Method of producing metal ferrules and device therefor

A manufacturing method and a manufacturing device technology, which are applied in the field of the manufacture of metal ferrules and the manufacturing device thereof, can solve the problems such as the lack of uniform dimensional accuracy ferrules, the lack of uniformity of the electroforming body, the difference in the outer diameter of the electroforming body, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

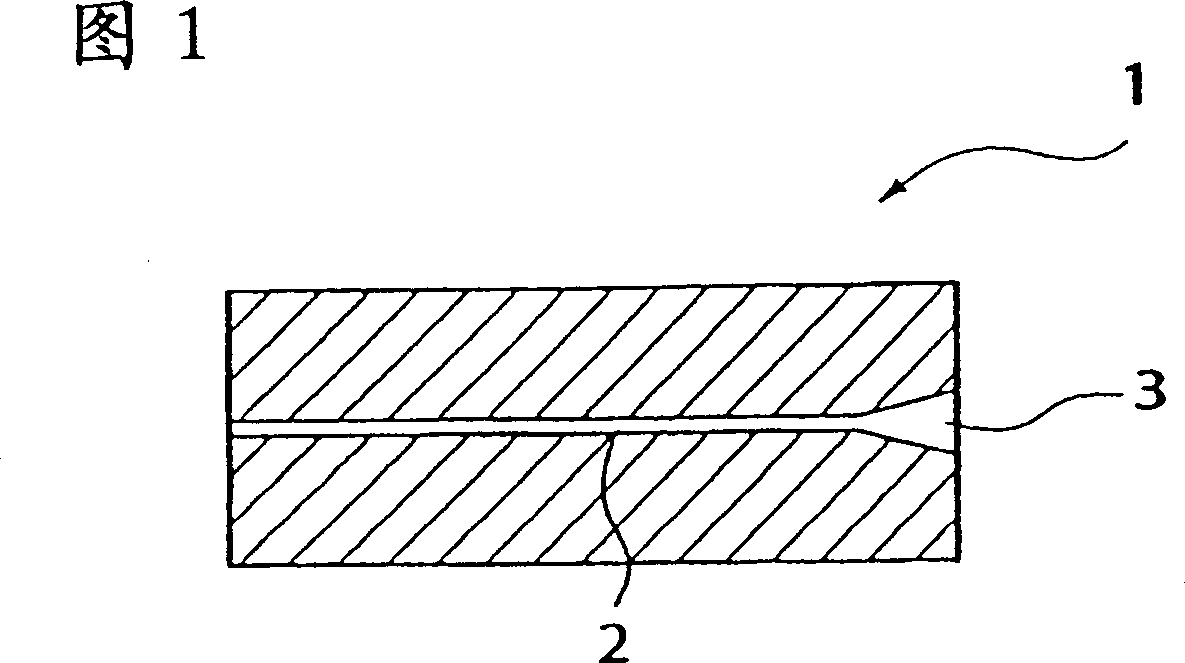

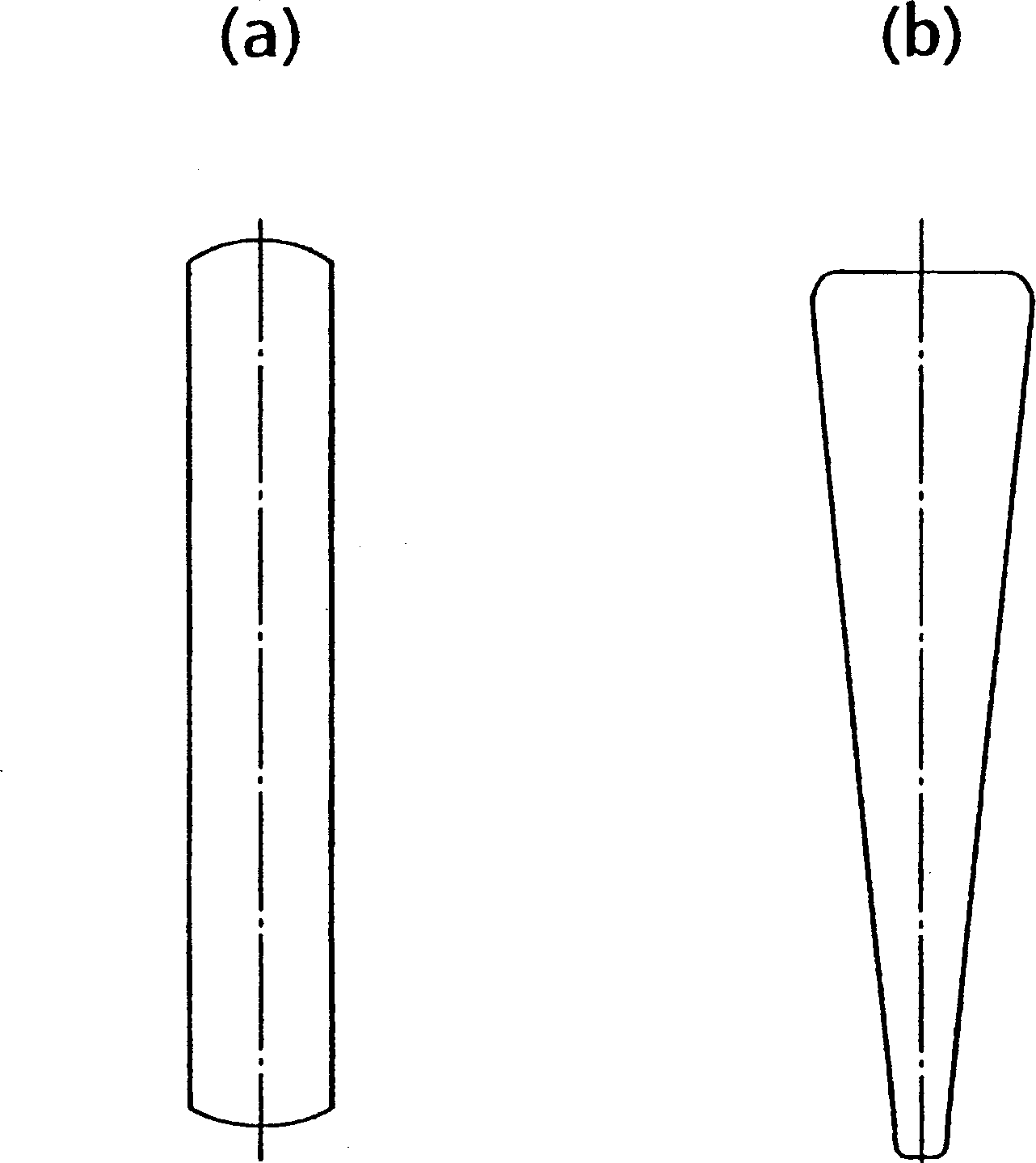

[0086] The present invention will be described below based on examples. A phosphor bronze wire with a circular cross section, a diameter of 0.126 mm and a length of 35 cm is installed on the core wire frame 21. 100 core wire frames were placed on the holder 28 and immersed in the electroforming solution 18 . The core frame is made to rotate at a speed of 60 revolutions per minute, and the holder is made to rotate at a speed of 30 revolutions per minute. The electroforming solution is a liquid whose main component is nickel sulfamate. Fifty anodes were placed around the holder. The anodes were formed by placing a titanium mesh in a polyester bag and placing nickel balls in the mesh. In this state, use 9A / dm 2 The cathodic current density was implemented for 10 hr electroforming. By electroforming, a nickel electroformed product with an average diameter of 2 mm was obtained. This electroformed body was cut to a length of 12 mm with an NC automatic processing machine, and on...

Embodiment 2

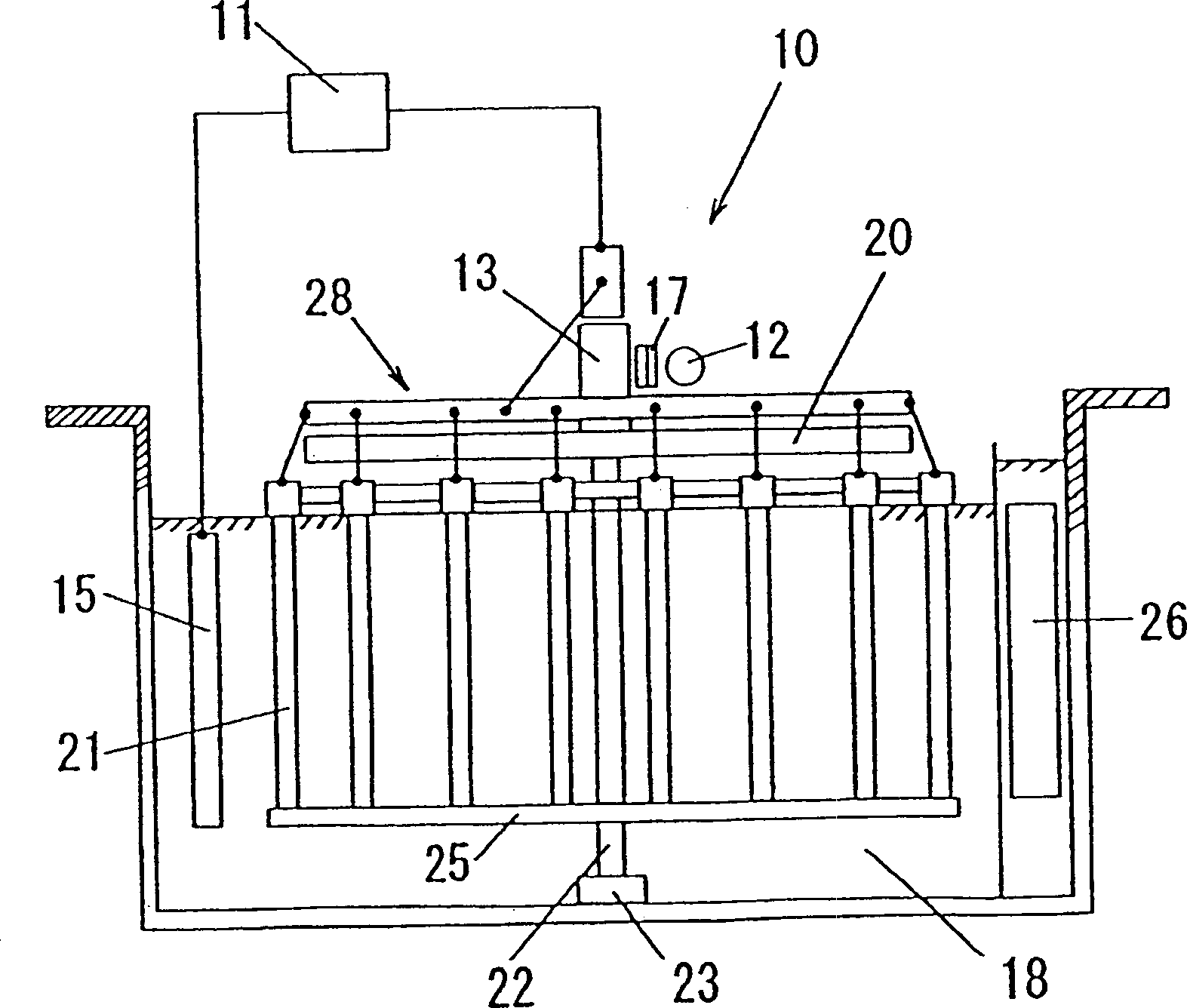

[0088] Take a stainless steel core wire with a circular cross section, a diameter of 0.126mm, and a length of 355mm, such as figure 2 Place on the electroforming tool as shown. Such as Figure 6 As shown, in the lower part of the core wire, the connection surface area is 0.2cm 2 The copper ball, as the discharge body. The nickel metal plate is placed in an electroforming solution mainly composed of nickel sulfamate. Dip the core wire in the electroforming solution. Use the stainless steel core wire as the cathode, and the nickel plate as the anode, use 10A / dm 2 The current density, electroforming for 18 hours. Electroforms with an average diameter of approximately 2.5 mm were obtained. The outer diameter of the electroformed body is within the range of 2.5±0.05mm along the length direction. The ferrule obtained from the electroforming body has good uniformity, high roundness and coaxiality.

Embodiment 3

[0090] On a stainless steel wire with a circular cross-section, a diameter of 0.126mm, and a length of 355mm, electroplate 10μm thick gold (resistivity 2.05×10 -6 Ωcm), to obtain a core wire with a diameter of 0.136mm. Such as figure 2 As shown, put the core wire on the jig for electroforming. The nickel metal plate is placed in the electroforming solution mainly composed of nickel sulfamate, and immersed in the electroforming solution. Use the core wire as the cathode and the nickel plate as the anode, use 10A / dm 2 The current density, electroforming for 18 hours. Through electroforming, a nickel electroformed product with an average diameter of about 2.5 mm is obtained. The outer diameter of the electroformed body is within the range of 2.5±0.05mm along the length direction. The resulting homogeneous electroformed product. Ferrules obtained from this electroformed product also have high roundness and concentricity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com