Circuit board, circuit board manufacturing method and display apparatus provided with circuit board

A technology of circuit substrate and manufacturing method, which is applied in the direction of printed circuit manufacturing, circuit, circuit cover, etc., and can solve problems such as material degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

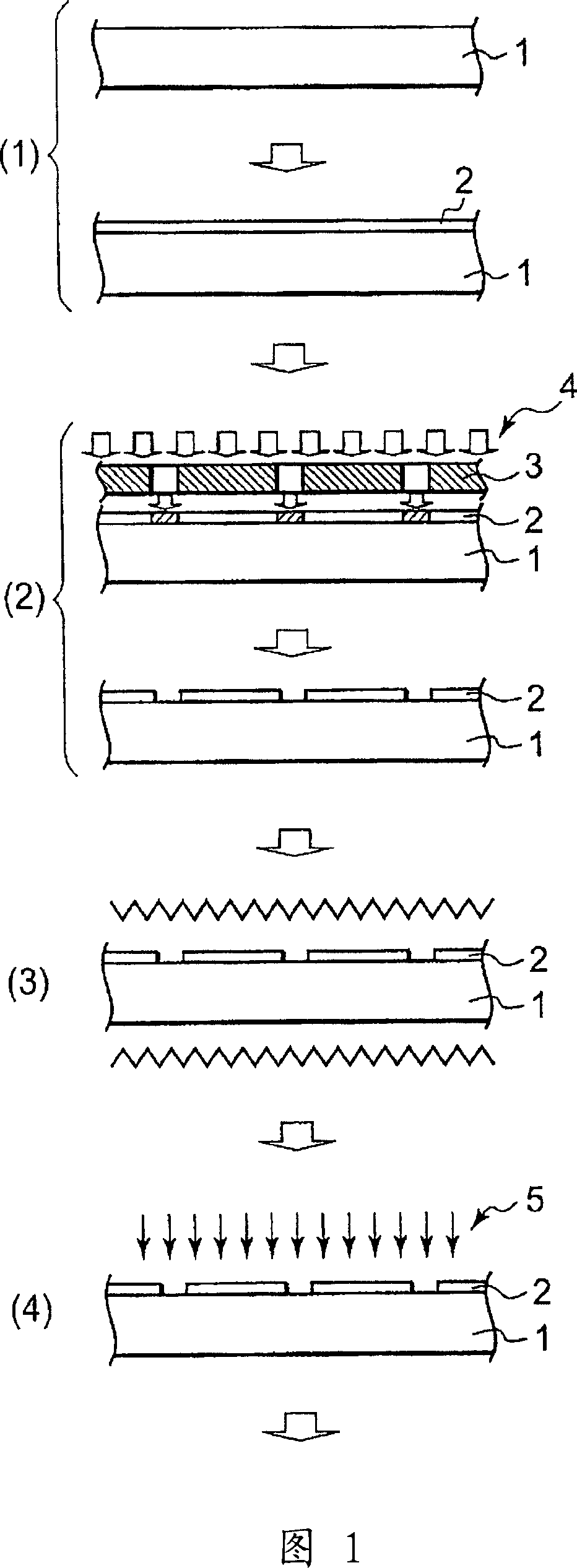

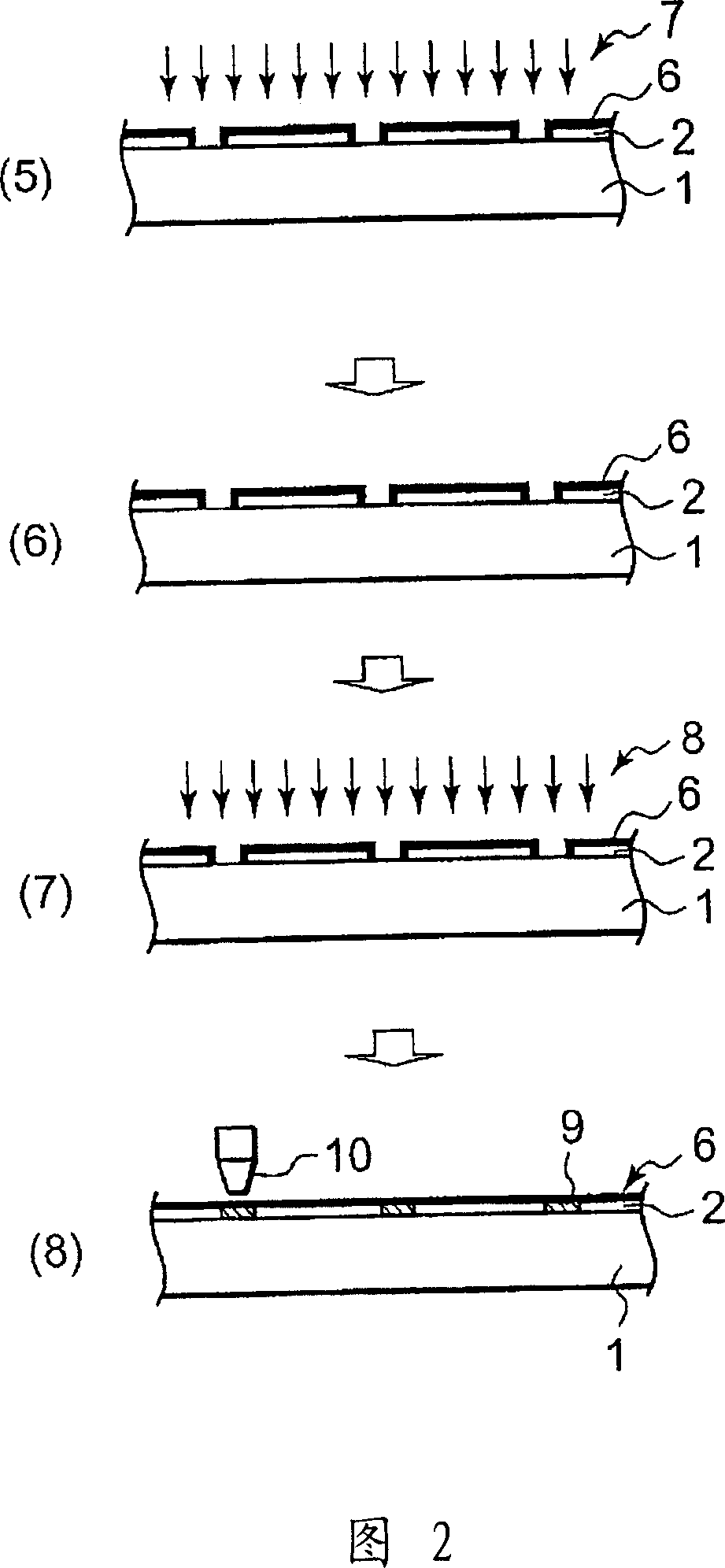

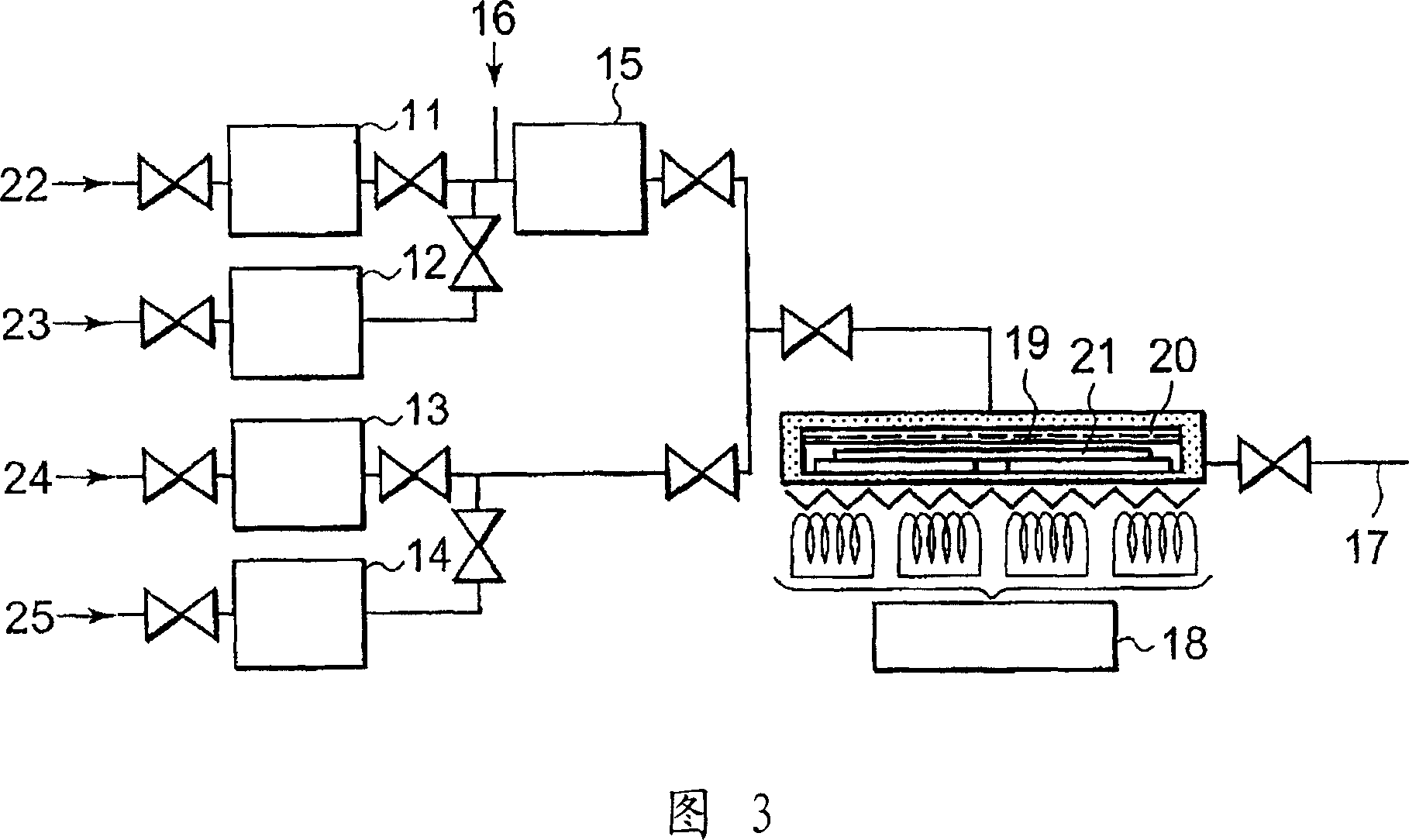

Method used

Image

Examples

Embodiment

[0107] Examples of the present invention are described below. In addition, this invention is not limited to the following Examples. In addition, the analysis values in the following examples and comparative examples are all values obtained by rounding off, and "parts" represent "parts by weight".

[0108] In addition, the analysis conditions in the following examples and analysis examples are as follows.

[0109] (Test 1) Temperature rise detachment analysis (hereinafter abbreviated as "TDS analysis".)

[0110] Device: EMD-WA1000S / W manufactured by Electronic Science Corporation

[0111] (Test 2) Fourier transform infrared spectrophotometric analysis (hereinafter abbreviated as "FT-IR analysis".)

[0112] Installation: Spectrum One, PerkinElmer

[0113] (Test 3) Cavity Ring Drop Spectroscopy (hereinafter abbreviated as "CRDS analysis".)

[0114] Device: MTO-1000H2O manufactured by Tiger Optics

[0115] (Test 4) Measurement of contact angle

[0116] Device: CA-D made...

manufacture example 1

[0124] [Adjustment of thermosetting photosensitive resin composition (positive type)]

[0125] The 8-hydroxycarbonyltetracyclo[4.4.0.1 2,5 1 7,10 ] 62.5 parts of dodec-3-ene, 37.5 parts of N-phenyl (5-norbornene-2,3-dicarboxyimide), 1.3 parts of 1-hexene, 1,3 dimethylimidazoline - 2-indene (tricyclohexylphosphine) benzylidene, 0.05 parts of ruthenium chloride and 400 parts of tetrahydrofuran were installed in a nitrogen-substituted glass pressure-resistant reactor, and reacted at 70°C for 2 hours while stirring to obtain a polymer Product solution A (solid concentration about 20%).

[0126] Part of this polymer solution A was transferred into an autoclave with a stirrer, and hydrogen was dissolved and reacted for 5 hours at 150° C. with a pressure of 4 MPa to obtain a polymer solution B containing a hydrogenated polymer (hydrogenation rate 100%) (Concentration of solid content: about 20%).

[0127] A heat-resistant container in which a part of activated carbon powder was a...

manufacture example 2

[0130] [Adjustment of thermosetting photosensitive resin composition (negative type)]

[0131] 300.0 parts of methyltrimethoxysilane, 47.5 parts of conductivity are 8×10 -5 S cm -1 The ion-exchanged water and 0.1 part of oxalic acid were put into a container with a stirrer, and heated and stirred at 60° C. for 6 hours to hydrolyze methyltrimethoxysilane. Then, after adding 1,000 parts of propylene glycol monomethyl ether into the container, ion-exchanged water and hydrolyzed by-product methanol were removed using an evaporator to obtain a solution adjusted to a solid content of 25% by weight.

[0132] After 400 parts of the above solution and 2.0 parts of phenyl 4-(2'-hydroxy-1'-tetradecyloxy)phenyliodonium-p-toluenesulfonate as a radiation-sensitive acid generator were uniformly mixed and dissolved, Filtration was performed with a membrane filter having a pore diameter of 0.2 μm to obtain a thermosetting photosensitive resin composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com