Method for producing hydrophilic foam dressing and hydrophilic foam dressing produced thereby

A foam and waterproof technology, applied in the field of polyurethane foam dressing preparation, can solve problems such as insufficient absorption of exudates or blood, difficult to produce products, and limited storage period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

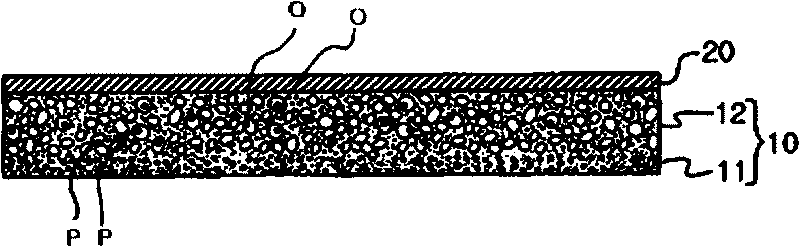

[0039] The preparation method of the polyurethane foam dressing of the present invention selectively or completely comprises: the preparation step of the moisture-permeable and waterproof polyurethane film layer; the preparation step of the polyurethane prepolymer; the preparation step of the foaming composition; the preparation step of the foaming mixed solution; Tack the colloidal polyurethane foam layer and polyurethane film layer and adjust the thickness of the foam dressing; the surface modification step and the aging step to increase the absorption speed of the foam layer.

[0040] Next, each step will be described in detail.

[0041] Preparation of moisture-permeable and waterproof polyurethane film layer

[0042] Add 20-70 parts by weight of methyl ethyl ketone and 5-30 parts by weight of dimethylformamide to 100 parts by weight of polyurethane resin, stir, remove air bubbles, apply to release paper and dry to prepare non-porous waterproof Durable polyurethane film ...

Synthetic example

[0097] According to the conditions and methods shown in Table 2, the moisture-permeable and waterproof polyurethane resin was synthesized.

[0098] 【Table 2】

[0099]

[0100]

preparation example

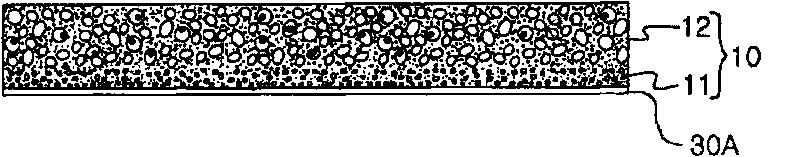

[0102] The preparation of the moisture-permeable and waterproof polyurethane film is as follows: first, 50 parts by weight of methyl ethyl ketone, 15 parts by weight of dimethylformamide, 5 parts by weight of dimethyl formamide, Parts of paint and stir to prepare polyurethane mixture.

[0103] After coating the prepared polyurethane mixture with a certain thickness on the matt release paper 30B (Youlchon Chemical Company) by using a coating thickness gauge, etc., dry it in a hot air dryer at 100°C for 30 minutes, so that the matt One side of the release paper 30B is formed with a moisture-permeable and waterproof polyurethane film. The thickness of the moisture-permeable and waterproof polyurethane film prepared by the above method is 20 μm.

[0104] Example of Foaming Mixture Preparation (#1~3)

[0105] #1, #2, #3 foaming mixtures were prepared according to the conditions shown in Table 3.

[0106] 【table 3】

[0107] distinguish

#1

#2

#3

Rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com