Ionic gel based on multiple physical crosslinking effects, preparation method and strain sensor

A technology of ion gel and physical cross-linking, which is applied in the fields of electric/magnetic solid deformation measurement, bulk chemical production, electromagnetic measurement devices, etc., can solve the problems of increasing preparation difficulty, affecting conductivity, reducing sensitivity, etc., and achieves good reliability Reproducible, well-touched, technically complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

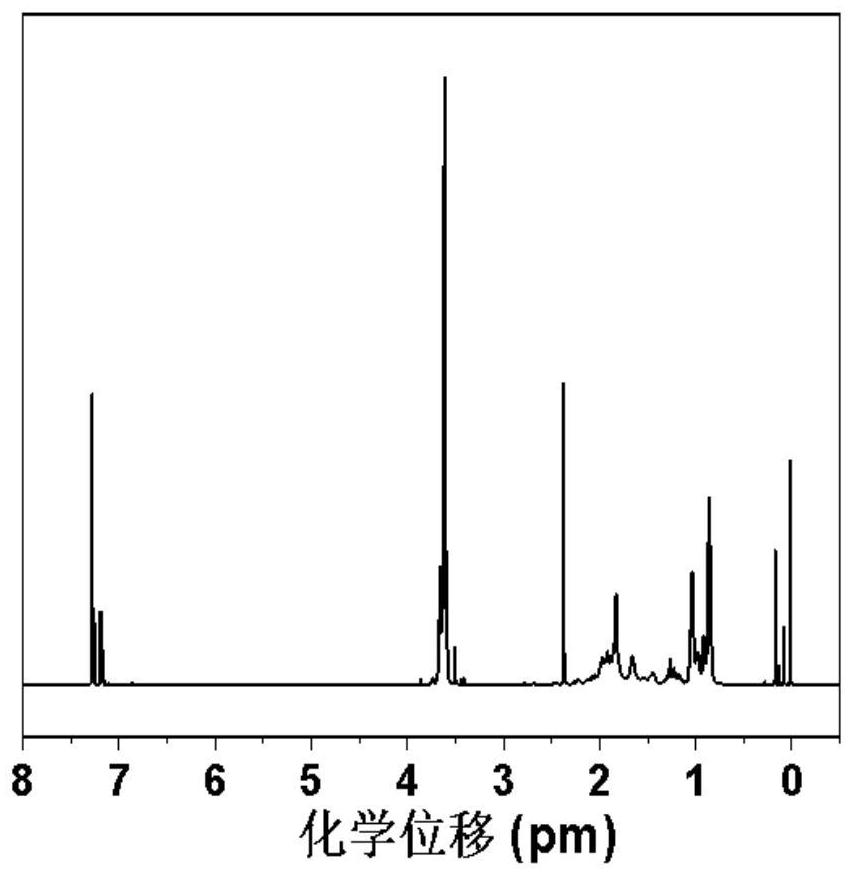

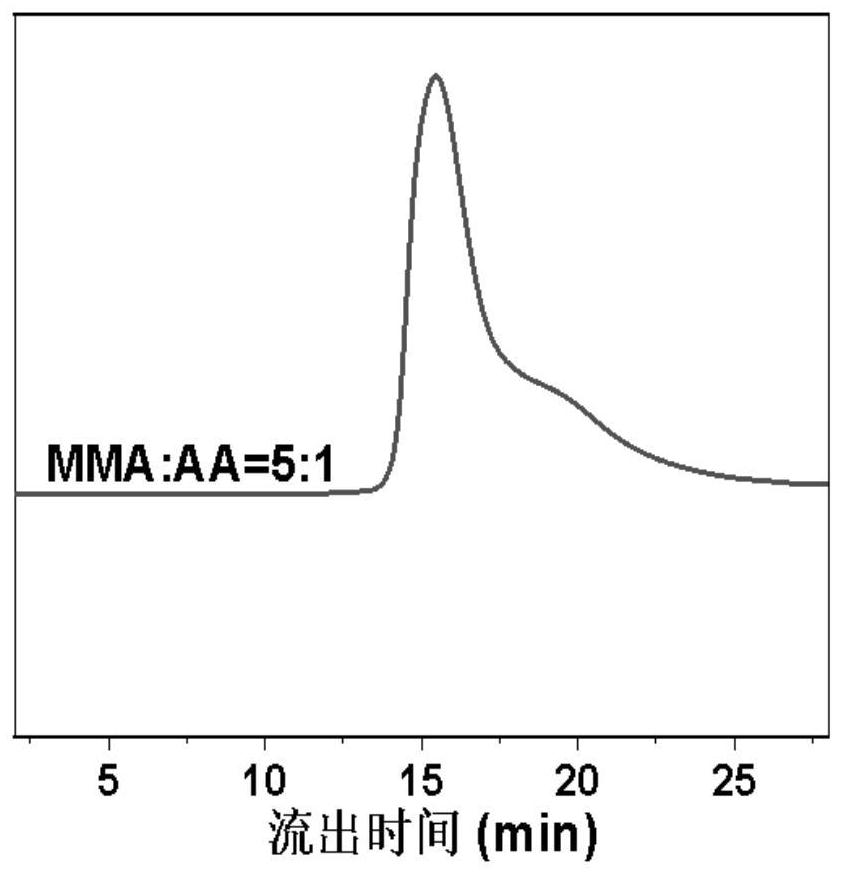

[0068] Embodiment 1, the synthesis of the poly(methyl methacrylate-acrylic acid) of formula III, the steps are as follows:

[0069]

[0070] Take the case where the molar ratio of the monomer A and the monomer B is 5 as an example.

[0071] (1) Weigh 5.60 g (0.56 mmol) of monomer A methyl methacrylate (MMA), 0.80 g (0.112 mmol) of monomer B acrylic acid (AA), and 8.0 mg of initiator azobisisobutyronitrile (AIBN) , 12ml of dioxane were added into the polymerization tube and stirred evenly.

[0072] (2) In the state of high-purity argon, put the solution in the polymerization tube in (1) into liquid nitrogen, after the freezing is complete, the ventilation port of the double-row tube is switched to the air-pumping state, and the interior of the polymerization tube is evacuated , followed by three cycles of ventilation and pumping again, and then thawed at room temperature under ventilation.

[0073] (3) Repeat the step in (2) at least three times to ensure that there is no ...

Embodiment 2

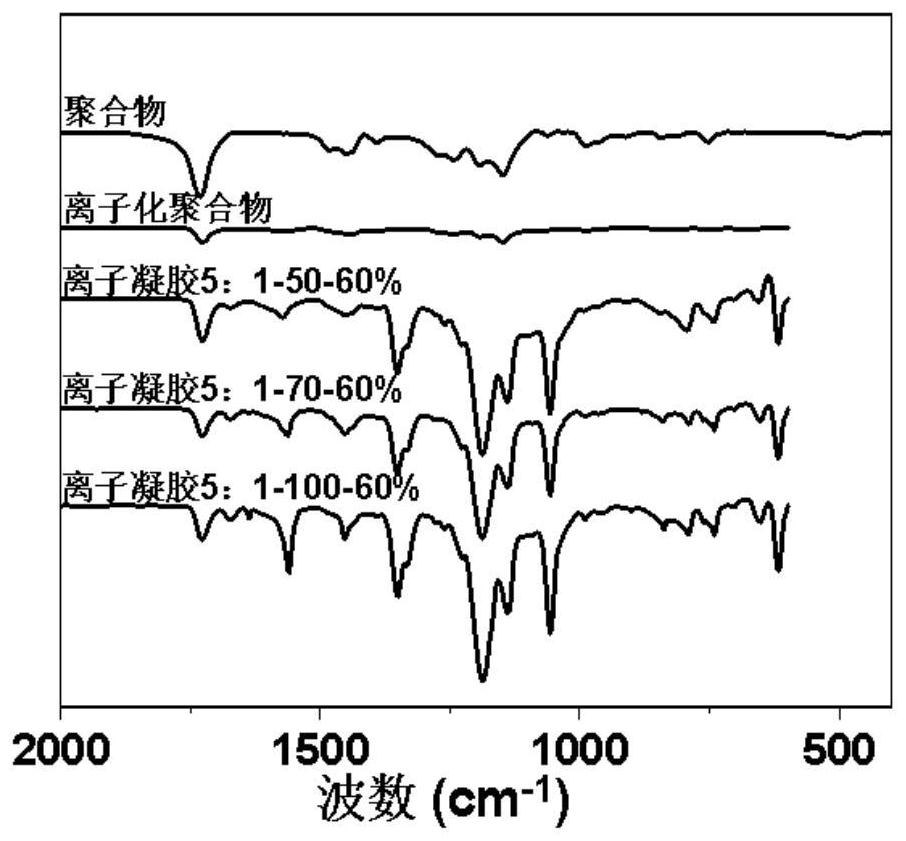

[0076] Embodiment 2, the preparation of described ion gel, concrete steps are as follows:

[0077](1) Take 600 mg of the copolymer prepared in Example 1, dissolve it in a mixed solvent of 6 g of methanol and 1.2 g of toluene, and then add 20.7 mg (with a degree of ionization of 50%) and 29.0 mg (with a degree of ionization of 70%) , 41.4 mg (the degree of ionization is 100%) sodium hydroxide, and stirred for about 4 h until the ionization was completed. Its structure is shown in formula III, wherein M=Na.

[0078]

[0079] (2) 900 mg of ionic liquid [EMIM][TFSI] was added to each of the above solutions, stirred for 6 h, and named as 50-60%, 70-60%, and 100-60%, respectively. Further, the solution is poured into the mold. After drying at room temperature for 12 hours, the solvent was removed, and then it was dried in a vacuum oven at 65°C for 24 hours to obtain a conductive ion gel.

Embodiment 3

[0080] Embodiment 3, the preparation and testing method of described ion gel strain sensor, the concrete steps are as follows:

[0081] (1) The gel material of the ion gel strain sensor to be tested prepared in Example 2 is cut into a rectangle with a cutter. Then connect the two copper wires to both ends of the conductive gel fixed at the mechanical motion joint with conductive tape, and then connect to the Keithley 2601B system source meter to assemble the flexible strain sensor.

[0082] (2) Select the measurement R-T mode in the control software system. After the initial resistance is stabilized, the mechanical movement drives the strain change of the conductive gel at the joint movement, resulting in a change in its resistance. Depending on the magnitude of the movement, the resistance changes are also different, so as to achieve the monitoring purpose of the strain sensor that detects the movement.

[0083] Result analysis:

[0084] figure 1 For the ion gel prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com