Composite processing technology of fine injection type hole

A compound machining and jetting technology, which is applied in the field of compound machining technology of fine jetting holes, can solve the problems of poor shape accuracy and surface roughness, difficulty in precise control of dimensional accuracy, and difficulty in ensuring machining accuracy, and achieves less deformation and wear. , good consistency, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

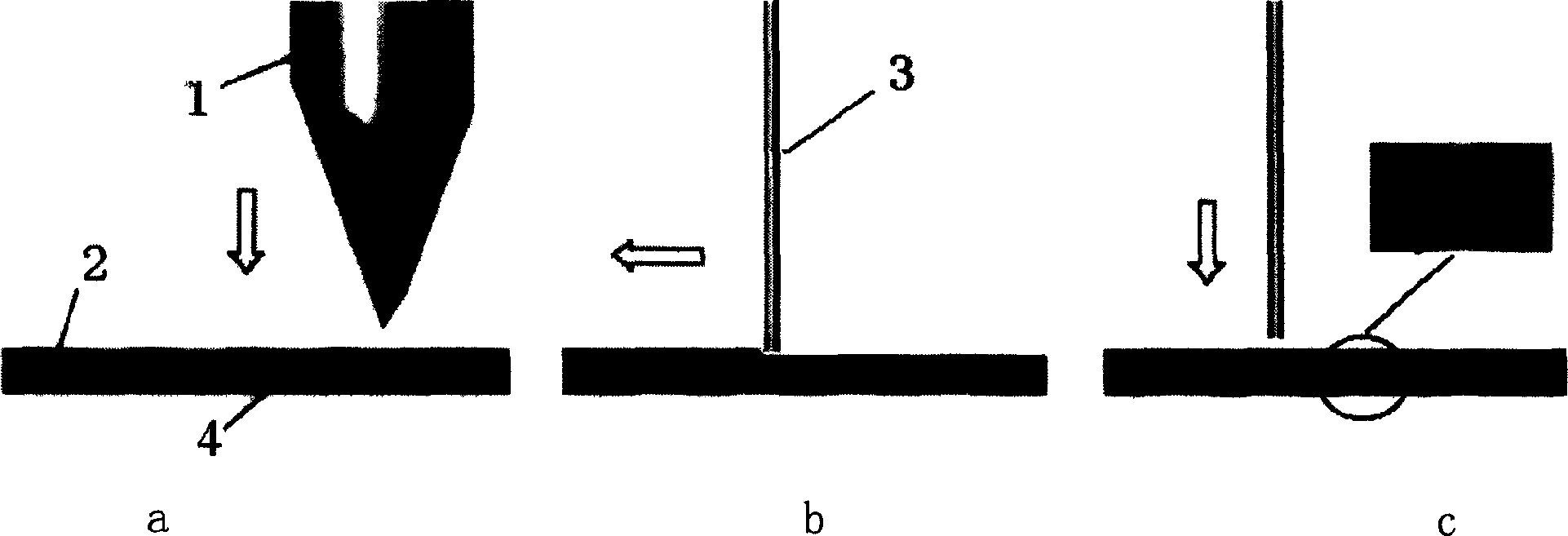

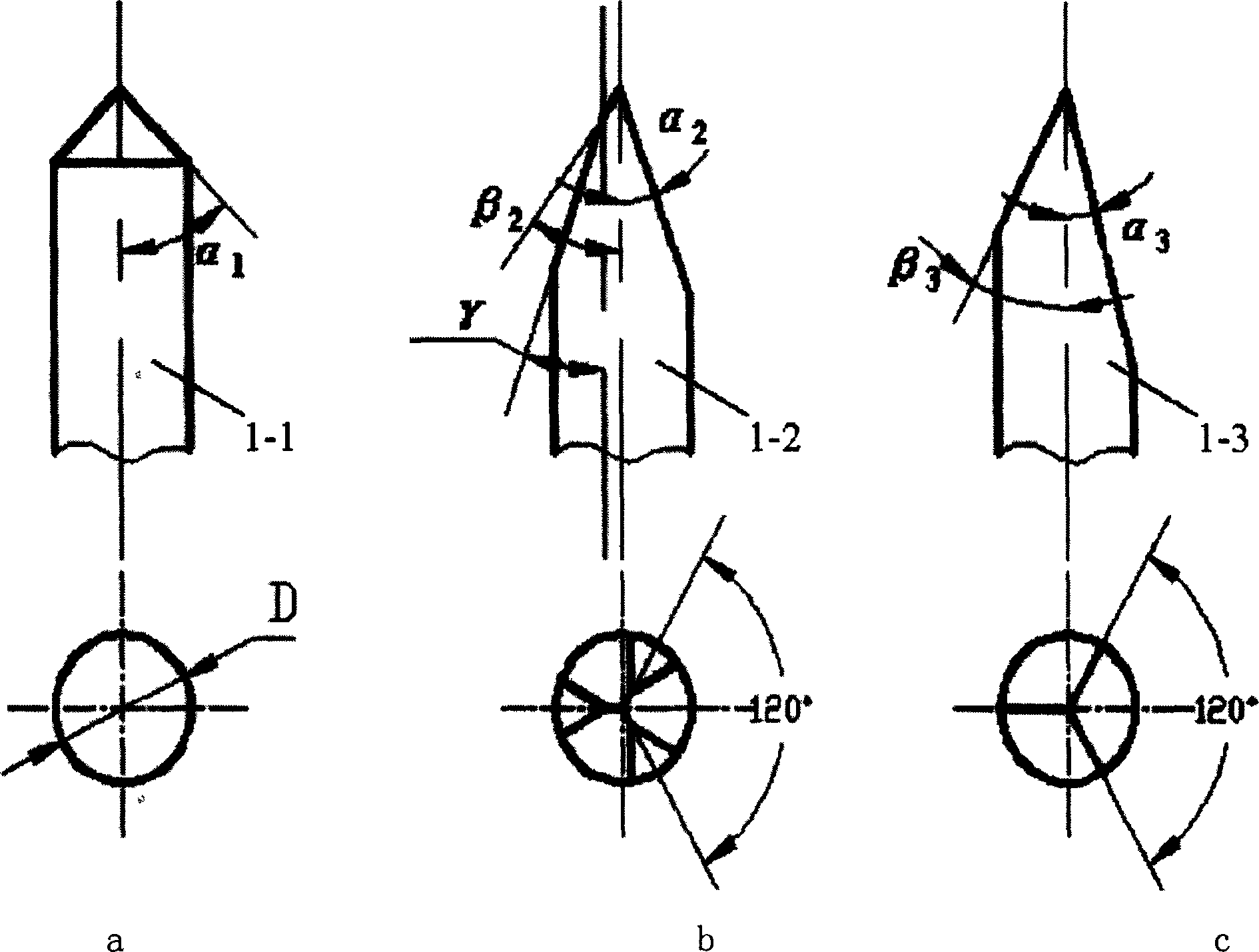

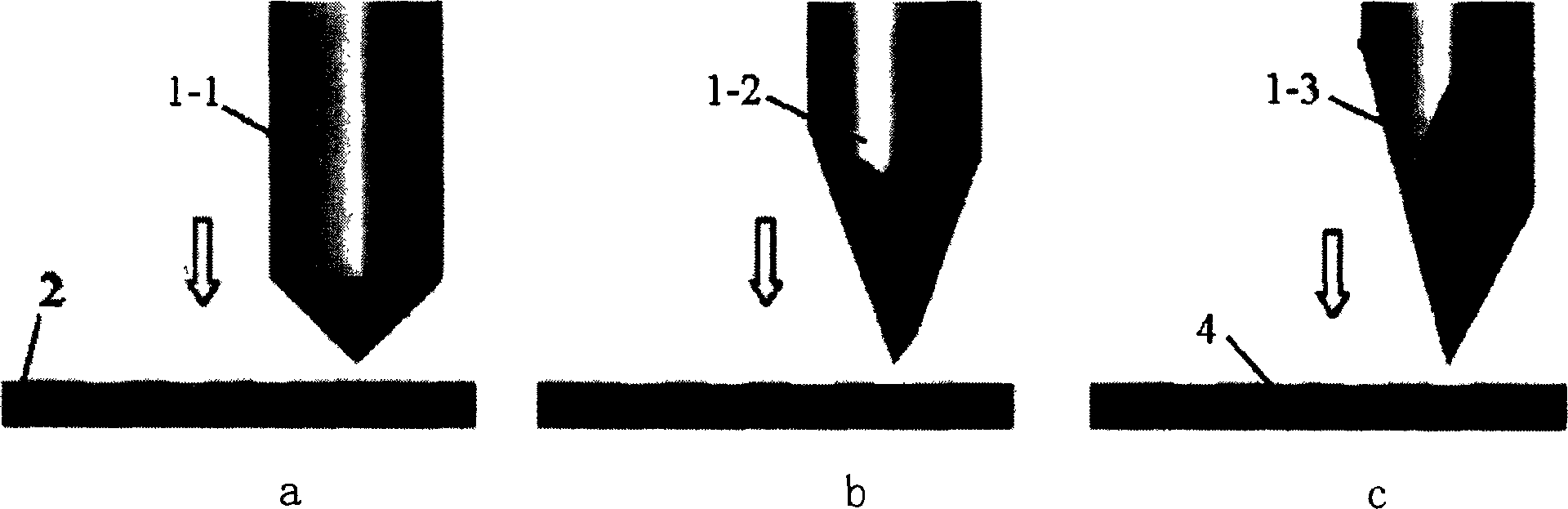

[0027] The invention provides a compound processing technology for micro-spray holes, which is composed of micro-plastic deformation stamping processing and micro-electric discharge machining. Its combined processing process is as follows: (1) A series of punches 1 with different tip shapes and sizes are used. Firstly, according to the principle of rough machining first and then fine machining, multiple micro-stamping processes are performed to process strips on one side of the workpiece 2. There is a thin layer of metal with a thickness of less than 0.1mm left at the bottom of the bottom cavity with a fine inverted cone 4 (such as figure 1 (a) shown); (2) then turn over the workpiece 2, on its back side with the position of the inverted cone of the bottom die cavity 4 with the micro electric discharge machining electrode 3 (as figure 1 (b), figure 1 As shown in (c), the workpiece 2 is thinned by the micro electric discharge process, and the bottom cavity 4 is exposed at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com