Heat storage type incinerating method for treating Dioxin-like compounds

A compound and regenerative technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as high catalyst prices, high operating costs, and reduced adsorption efficiency of activated carbon to dioxin, achieving low operating costs and heat recovery High efficiency and low energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

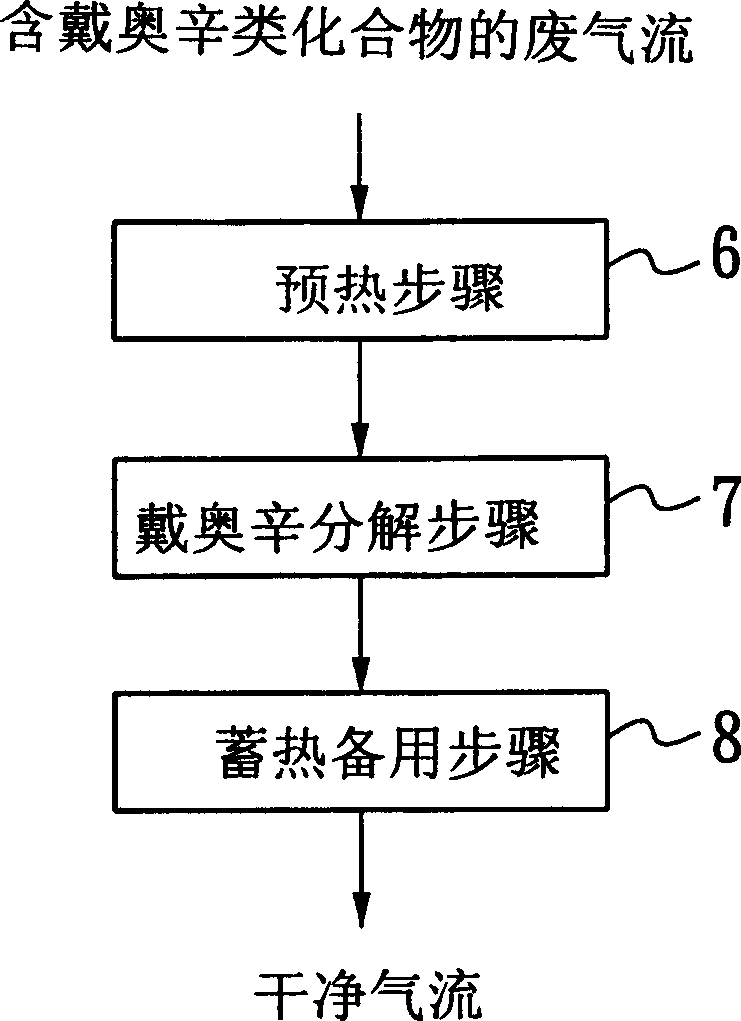

[0038] Such as figure 1 As shown, the preferred embodiment of the thermal storage incineration method for treating dioxin compounds of the present invention includes a preheating step 6 , a dioxin decomposition step 7 , and a thermal storage backup step 8 .

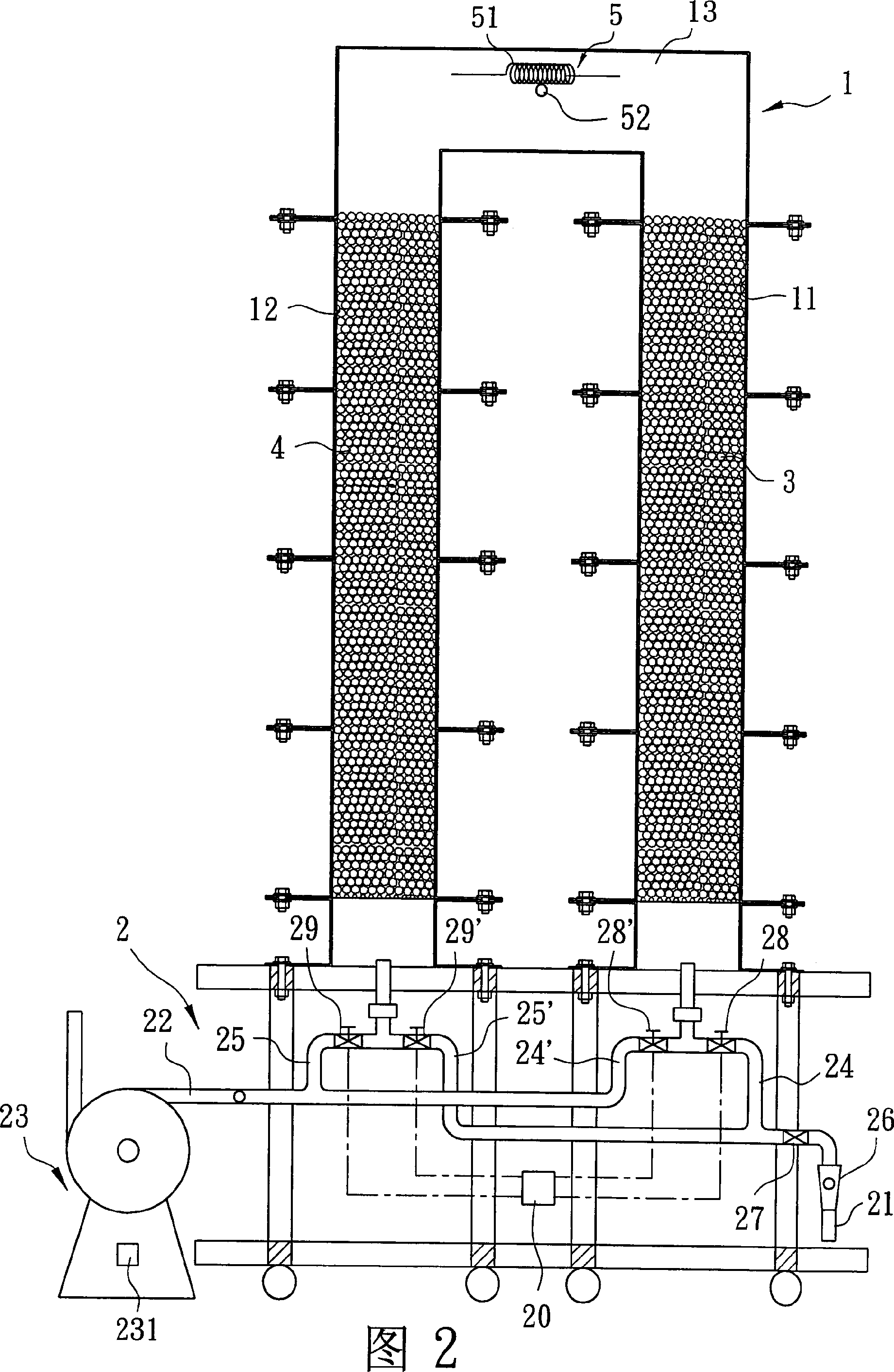

[0039] As shown in Figure 2, firstly, a heat storage type incinerator is prepared. The regenerative incineration device comprises an incinerator body 1, a gas guiding unit 2 arranged in the bottom of the incinerator body 1, a first heat storage material 3 filled in the incinerator body 1, a filling The second heat storage material 4 in the incinerator body 1 , and a temperature control unit 5 arranged in the incinerator body 1 and distributed between the first and second heat storage materials 3 and 4 .

[0040] The incinerator body 1 has a long cylindrical first heat storage area 11 for filling the first heat storage material 3 , and a long columnar first heat storage area 11 which communicates with the first heat stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com