Pearlescent pigment for water-borne surface-coating systems

a surface coating and pearlescent technology, applied in the direction of pigment pastes, pigment treatment with organosilicon compounds, coatings, etc., can solve the problems of reducing the distinctness of images, adversely affecting the gloss and color, and unsuitable for use in water-thinnable surface coating systems, and achieve excellent weathering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0061]100 g of Iriodin® 504 Red (iron(III) oxide-coated mica pigment from E. Merck, Darmstadt) are suspended in 900 ml of demineralized water, and the suspension is heated to 40° C. with vigorous, stirring.

[0062]The pH is adjusted to 9.0 by means of 2.5% sodium hydroxide solution. All the pH values indicated are determined with the aid of suitable pH indicator paper.

[0063]A solution of 2.7 ml of sodium water glass (370 g of SiO2 per liter) in 150 ml of demineralized water is subsequently added dropwise over the course of 30 minutes to the pigment suspension. During this addition, the pH is kept constant by means of 2.5% hydrochloric acid. When the addition is complete, the mixture is stirred at 40° C. for a further 15 minutes. The pH is then adjusted to 6.5 over the course of 10 minutes by means of 2.5% hydrochloric acid, and the mixture is stirred at 40° C. for a further 15 minutes. 1.35 g of sodium sulfate, 2.30 g of aluminum chloride hexahydrate and 1.10 g of cerium(III) chloride...

example 2

[0069]100 g of Iriodin® 225 Rutile Pearlescent Blue (titanium dioxide-coated mica pigment from E. Merck, Darmstadt) are suspended in 900 ml of demineralized water, and the suspension is heated to 40° C. with vigorous stirring. The procedure of Example 1 is then followed as far as the addition of the coupling reagents.

[0070]3.0 g of pure Dynasilan AMMO (3-aminopropyltrimethoxysilane from Huls AG, Troisdorf) are then added over the course of 10 minutes. During this addition, the pH is kept constant at 3.3 by means of 2.5% hydrochloric acid.

[0071]5.0 g of pure Z 6040 (3-glycidoxypropyltrimethoxysilane from Dow Corning chemicals) are then added over the course of 10 minutes. During this addition, the pH remains constant at 3.3.

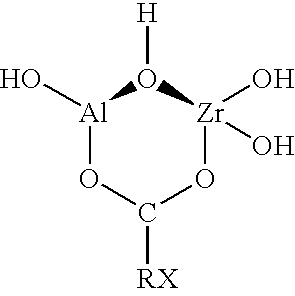

[0072]13.2 g of pure Manchem C (carboxyzirconium aluminate solution from Rhone-Poulenc Chemicals) are subsequently added over the course of 10 minutes. During this addition, the pH is kept constant at 3.3 by means of 2.5% hydrochloric acid. When the addition is co...

example 3

[0076]100 g of Iriodin® 225 Rutile Pearlescent Blue (titanium dioxide-coated mica pigment from E. Merck, Darmstadt) are suspended in 900 ml of demineralized water, and the suspension is heated to 40° C. with vigorous stirring. The procedure of Example 1 is then followed as far as the addition of the coupling reagents.

[0077]3.0 g of pure Dynasilan MEMO (3-methacryloxypropyltrimethoxysilane from Huls AG, Troisdorf) are then added over the course of 10 minutes. During this addition, the pH remains constant at 3.3.

[0078]In addition, 5.0 g of pure Z 6040 (3-glycidoxypropyltrimethoxysilane from Dow Corning chemicals) are then added over the course of 10 minutes. During this addition, the pH remains constant at 3.3.

[0079]13.2 g of pure Manchem C (carboxyzirconium aluminate solution from Rhone-Poulenc Chemicals) are subsequently added over the course of 10 minutes.

[0080]During this addition, the pH is kept constant at 3.3 by means of 2.5% hydrochloric acid. When the addition is complete, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com