Directional solid phase crystallization of thin amorphous silicon for solar cell applications

a technology of solar cells and solid phase crystallization, which is applied in the direction of crystal growth process, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of high surface recombination velocity of minority charge carriers, and process complexity. complex gaseous diffusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

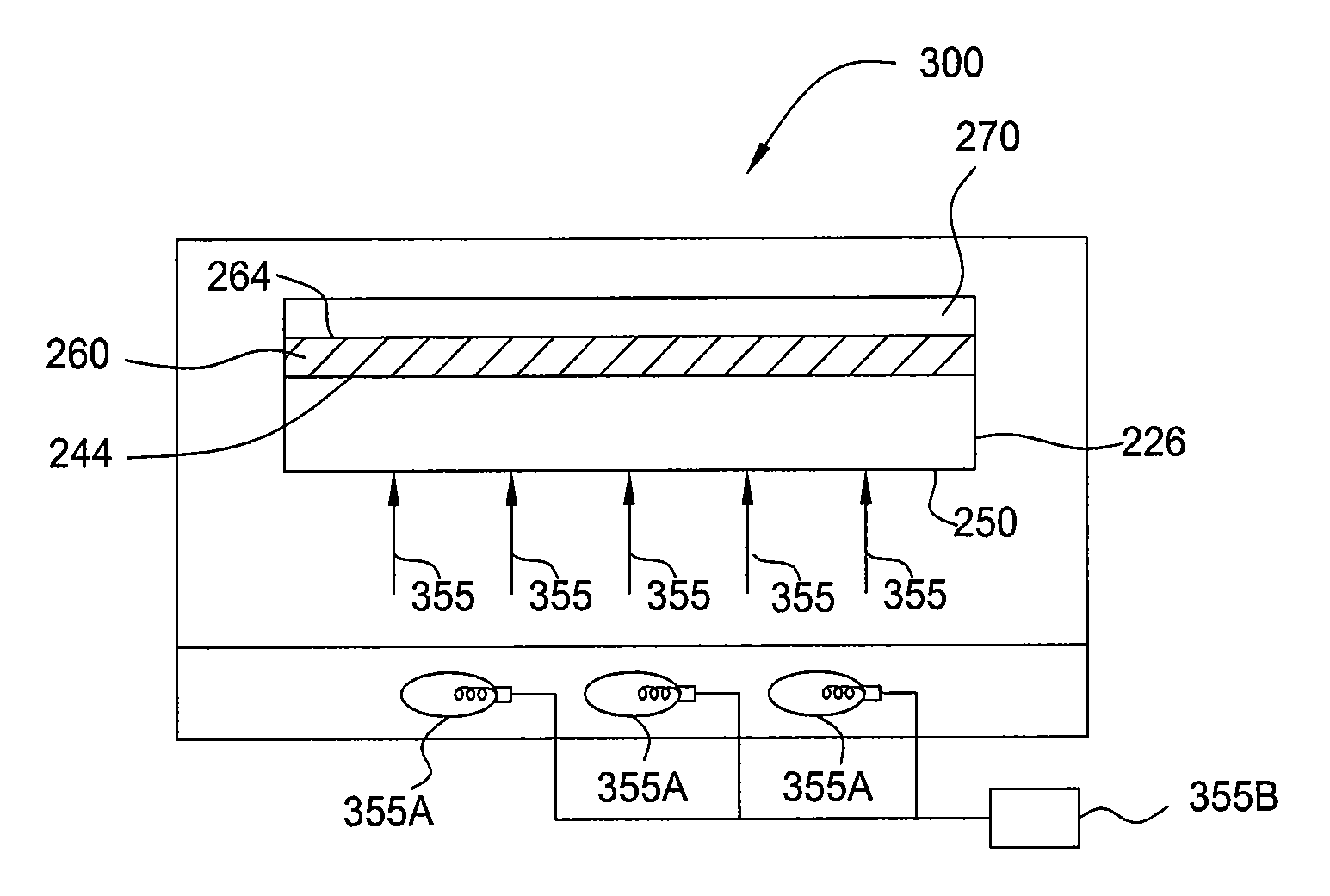

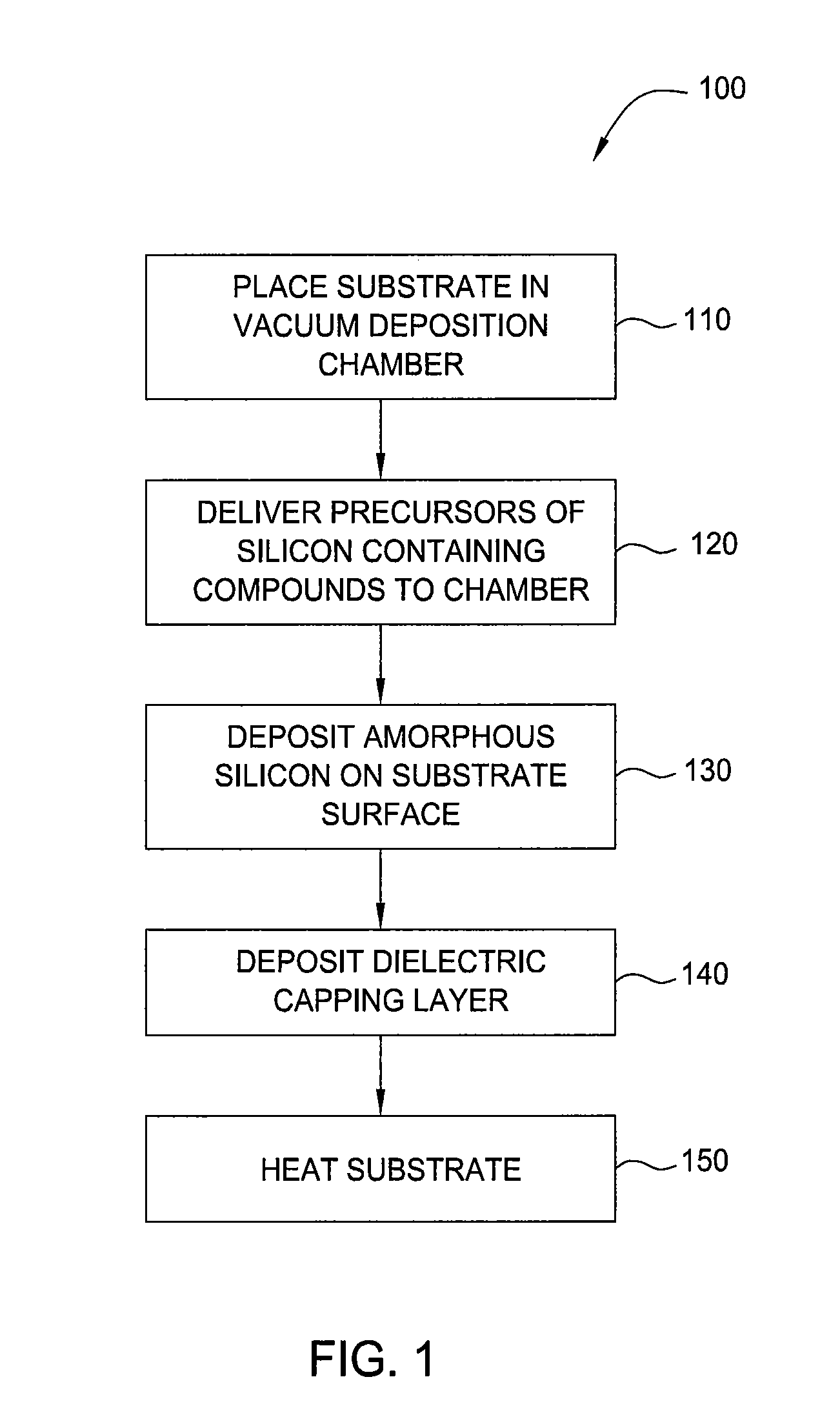

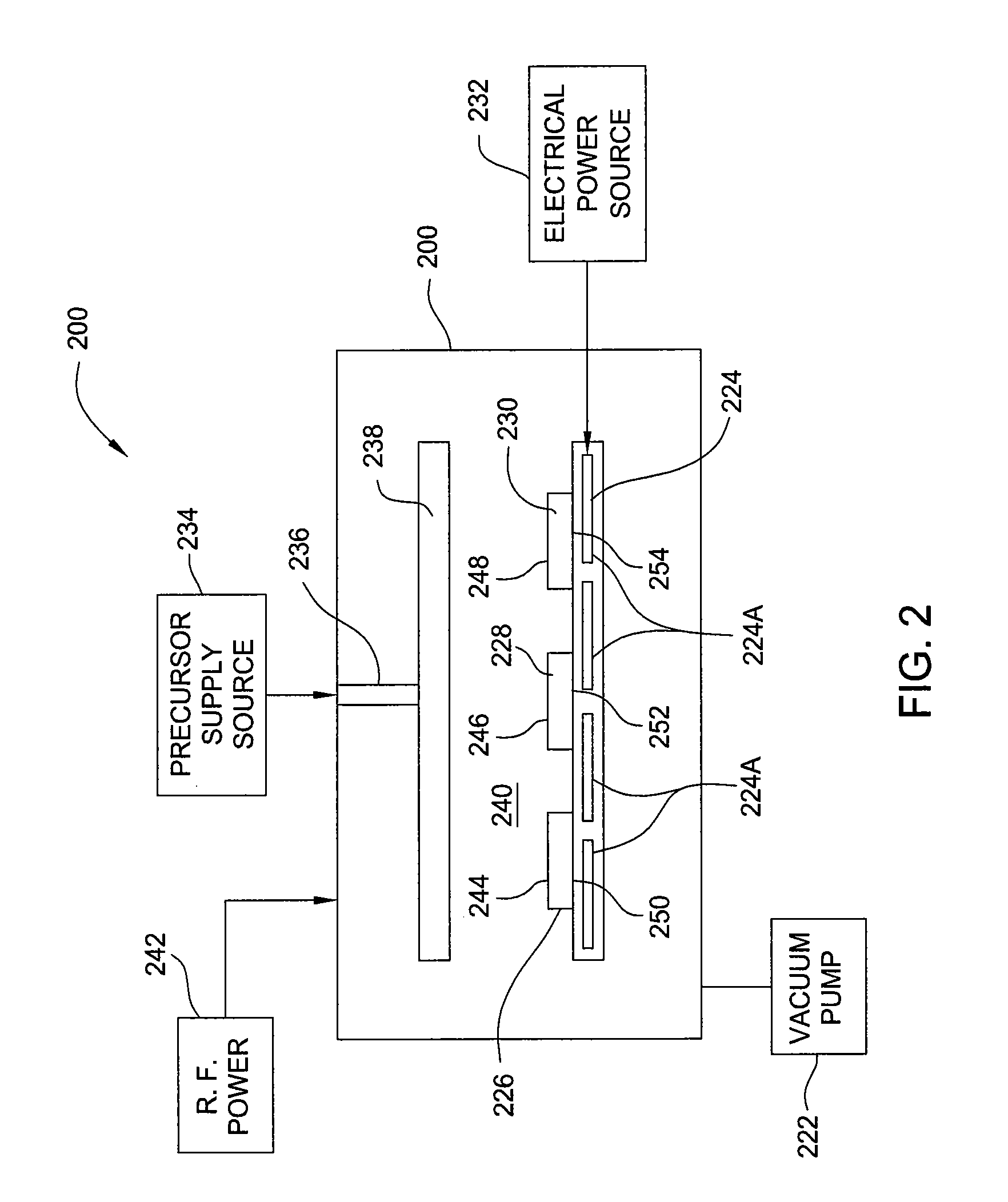

Method used

Image

Examples

example 1

[0048]In one example, a 100 Å thick amorphous silicon film was deposited via plasma enhanced chemical vapor deposition onto a crystalline silicon substrate with a phosphorous doping concentration of 1.5×1021 atoms / cm3. A 900 Å thick silicon nitride film was then deposited over the phosphorous doped amorphous silicon film in the same chamber. The resulting structure was annealed via RTP at 950° C. for 120 seconds in a nitrogen environment. The phosphorous concentration in contact with the silicon nitride layer remained heavily doped. The phosphorous in contact with the crystalline substrate diffused into the substrate resulting in a p-n junction depth of 900 Å. The resulting structure had a dopant profile with a high concentration of dopant collected at the interface between the silicon, nitride layer and the silicon layer decreasing to a lower concentration of dopant at the p-n junction.

example 2

[0049]In another example, a 100 Å thick amorphous silicon film was deposited via plasma enhanced chemical vapor deposition onto a crystalline silicon substrate with a phosphorous doping concentration of 1.5×1021 atoms / cm3. A 900 Å thick silicon nitride film was then deposited over the phosphorous doped amorphous silicon film in the same chamber. The resulting structure was annealed via RTP at 1,000° C. for 120 seconds in a nitrogen environment. The phosphorous concentration in contact with the silicon nitride layer remained heavily doped. The phosphorous in contact with the crystalline substrate diffused into the substrate resulting in a p-n junction depth of 1,350 Å. The resulting structure had a dopant profile with a high concentration of dopant collected at the interface between the silicon nitride layer and the silicon layer decreasing to a lower concentration of dopant at the p-n junction.

[0050]Although the invention has been described in accordance with certain embodiments and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com