Monofilament yarn and process for producing same

A manufacturing method and monofilament technology, which is applied in the direction of single-component polyester rayon, thin material handling, transportation and packaging, etc., can solve the problems of low elastic recovery rate, poor bristle erection, low degree of polymerization, etc. Achieve the effect of good shape stability, high napping and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

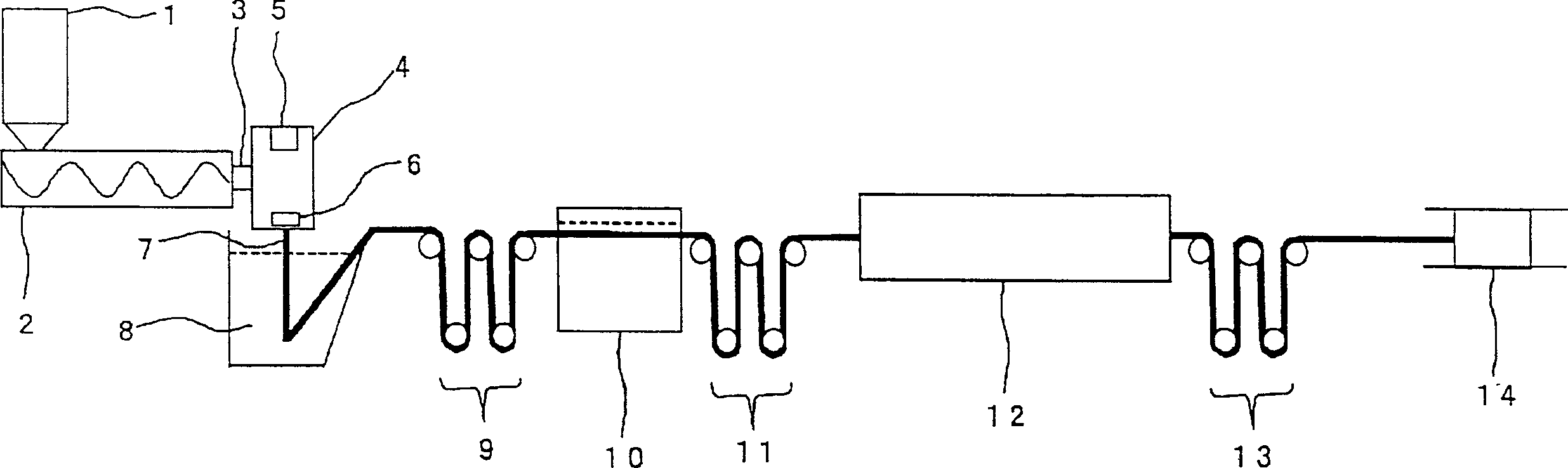

Method used

Image

Examples

Embodiment 1

[0102] Using a PTT polymer having an intrinsic viscosity [η] of 0.92 dl / g and a titanium oxide content of 0.1% by weight, a PTT monofilament was produced under the following production conditions.

[0103] Polymer output: 2.52g / min

[0104] Spinning temperature: 260°C

[0105] Cooling bath water temperature: 40°C

[0106] Peripheral speed of traction roller (1st roller): 15.8m / min

[0107] Stretching bath water temperature: 55°C

[0108] Peripheral speed of stretching roller (2nd roller): 79.2m / min

[0109] Heat treatment bath steam temperature: 120°C

[0110] Peripheral speed of the third roller: 72m / min

[0111] Winding speed: 72m / min

[0112] The physical properties of the PTT monofilament produced under the above-mentioned production conditions are as follows.

[0113] Intrinsic viscosity: 0.90dl / g

[0114] Diameter: 0.18mm

[0115] Denier: 355dtex

[0116] Breaking strength: 3.0cN / dtex

[0117] Elongation at break: 48.1%

[0118] Boiling water shrinkage: 6.4% ...

Embodiment 2~6

[0126] A PTT monofilament and a toothbrush were produced in the same manner as in Example 1 except that heat treatment was performed under the heat treatment conditions shown in Table 1. Table 1 shows the physical properties and bending recovery properties of the obtained PTT monofilament and the evaluation results of the toothbrush.

Embodiment 7

[0128] Using a PTT polymer with an intrinsic viscosity [η] of 1.13dl / g and a titanium oxide content of 0.1% by weight, a PTT monofilament was produced under the same manufacturing conditions as in Example 1, and heat treated under the same heat treatment conditions as in Example 3, A PTT monofilament is produced. A toothbrush was produced in the same manner as in Example 1 using the obtained monofilament.

[0129] Table 1 shows the physical properties and bending recovery properties of the obtained PTT monofilament and the evaluation results of the toothbrush.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com