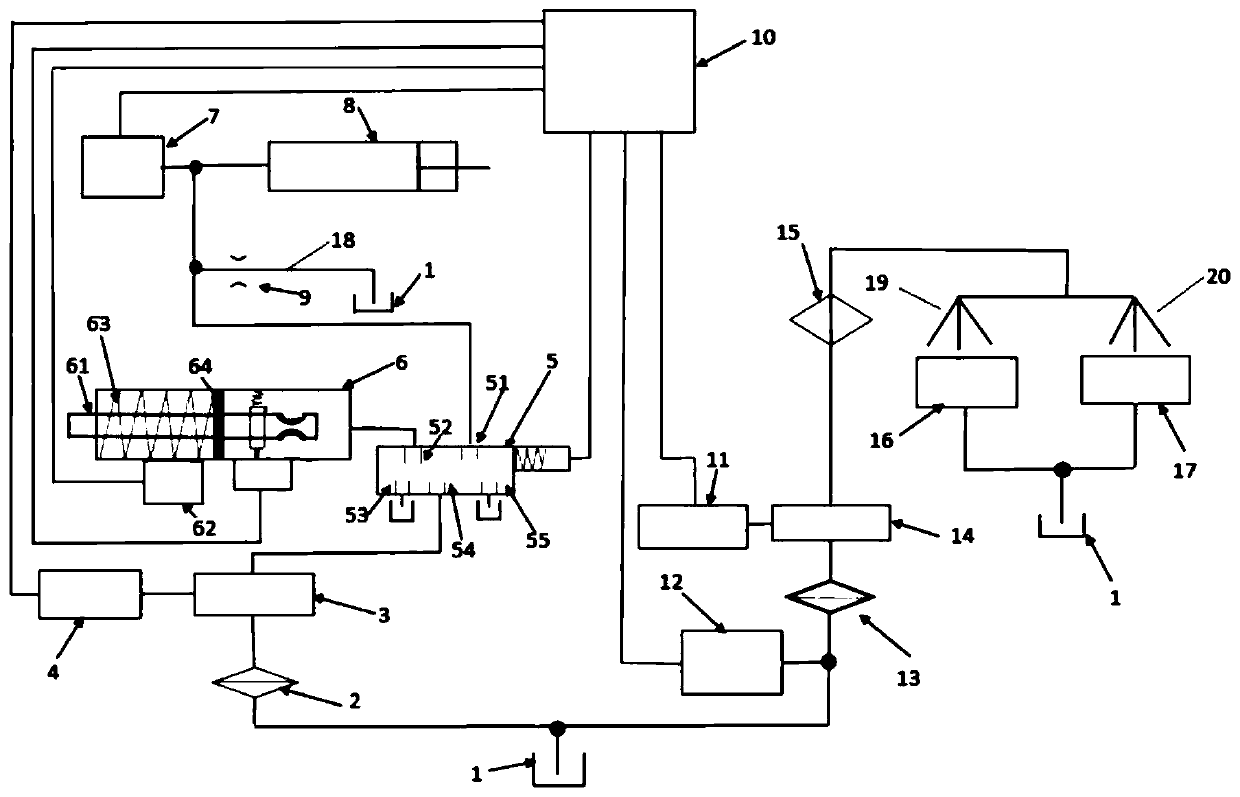

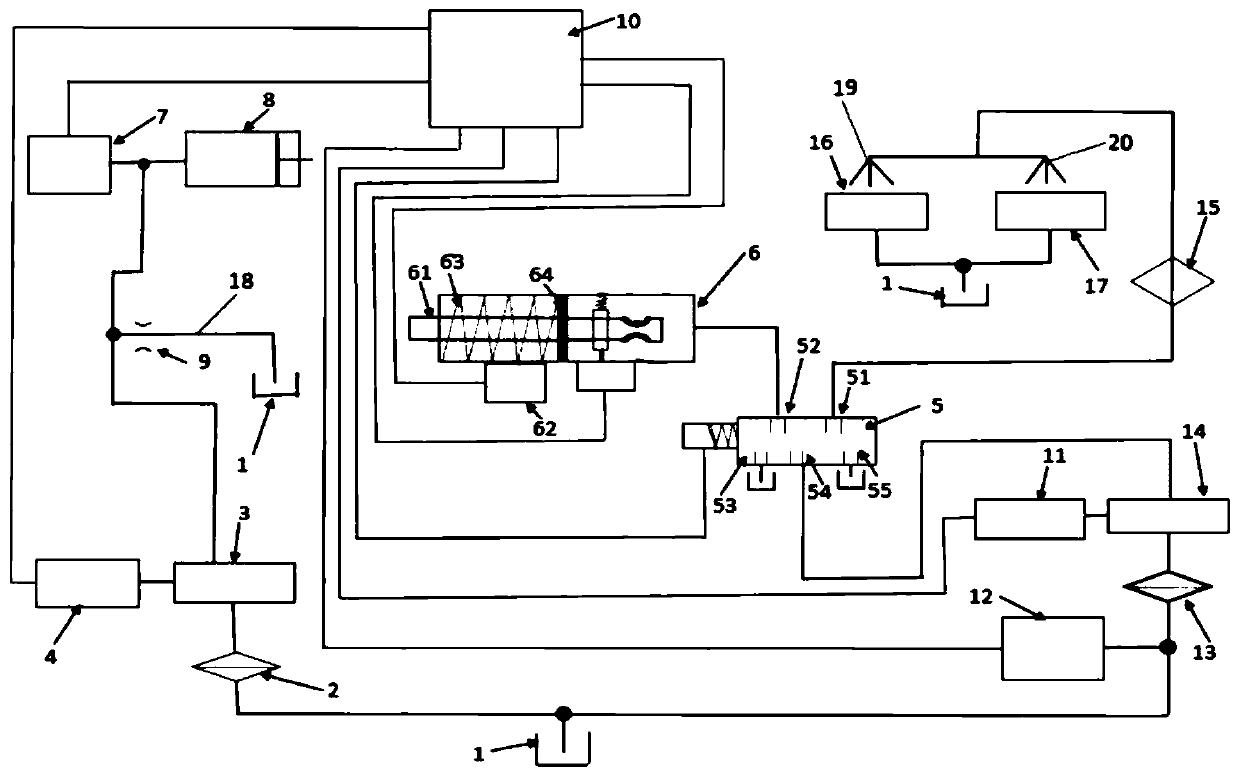

Hydraulic control method and system of hybrid power gearbox

A technology of hybrid power and control method, which is applied in the direction of transmission control, clutch, components with teeth, etc., can solve the problems of many control system components, complex control strategies, complex structure, etc., and achieves small assembly space and improved system. The effect of integration and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0030] The present invention has a second embodiment: the reversing valve 5 and the parking hydraulic cylinder 6 are integrated into the circuit of the second motor 11 and the cooling oil pump 14, and the oil pressure output channel 51 of the connecting part of the reversing valve 5 outputs a large flow of oil The generator 16 and the driving motor 17 are sprayed and cooled by the cooler 15, and the bearings inside the motor can be lubricated at the same time. The parking hydraulic cylinder oil pressure output channel 52 of the reversing valve 5 also outputs the control hydraulic oil of the parking hydraulic cylinder 6, which can unlock the parking mechanism of the gearbox. The reversing valve 5 and the parking hydraulic cylinder 6 are integrated in the circuit of the motor cooling system. Since the parking unlocking action can be completed in a short time, the cooling and lubrication circuit can pass the gearbox controller 10 to the second motor at other times. 11 for long-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com