Preparation method of carbon-cladded magnetic metal nanometer material

A magnetic metal nano and carbon-coated technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as difficulty in large-scale production, high preparation temperature, and complex equipment, and achieve easy control of reaction parameters , low energy consumption, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Under argon protection, 1.9568g CoCl 2 ·6H 2 O is completely dissolved in 20mL of absolute ethanol, and a reducing agent is added while stirring, and the reducing agent is composed of 85% weight concentration of NH 2 -NH 2 ·H 2 O aqueous solution 12mL and 2.0382g NaOH composition. After reacting at 35°C for 30 minutes, the obtained product was centrifuged and washed twice with water and ethanol in sequence to obtain 340 mg of dendritic metal cobalt.

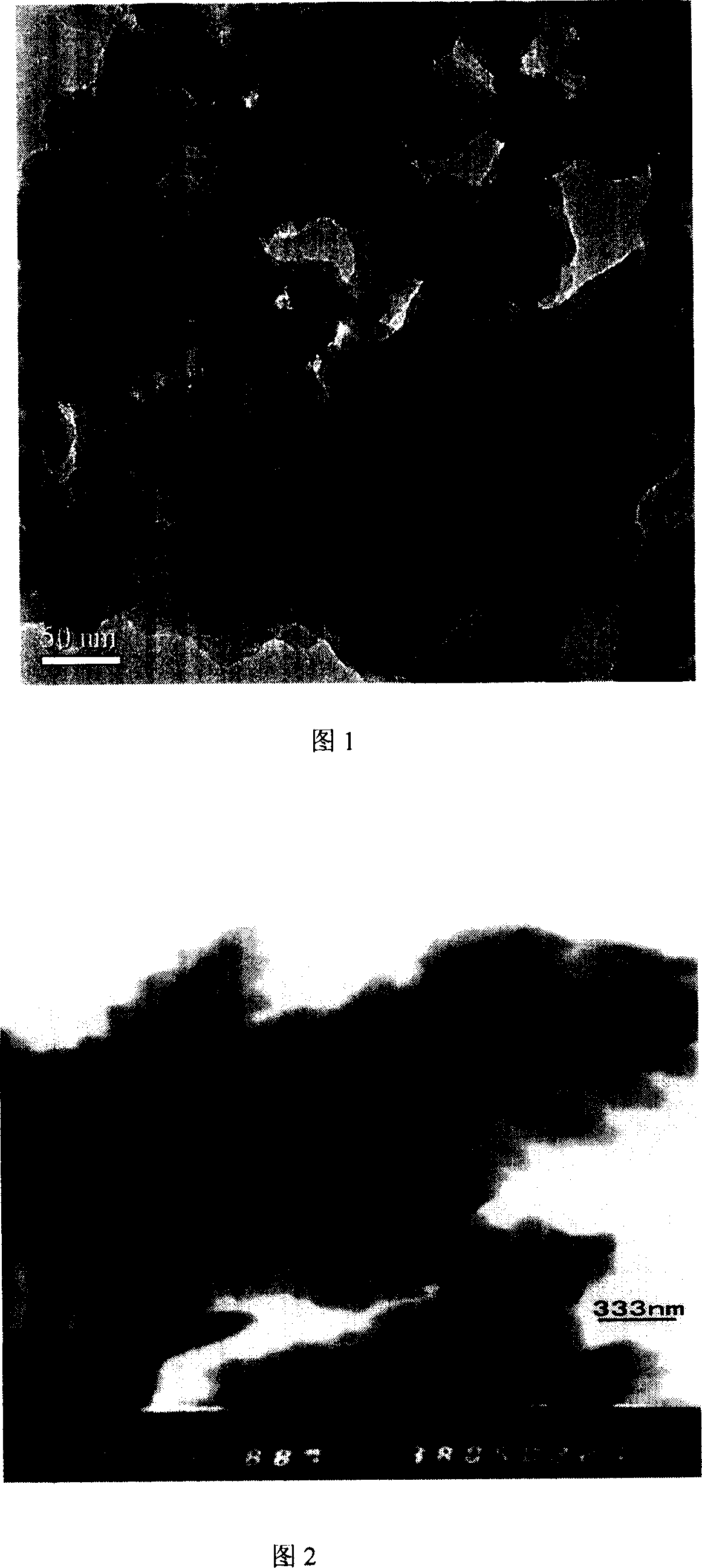

[0022] 40 mg of the obtained cobalt metal was placed in 40 mL of 0.13 M aqueous glucose solution. Sonicate for 15 minutes and place the mixture in a polytetrafluoroethylene reactor. React at 160°C for 16 hours. Cool naturally at room temperature, centrifuge, wash with water and acetone twice in sequence, and dry in vacuum at room temperature. The carbon-coated dendritic cobalt material can be obtained, and the thickness of the carbon coating is about 250 nanometers.

Embodiment 2

[0024] Take 160 mg of the dendritic metal cobalt obtained in Example 1 and place it in 40 mL of 0.13 M glucose deoxygenated aqueous solution. After ultrasonication for 15 minutes, place the mixture in a polytetrafluoroethylene reactor and react at 180° C. for 16 hours. Cool, centrifuge, wash with water and acetone in turn, and dry under vacuum at room temperature. A carbon-coated dendritic cobalt material can be obtained, and the thickness of the carbon coating is about 100 nanometers.

[0025] In Examples 1 and 2, different carbon coating thicknesses can be obtained by controlling the weights of glucose and metal cobalt.

Embodiment 3

[0027] Under argon protection, 0.1396g FeSO 4 ·7H 2 O and 0.1492g NiSO 4 ·6H 2 O was completely dissolved in 10 mL of water, then 1.3601 g of polyethylene glycol (Mw=20000) and 0.5 mL of cyclohexane were added, ultrasonicated at room temperature for 80 minutes, then the mixture was heated to 78 °C, and a reducing agent was added. Consisting of 85% by weight NH 2 -NH 2 ·H 2 O aqueous solution 5mL and 1.0352g NaOH, reacted for 30 minutes to obtain a black sample, centrifuged, washed with water and ethanol twice to obtain 50 mg of iron-nickel alloy nanoparticles with a diameter of about 35 nanometers.

[0028] 19.6 mg of the obtained iron-nickel alloy nanoparticles were placed in 38 mL of deoxygenated water, and then dissolved in 3.0159 g of glucose. After ultrasonication for 15 minutes, the mixture was placed in a polytetrafluoroethylene reactor and reacted at 170° C. for 3.5 hours. Cool naturally at room temperature, centrifuge, wash with water and acetone twice in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com