Polyethylene color master batch suitable for irradiation crosslinking process and preparation method thereof

A polyethylene and color masterbatch technology, applied in the direction of organic chemistry, etc., can solve the problems of poor effect, poor flame retardant performance of color masterbatch, low degree of cross-linking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

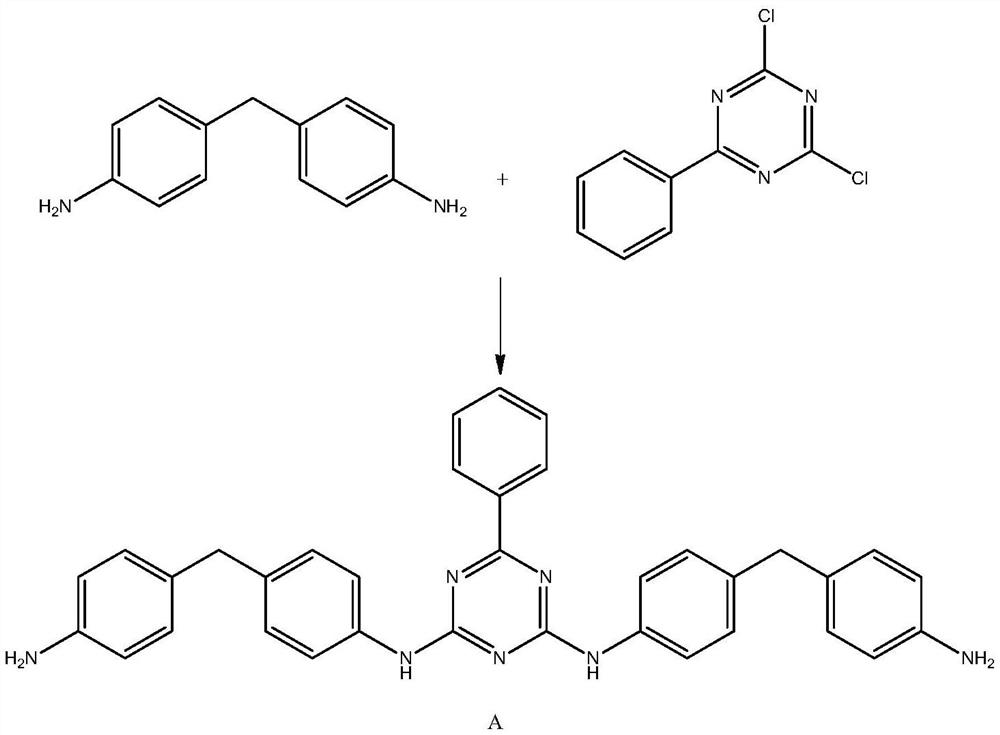

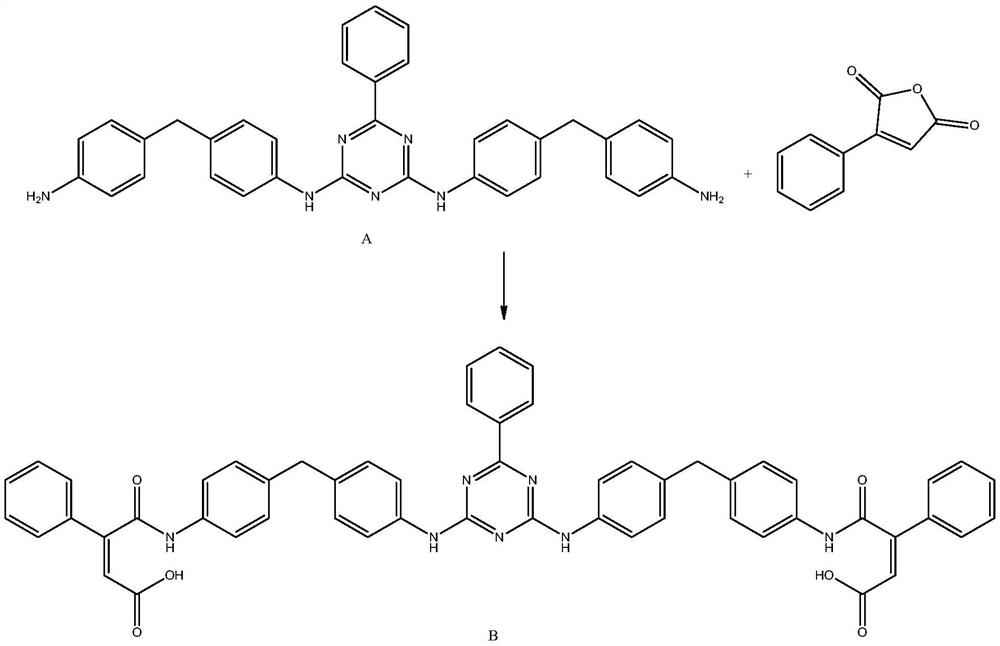

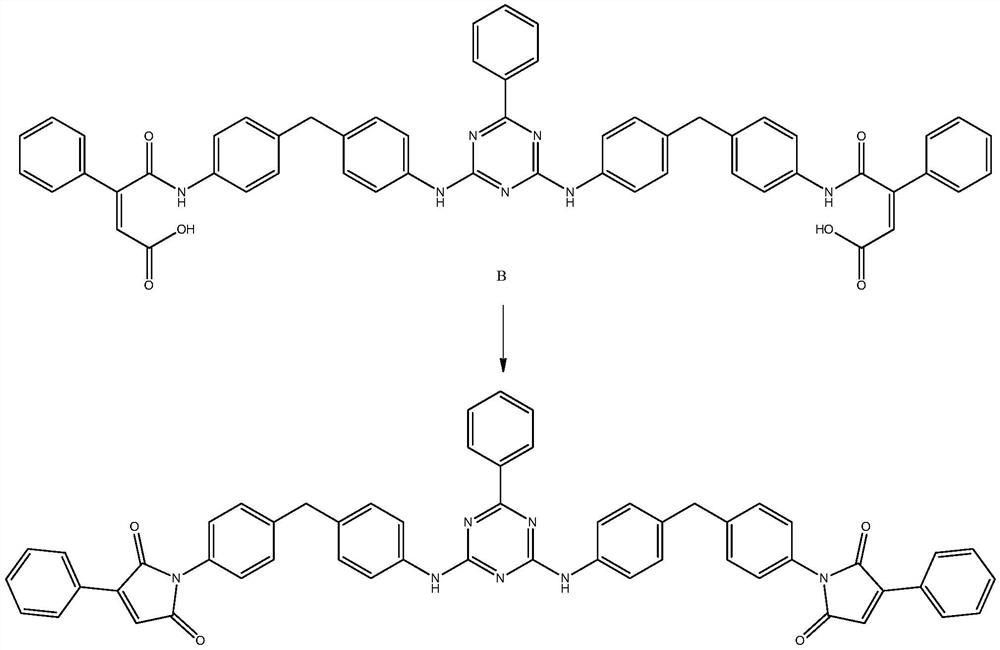

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is a polyethylene masterbatch suitable for irradiation cross-linking process, including the following components in parts by weight:

[0052] 30 parts of linear low density polyethylene, 40 parts of high density polyethylene, 25 parts of maleic anhydride grafted polyethylene, 15 parts of magnesium hydroxide, 15 parts of heavy calcium, 6 parts of titanium dioxide, 1 part of antioxidant, butyl titanate 3 parts, 0.5 parts of chlorinated paraffin, 5 parts of cross-linking assistant, 3 parts of flame retardant, 15 parts of pigment;

[0053] The polyethylene masterbatch suitable for irradiation cross-linking process is prepared by the following steps:

[0054] S1: linear low density polyethylene, high density polyethylene, maleic anhydride grafted polyethylene, magnesium hydroxide, heavy calcium, titanium dioxide, antioxidant, butyl titanate, chlorinated paraffin, cross-linking aid by weight Agent, pigment and flame retardant are evenly mixed to obtain a blen...

Embodiment 2

[0066] This embodiment is a polyethylene masterbatch suitable for irradiation cross-linking process, including the following components in parts by weight:

[0067] 30 parts of linear low density polyethylene, 35 parts of high density polyethylene, 30 parts of maleic anhydride grafted polyethylene, 25 parts of magnesium hydroxide, 15 parts of heavy calcium, 6 parts of titanium dioxide, 1 part of antioxidant, butyl titanate 3 parts, 0.5 parts of chlorinated paraffin, 5 parts of cross-linking auxiliary, 5 parts of flame retardant, 15 parts of pigment;

[0068] The polyethylene masterbatch suitable for irradiation cross-linking process is prepared by the following steps:

[0069] S1: linear low density polyethylene, high density polyethylene, maleic anhydride grafted polyethylene, magnesium hydroxide, heavy calcium, titanium dioxide, antioxidant, butyl titanate, chlorinated paraffin, cross-linking aid by weight Agent, pigment and flame retardant are evenly mixed to obtain a blen...

Embodiment 3

[0081] This embodiment is a polyethylene masterbatch suitable for irradiation cross-linking process, including the following components in parts by weight:

[0082] 40 parts of linear low density polyethylene, 40 parts of high density polyethylene, 30 parts of maleic anhydride grafted polyethylene, 25 parts of magnesium hydroxide, 15 parts of heavy calcium, 8 parts of titanium dioxide, 3 parts of antioxidant, butyl titanate 5 parts, 1 part of chlorinated paraffin, 8 parts of cross-linking assistant, 5 parts of flame retardant, 30 parts of pigment;

[0083] The polyethylene masterbatch suitable for irradiation cross-linking process is prepared by the following steps:

[0084] S1: linear low density polyethylene, high density polyethylene, maleic anhydride grafted polyethylene, magnesium hydroxide, heavy calcium, titanium dioxide, antioxidant, butyl titanate, chlorinated paraffin, cross-linking aid by weight Agent, pigment and flame retardant are evenly mixed to obtain a blend;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com