Microwave pretreatment of logs for use in making paper and other wood products

a technology for pretreatment and wood products, applied in the direction of cellulose treatment using microorganisms/enzymes, finely divided material pretreatment, papermaking, etc., can solve the problems of limiting the use of mechanical pulp in many grades of paper, high cost of mechanical pulp, and high energy consumption of mechanical pulping. , to achieve the effect of reducing the amount of bleaching chemicals, reducing the cost of effluent treatment, and increasing the opacity of the resulting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Microwaving Logs and Structural Effects

[0053] Microdry, Inc. (Crestwood, Ky.) is a manufacturer of custom industrial microwave ovens suitable for use in the present invention. A high capacity microwave oven was used for initial tests (FIG. 1). This oven is connected to a variable-power (up to 60 kW) 915-MHz frequency generator. Individual logs can be manually placed in the microwave chamber until appropriate treatment time, frequency and power are determined. Treatment parameters are dependent upon a number of factors, including type of wood, diameter of the log and moisture content. After optimization of treatment parameters, however, a continuous belt transport system capable of accommodating logs can be used.

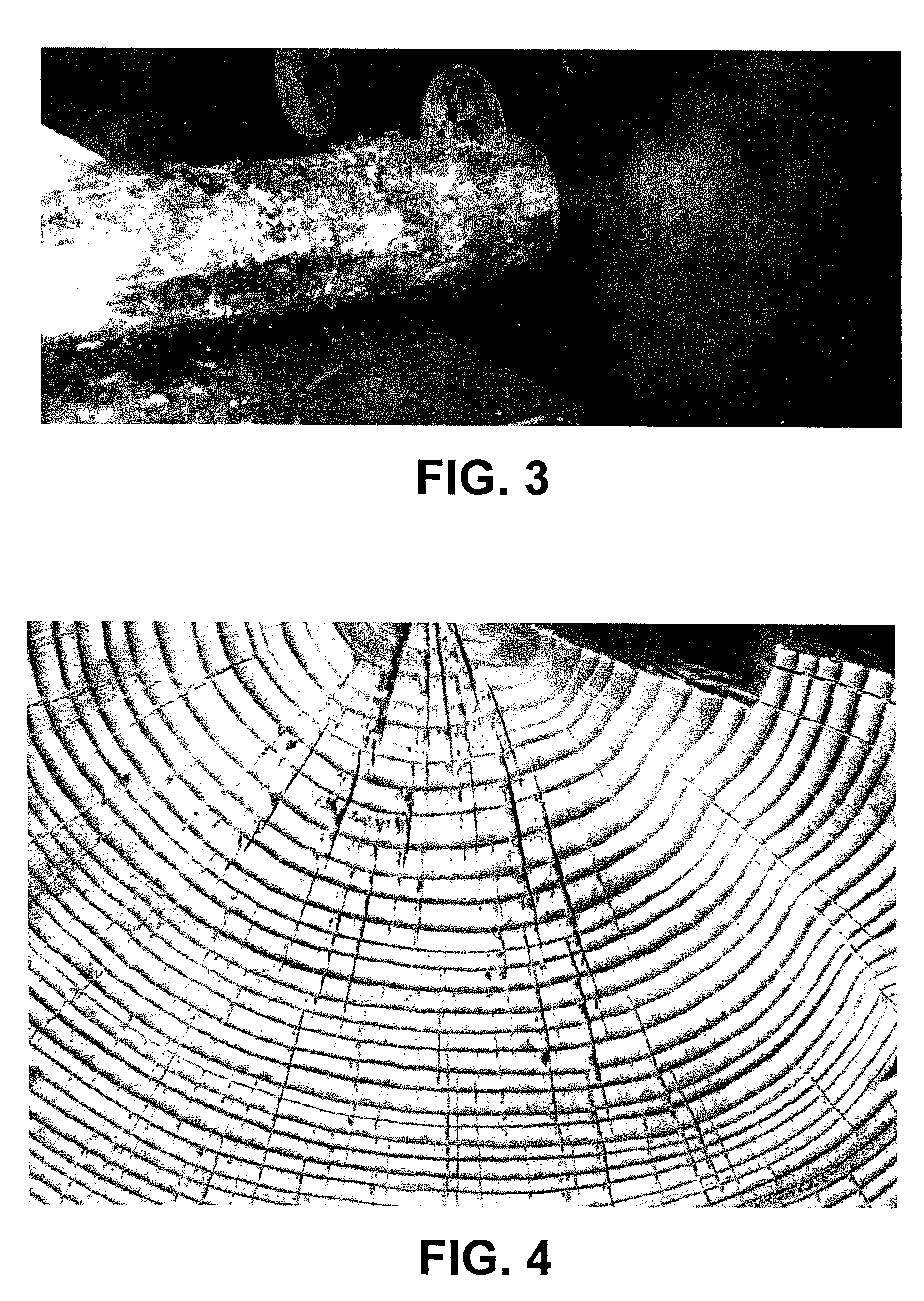

[0054] Microwaved logs or chips obtained from these logs demonstrate increased porosity as has been observed in treated logs. In general, as shown in FIG. 2, it has been determined that higher power levels result in higher log temperatures, with steeper temperature gradient...

example 2

Microwave Pretreatment of Spruce Logs

[0056] Spruce logs were divided into two lots. One lot was frozen and used as a control. The other lot was treated for 5 minutes with a high power microwave generator (50 kW at 915 MHz). During microwaving, significant moisture loss was observed and a temperature of 130° C. inside the log was recorded. Prior to refining atmospherically, both the control and the microwaved logs were completely submerged in water overnight to maintain the same moisture content in both the logs. Logs were then debarked, chipped, and refined through the RMP process. Following results were obtained (Table 1):

TABLE 1Energy requirements and paper strengthproperties during RMP processParametersControlTreatment (Microwaved)Energy during refining (Wh / kg)24112051Burst index (kN / g)0.981.33Tear index (mNm2 / g)3.313.91Tensile index (Nm / g)23.628.6Breaking length (m)24082912

[0057] The data in Table 1 indicates that the microwave treatment improved all major strength properties...

example 3

Microwave Pretreatment of Pine Logs

[0060] Objective: To achieve electrical energy savings and improvements in paper strength by microwaving pine logs prior to mechanical pulping.

[0061] Materials: Pine logs were received from a mill specializing in the production of light weight coated paper. Logs were microwaved at Microdry in Louisville, Ky. Logs were debarked and chipped to a nominal size of 6-14 mm. Chips were placed in plastic freezer bags and frozen to prevent the growth of contaminating microorganisms. Log discs were cut before debarking and chipping that was approximately 3 centimeters thick. Moisture content varies from approximately 50%-56% depending on the microwave treatment time.

[0062] Microwave Treatments: Logs were subject to three microwaving conditions. Logs were microwaved at 50 kW for 5 minutes (50 / 5), 20 kW for 6 minutes (20 / 6), and 20 kW for 8 minutes (20 / 8).

[0063] Chip fiberization, pulp refining and handsheet production: Microwaved wood chips were fiberized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| softening temperature | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com