Joint tool for supersonic wave joint

A bonding tool, ultrasonic technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as insufficient hardness, damage to tool surface shape accuracy, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

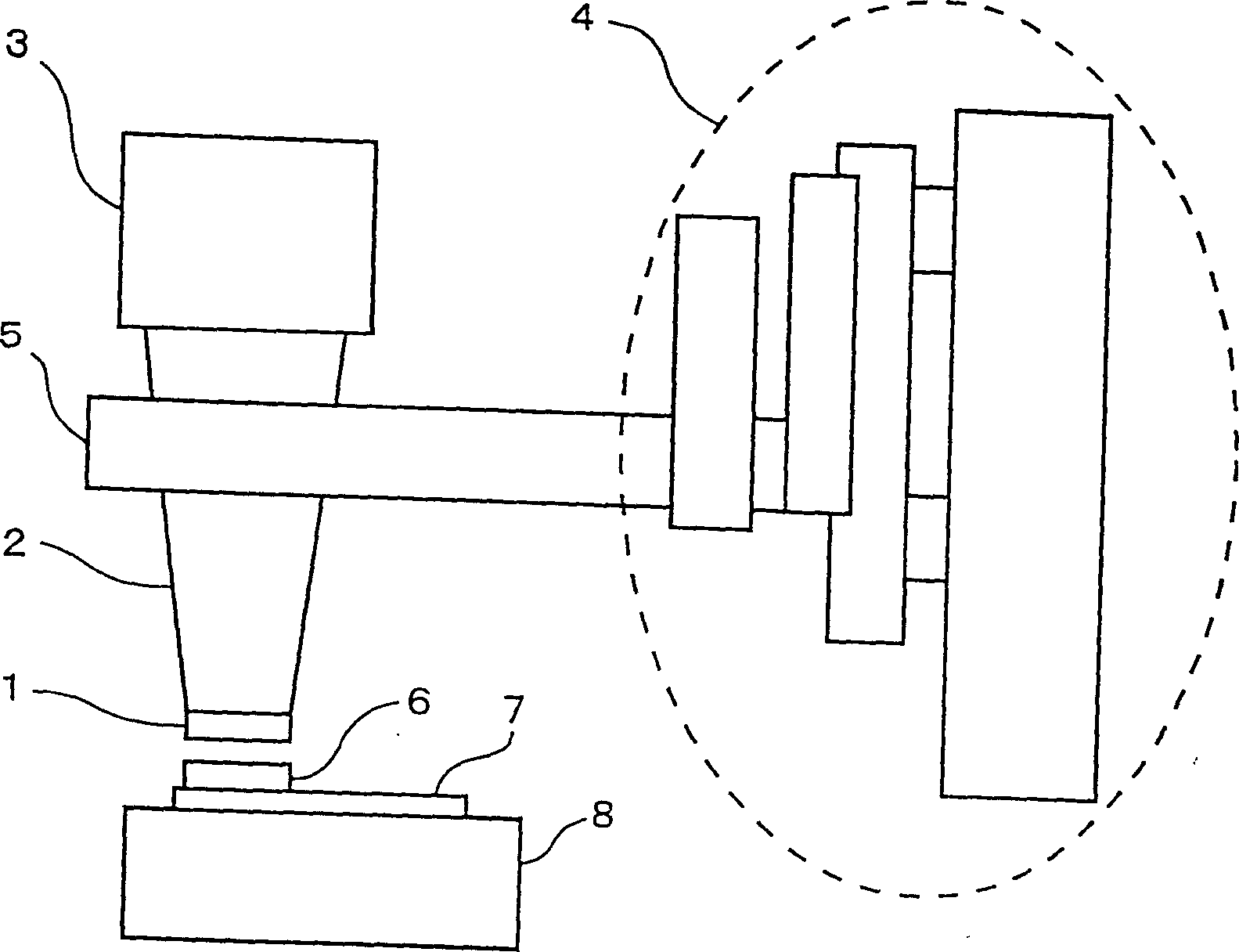

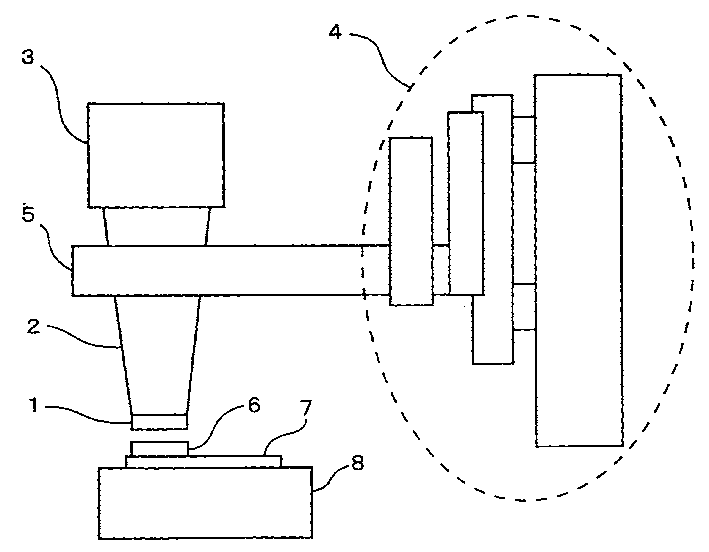

[0024]Sintered diamond, ceramic formed body coated with vapor phase synthetic diamond and cubic boron nitride sintered body are used as the material of the tool tip to make a bonding tool with ultrasonic waves. After the tool tip is formed into a necessary shape, the surface roughness of the tool surface is adjusted. If the surface roughness Rt of the tool face is less than 0.2 μm, the surface of the tool face should be ground, and if the Rt is greater than 0.2 μm but less than 5 μm, the surface of the tool face should be finished by surface grinding. If the Rt is more than 5 μm, after surface grinding of the surface of the tool face, laser processing is used to roughen the surface. As the horn part, FeNiCo alloy, nickel-iron-molybdenum permeable alloy, superhard alloy, stainless steel and cermet can be processed into the shape of ultrasonic horn respectively.

[0025] In a vacuum furnace, the front end of the tool and the horn are metal-bonded with an active brazing filler m...

Embodiment 2

[0031] FeNiCo alloys, nickel-iron-molybdenum permeable alloys, superhard alloys and cermets are used to make the horns of ultrasonic bonding tools, and the front faces of these horns are coated with diamond films by vapor phase synthesis. As the vapor phase synthesis method, a hot-filament CVD (chemical vapor deposition) method is used.

[0032] The synthesis condition of the hot wire CVD (chemical vapor deposition) method is to make the flow rate H of the gas raw material 2 10-100 sccm, CH 4 1-5 sccm, the filament temperature is 1500-2200°C, the substrate temperature is 500-900°C, the pressure is 10-500 Torr, and the synthesis time is changed according to the necessary film thickness. After the diamond film is coated, the diamond film is thick, and the flatness and surface roughness of the diamond surface cannot meet the required precision. Therefore, it is necessary to grind and grind it into the necessary shape with a diamond grindstone. In addition, for comparison, a hor...

Embodiment 3

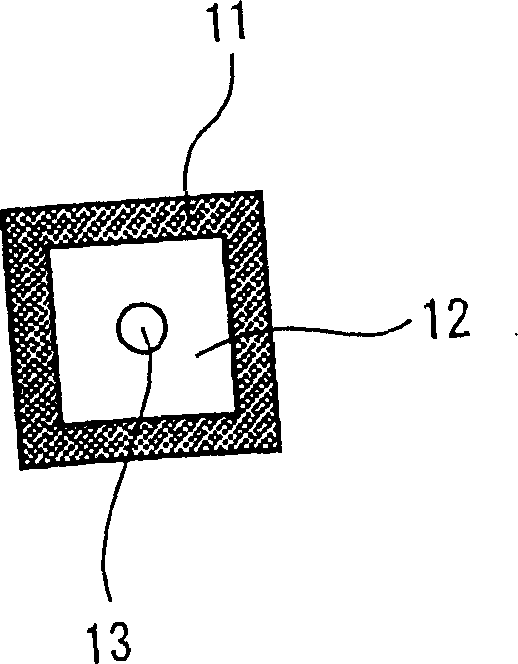

[0037] Five types of tools were manufactured by laser processing by partially changing the roughness of the front end surface of the bonding tool produced in the same manner as in Example 1 1-1, and bonding of 5000 semiconductor elements was carried out in the same manner as in Example 1. The bonding tool was produced so that the surface roughness of the outer peripheral portion of the tool tip surface was greater than that of the central portion, and the ratio of the overall area of the tool tip surface to the portion with a large surface roughness was varied. A tool not provided with a rough surface was also produced as a comparative example, and the same mounting evaluation was performed. figure 2 It is a plan view schematically showing the tool front end surface of the produced bonding tool. The results of bonding are shown in Table 3.

[0038] Ratio of Roughness

detailed status

3-1

10%

Displacement of substrate electrodes and elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com