Preparation of ceramic coat die by static self-spreading method for ferrous metal semi-solid processing

A static self-propagating, ferrous metal technology, applied in the field of material processing, can solve the problems of thermal shock, brittleness and tensile strength that have not been fundamentally solved, and achieve the effects of low coating cost, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

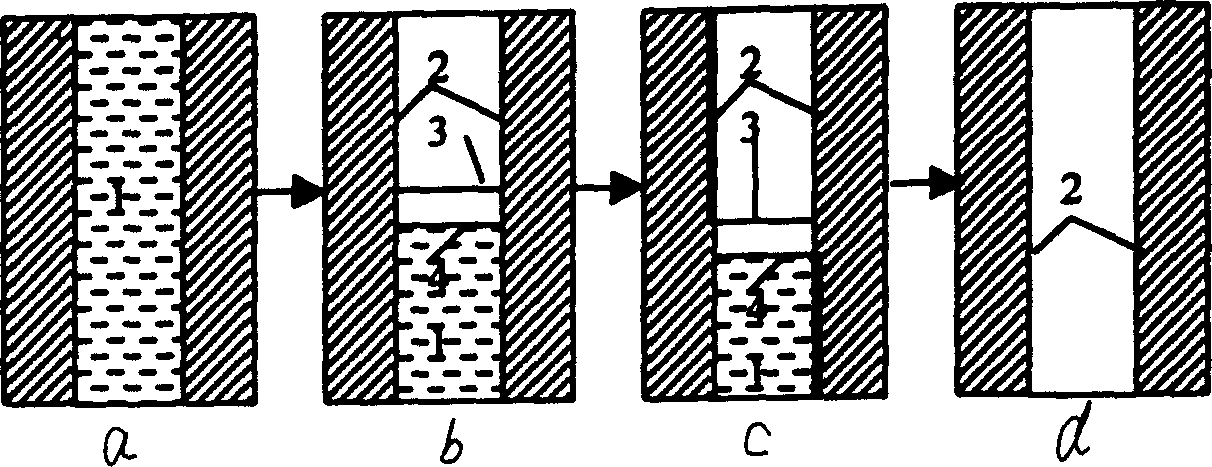

[0023] Mold ceramic coating fusion coating test: the outer diameter, inner diameter, and height of the die are: ¢100, ¢33, and 50mm, respectively. Material is 45 # steel. The inner surface of the die is made of Al by static white spreading method 2 o 3 , the transition layer is Fe-based Al 2 o 3 Gradient Ceramic Coatings for Particle Reinforced Composite Materials. Al powder and Fe 2 o 3 The powder is mixed according to the stoichiometric ratio, the purity of the Al powder is 97%, the particle size is 70 mesh, and the Fe 2 o 3 Powder particle size 200 mesh, industrial pure. Melting process such as figure 2 shown. Among the figure, medicinal powder 1, guide tube 2, die 3, conduit 4, asbestos pad 5 and stopper 6. The inner surface of the die is roughly machined, and the powder is mixed uniformly, according to the filling density of 1.4-1.5 / cm 3 Fill the die. Guide tube up, catheter down. Fix the die, guide pipe and conduit together, and plug the openings of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com