Light metal surface micro plasma ceramic coating technology

A micro-plasma and ceramic coating technology, applied in a light field, can solve the problems of limited wear life, low hardness, poor bonding strength, etc., and achieve the effects of good overall toughness, high bonding strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

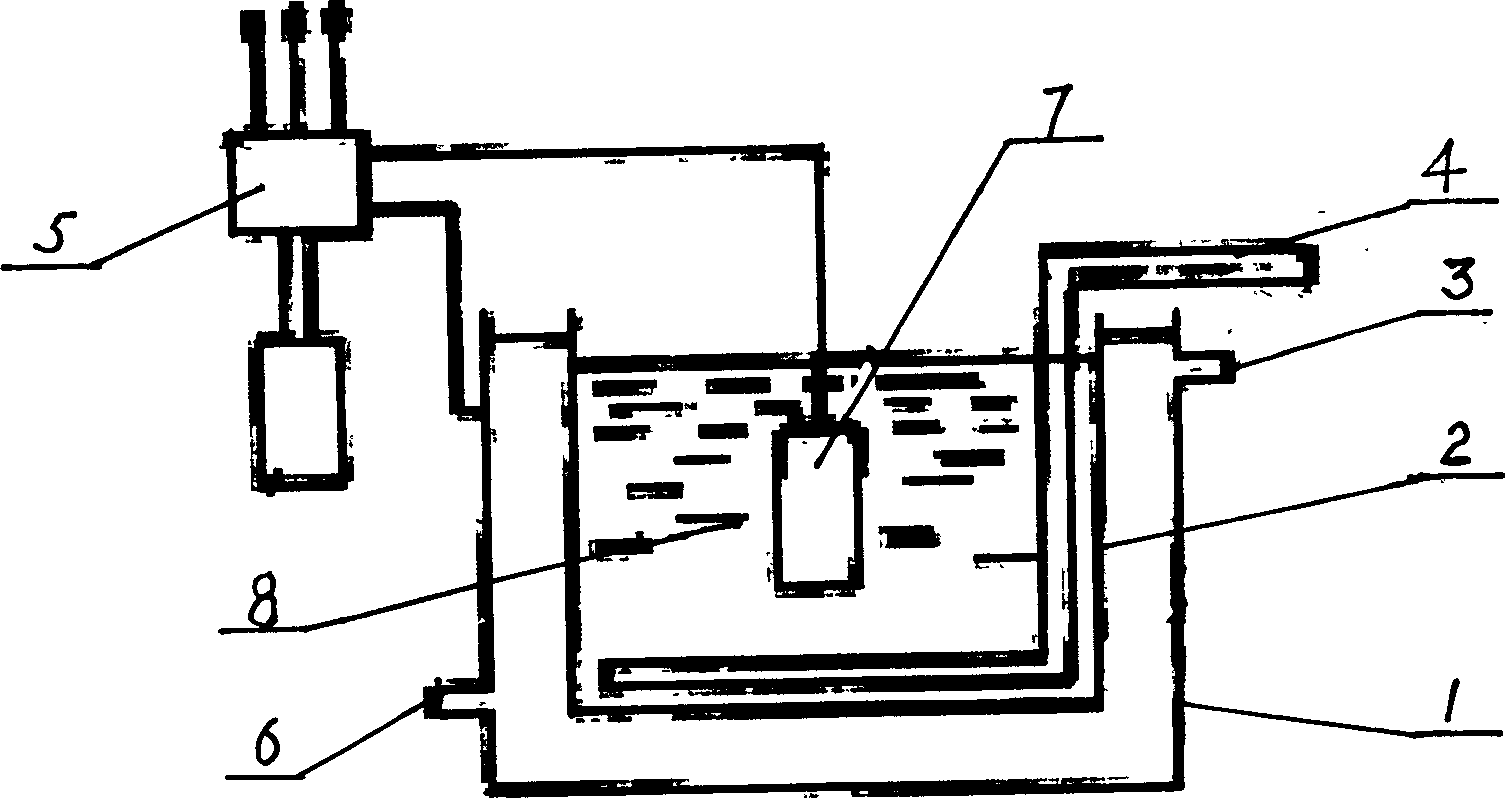

[0032] like figure 1 As shown, it is a schematic structural diagram of the micro-arc oxidation equipment used for the micro-plasma ceramic coating process on the surface of light metal. The micro-arc oxidation equipment used for the micro-plasma ceramic coating process on the surface of light metal is characterized in that the Tube 1, inner electrolytic tube 2, circulating cooling water outlet 3, pipeline 4, control power supply 5, circulating cooling water inlet 6, inner electrolytic tube 2 is installed in outer electrolytic tube 1, between outer electrolytic tube 1 and inner electrolytic tube 2 There is circulating cooling water, the circulating cooling water outlet 3 is set at the upper end of the outer electrolytic tube 1, the circulating cooling water inlet 6 is set at the lower end of the outer electrolytic tube 1, the pipeline 4 with compressed air is placed in the inner electrolytic tube 2, and the control The power supply 5 is located above the outer electrolytic cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com