Nuclear radiation detector and producing technology thereof

A nuclear radiation detector and manufacturing process technology, applied in the field of nuclear radiation detectors, can solve problems such as inability to realize simultaneous measurement, poor long-term stability, poor energy resolution, etc., and achieve excellent electrical characteristics and detection characteristics, and excellent energy resolution The effect of high rate and good position resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

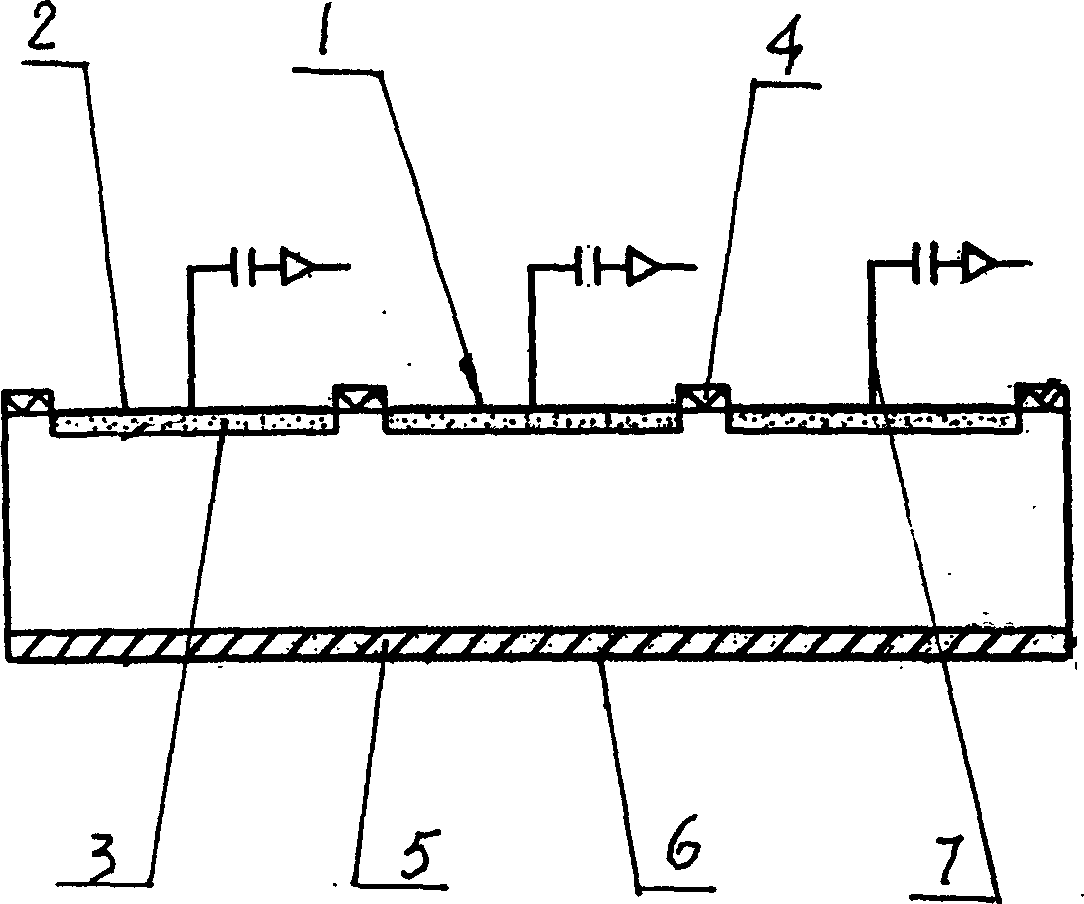

[0032] Example 1: See figure 1 , Nuclear radiation detector, the effective area is 50×20mm 2 Silicon substrate, N type, detection window 1 is composed of 16 parallel detection windows 1, each silicon strip is 3mm wide and 20mm long, with B + The doped area 3 forms a PN junction, on which there is an Al layer 2 and a lead 7; SiO is arranged between the two detection windows 1 2 Insulation partition 4, SiO 2 The width of the partition is 140μm; there is P on the back of the silicon substrate - Doped region 5, forming N + The ohmic contact is covered with an Al layer 6 to form a back electrode. The resistivity of the silicon substrate is 8000-12000Ω·cm, the thickness is 300μm, the crystal orientation is [111], the life of the charged carrier is 1 to 3ms, and there is no dislocation. Lead 7 is connected to the radio frequency cable socket.

Embodiment 2

[0033] Embodiment 2: Manufacturing process of nuclear radiation detector:

[0034] A. Surface oxidation passivation: N-type silicon wafers are used. After cleaning, a 7000 oxide layer is generated at 1030°C. When the surface is oxidized and passivated, the atmosphere of chloride ions is brought in by nitrogen through trichloroethylene liquid. , The flow rate is 0.2 liters / minute, the oxygen flow rate is 6 liters / minute, and the temperature is 950℃~1050℃.

[0035] B. Lithography detector detection window 1.

[0036] C. Ion implantation: implant B on the side of the detector detection window 1 + Ions, the implanted ion concentration is 5×10 13 / cm 2 -1×10 14 / cm 2 .

[0037] D. Remove the SiO on the back of the silicon substrate 2 Layer, inject P - Phosphorus ion concentration is 5×10 15 / cm 2 -1×10 16 / cm 2 . P - Doped region 5 forms N + The thickness of the layer is 1.5 to 2.0 μm.

[0038] E. After ion implantation, annealing to form PN junction and N + For ohmic contact, the annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com