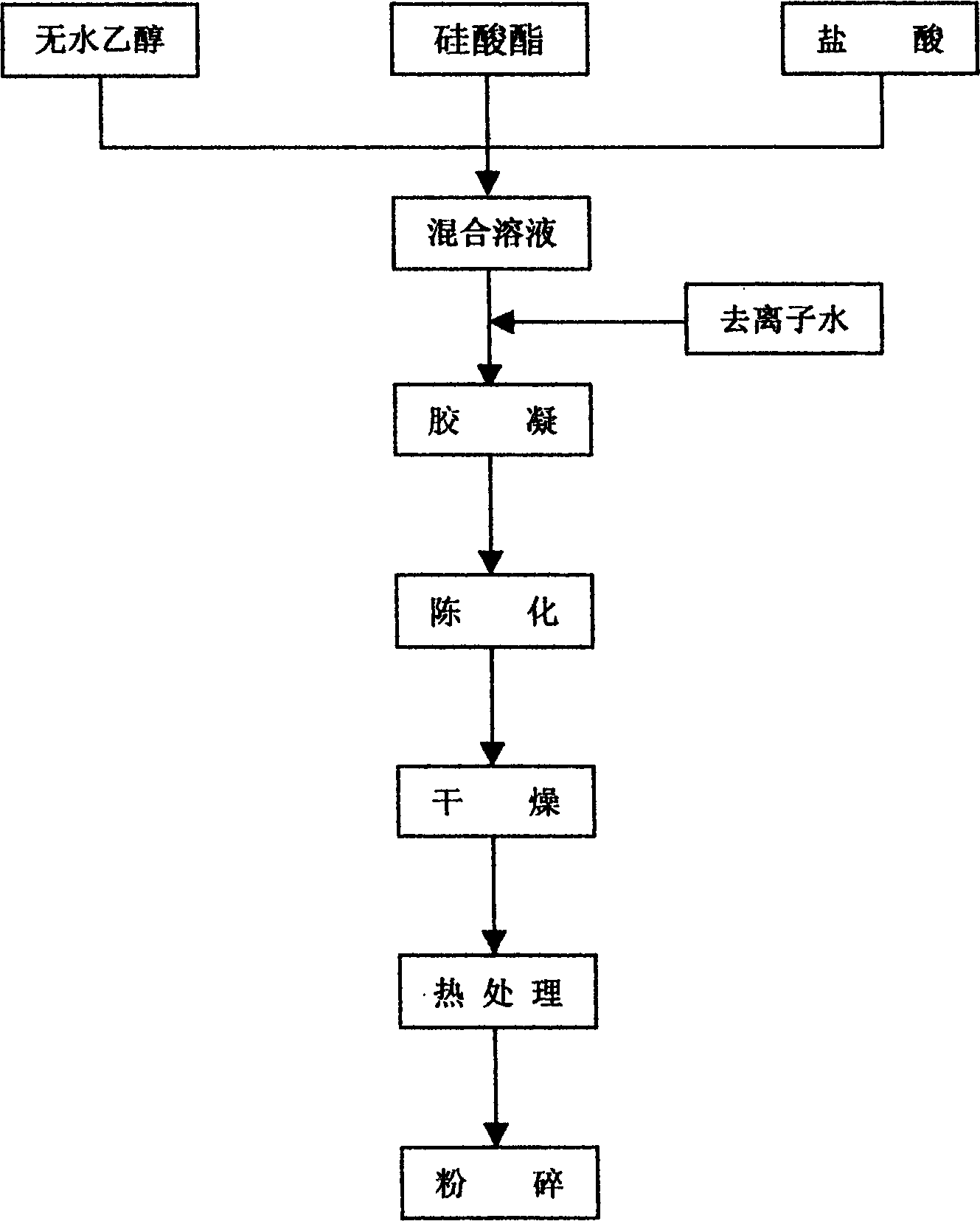

Process for preparing medium porous nano silicon dioxide powder with high activity

A nano-silica, high-activity technology, applied in silica, silica, chemical instruments and methods, etc., can solve the problems of easy agglomeration and growth of original particles, high heat treatment temperature, large particle size, etc., and achieve reflection. The effect of strong UV ability, low heat treatment temperature and high interface ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare tetraethyl orthosilicate, absolute ethanol, hydrochloric acid, and distilled water at a volume ratio of 16:20:2:21. Preparation of SiO by hydrolysis-polycondensation reaction of silicates 2 Gel, after aging the wet gel at room temperature for 1 to 7 days, dry it in a vacuum oven at 50°C for 12 hours, then put the gel in a furnace preheated to 200°C for heat treatment , for 8 hours, after the furnace cools down naturally to obtain pure white, amorphous SiO with a particle size of 100-120nm 2 Secondary particle powder.

Embodiment 2

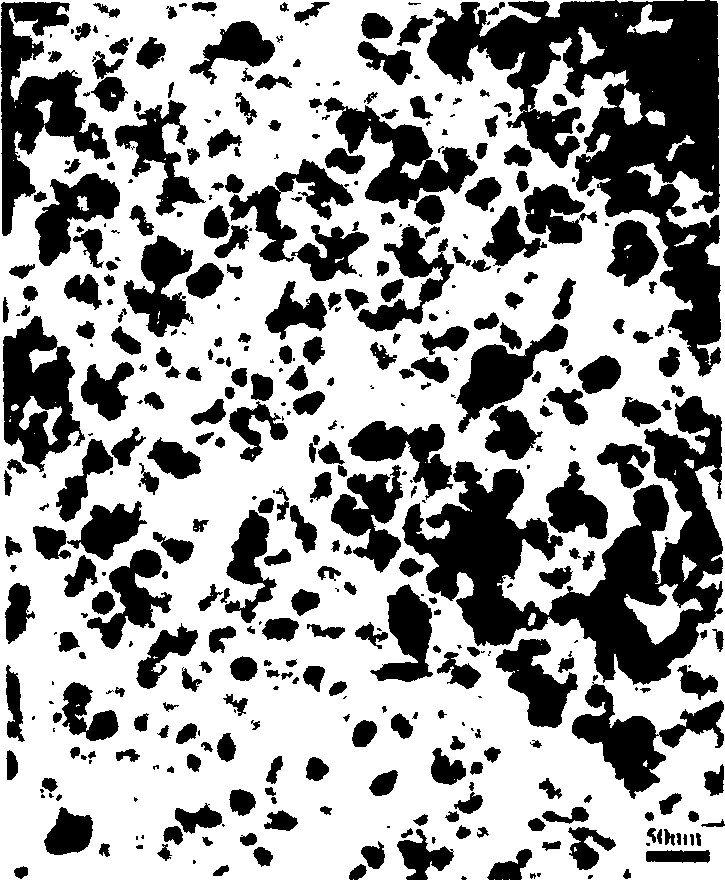

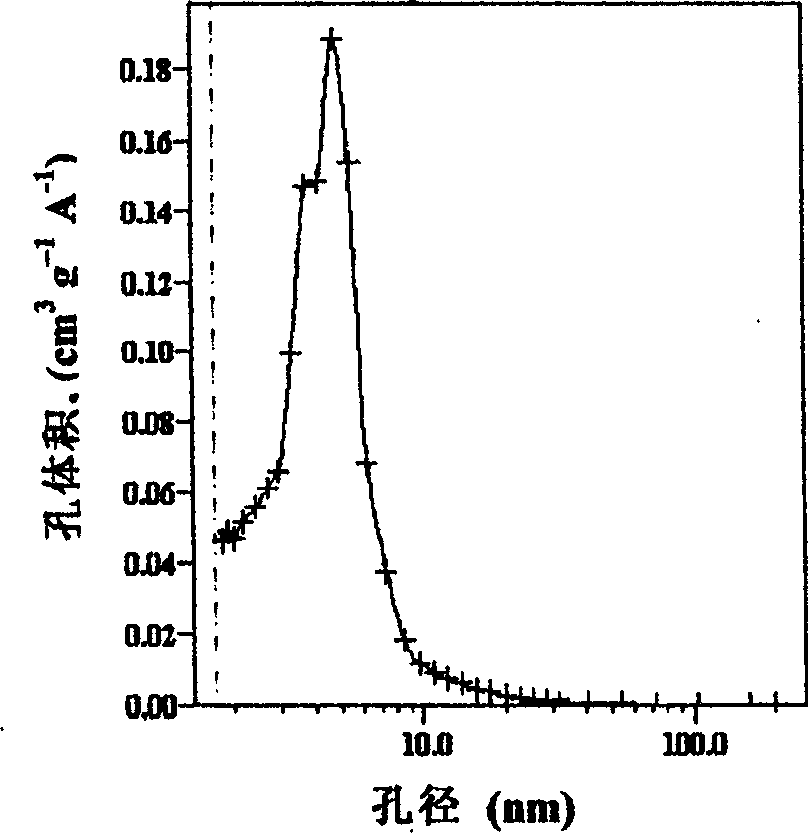

[0031] Prepare tetraethyl orthosilicate, absolute ethanol, hydrochloric acid, and distilled water at a volume ratio of 16:20:2:21. Preparation of SiO by hydrolysis-polycondensation reaction of silicates 2 Gel, after aging the wet gel at room temperature for 1-7 days, dry it in a vacuum oven at 50°C for 12 hours, then put the gel in a furnace preheated to 200°C for heat treatment , for 8 hours, after the furnace cools down naturally, pure white, amorphous SiO 2 Powder. The powder obtained above was ball milled for 48 hours to obtain a highly active powder with a particle size distribution of 5-30nm, an average pore size of 5.1-5.9nm, a porosity of 92%, a purity of 99.9%, and a surface hydroxyl content of 52%. Mesoporous nano-SiO 2 powder.

Embodiment 3

[0033] Prepare tetraethyl orthosilicate, absolute ethanol, hydrochloric acid, and distilled water at a volume ratio of 16:20:2:15. Preparation of SiO by hydrolysis-polycondensation reaction of silicates 2 Gel, after aging the wet gel at room temperature for 1-7 days, dry it in a vacuum oven at 40°C for 12 hours, then put the gel in a furnace preheated to 160°C for heat treatment , for 8 hours, after the furnace cools down naturally, pure white, amorphous SiO 2 Powder. The powder obtained above was ball milled for 20 hours to obtain a highly active powder with a particle size distribution of 20-50 nm, an average pore size of 5.1-5.9 nm, a porosity of 88%, a purity of 99.9%, and a surface hydroxyl content of 55%. Mesoporous nano-SiO 2 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com