Conjugated polymer loaded high-concentration monatomic metal site heterogeneous catalyst and preparation method thereof

A technology of conjugated polymers and heterogeneous catalysts, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Construct high-loaded single-atom sites, shape and crystal phase changes, etc., to achieve the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

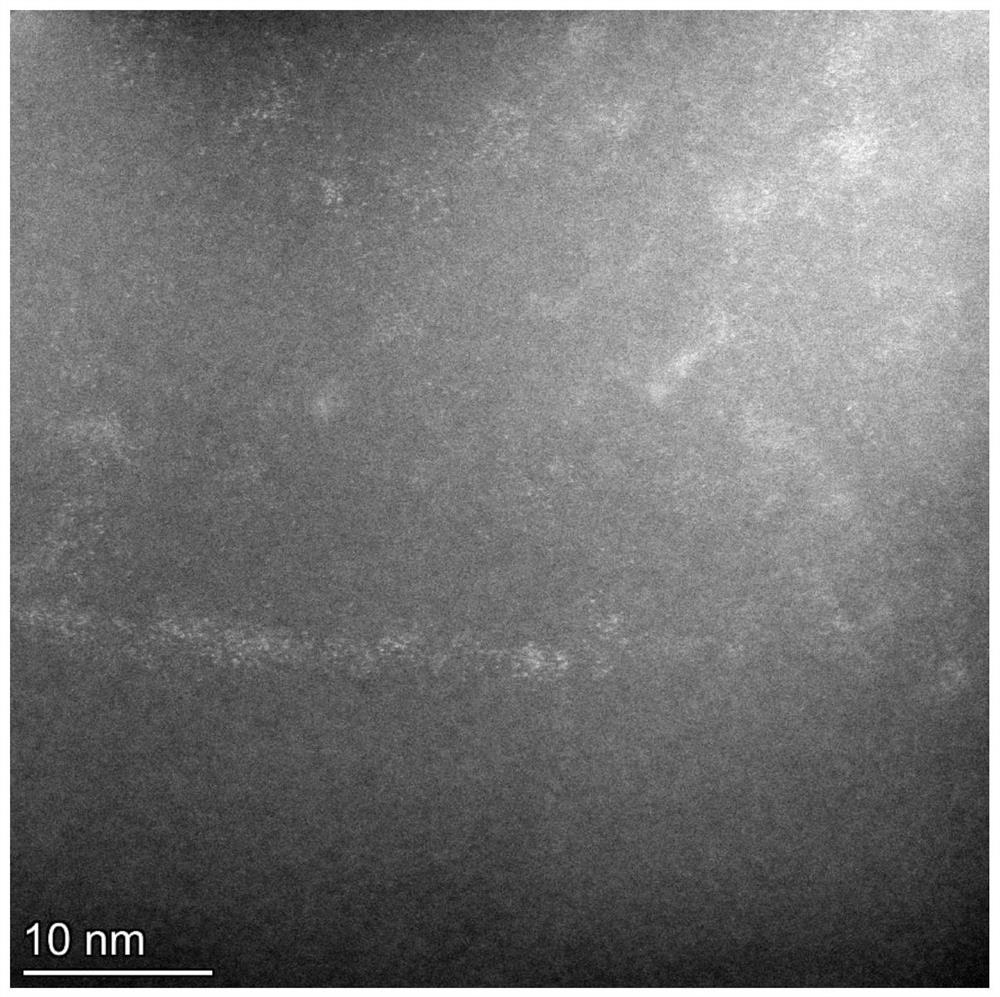

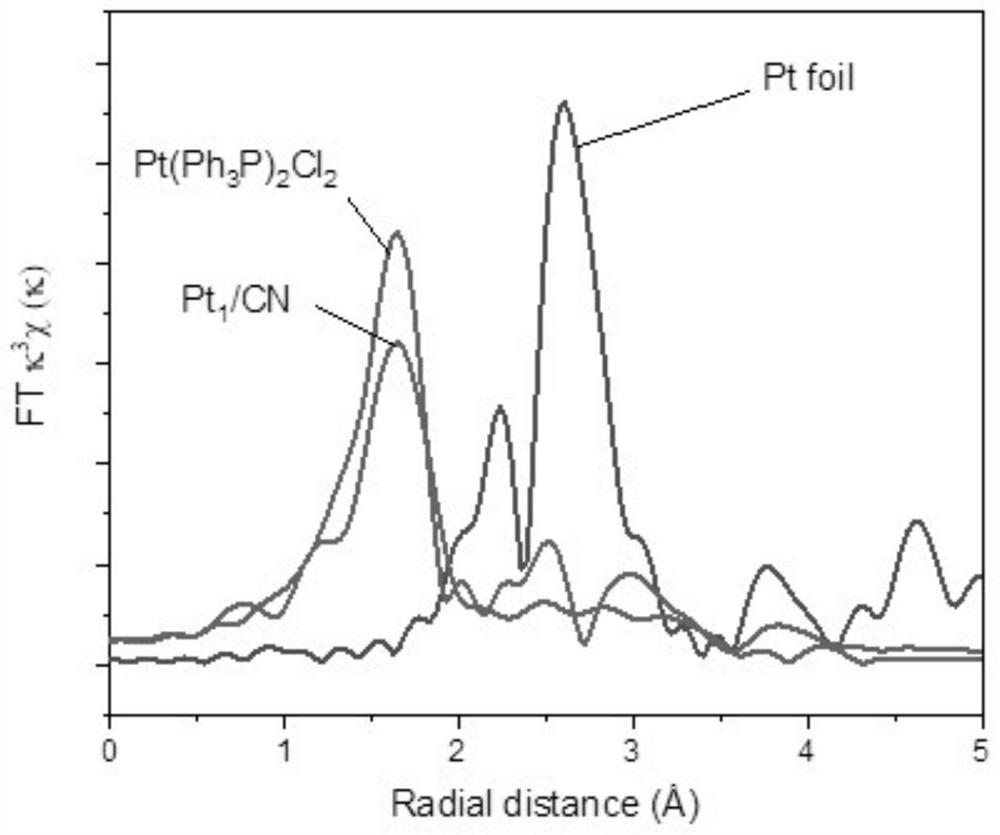

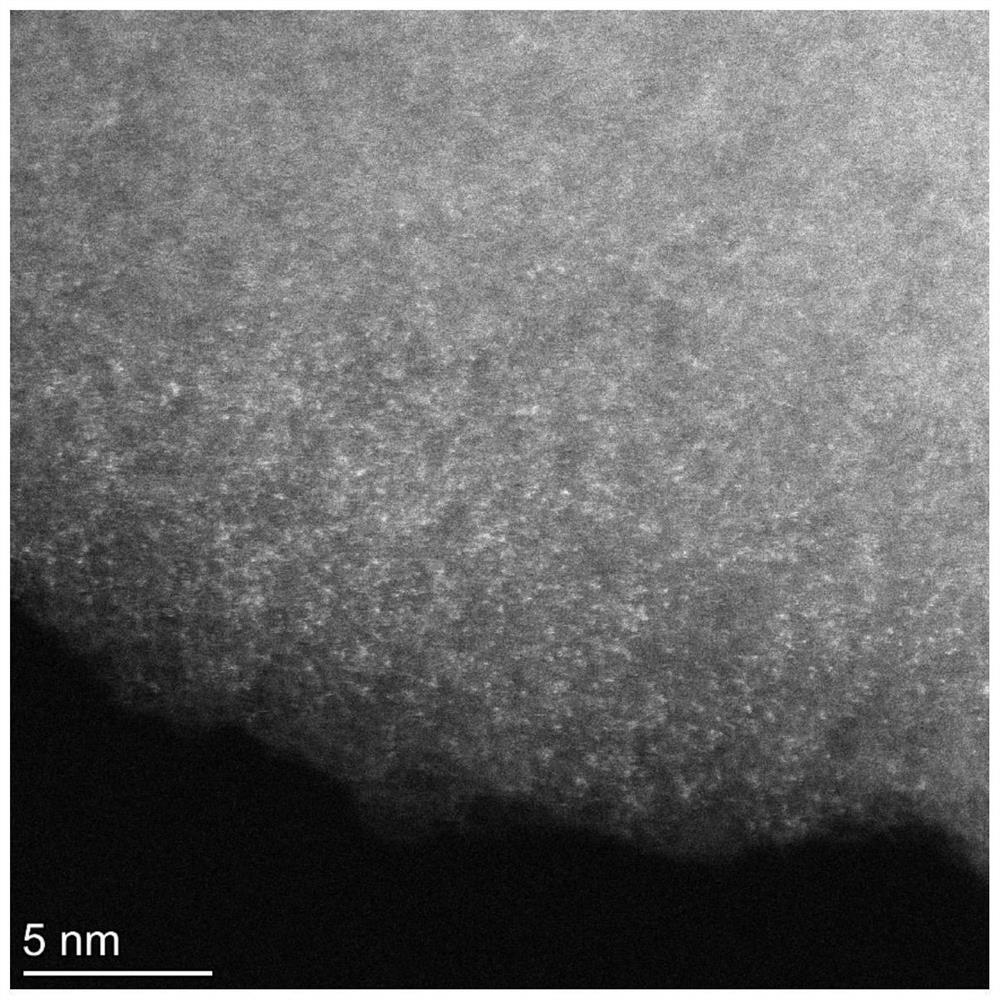

[0050] The present embodiment provides a heterogeneous catalyst with a conjugated polymer (carbon nitride) loaded with a high concentration of single-atom metal (platinum) sites, and the preparation method is as follows:

[0051] 100 mg of carbon nitride was dispersed in 20 mL of toluene, and 8 mg of platinum dibenzylideneacetone was added, followed by mixing and stirring for 3 hours.

[0052] Toluene was removed by rotary evaporation and dried in an oven at 100°C for 5 hours.

[0053] The obtained dry solid was dispersed in 200 mL of water, replaced with argon gas, and illuminated under an LED lamp for 1 hour.

[0054] The light-treated solid was centrifuged and dried in an oven at 100°C for 5 hours.

[0055] After the temperature dropped to room temperature, the solid powder was repeatedly washed with toluene, and then dried in an oven at 100° C. for 5 hours to obtain the target platinum carbon nitride single-atom heterogeneous photocatalyst.

[0056] The platinum loading ...

Embodiment 2

[0059] The present embodiment provides a conjugated polymer (modified carbon nitride) loaded heterogeneous catalyst with high concentration of single-atom metal (palladium) sites, and its preparation method is as follows:

[0060] 1 g of modified carbon nitride (phosphorus-doped carbon nitride) was dispersed in 100 mL of cyclohexane, then 300 mg of bis(tri-tert-butylphosphine)palladium was added, and the mixture was mixed and stirred for 24 hours.

[0061] Cyclohexane was removed by rotary evaporation and dried in an oven at 70°C for 15 hours.

[0062] The obtained dry solid was dispersed in 1 L of water, nitrogen was replaced, and the mixture was exposed to sunlight for 10 hours.

[0063] The light-treated solids were centrifuged and dried in an oven at 120°C for 3 hours.

[0064] After the temperature dropped to room temperature, the solid powder was repeatedly washed with cyclohexane, and then dried in an oven at 70° C. for 15 hours to obtain the target palladium-modified ...

Embodiment 3

[0068] The present embodiment provides a heterogeneous catalyst with a conjugated polymer (covalent organic framework) loaded with a high concentration of single-atom metal (copper) sites, and the preparation method is as follows:

[0069] 100 mg of the covalent organic framework (COF-LZU-1) was dispersed in 20 mL of dichloromethane, then 15 mg of copper bis(acetylacetonate) was added, and the mixture was mixed and stirred for 8 hours.

[0070] The dichloromethane was removed by evaporation in a fume hood and dried in an oven at 50°C for 8 hours.

[0071] The resulting dry solid was dispersed in 150 mL of water and illuminated under a xenon lamp for 6 hours under air.

[0072] The light-treated solid was centrifuged and dried in an oven at 150°C for 2 hours.

[0073] After the temperature dropped to room temperature, the solid powder was repeatedly washed with dichloromethane, and then dried in an oven at 50° C. for 8 hours to obtain the target copper covalent organic framewo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com