Ultrasonic-assisted fluid cavitation grinding equipment

An auxiliary fluid and ultrasonic technology, applied in the direction of metal processing equipment, abrasives, abrasive jet machine tools, etc., can solve the problems of damaged dimensional integrity, uneven processing, abrasive aggregation, etc., to achieve enhanced surface quality, faster movement speed, air The effect of chemical strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be clear to those skilled in the art that this embodiment is only for better explaining and illustrating the usage method of the present invention, and cannot be used to limit the present invention.

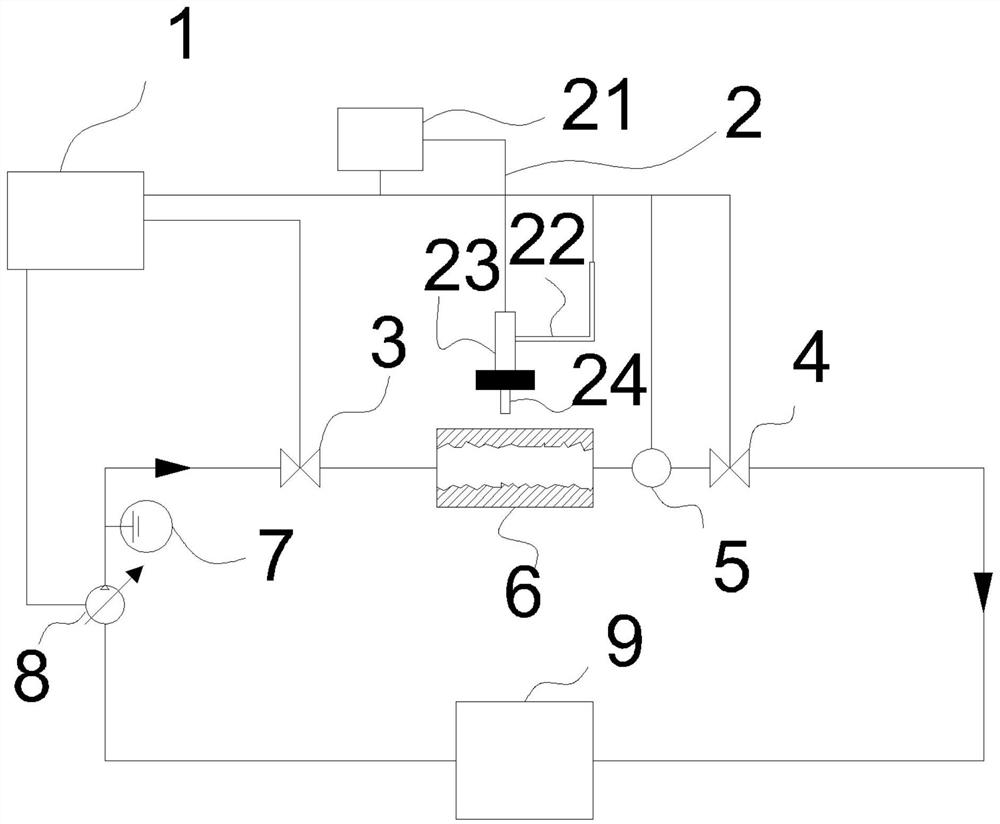

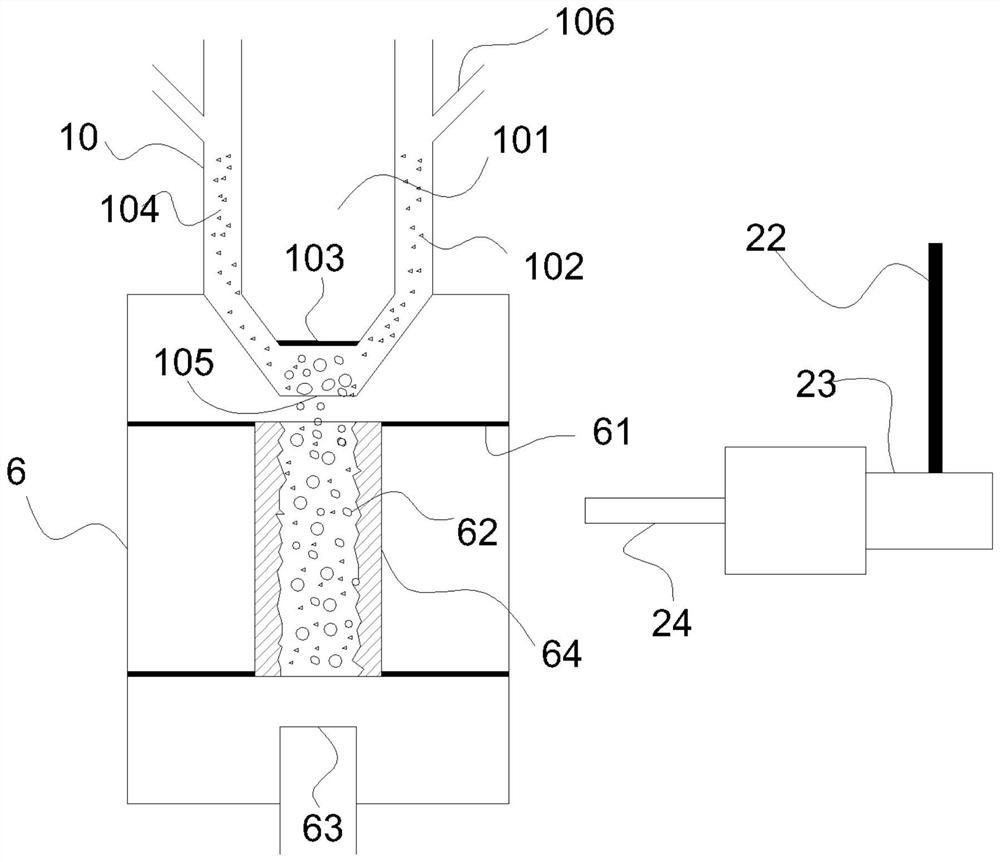

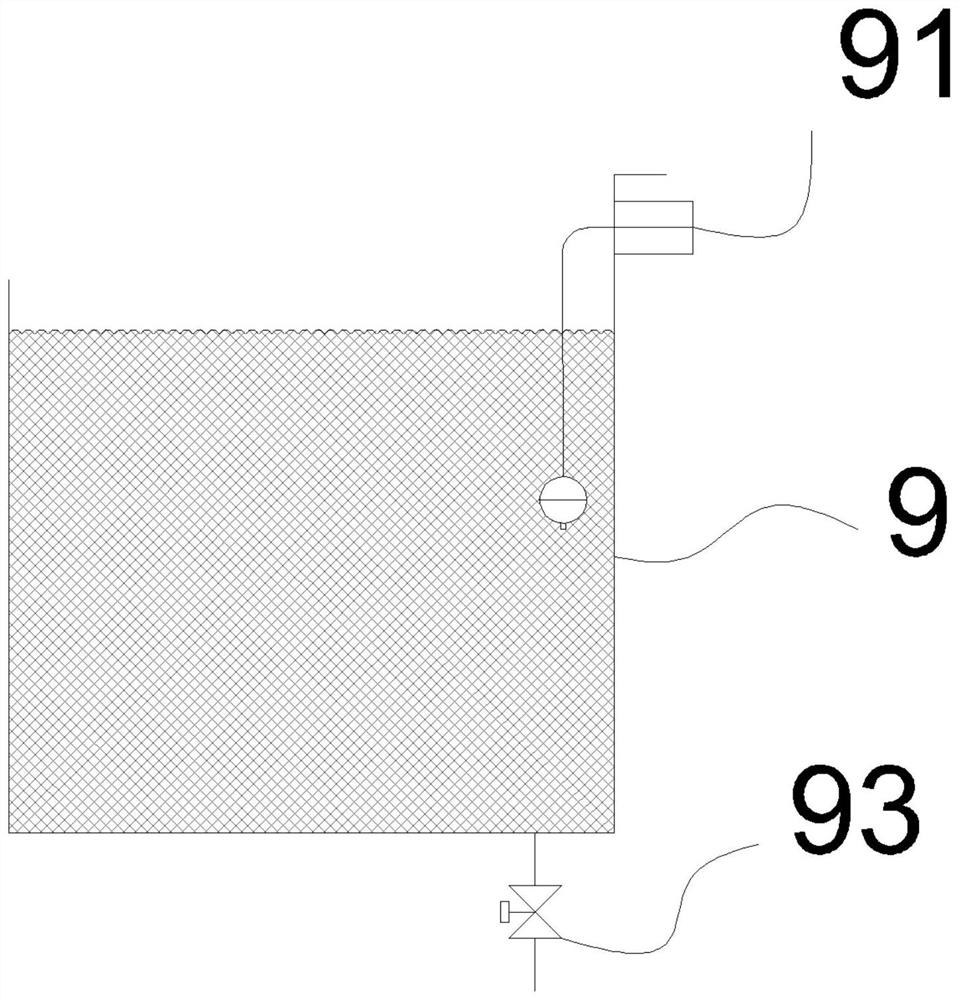

[0034] Such as figure 1 As shown, the present invention includes a bracket, a controller 1, an ultrasonic auxiliary system 2, an upstream valve 3, a downstream valve 4, a cavitation intensity monitor 5, a cavitation chamber 6, an accumulator 7, a variable flow pump 8 and a fluid source 9. The outlet of the variable flow pump 8 is connected to the inlet of the variable flow pump 8 after passing through the accumulator 7, the upstream valve 3, the cavitation chamber 6, the cavitation intensity monitor 5, the downstream valve 4 and the fluid source 9, A closed loop is formed; wherein, the cavitation intensity monitor 5 is an acoustic sensor, an acoustic emission sensor or a PVDF sensor; the variable flow pump 8 is a plunger pump or a peristaltic pump, which can tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com