Metal phthalocyanine loaded fiber with catalytic activity and preparing method

A metal phthalocyanine and catalytically active technology, applied in the field of metal phthalocyanine supported fibers and their preparation, can solve the problems of reducing axial coordination active points, reducing catalytic efficiency, forming inactivity, etc., reducing secondary pollution, improving Utilization, simple effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

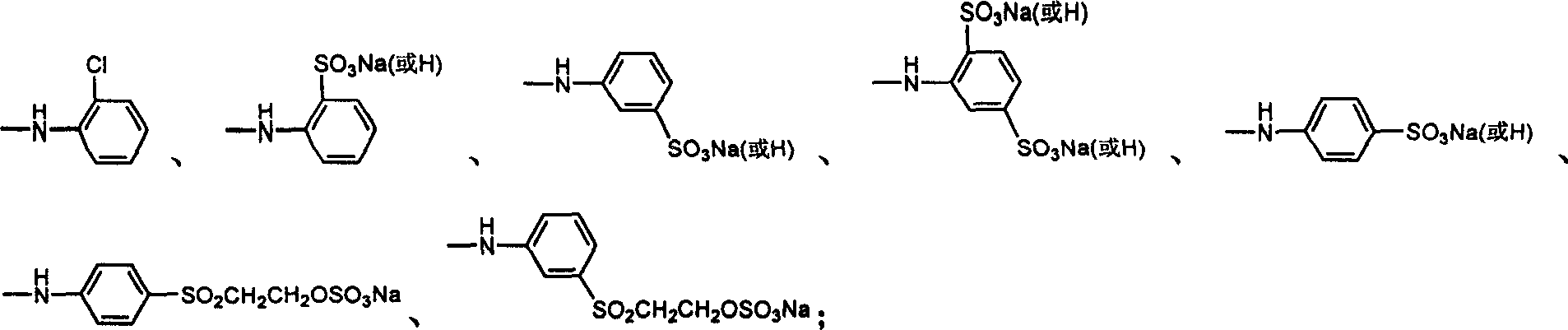

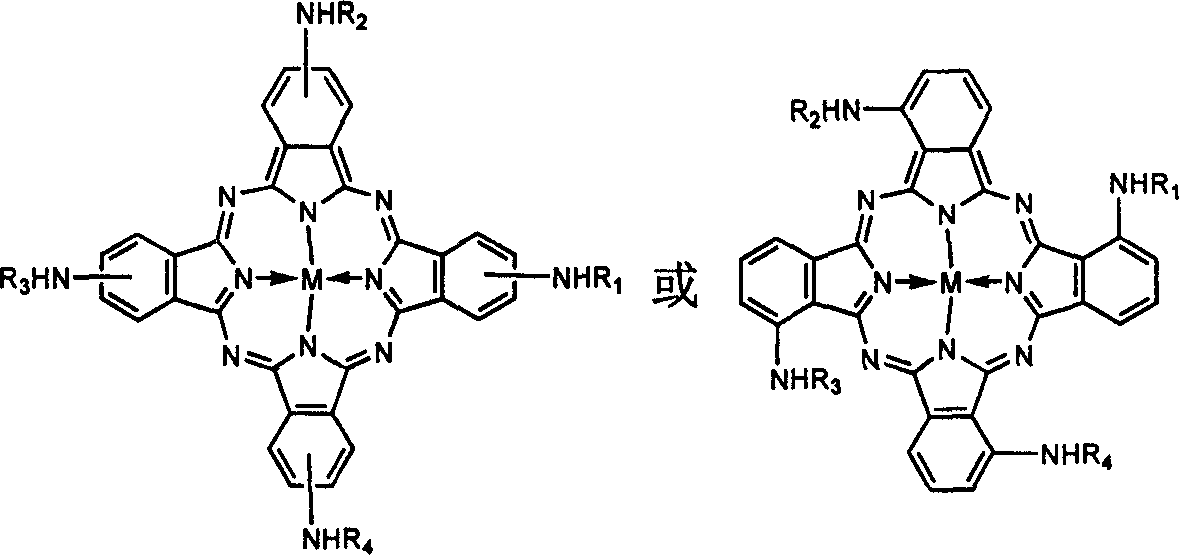

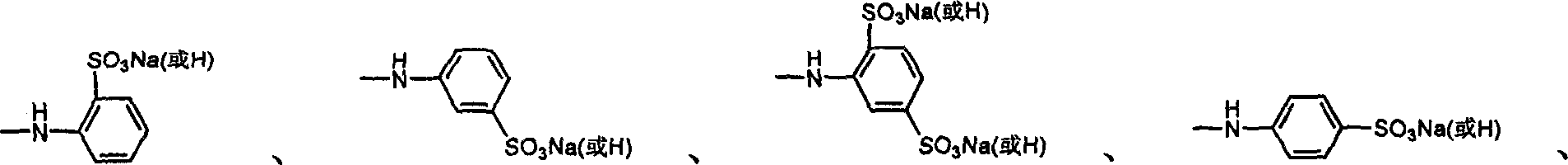

Method used

Image

Examples

preparation example Construction

[0023] The specific preparation method is as follows: when the selected metal phthalocyanine is a reactive group with a triazine structure, it is loaded on the fiber or fabric by the following two methods: first, at a pH of 8 to 11, the reaction At a temperature of 45-95°C, add fibers or fabrics to a certain concentration of metal phthalocyanine aqueous solution with a triazine structure, stir continuously during the reaction, take out the fibers or fabrics after the reaction, and wash them with alkali and water respectively , drying to obtain metal phthalocyanine-loaded fibers or fabrics; second, dissolving reactive metal phthalocyanines in water, adjusting the pH to 8-11, immersing the fibers or fabrics in the above solution for a period of time or by padding The metal phthalocyanine with a triazine structure is adsorbed on the fiber or fabric, and then the metal phthalocyanine is steamed at high temperature to form a covalent bond between the fiber or fabric. After the react...

Embodiment 1

[0027] Weigh 2g of viscose fiber after vacuum drying, remove the organic impurities attached to the fiber with acetone, put it into the pre-prepared tetrakis (2,4-dichloro-1,3,5-triazinyl) cobalt amino In the phthalocyanine solution (1% o.w.f.), the concentration of Pingping O is 2g / L, the bath ratio is 1:30, the reaction is shaken at 25°C for 30min, and the temperature is raised to 65°C at a speed of 1°C / min, and then added to the reaction solution Add 0.24g of Na 2 CO 3 , so that the initial concentration is 4g / L, constant temperature oscillation reaction for 1h, the taken out fibers are washed once with warm water and cold water, dried and then put into 2g / L Na with a bath ratio of 1:60 2 CO 3Treat it in the solution at 60°C for 30 minutes, take it out after washing with water, and boil it in 2 g / L Pingping O solution for 15 minutes. Finally, the obtained fibers were rinsed twice with double distilled water, and dried under reduced pressure at room temperature (25° C.) t...

Embodiment 2

[0029] Weigh 2g of viscose fiber after vacuum drying, use acetone to remove the organic impurities attached to the fiber, put it into the pre-prepared four (2,4-dichloro-1,3,5-triazinyl) amino iron In the phthalocyanine solution (1% o.w.f.), the concentration of Pingping O is 2g / L, the bath ratio is 1:30, the reaction is shaken at 25°C for 30min, and the temperature is raised to 65°C at a speed of 1°C / min, and then added to the reaction solution Add 0.24g of Na 2 CO 3 , so that the initial concentration is 4g / L, constant temperature oscillation reaction for 1h, the taken out fibers are washed once with warm water and cold water, dried and then put into 2g / L Na with a bath ratio of 1:60 2 CO 3 Treat it in the solution at 60°C for 30 minutes, take it out after washing with water, and boil it in 2 g / L Pingping O solution for 15 minutes. Finally, the obtained fibers were rinsed twice with twice distilled water, and dried under reduced pressure at room temperature (25° C.) to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com