Gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating and preparation method thereof

A diamond coating and engineering ceramic technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of toughness, insufficient hardness and binding force, and achieve high internal toughness, high binding force, internal The effect of high toughness and surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

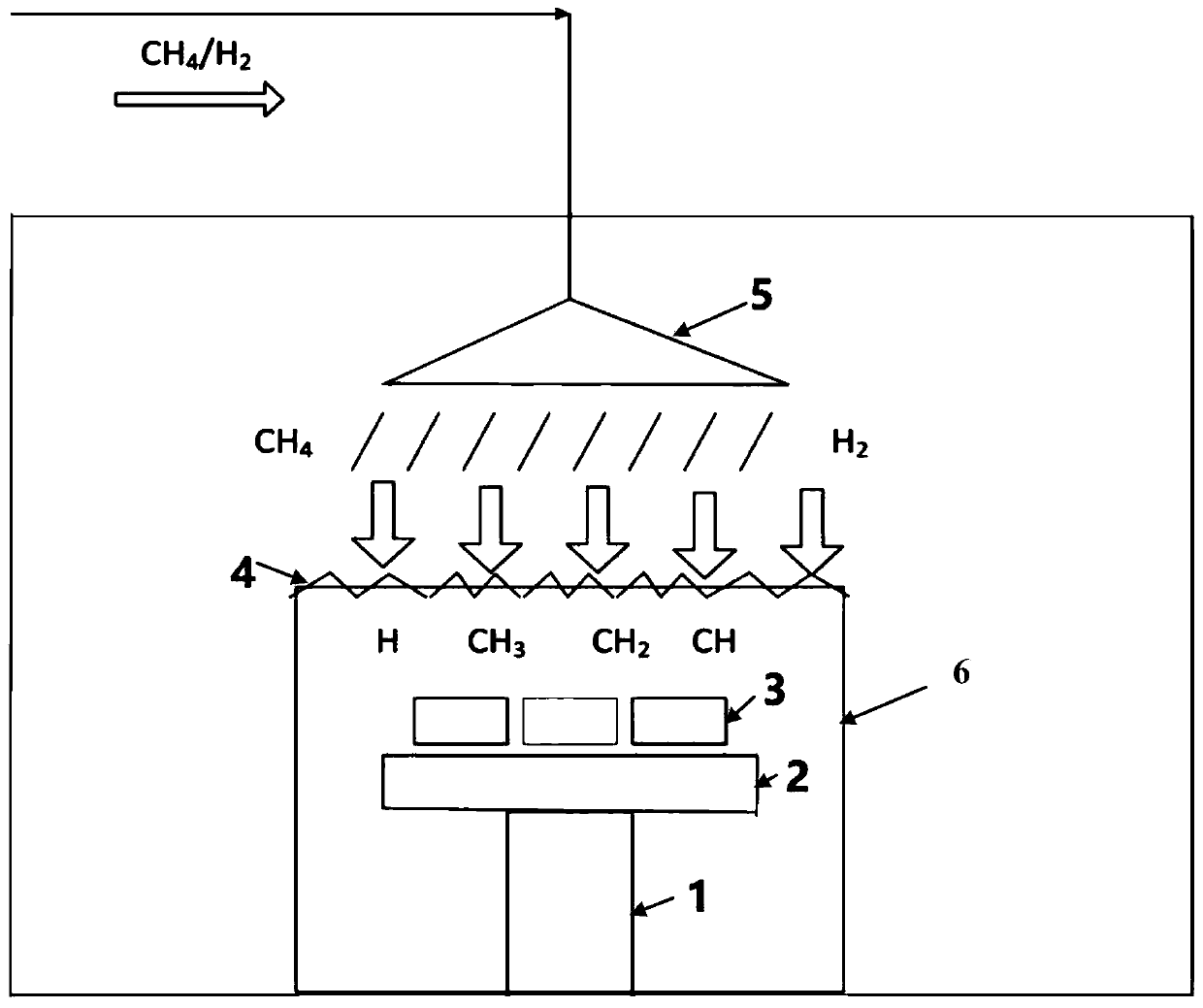

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, silicon nitride (Si 3 N 4 ) ceramics as an example, a composite self-lubricating anti-friction engineering ceramic coating is deposited on the surface of the silicon nitride ceramic substrate, the diameter of the silicon nitride ceramic substrate is 100mm, and the thickness is 10mm;

[0060] In this example:

[0061] In the micro-roughening treatment, the grade of abrasive paste used is W0.5;

[0062] In the chemical pretreatment, the composition of the prepared mixed acid solution is: sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ), its volume ratio is: H 2 SO 4 :H 2 o 2 =1:5;

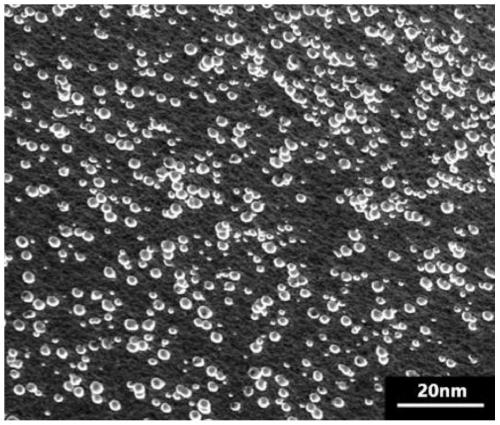

[0063] Parameters of the nano-diamond particle suspension: in the nano-diamond particle suspension, the nano-diamond particle accounts for 10-15% of the total mass of the nano-diamond particle suspension.

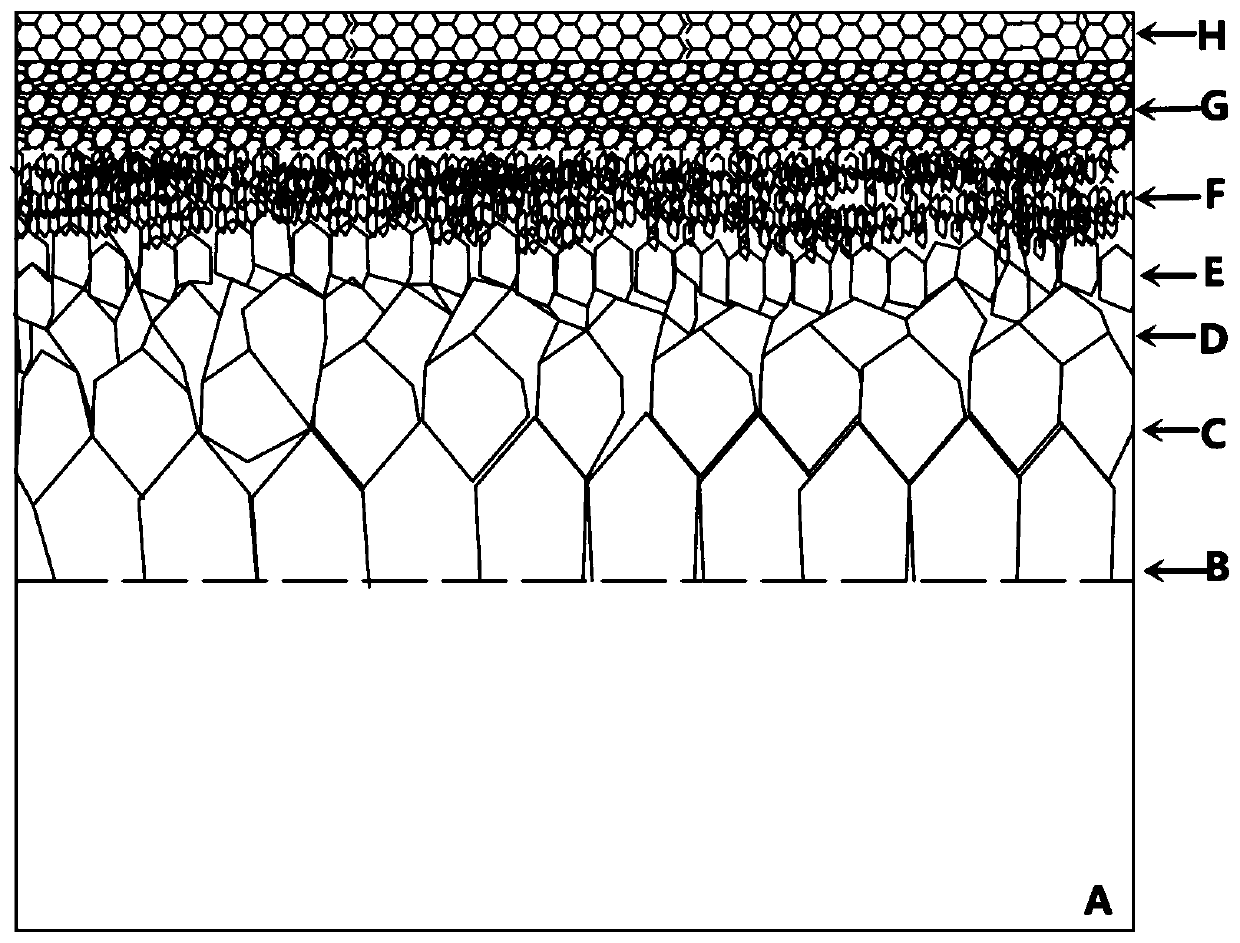

[0064] A gradient diamond / graphite composite self-lubricating and anti-friction engineering ceramic coating, the self-lubricating and anti-friction ...

Embodiment 2

[0088] In this example, zirconia (ZrO 2 ) ceramics as an example, a composite self-lubricating anti-friction engineering ceramic coating is deposited on the surface of the zirconia ceramic substrate, the diameter of the zirconia ceramic substrate is 100mm, and the thickness is 10mm;

[0089] In this example:

[0090] In the micro-roughening treatment, the grade of abrasive paste used is W0.5;

[0091] In the chemical pretreatment, the composition of the prepared mixed acid solution is: sulfuric acid (H 2 SO 4 ) and hydrogen peroxide (H 2 o 2 ), its volume ratio is: H 2 SO 4 :H 2 o 2 =1:5;

[0092] Parameters of the nano-diamond particle suspension: in the nano-diamond particle suspension, the nano-diamond particle accounts for 10-15% of the total mass of the nano-diamond particle suspension.

[0093] A gradient diamond / graphite composite self-lubricating and anti-friction engineering ceramic coating, the self-lubricating and anti-friction engineering ceramic coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com