Method of synthesis of high dispersed spherical Y or Nb doped lithium titanate oxide using titanium tetrachloride and lithium hydroxide

a lithium titanate oxide and spherical y or nb technology, applied in the direction of lithium compounds, alkali titanates, cell components, etc., can solve the problems of low power density per unit volume, low electrical conductivity of lithium titanate oxide, and failure to charge or discharge, etc., to achieve effective doping of y or nb, improve electrochemical properties of lithium titanate oxide, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Y Doped Lithium Titanate Oxide

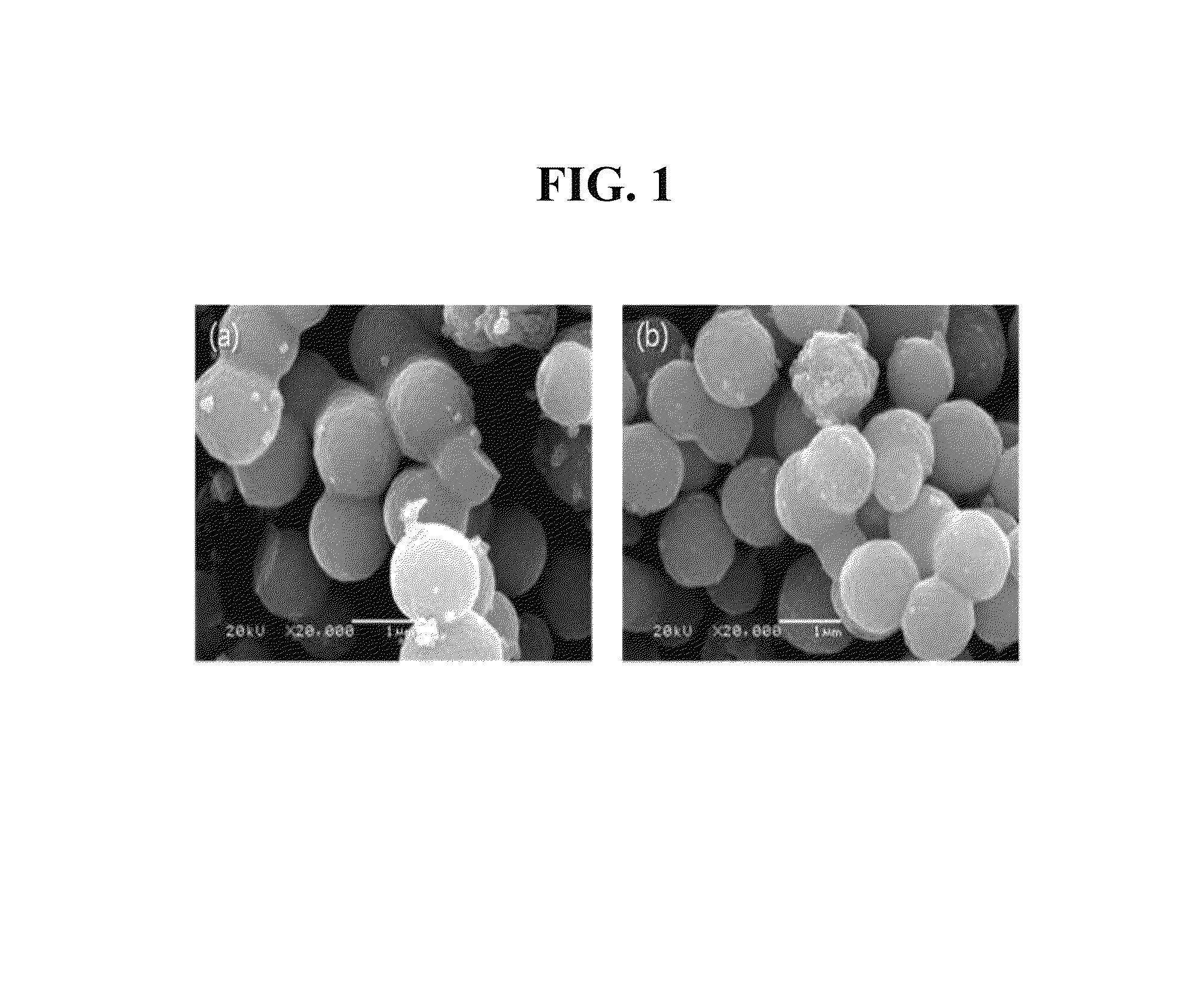

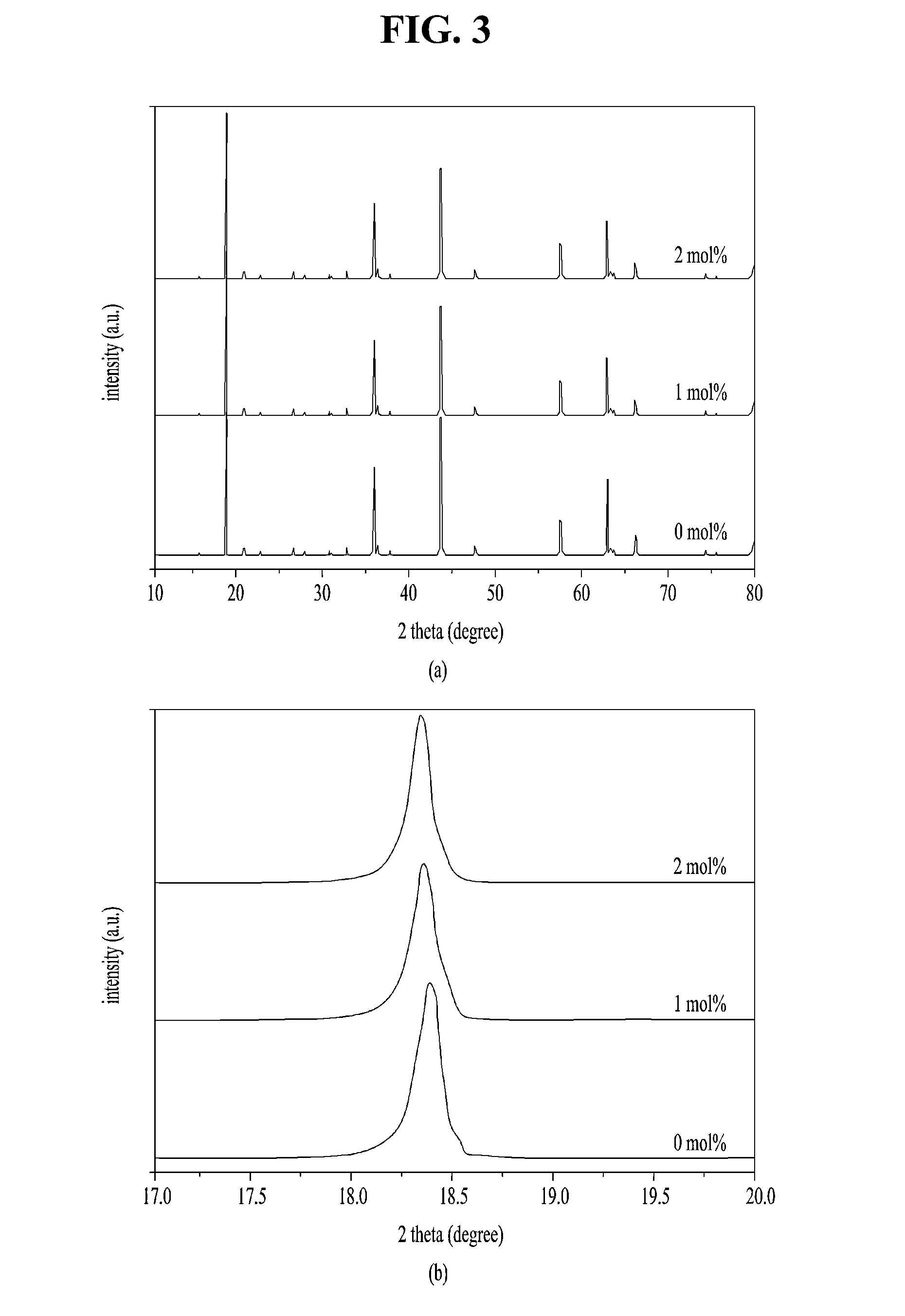

[0030]Prior to synthesizing Li4Ti5O12, the present inventors mixed TiCl4 with distilled water in a low temperature, weighed and diluted it to become 0.05 mol of TiOCl2 solution in order to synthesize a Ti-precursor. The present inventors added 1 mol % of YCl36H2O to Ti(mol) while weighed TiCl4 in the synthesis process of the Ti-precursor in order to synthesize Y doped Li4Ti5O12. The present inventors dissolved Hydroxy propyl cellulose and Polyethylene glycol together in a solvent, i.e., 1-propanol, thereby used the solution as a dispersing agent, and reacted to synthesize it in a temperature of 50° C. Then, the present inventors added 9.8 mole / l of an aqueous ammonia solution to synthesize a titanium precursor. Then, the present inventors heat-treated the synthetic product in a temperature of 600° C. to obtain anatase TiO2 powder, and then mixed it with Lithium hydroxide and heat-treated the mixture in a temperature of 850° C., and therefor...

example 2

Synthesis of Y Doped Lithium Titanate Oxide

[0031]Prior to synthesizing Li4Ti5O12, the present inventors mixed TiCl4 with distilled water, weighed and diluted it to become 0.05 mol of TiOCl2 solution in order to synthesize a Ti-Precursor. The present inventors added 2 mol % of YCl36H2O to Ti(mol) while weighed TiCl4 in the synthesis process of the Ti-precursor in order to synthesize Y doped Li4Ti5O12. The present inventors dissolved Hydroxy propyl cellulose in a solvent, i.e., 1-propanol, thereby used the solution (0.07 mole %) as a dispersing agent, and reacted to synthesize it in a temperature of 50° C. Then, the present inventors added 9.8 mole / l of an aqueous ammonia solution to synthesize a titanium precursor. Then, the present inventors heat-treated the synthetic product in a temperature of 600° C. to obtain anatase TiO2 powder, and then mixed it with Lithium hydroxide and heat-treated the mixture in a temperature of 850° C., and therefore synthesized high dispersed spherical Y...

example 3

Synthesis of Nb Doped Lithium Titanate Oxide

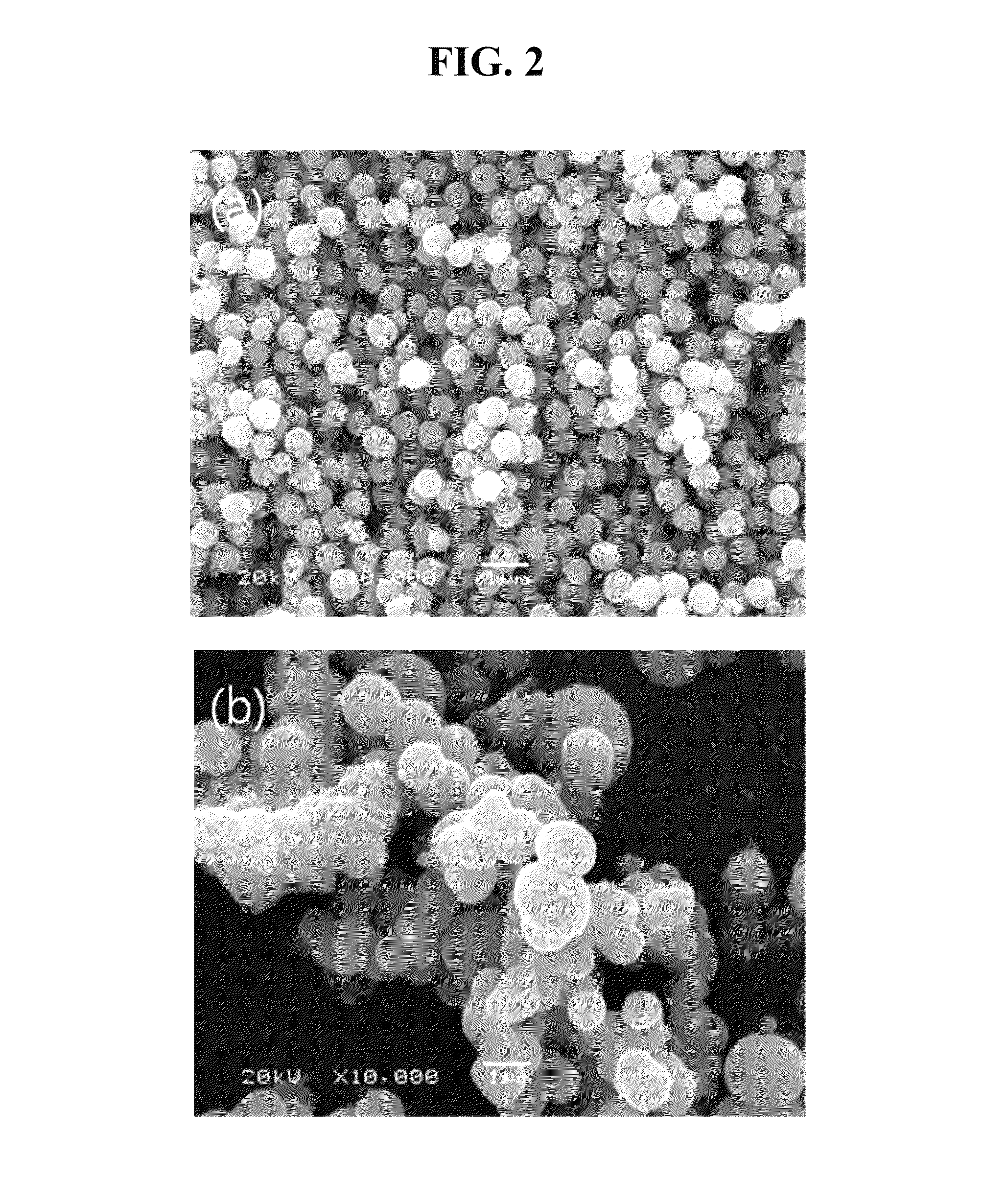

[0032]Prior to synthesizing Li4Ti5O12, the present inventors mixed TiCl4 with distilled water in a temperature of 10° C. or less than 10° C., weighed and diluted it to become 0.05 mol of TiOCl2 solution in order to synthesize a Ti-Precursor. The present inventors added 0.5 mol % of NbCl5 hydrate to Ti(mol) while weighed TiCl4 in the synthesis process of the Ti-precursor in order to synthesize Nb doped Li4Ti5O12. The present inventors dissolved Hydroxy propyl cellulose and Polyethylene glycol together in a solvent, i.e., 1-propanol, thereby used the solution as a dispersing agent, and reacted to synthesize it in a temperature of 50° C. Then, the present inventors added 9.8 mole / l of an aqueous ammonia solution to synthesize a titanium precursor. Then, the present inventors heat-treated the synthetic product in a temperature of 600° C. to obtain anatase TiO2 powder, and then mixed it with Lithium hydroxide and heat-treated the mixture in a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com