Groove silicon carbide MOSFET integrated with high-speed fly-wheel diode and preparation method

A freewheeling diode, silicon carbide technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high conduction voltage drop of SiC body diode, high density of JFET area, and increased dynamic loss of devices, etc. Achieve the effect of improving long-term reliability, reducing on-voltage and reducing Miller capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] like figure 1 As shown, this embodiment provides a trench silicon carbide MOSFET with integrated high-speed freewheeling diode, including a backside ohmic contact alloy 1, an N-type doped silicon carbide substrate 2, an N-type doped silicon carbide epitaxial layer 3, a first P-type doped buried layer 41, second P-type doped buried layer 42, third P-type doped buried layer 43, first gate oxide layer 51, second gate oxide layer 52, first polysilicon 61, Two polysilicon 62, a first P-type doped well region 71, a second P-type doped well region 72, a third P-type doped well region 73, a first N-type doped source region 81, a second N-type doped well region 81 Doping source region 82, P-type doping source region 9, interlayer dielectric 10, front ohmic contact alloy 11;

[0043] On the plane formed by the x-axis and the y-axis, the N-type doped silicon carbide substrate 2 is located above the backside ohmic contact alloy 1; the N-type doped silicon carbide epitaxial layer 3...

Embodiment 2

[0050] like Figure 2 to Figure 9 As shown, this embodiment provides a method for fabricating a trench silicon carbide MOSFET integrated with a high-speed freewheeling diode, including the following steps:

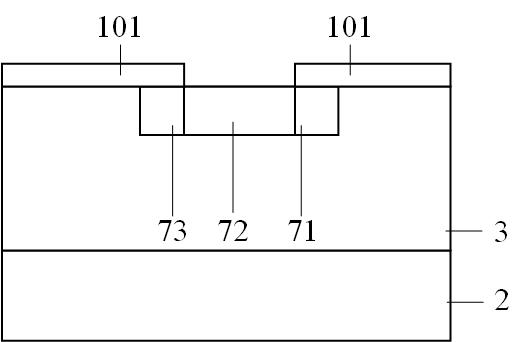

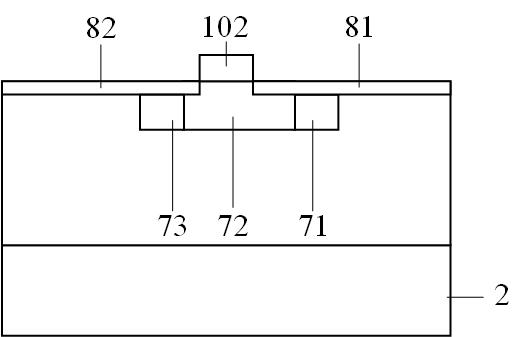

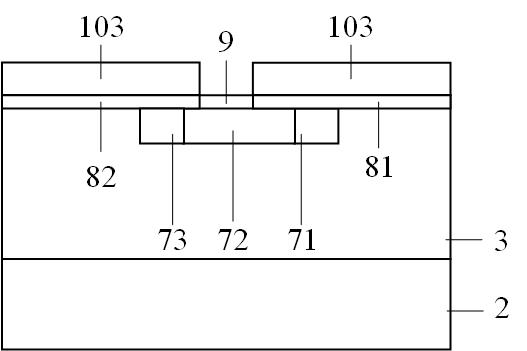

[0051] Step 1: An oxide layer is deposited on the N-type silicon carbide epitaxial wafer. After photolithography, an ion-implanted P-well ion-implantation mask layer 101 is formed, and then Al ion implantation is performed at a temperature of 300K~1000K to form a second P-type dopant. In the miscellaneous well region 72, at the same time, since the Al ion implantation in silicon carbide will cause lateral scattering, P-type doping scattering regions with laterally graded concentration will be simultaneously formed on the left and right sides of the second P-type doping well region 72, respectively. For the first P-type doped well region 71 and the third P-type doped well region 73, the following figure 2 structure. After the injection is completed, the mask layer is rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com