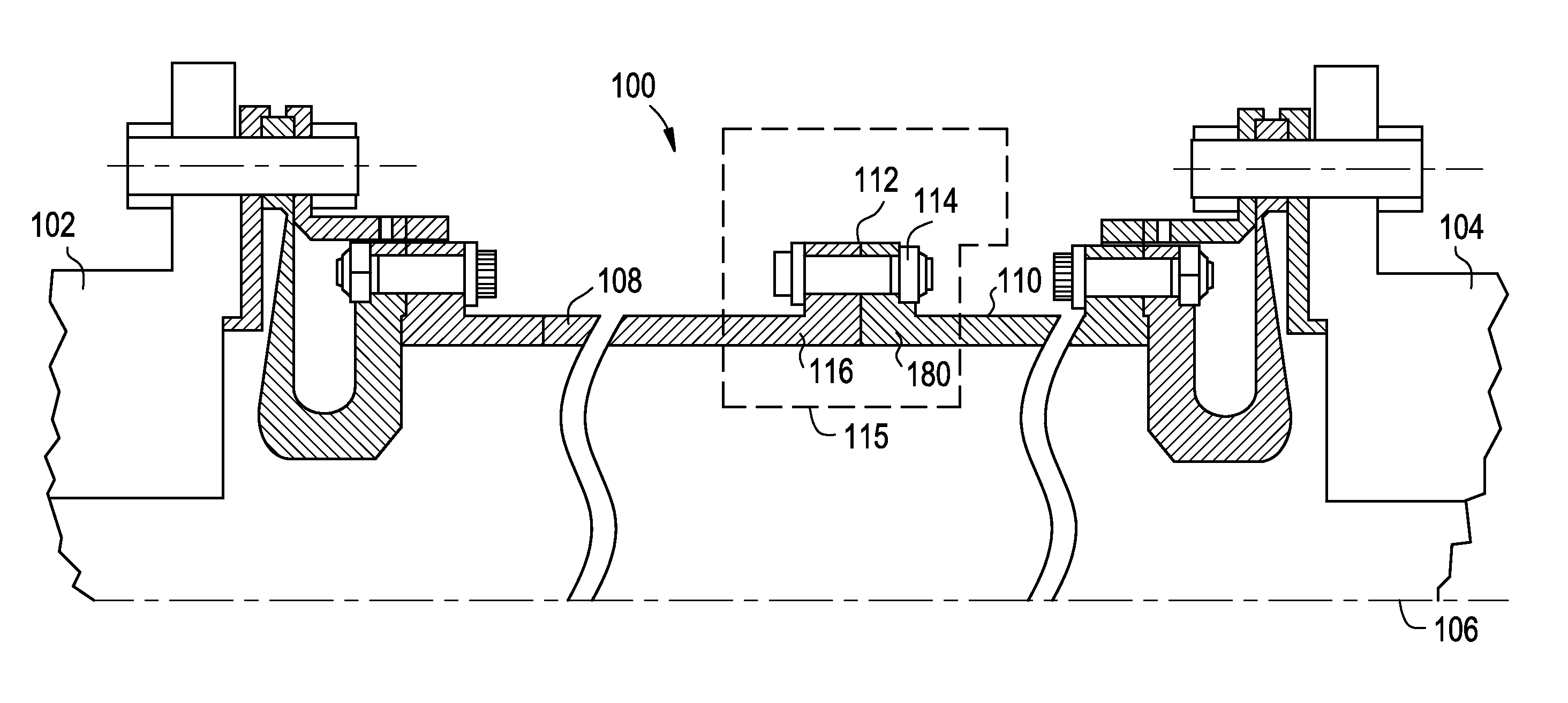

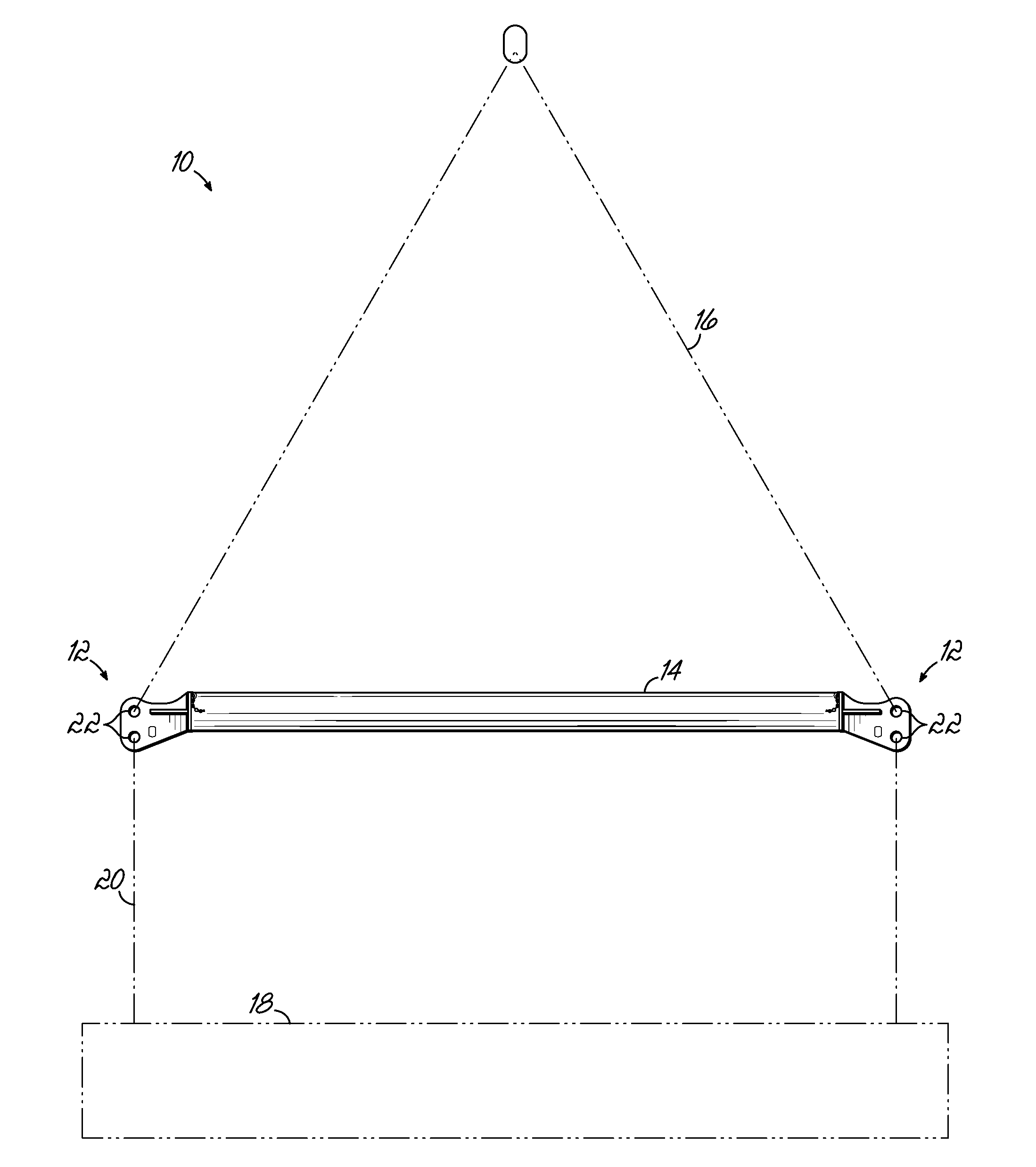

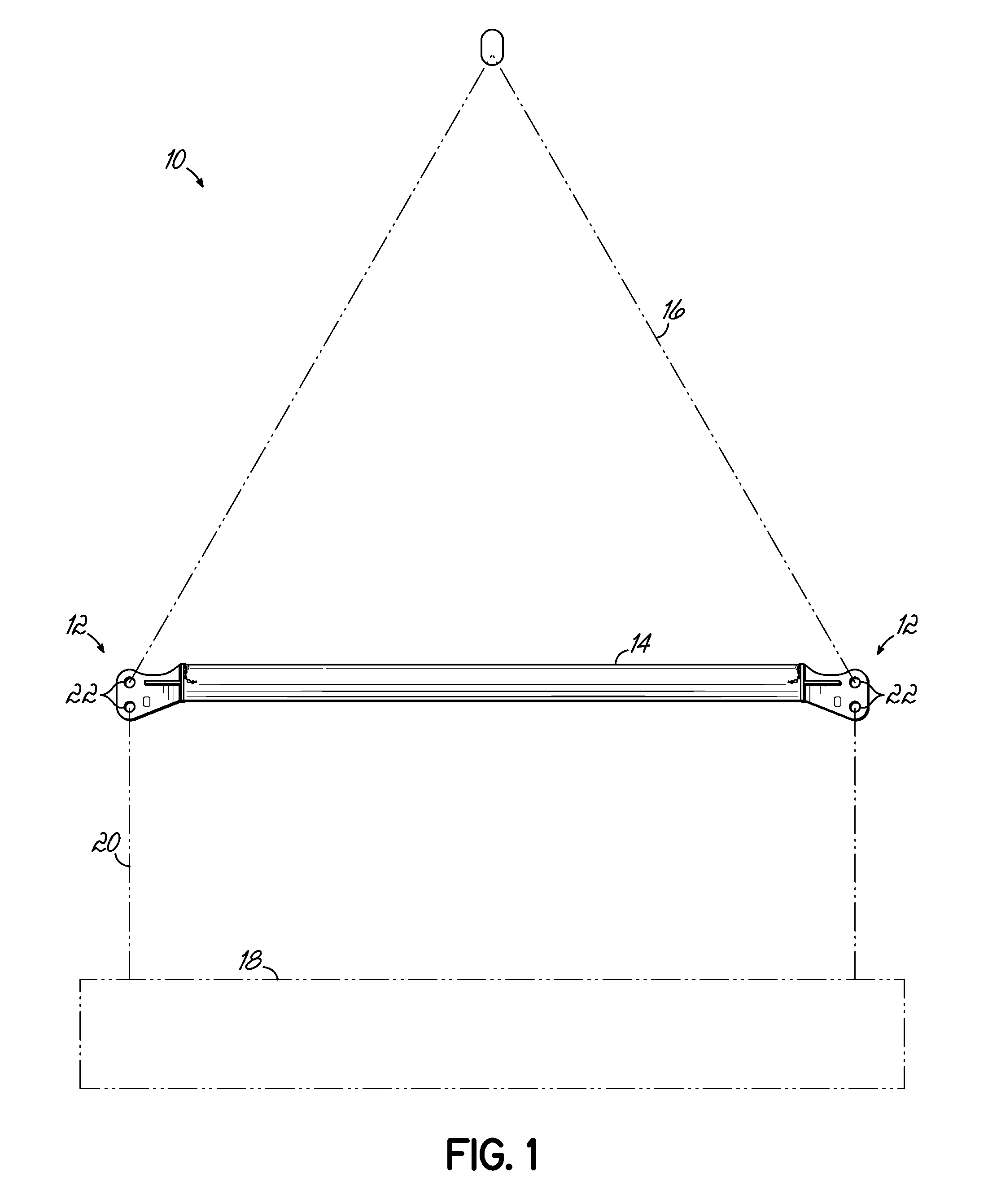

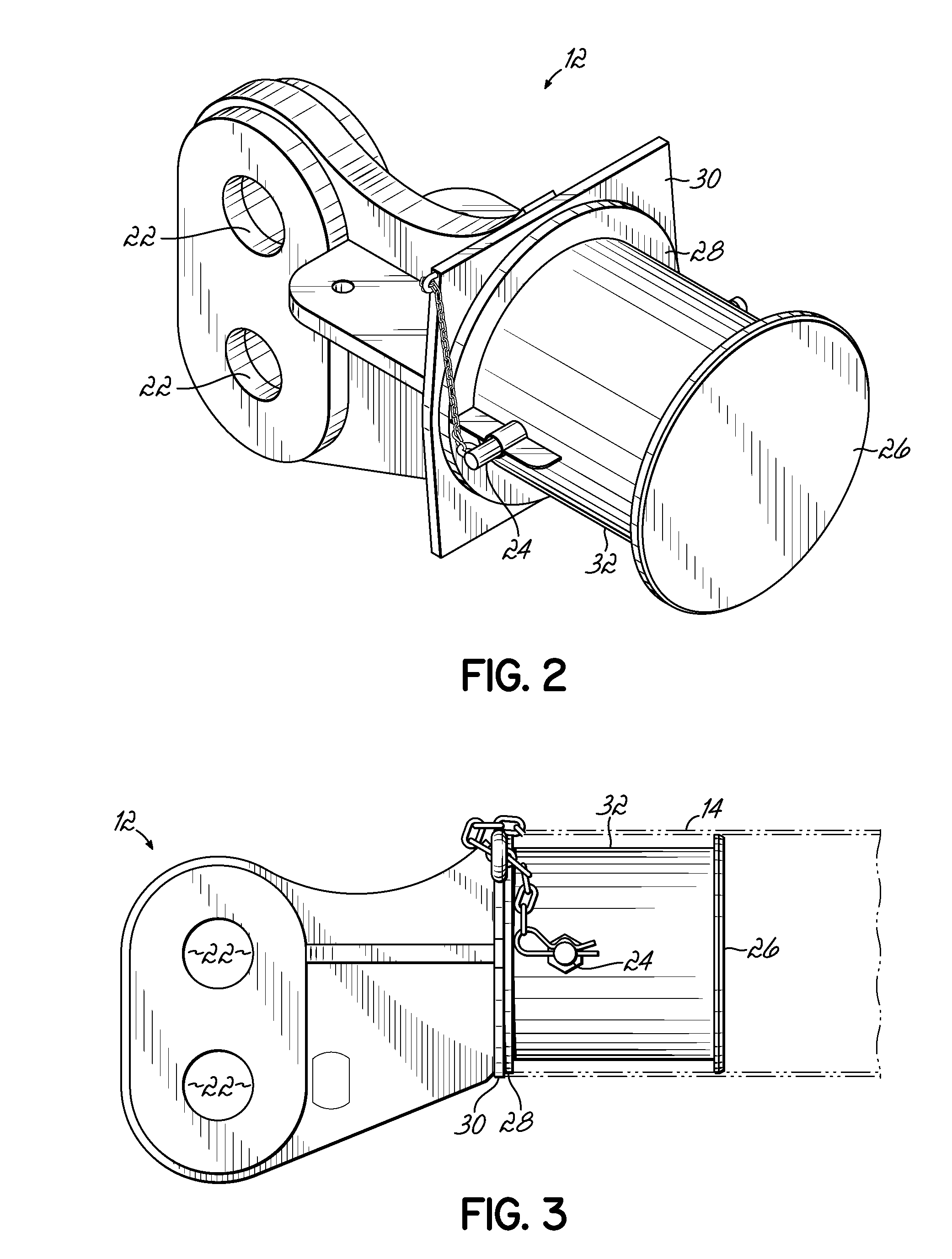

Load Spreader Bar System

A spreader bar assembly includes an end cap having a shackle connection part and an insertion part adapted for detachable connection to a spreader pipe. A connection sleeve may include multiple insertion ends for respective connection to respective spreader pipes. Where so configured, the pipes may have different diameters.

Owner:TANDEMLOC

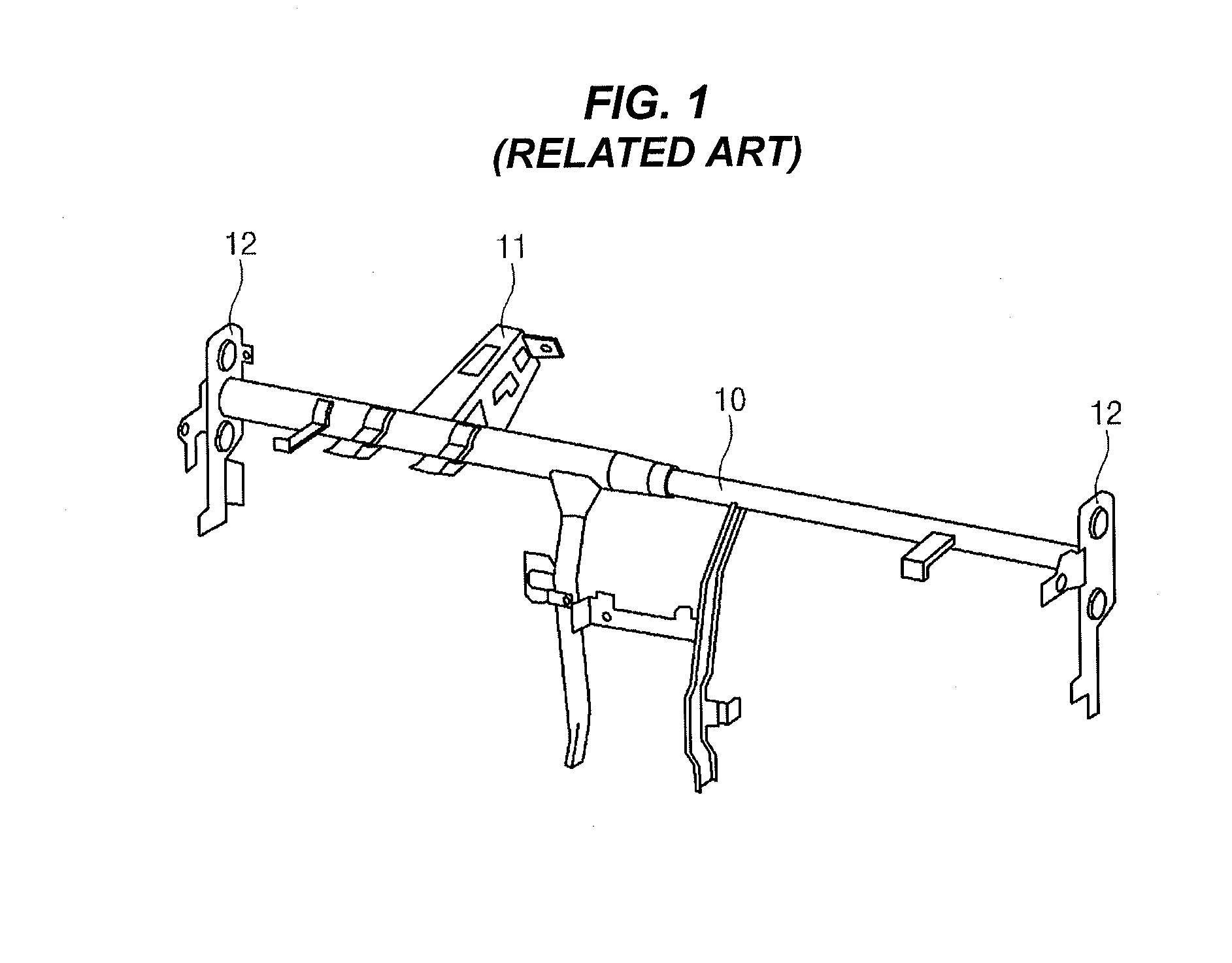

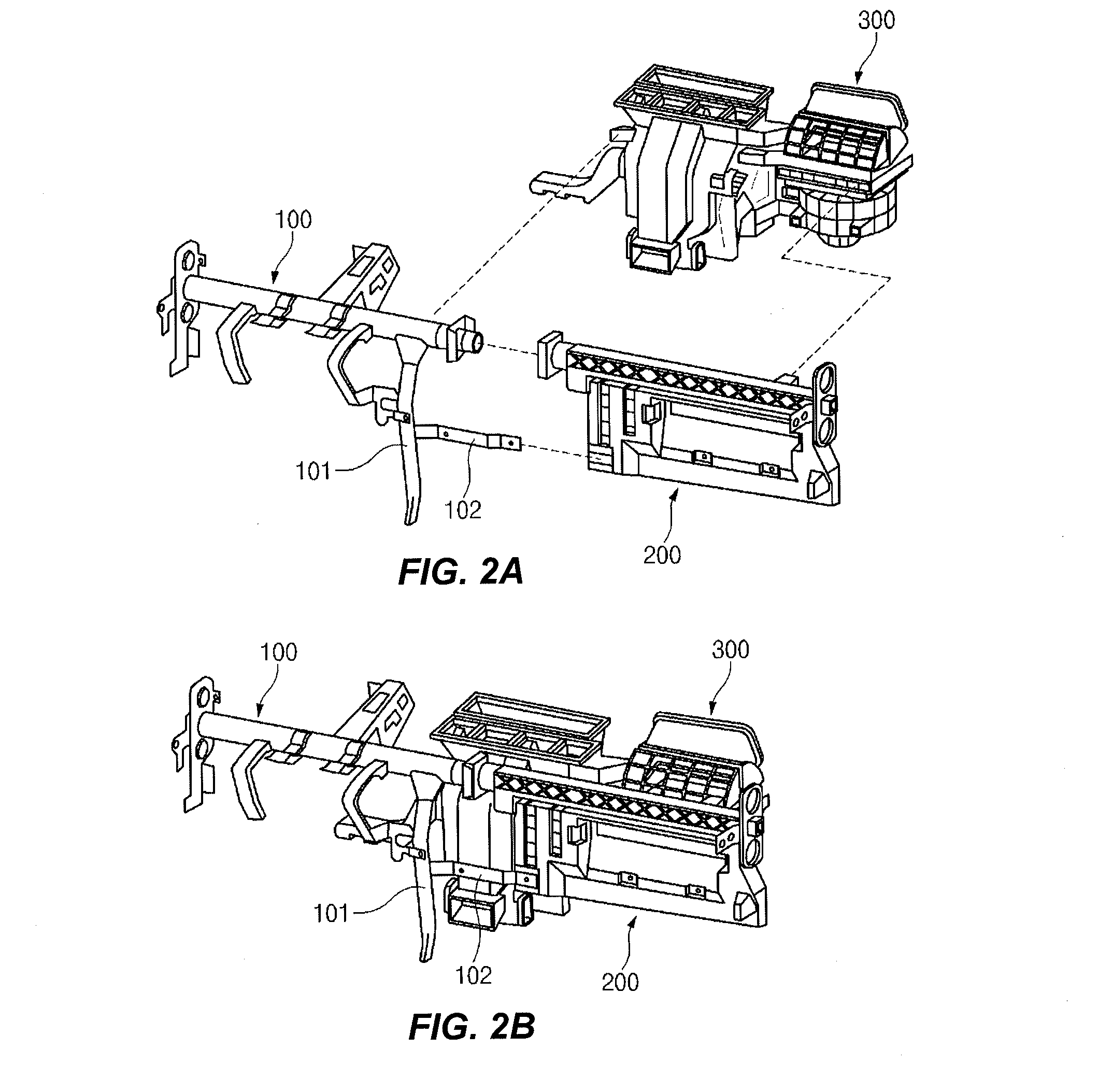

Cowl cross assembly

ActiveUS20130057026A1Improve coupling strengthReduce weightVehicle heating/cooling devicesSuperstructure subunitsPlastic materialsAir conditioning

A cowl cross assembly includes a cowl cross bar positioned in front of a vehicle body, and a cowl cross half-panel joined to one end of the cowl cross bar. A part of the cowl cross bar made of a steel material is cut, and the cowl cross half-panel made of a plastic material is mounted to the cowl cross bar, thereby reducing the weight and the cost and reinforcing the strength to support the air conditioning equipment. In addition, the cowl cross bar can be easily joined to the cowl cross half-panel to improve the workability.

Owner:HYUNDAI MOTOR CO LTD

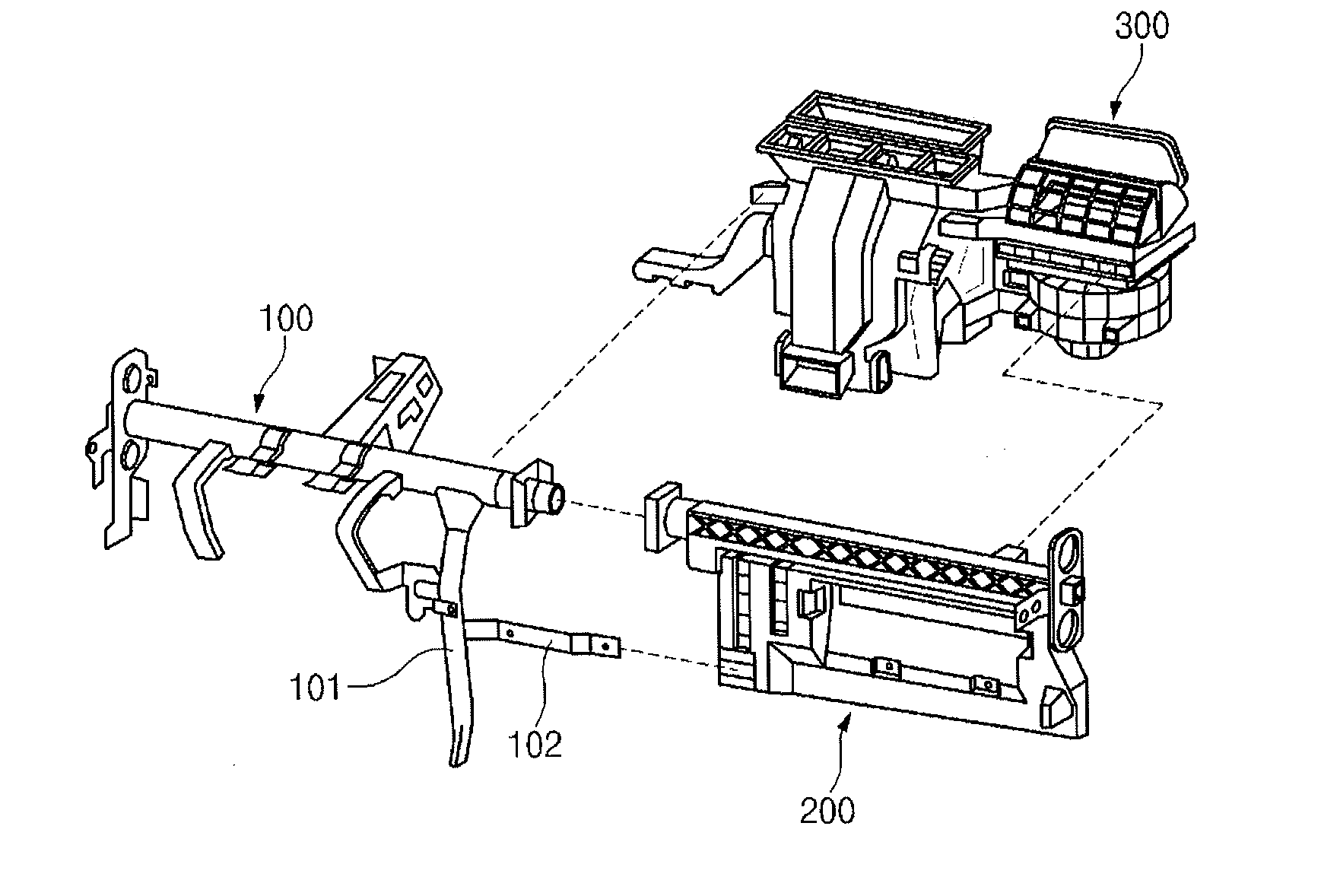

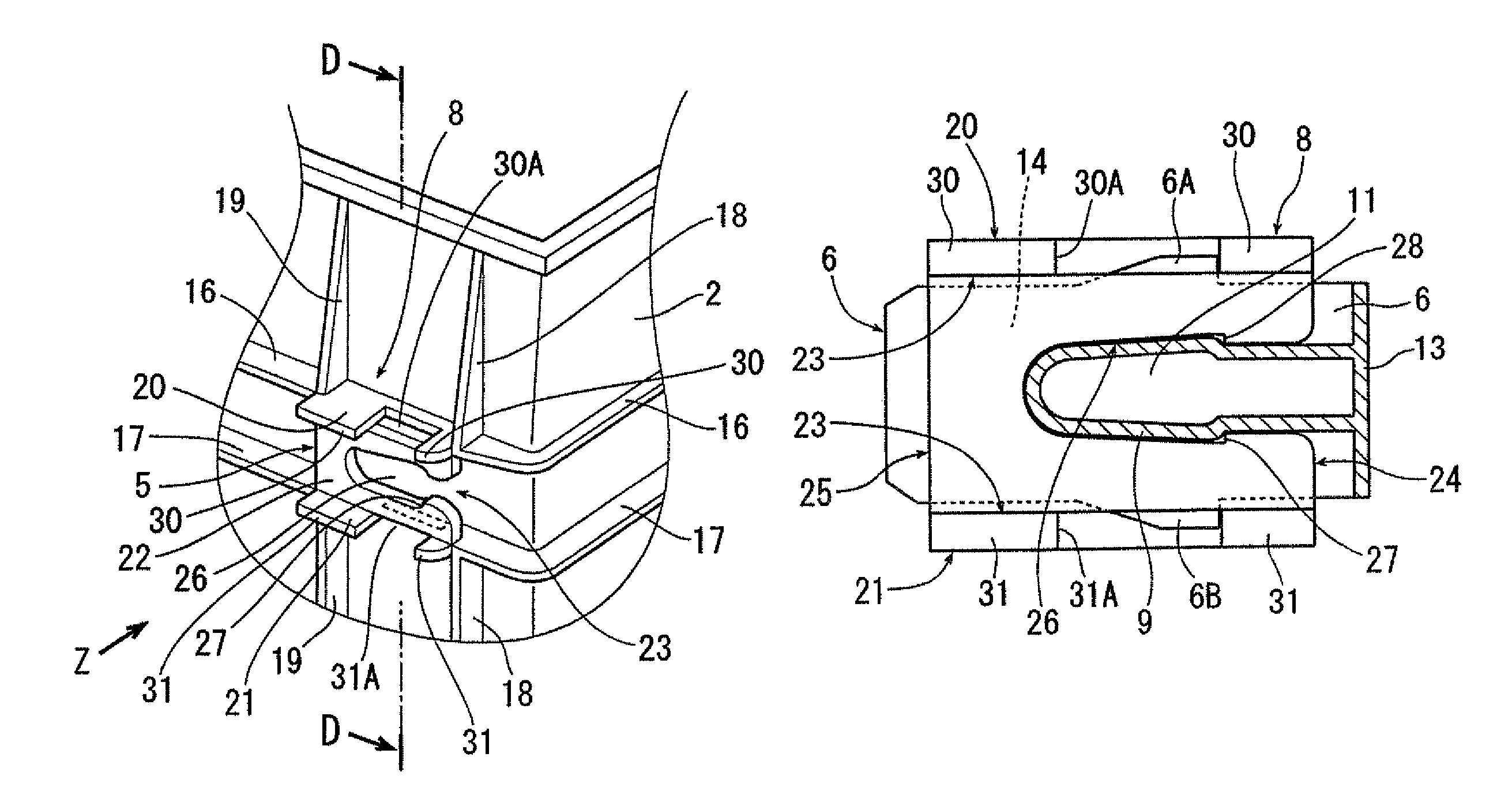

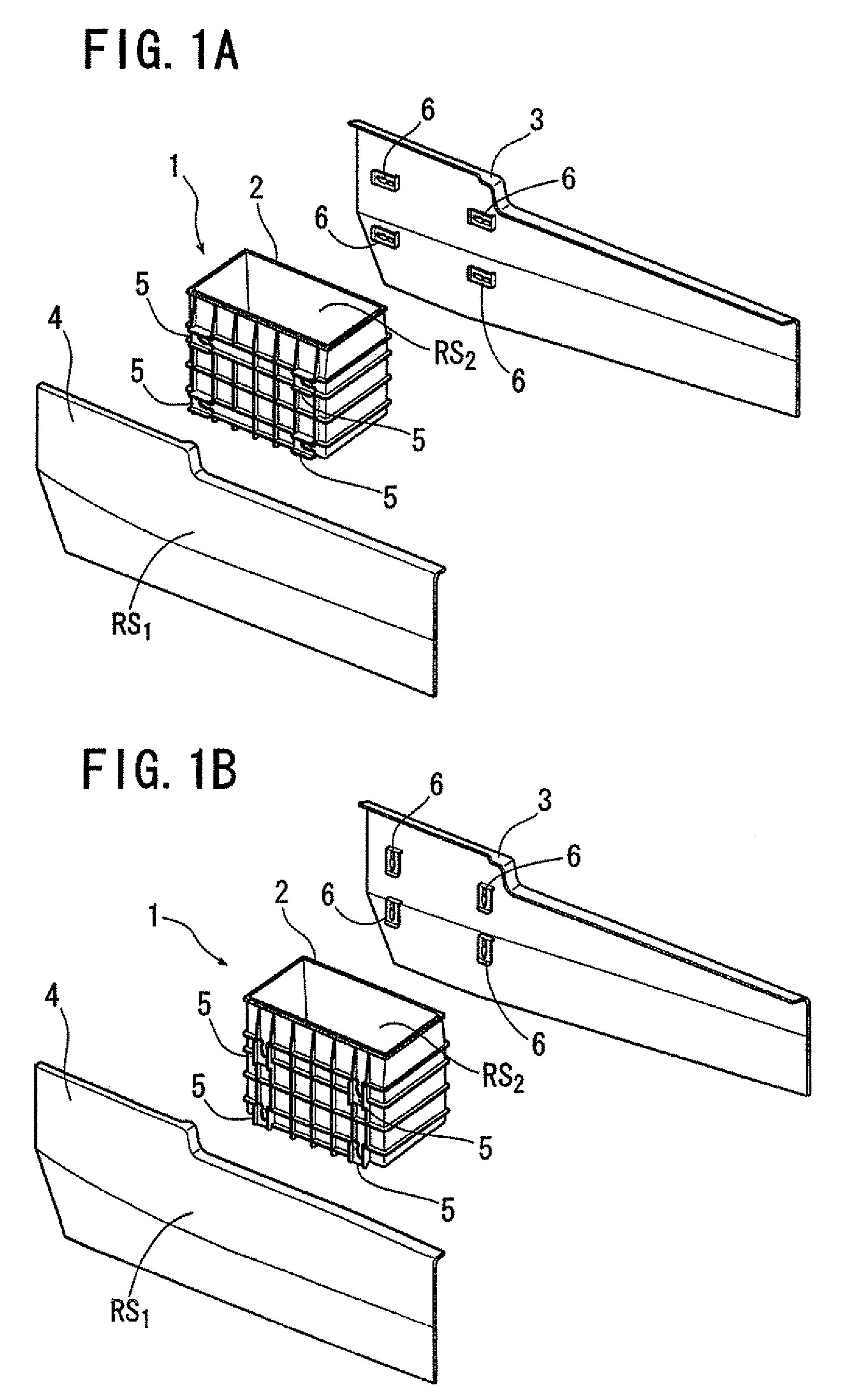

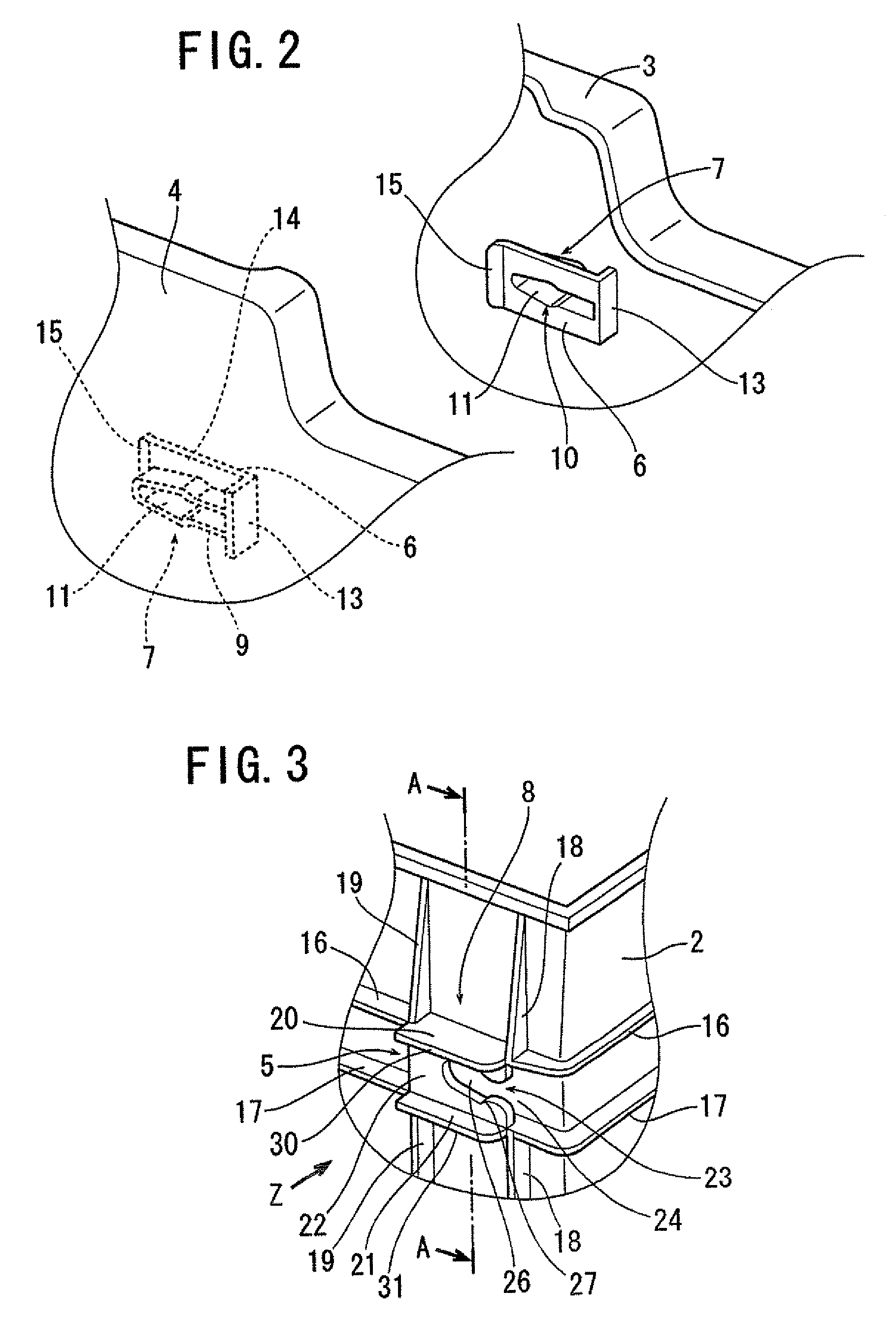

Component parts joining structure

ActiveUS7410206B2Enhanced couplingSimplifies connecting activityVehicle seatsDrilling rodsCouplingEngineering

In a joining structure, a protruding portion on the side of a first component is a hollow body that prevents bringing about sinking, deforming, and cracking of the side surface of the first component part, even in the event that the protruding portion is enlarged in order to increase strength for connecting the first component part and a second component part. In addition, the connecting groove on the side of the second component part is also defined by a hollow body that includes a pair of supporting ribs and a supporting plate bridging the pair of supporting ribs. Consequently, the hollow body can prevent defects of sinking, deforming, and cracking in the side surface of the second component part, even in the event that the supporting ribs and the supporting plate are increased in thickness in order to enhance the rigidity of the coupling arrangement between the first and second component parts.

Owner:MORIROKU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com