Bismaleimide resin hollow polymer microsphere, preparation method thereof and method for modifying cyanate ester resin

A technology of maleimide resin and bismaleimide, which is used in the field of high-performance substrates and base materials for radar shields, can solve the problem that CE resin dielectric constant and dielectric loss cannot be effectively reduced, laboratory environment High requirements, complex process flow, etc., to achieve the effect of reducing density and dielectric constant, high reactivity, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

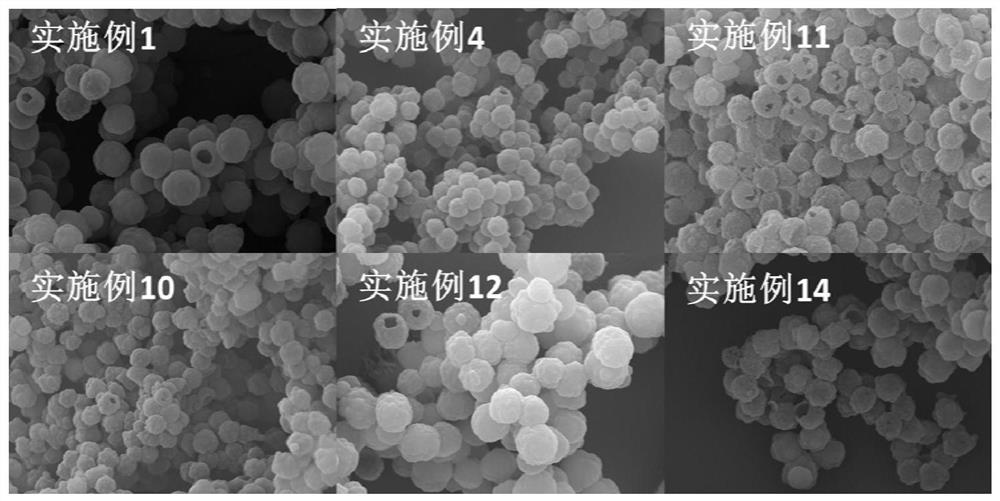

Embodiment 1

[0044] First, select 30 mL of isoamyl acetate and 10 mL of n-heptane as a mixed solvent and add it to the flask, add 0.596 g of styrene-maleic anhydride polymer microspheres (with a particle size of 600 nm) as a template under stirring conditions, and stir the solution to The polymer microspheres are uniformly dispersed; then add shell monomer 2,2'-bis-4-[(4-maleimidophenoxy)phenyl]propane 0.342g and DVB-55 0.254g and initiator Azobisisobutyronitrile 0.018g, stir until the monomer and the initiator are completely dissolved, and the core-shell mass ratio is 1:1; relative to the total mass of the reaction system, the total monomer mass percentage concentration in the reaction system is 1.5% by mass , the dosage of the initiator is 3% by mass of the total mass of the shell monomers. Secondly, after the reaction system was deoxygenated by nitrogen for 10 minutes, it was placed in an oil bath at 75° C. to react for 6 hours. After the reaction, a solid-liquid dispersion system of bi...

Embodiment 2

[0046] First, select 30 mL of ethyl acetate and 10 mL of n-hexane as a mixed solvent to add to the flask, add 0.596 g of styrene-itaconic anhydride polymer microspheres (with a particle size of 600 nm) as a template under stirring conditions, and stir the solution until the polymer The microspheres are uniformly dispersed; then add shell monomer 2,2'-bis-4-[(4-maleimidophenoxy)phenyl]propane 0.342g and DVB-55 0.254g and azodiiso Nitrile initiator 0.018g, stir until the monomer and the initiator are completely dissolved, and the core-shell mass ratio is 1:1; relative to the total mass of the reaction system, the total monomer mass percentage concentration in the reaction system is 1.5% by mass. The dosage of the agent is 3% by mass of the total mass of the shell monomers. Secondly, after the reaction system was deoxygenated by nitrogen for 10 minutes, it was placed in an oil bath at 75° C. to react for 6 hours. After the reaction, a solid-liquid dispersion system of bismaleimid...

Embodiment 3

[0048] First, select 30mL of ethyl benzoate and 10mL of n-heptane as a mixed solvent to add to the flask, add 0.596g of styrene-maleimide polymer microspheres (particle size is 600nm) under stirring conditions as a template, stir Solution to polymer microspheres uniformly dispersed; then add shell monomer 2,2'-bis-4-[(4-maleimidophenoxy)phenyl]propane 0.342g and DVB-55 0.254g and The initiator azobisisobutyronitrile 0.018g, stir until the monomer and the initiator are completely dissolved, and the core-shell mass ratio is 1:1; relative to the total mass of the reaction system, the total monomer mass percentage concentration in the reaction system is 1.5 mass %, and the amount of initiator used is 3 mass % of the total mass of shell monomers. Secondly, after the reaction system was deoxygenated by nitrogen for 10 minutes, it was placed in an oil bath at 75° C. to react for 6 hours. After the reaction, a solid-liquid dispersion system of bismaleimide resin core-shell polymer mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com