3D networked vacuum-air pressure method for casting friction composite material of ceramics-metals

A three-dimensional network, composite material technology, applied in the field of friction composite material preparation, can solve the problems of poor interface wettability, difficulty in metal penetration, and chemical reaction between ceramics and metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of three-dimensional network SiC ceramics-40Cr steel composite material

[0029] 1. Oxidize the three-dimensional network SiC skeleton at 1300°C for 3 hours under oxidation conditions. The oxidation condition is to feed flowing air or flowing oxygen into the furnace. The purpose of oxidation treatment is to form SiO on the surface of the SiC skeleton. 2 layer to delay the corrosion of the SiC skeleton by molten steel.

[0030] 2. Configure BN acetone paint with a mass ratio of BN and acetone of 1:2, and coat a layer of BN acetone paint in the metal mold. The purpose of coating the mold surface is to prevent the liquid metal from reacting with the metal mold.

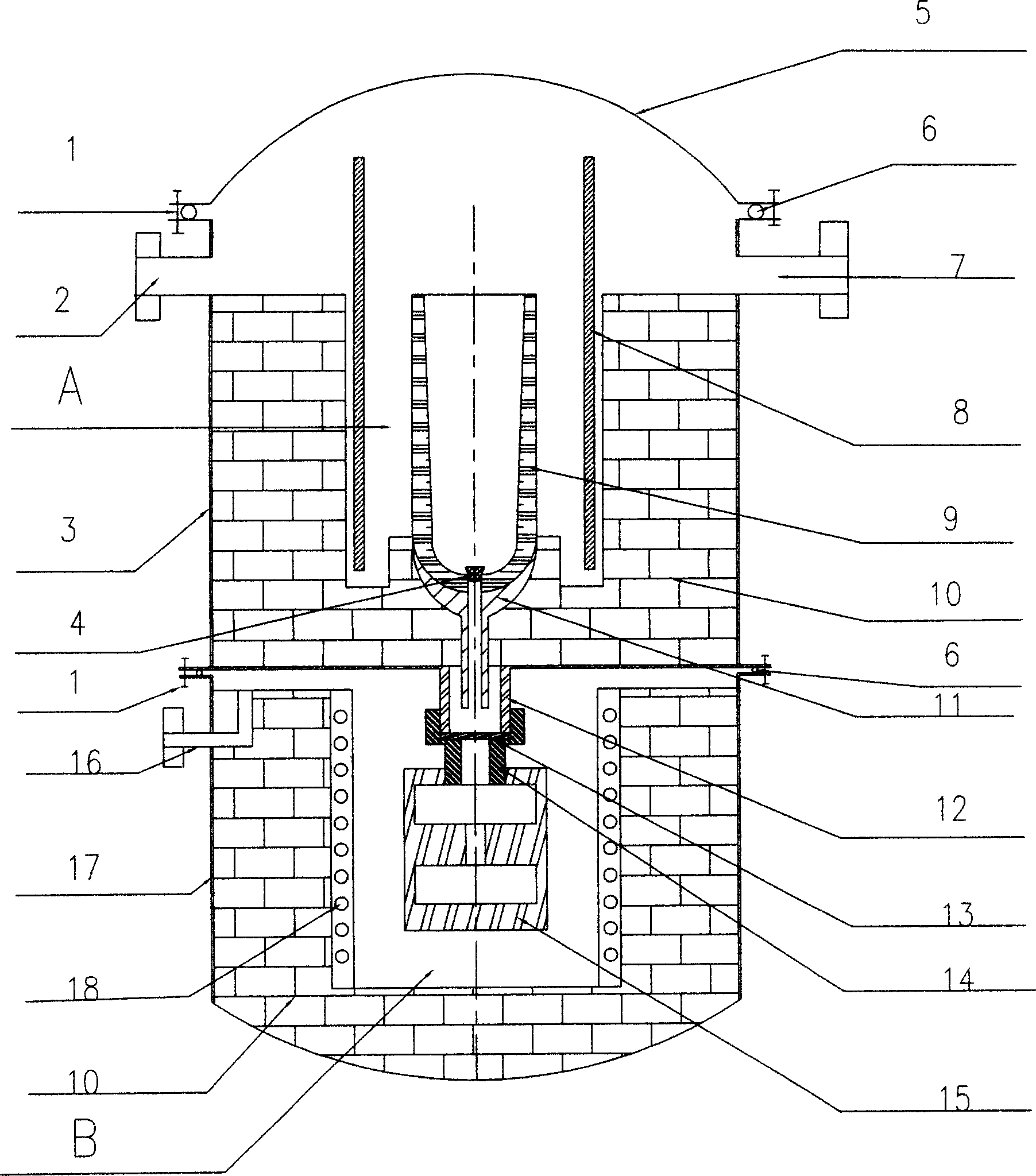

[0031] 3. Put the surface-treated three-dimensional network ceramic skeleton into the metal mold, then put steel (40Cr) into the crucible on the upper layer of the vacuum-air pressure casting furnace, and put the metal mold with the three-dimensional network ceramic skeleton on the lower laye...

Embodiment 2 3

[0032] Embodiment 2 Preparation of three-dimensional network SiC ceramics-copper alloy (663) composite material

[0033] 1. Oxidize the three-dimensional network SiC skeleton at 1300°C for 3 hours under oxidation conditions. The oxidation condition is to feed flowing air or flowing oxygen into the furnace. The purpose of oxidation treatment is to form SiO on the surface of the SiC skeleton. 2 layer to delay the corrosion of the SiC skeleton by the copper alloy melt.

[0034] 2. Configure BN acetone paint as 1:2 by BN and acetone mass ratio, coat one deck of BN acetone paint in the metal mold, and the purpose of coating the mold surface is in order to prevent the reaction of liquid copper alloy and metal mould.

[0035] 3. Put the surface-treated three-dimensional network ceramic skeleton into the metal mold, then put the copper alloy (663) into the crucible on the upper layer of the vacuum-air pressure casting furnace, and put the metal mold with the three-dimensional network ...

Embodiment 3 3

[0036] Embodiment 3 Preparation of three-dimensional network SiC ceramics-titanium alloy (TC4) composite material

[0037] 1. First, modify the three-dimensional network SiC ceramics with inorganic substances: ① Weigh 200 mesh industrial alumina and silica according to the mass percentage of alumina and silica at 60:40, and use a ball mill to grind the mixed powder of alumina and silica to The particle size is 10 μm, alumina balls are used as grinding balls in the ball milling process, the mass ratio of material and balls is 1:2, the ball milling medium is water, and the mass ratio of material and water is 1:1.5, and the total amount of materials Amount of 0.2% tetramethylammonium hydroxide aqueous solution (concentration is 20%) is used as dispersant, adds 4% polyvinyl alcohol aqueous solution (concentration is 10%) of material total amount as suspending agent, adds the phosphoric acid of material total amount 3% Aluminum dihydrogen is used as a binder, and the slurry is pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com