Manufacture and use of engineered carbide and nitride composites

a technology of nitride and carbide, which is applied in the field of carbide and nitride composite materials, can solve the problems of high cost, limited use of glass and ceramic manufacturing, and high production cost of technical grade products, which are generally less expensive than commercial grade products, and achieve the effect of reducing production cost and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0058]Example 1 illustrates a method of manufacturing a mostly amorphous silicon carbide product by using a pyrolyzed carbonaceous source and a siliceous source.

[0059]A mixture was made from 1 part by weight of silica fume, three parts of sugar, and sufficient water to form a slurry with a syrupy consistency. The slurry was dried at 105° C. to form a brittle solid cake. The solid cake was then coarsely ground into a precursor powder having a nominal size of 500 um.

[0060]An enclosed graphite crucible was filled with the precursor powder and heated at 200° C. for 1 hour, and then at 400° C. for 3 hours to melt and pyrolyze the sugar. The crucible was then heated at 1500° C. for 5 hours to allow graphite formation, and then cooled to room temperature. The graphite wall of the crucible acted as an oxygen scavenger and ensured a non-oxidizing atmosphere within the crucible for sugar pyrolysis and carbide formation.

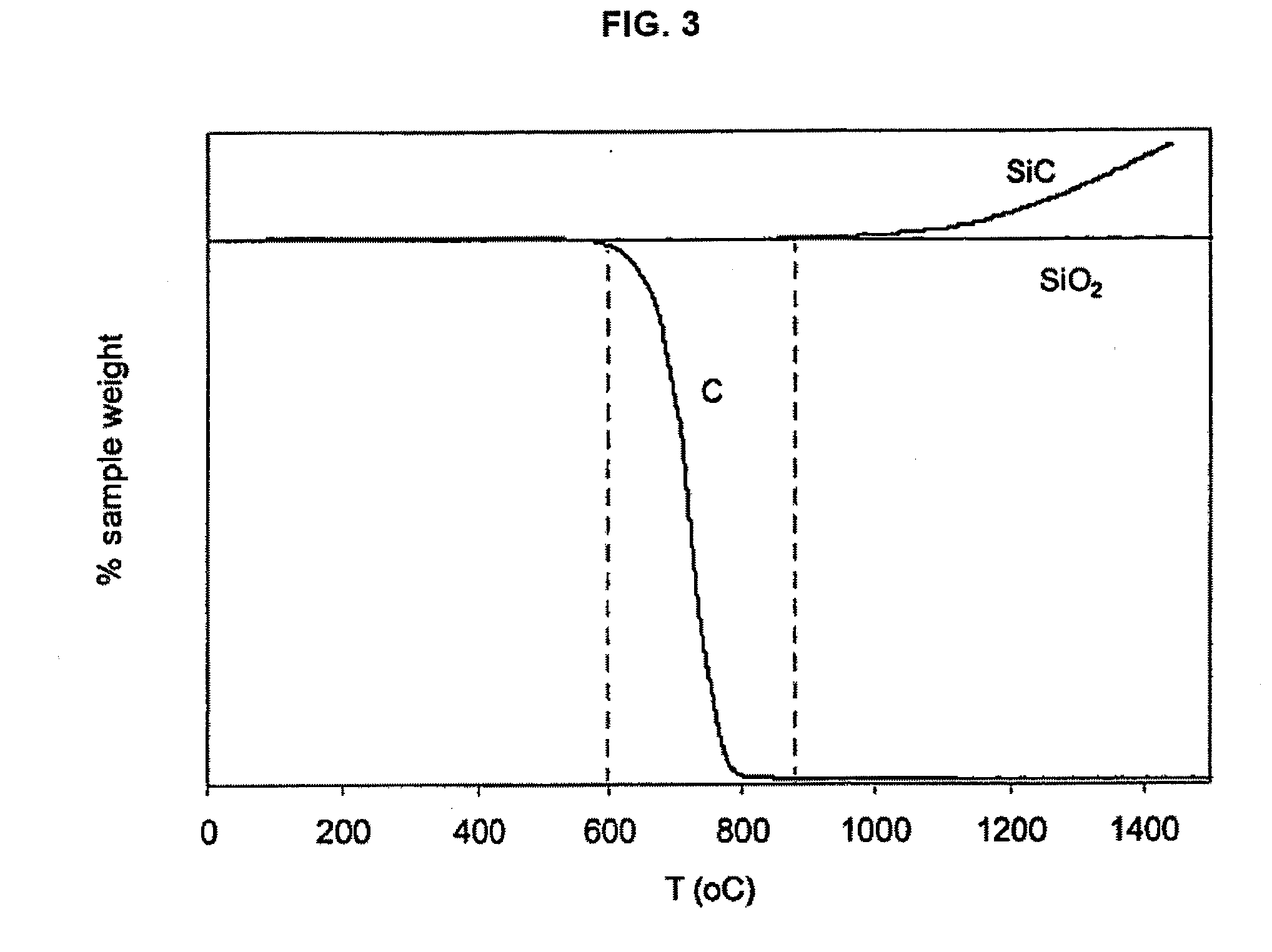

[0061]A sample of the powder formed in the crucible was then subjected to ...

example 2

[0066]Example 2 illustrates the use of a binder with siliceous and carbonaceous starting materials used to produce silicon carbide in a crystallite form.

[0067]A mixture was prepared from 3 parts by weight of a silica fume, 6 parts of graphite powder, and 1 part of sodium silicate. The mixture was then placed into an alumina crucible. An extra 3 parts of graphite powder was then placed on top of the mixture to completely fill the crucible. A lid was placed on top to enclose the crucible. The crucible was then heated at 1500° C. for 4 hours, and then allowed to cool to room temperature.

[0068]The extra graphite acted as an oxygen scavenger to ensure a non-oxidizing environment in the crucible during the carbide formation. The sodium silicate is used as a fluxing and binding agent to bind the silicon carbide and unreacted carbon and silica in a uniform mass.

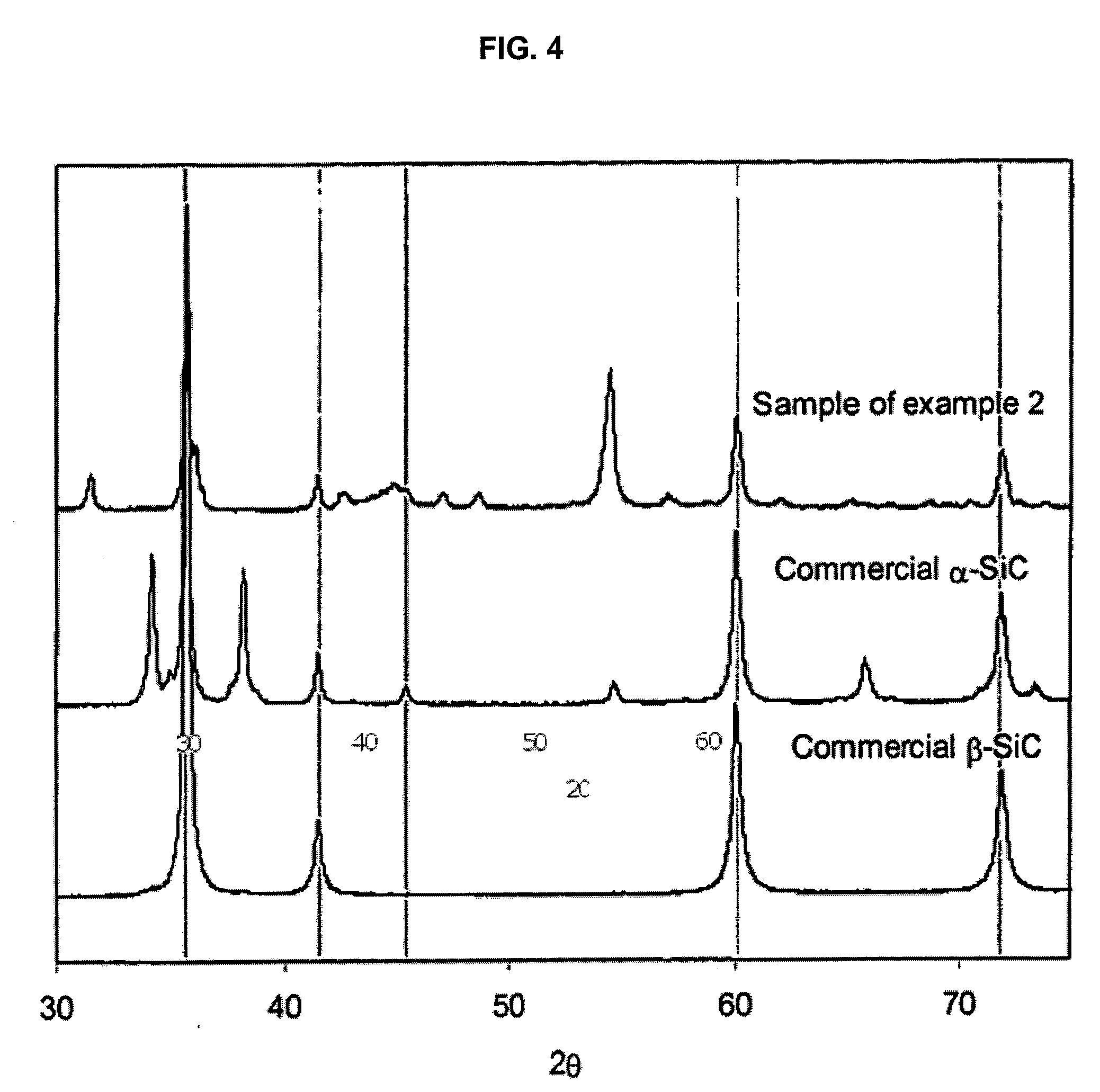

[0069]The powder formed in the crucible was then subjected to XRD analysis. FIG. 4 shows the XRD pattern for the sample, together w...

example 3

[0070]Example 3 was prepared my mixing 7.5 parts by weight of a powdered commercial montmorillonite clay containing 60% by weight silica with an average particle size of 5 microns with 1 part sugar in water to form pumpable slurry. The slurry was simultaneously spray dried and pyrolyzed in air using a conventional spray drier to form round pellets with an average diameter of 50 microns. The spray drier outlet temperature was maintained at 275° C. The pellets were subsequently heated at 1200° C. in nitrogen to form a powdered material containing silicon carbide dispersed in a diluent of alumina and calcined montmorillonite clay. This SiC rich material is suitable for addition to ceramics or glasses using montmorillonite clays as a raw material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com