Calcium nervonate and its preparing method and use

A technology of calcium nervate and nervus acid, applied in the field of chemistry, can solve the problems of poor calcium supplementation, great irritation of gastric mucosa, difficulty in human absorption, etc., and achieve the effect of improving effect, improving brain and promoting intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

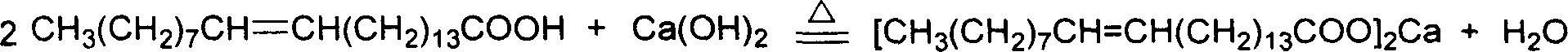

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Add 0.153g (2.73 mmol) calcium oxide (CaO) and 1.5mL distilled water in 50mL round-bottomed flask, make milk of lime under magnetic stirring, slowly add 2.0g (5.46mL mol) of nervonic acid and 20mL of absolute ethanol prepared nervonic acid ethanol solution, and reacted under magnetic stirring for 150min; after hot suction filtration, washed twice with ethanol and water respectively, and dried to obtain a white powdery solid, which was Dry in a constant temperature drying oven at 80°C for 2 to 3 hours to obtain the finished product of calcium neural acid, weighing 1.95g, with a yield of 92.8%. The elemental analysis, infrared spectrum analysis and calcium content determination of the product conform to the theoretical value.

Embodiment 2

[0014] Embodiment 2: Add 3.06g (54.64 mmol) calcium oxide (CaO) and 15mL distilled water in 500mL round bottom flask, make milk of lime under magnetic stirring, slowly add by 20g (54.64 mmol) under 65 ℃ of water bath conditions Nervous acid ethanol solution prepared by nervonic acid and 200mL 95% ethanol, and reacted under magnetic stirring for 180min; after hot suction filtration, washed twice with ethanol and water respectively, and dried to obtain a white powdery solid, at 80°C Dry in a constant temperature drying oven for 2 to 3 hours to obtain the finished product of calcium neural acid, weighing 20.6 g, with a yield of 98.1%. The elemental analysis, infrared spectrum analysis and calcium content determination of the product conform to the theoretical value.

Embodiment 3

[0015] Example 3: Add 1.0g (2.73 mmol) of nervonic acid in a 100mL round bottom flask, add 50mL of ethanol, fully stir to make it dissolve, slowly add 65mL of sodium hydroxide solution with concentration C=0.0426mol / L, until the pH is 7-8, heated in a water bath to 75°C, added 76 mg (1.37 mmol) of calcium oxide under magnetic stirring, and reacted for 150 minutes. During the reaction, a white precipitate was produced, and the reaction system changed from transparent to a white suspension. Suction filtration while it was hot, and obtained The solid was washed twice with ethanol and water respectively, drained and dried in a constant temperature drying oven at 80°C for 2 to 3 hours to obtain the finished product calcium neural acid with a yield of 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com