Injection molding aluminum oxide ceramic material and injection molding method thereof

A kind of alumina ceramics, injection molding technology, applied in the field of ceramic materials, can solve the problems that affect the production efficiency of products, the injection process is not easy to control, and the mechanical strength of products is poor, so as to achieve excellent mechanical strength and impact resistance, moderate viscosity and fluidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

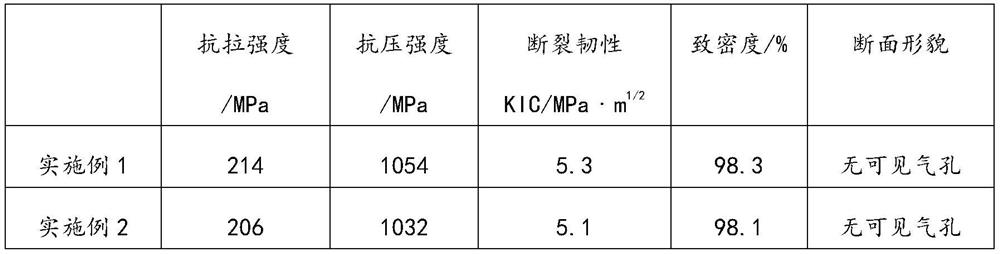

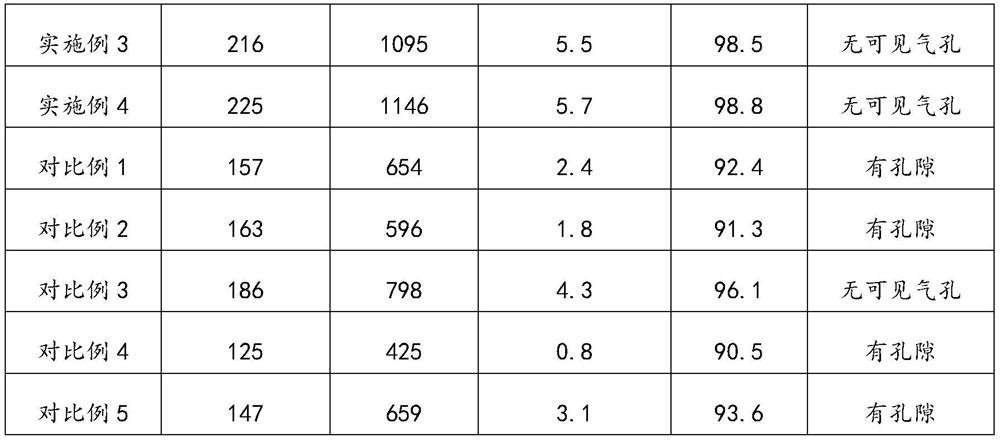

Examples

Embodiment 1

[0028] The injection molded alumina ceramic material of the present embodiment is made up of the following raw materials in weight percentage: ceramic powder 80.24%, APAO 5.15%, LLDPE 5.00%, stearic acid 1.58%, tributyl citrate 4.35%, titanate Coupling agent 2.53%, dinaphthyl methane disulfonic acid 1.15%, wherein ceramic powder is made up of the raw material of following mass percentage: aluminum oxide powder 95.4%, yttrium oxide powder 1.4% and magnesium oxide powder 3.2%, and this ceramic powder The particle size is 30-60nm.

[0029] The injection molding method of the above-mentioned injection molding alumina ceramic material specifically includes the following steps:

[0030] S1. Rough mixing: Weigh the raw materials according to the above mass percentage, first place the ceramic powder at 200°C to dry for 2 hours, then add all the raw materials in proportion to the constant temperature stirring mixer, set the stirring rate to 260r / min, and set the temperature at 110°C S...

Embodiment 2

[0037] The injection-molded alumina ceramic material of the present embodiment is made up of the following raw materials in percentage by weight: ceramic powder 80.75%, APAO 5.03%, LLDPE 4.88%, stearic acid 2.31%, tributyl citrate 3.36%, titanate Coupling agent 2.45%, dinaphthyl methane disulfonic acid 1.22%, wherein ceramic powder is made up of the raw material of following mass percentage: aluminum oxide powder 97.28%, yttrium oxide powder 0.93% and magnesium oxide powder 1.79%, and this ceramic powder The particle size is 30-60nm.

[0038] The specific steps of the injection molding method of the above-mentioned injection molding alumina ceramic material are the same as those in Example 1, specifically refer to Example 1, but differently, in the extrusion process of Example 2, four repeated extrusions were carried out at 155°C out to prepare a mixed material.

Embodiment 3

[0040] The injection-molded alumina ceramic material of the present embodiment is made up of the following raw materials in percentage by weight: ceramic powder 80.36%, APAO 5.12%, LLDPE 4.95%, stearic acid 2.08%, tributyl citrate 3.85%, titanate Coupling agent 2.46%, dinaphthyl methane disulfonic acid 1.18%, wherein ceramic powder is made up of the raw material of following mass percentage: aluminum oxide powder 96.81%, yttrium oxide powder 1.07% and magnesium oxide powder 2.12%, and this ceramic powder The particle size is 30-60nm.

[0041] The specific steps of the injection molding method of the above-mentioned injection molding alumina ceramic material are the same as those in Example 1, specifically refer to Example 1, but differently, in the extrusion process of Example 3, five repeated extrusions were carried out at 155°C out to prepare a mixed material.

[0042] Example 3:

[0043] The injection-molded alumina ceramic material of the present embodiment is made up of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com