Refrigerant compressor, cooling system and refrigerator

A technology for compressors and refrigerants, used in mechanical equipment, engine components, machines/engines, etc., can solve problems such as corrosion and sliding surface corrosion, reduce sliding loss, reduce friction coefficient, and achieve the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

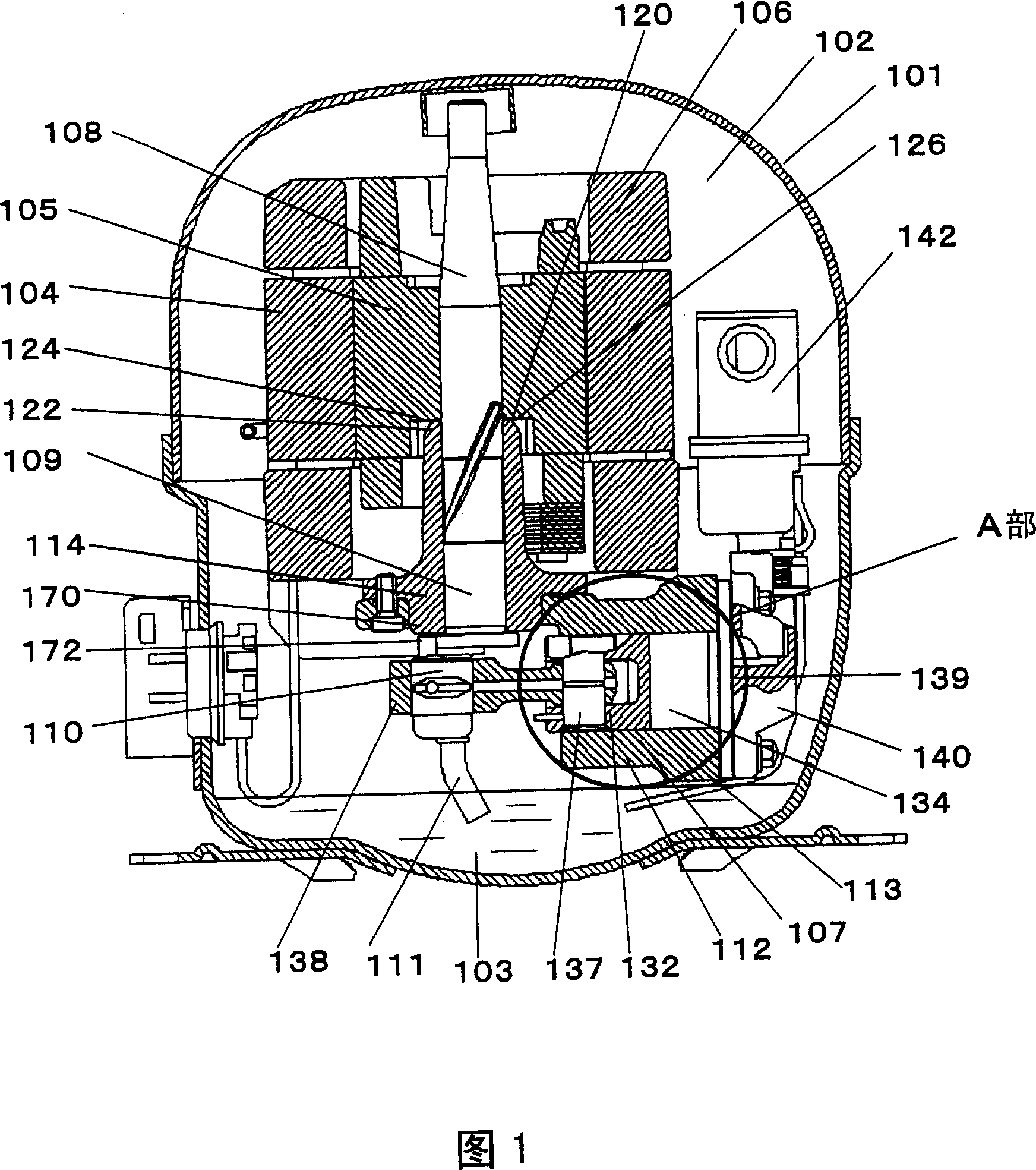

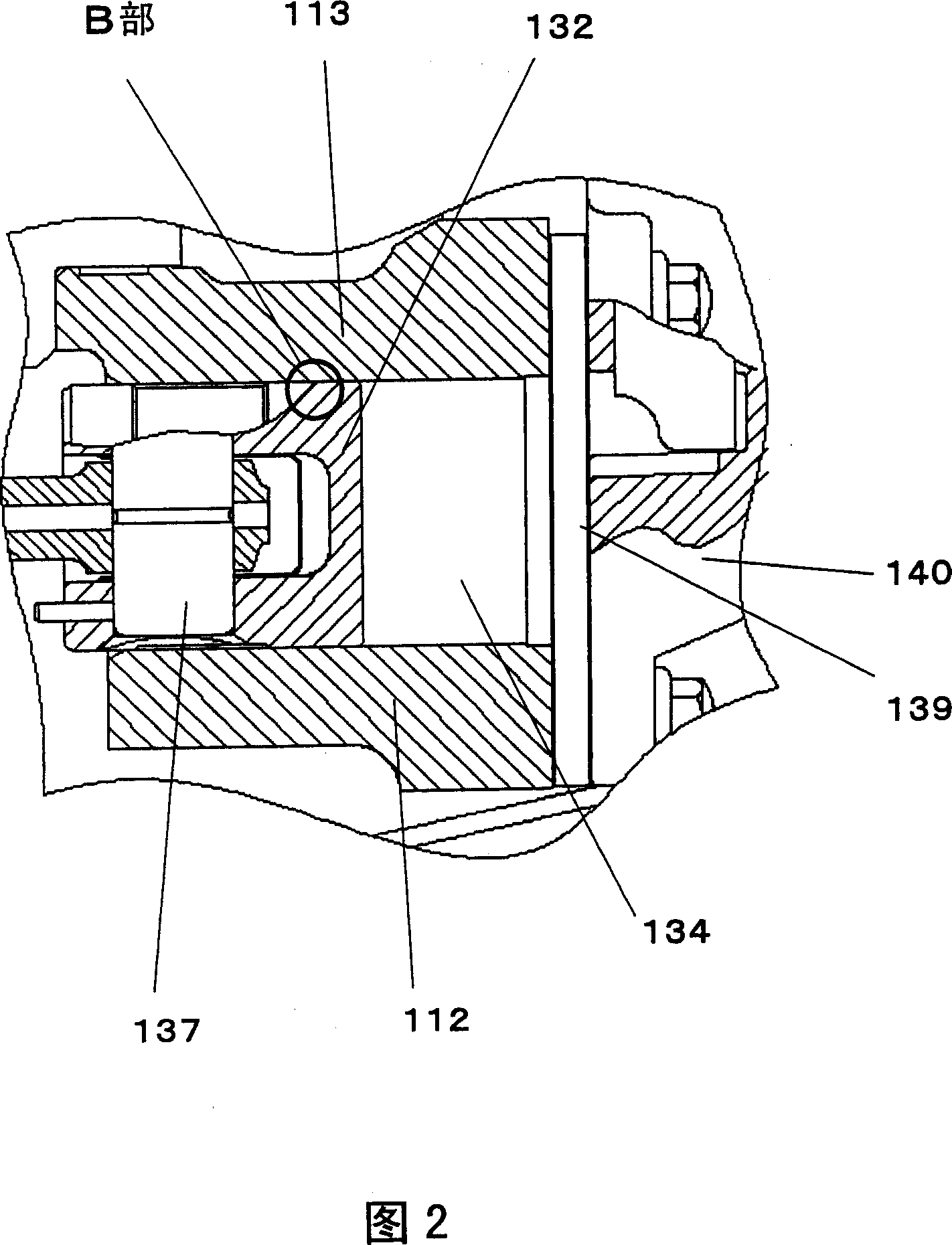

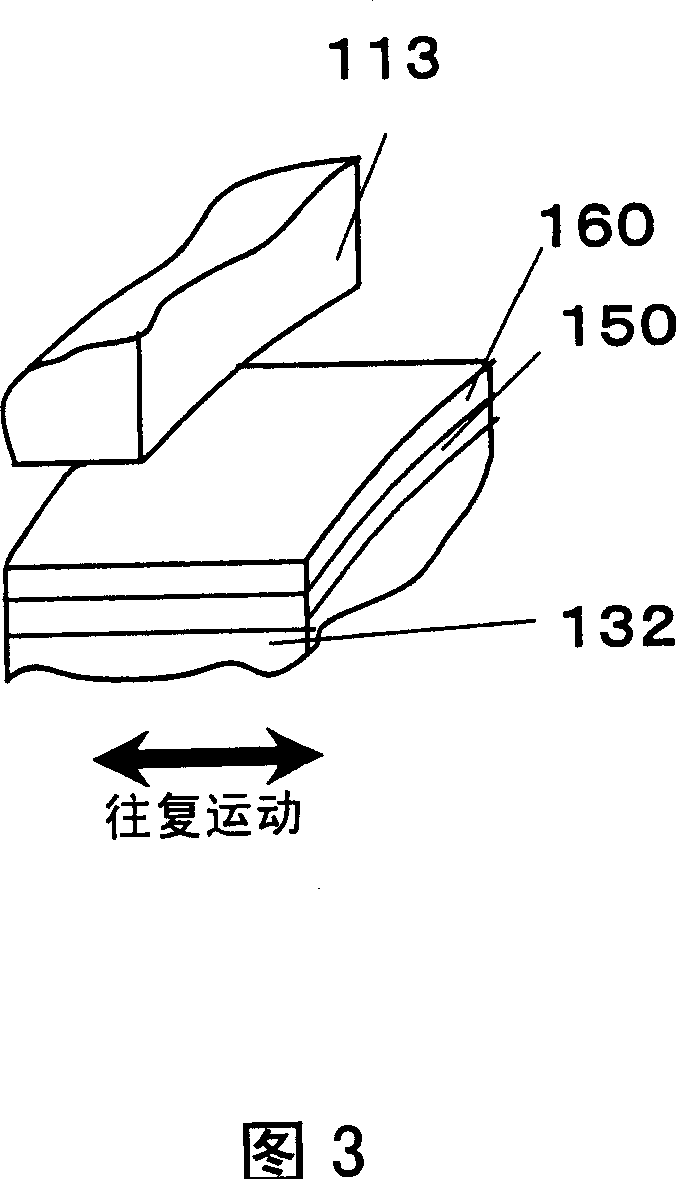

[0056] Fig. 1 is a cross-sectional view of a refrigerant compressor according to Embodiment 1 of the present invention, Fig. 2 is an enlarged view of part A in Fig. 1 , Fig. 3 is an enlarged view of part B in Fig. 2 , and Fig. 4 is a disulfide of this embodiment The formation diagram of molybdenum, Fig. 5 is a characteristic diagram showing the relationship between the gap of the piston / hole and the cooling capacity of this embodiment, Fig. 6 is a concentration distribution diagram of molybdenum disulfide of this embodiment, Fig. 7 is a graph showing this embodiment The characteristic diagram of the relationship between the concentration of molybdenum disulfide and the efficiency, Fig. 8 is the connecting rod assembly diagram of the embodiment in which the ball fixed on the connecting rod is riveted and fixed by the piston, and Fig. 9 is the household refrigerator of the embodiment Fig. 10 is a cross-sectional view of the expansion valve according to Embodiment 1.

[0057] In ...

Embodiment approach 2

[0102] 11 is a cross-sectional view of a refrigerant compressor according to Embodiment 2 of the present invention, FIG. 12 is a cross-sectional view along line C-D in FIG. 11 , and FIG. 13 is an enlarged view of part E in FIG. 12 .

[0103] In FIGS. 11 , 12 and 13 , an electric unit 204 composed of a stator 202 and a rotor 203 , and a rotary plunger compression unit 205 driven by the moving unit 204 are housed in a sealed container 201 together with oil 206 .

[0104] The compression unit 205 includes: a shaft 210 having an eccentric portion 207, a main shaft portion 208, and a sub shaft portion 209; a hydraulic cylinder 212 forming a compression chamber 211; both end surfaces of the hydraulic cylinder 212 are sealed, and the main shaft portion 208 and the sub shaft portion are respectively pivotally supported. The main bearing 213 and auxiliary bearing 214 of 209; the rotary plunger 215 that is loosely embedded in the eccentric part 207 and rolls in the compression chamber 21...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com