Injection type tissue engineering bone renovation material and construct method thereof

A tissue engineering bone and repair material technology, applied in medical science, prosthesis, etc., can solve problems such as lack of biomechanical strength, achieve good biodegradability, good biocompatibility, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: the cultivation of seed cell

[0031] Take 5-month-old healthy Chinese green goats (weight 35.0-40kg, male or female, provided by the Animal Experiment Center of Southern Medical University), perform iliac crest puncture with a 16-gauge bone puncture needle under aseptic operation after anesthesia, and extract bone marrow by multi-point puncture 10 mL, centrifuged and filtered with a 100-mesh stencil, inoculated into a culture bottle, added high-sugar DMEM medium (Hyclone, USA) containing 10% fetal bovine serum (Hyclone, USA), and placed in CO 2 Cultivate in an incubator (Harris Company, U.S.), change the medium every 3 days, and treat the primary cells to cover the bottom of the bottle, digest and separate the adherent cells with 0.25% trypsin-0.02% DMEM solution, add conditioned medium (DMEM+ 10% fetal bovine serum + dexamethasone 10-8mol / L + β-sodium glycerophosphate 10mmol / L + ascorbic acid 50mg / L), put in CO 2 The incubator continued to cultivate, ...

Embodiment 2

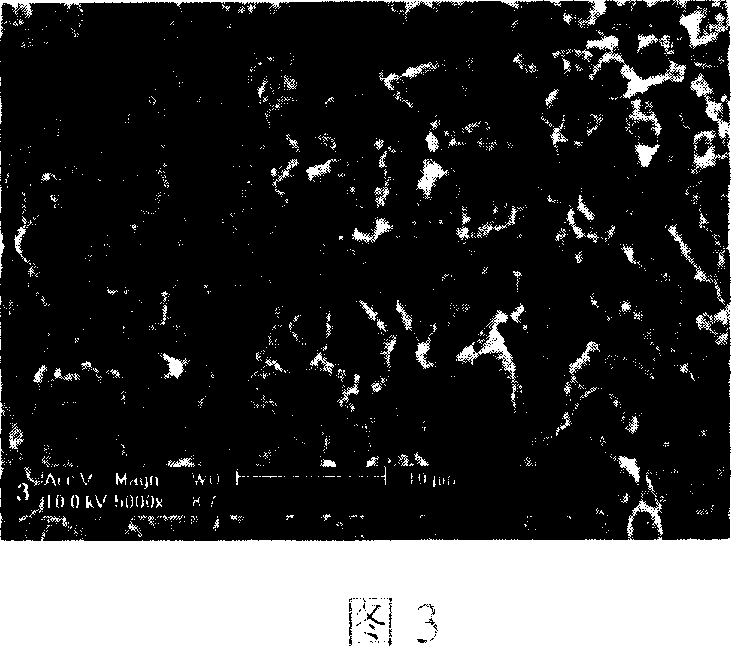

[0032] Example 2: Compounding of seed cells and injectable materials

[0033] The chitosan used in the experiment is a liquid material, and β-tricalcium phosphate (β-TCP) is a solid material (provided by the Department of Materials Science and Engineering of Jinan University). After 15 minutes, it gradually solidified into a solid state. In this experiment, 3ml of chitosan and 1.8g of β-TCP were compounded in vitro. After curing and forming, they were cut into 4mm×4mm×3mm sizes with a sterile scalpel for use. Take the third generation BMSCs (planting density 2×10 4 / hole) were inoculated in 24-well culture plates, and 1ml of medium was added to each well. The experiment was divided into two groups, namely the material group and the blank control group. In the experimental group, 4mm×4mm×3mm chitosan-β-TCP composite material was mixed with the cells in each hole, and the cells were simply inoculated in the control group, and treated at different times for MTT detection. Afte...

Embodiment 3

[0034] Embodiment 3: Inverted Microscope Observation

[0035] The growth of cells in each group was observed daily using an inverted microscope.

[0036] Results: 4 hours after cell inoculation, the cells were partially adhered to the wall, and 12 hours later, the cells were completely adhered to the wall, and the cells were polygonal and spindle-shaped. The cells grew rapidly, and the cell clones formed in 2 to 3 days, and merged into a monolayer after 8 to 10 days. The growth of the cells in the material group was similar to that of the control group (as shown in Figure 1 and Figure 2), and the cell morphology was normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com