Titanium and titanium alloys

a technology of titanium alloys and titanium halides, which is applied in the direction of improving process efficiency, etc., can solve the problems of uncontrollable and sporadic reaction, uncontrolled reaction, and contamination opportunities, and achieve the effect of capital and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

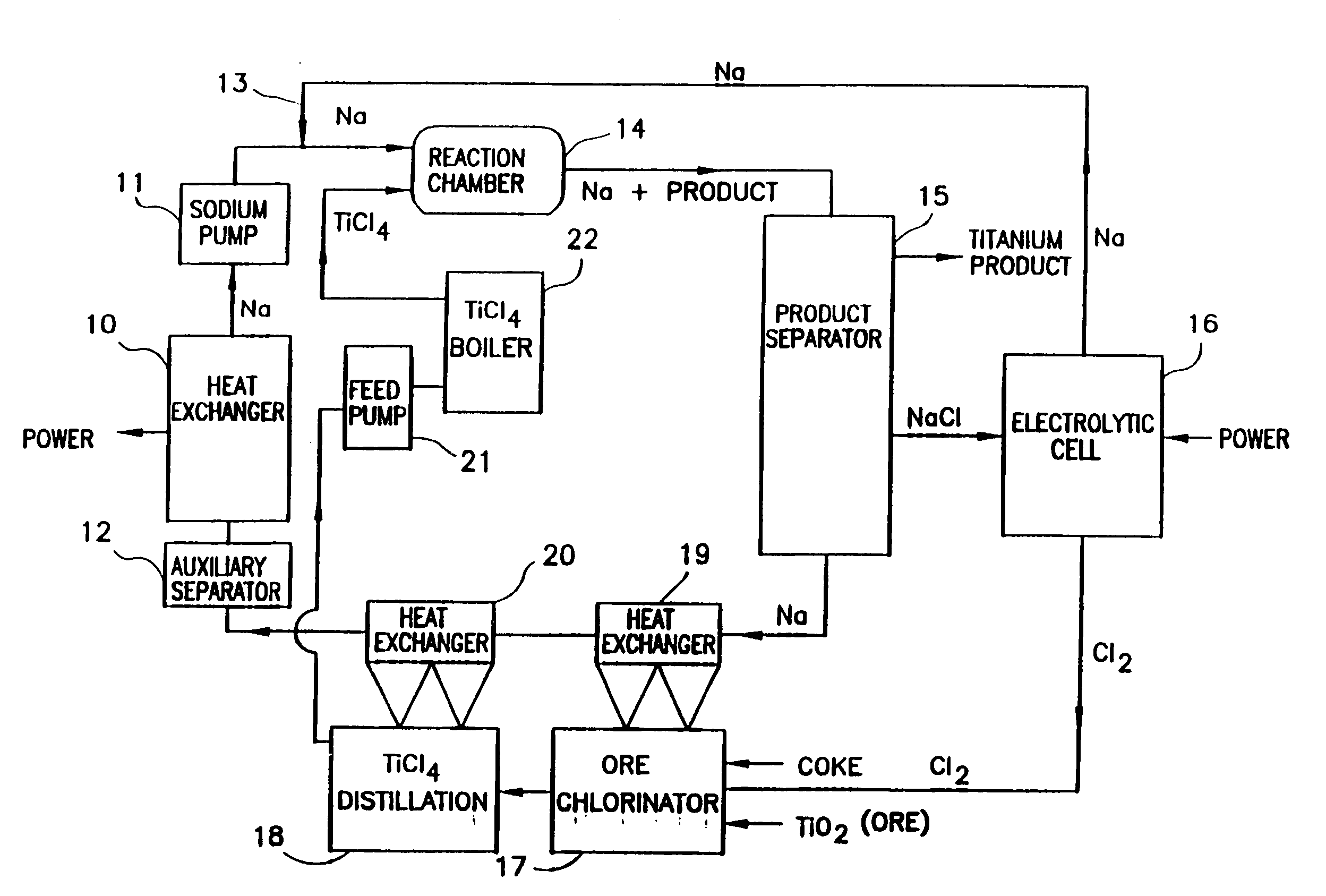

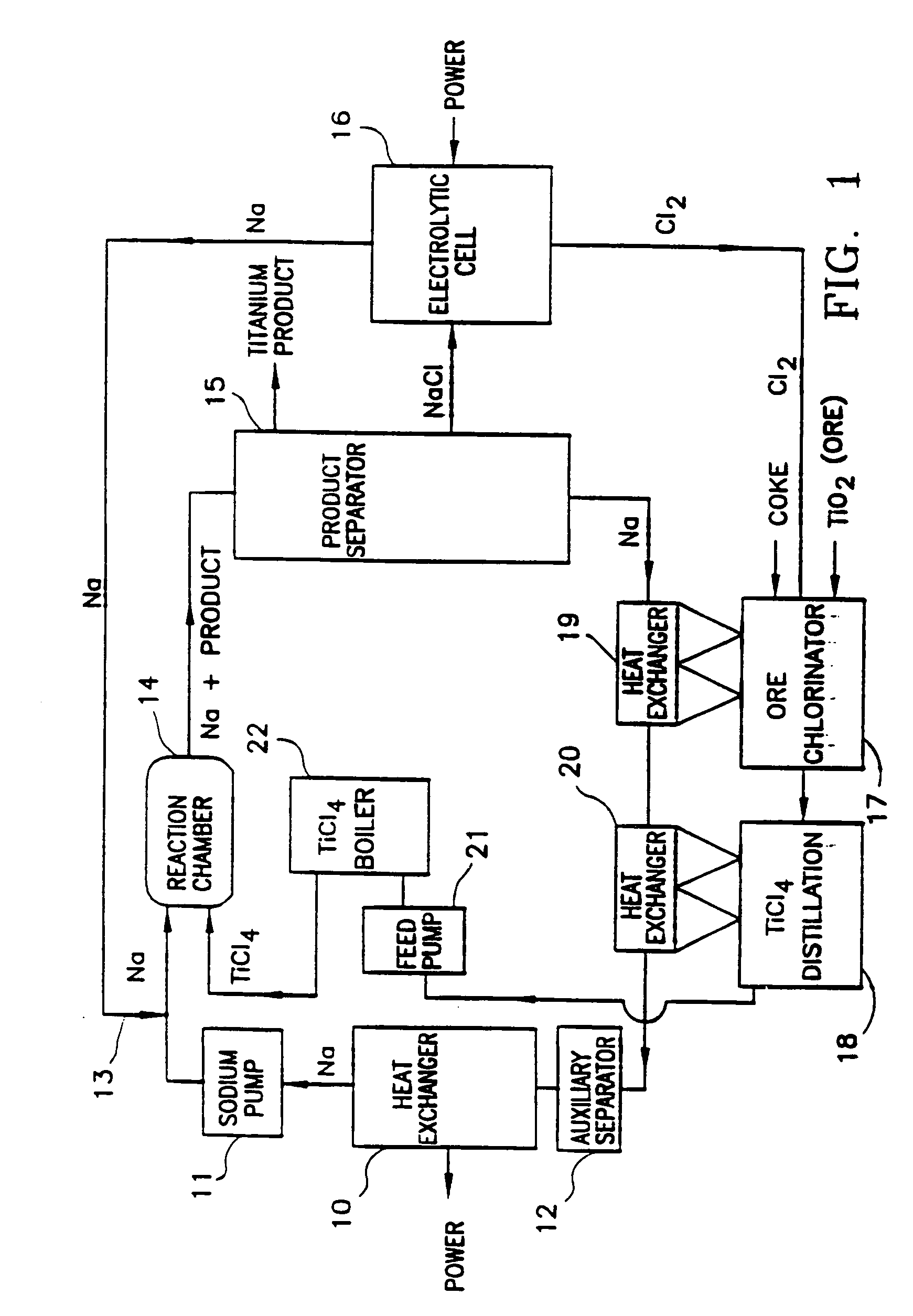

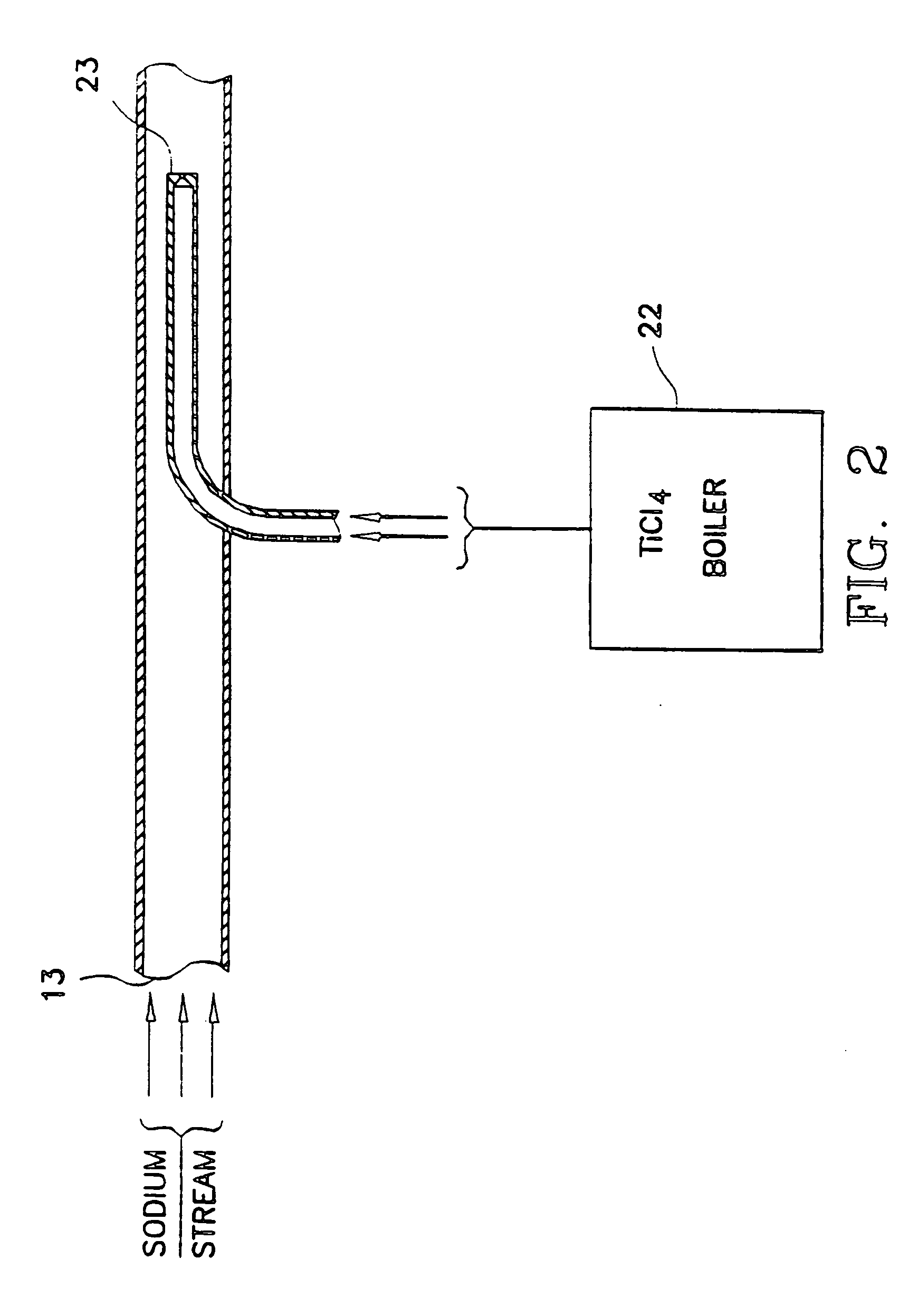

[0022]The process of the invention may be practiced with the use of any alkali or alkaline earth metal depending upon the metal or non-metal to be reduced. In some cases, combinations of an alkali or alkaline earth metals may be used. Moreover, any halide or combinations of halides may be used with the present invention although in most circumstances chlorine, being the cheapest and most readily available, is preferred. Of the alkali or alkaline earth metals, by way of example, sodium will be chosen not for purposes of limitation but merely purposes of illustration, because it is cheapest and preferred, as has chlorine been chosen for the same purpose.

[0023]Regarding the non-metals or metals to be reduced, it is possible to reduce a single metal such as titanium or tantalum or zirconium, selected from the list set forth hereafter. It is also possible to make alloys of a predetermined composition by providing mixed metal halides at the beginning of the process in the required molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com