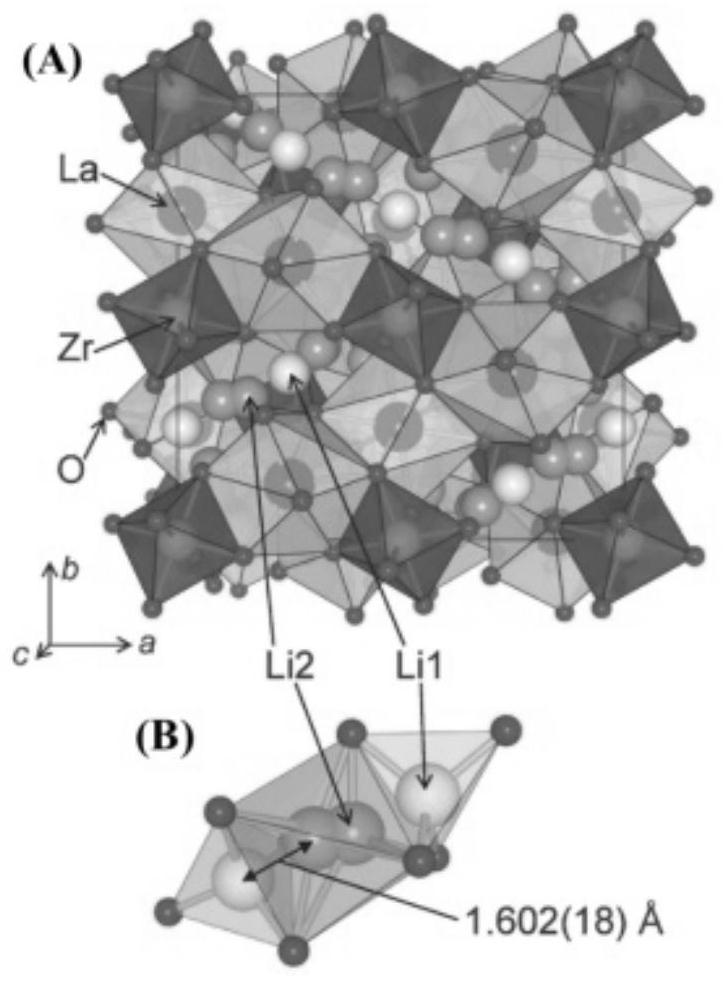

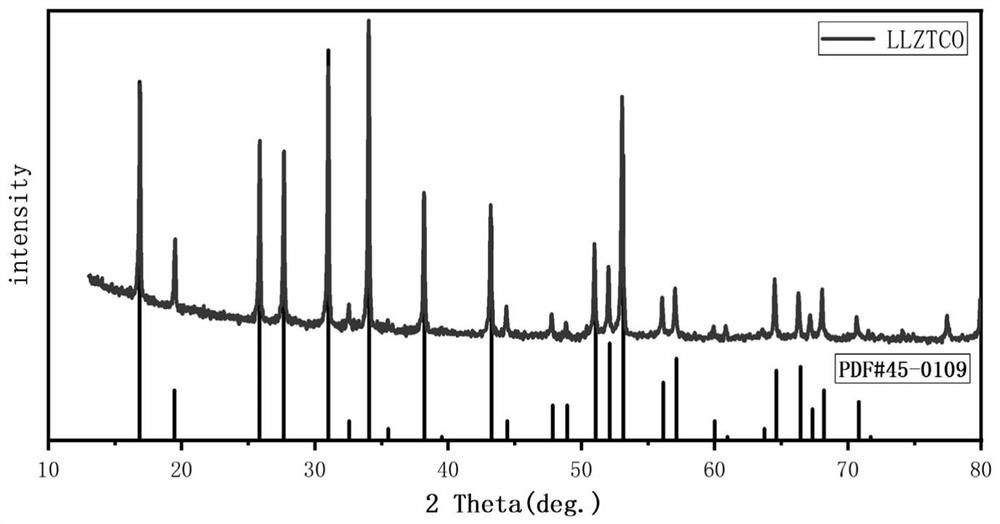

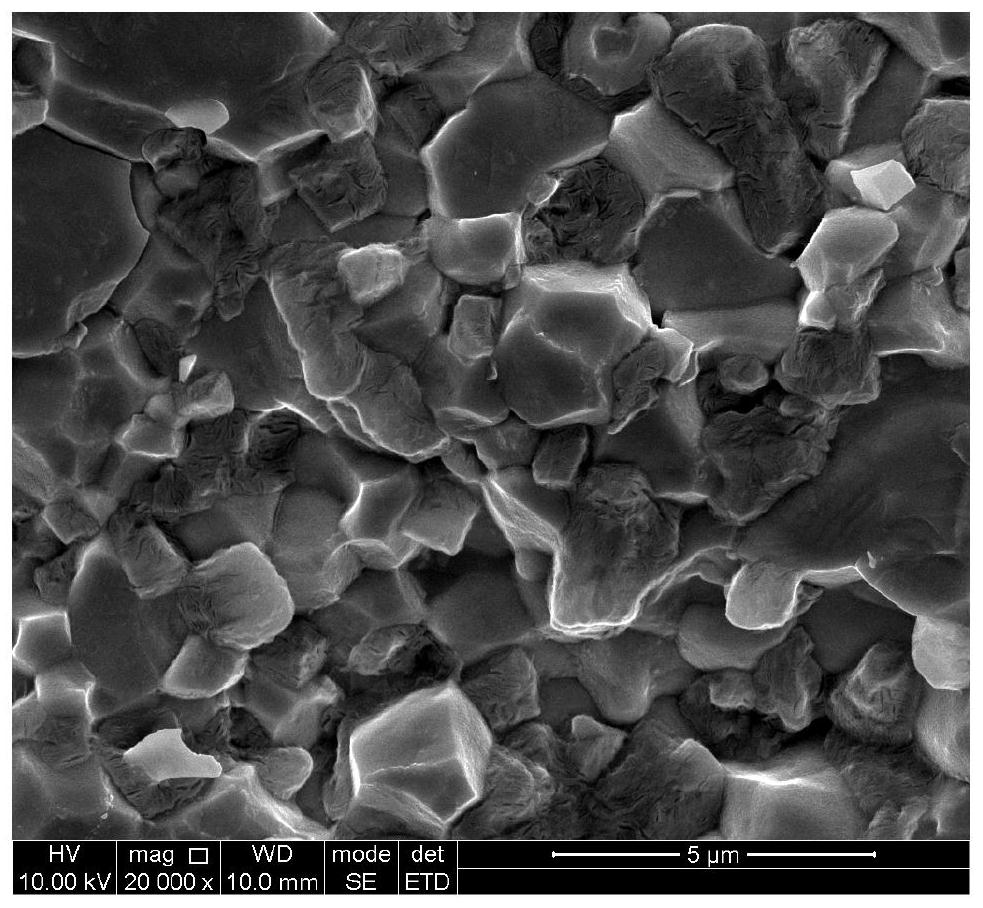

Cerium-doped garnet type LLZO solid electrolyte for inhibiting growth of lithium dendrites and preparation method of cerium-doped garnet type LLZO solid electrolyte

A technology of cerium-doped garnet and solid electrolyte, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as lithium dendrite growth, lithium metal negative electrode contact interface impedance, etc., to improve conductivity and reduce Sintering temperature, effect of inhibiting lithium dendrite growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Step 1: batching; LiOH, La2O3, ZrO2, Ta2O5 and CeO2 are weighed according to the chemical formula Li6.8La3Zr1.7Ta0.2Ce0.1O12, wherein in order to avoid volatilization of the lithium source, LiOH is weighed in excess of 10wt%;

[0051] Step 2: One-time ball milling; adopt wet ball milling process, use yttrium stabilized zirconia balls as the ball milling medium, use isopropanol as the ball milling solvent, and carry out according to the mass ratio of mixture: balls: isopropanol is 1:5:1 Grind for 8 hours to obtain a uniformly mixed ball mill;

[0052] Step 3: drying and sieving; drying the ball mill material obtained in step 2 and passing through a 100-mesh sieve to obtain a dry powder;

[0053] Step 4: pre-calcining; the dry powder obtained in step 3 is placed in a magnesia crucible, and pre-fired at 800°C for 10 hours to obtain a pre-fired powder;

[0054] Step 5: Secondary ball milling; the calcined powder obtained in step 4 is subjected to a second ball milling, wit...

Embodiment 2

[0059] Step 1: batching; LiOH, La2O3, ZrO2, Ta2O5 and CeO2 are weighed according to the chemical formula Li6.6La3Zr1.5Ta0.4Ce0.1O12, wherein in order to avoid volatilization of the lithium source, LiOH is weighed in excess of 10wt%;

[0060] Step 2: One-time ball milling; adopt wet ball milling process, use yttrium stabilized zirconia balls as the ball milling medium, use isopropanol as the ball milling solvent, and carry out according to the mass ratio of mixture: balls: isopropanol is 1:5:1 Grind for 6 hours to obtain a uniformly mixed ball mill;

[0061] Step 3: drying and sieving; drying the ball mill material obtained in step 2 and passing through a 100-mesh sieve to obtain a dry powder;

[0062] Step 4: pre-calcining; the dry powder obtained in step 3 is placed in a magnesia crucible, and pre-calcined at 850°C for 8 hours to obtain a pre-calcined powder;

[0063] Step 5: Secondary ball milling; the calcined powder obtained in step 4 is subjected to a second ball milling...

Embodiment 3

[0068] Step 1: batching; LiOH, La2O3, ZrO2, Ta2O5 and CeO2 are weighed according to the chemical formula Li6.4La3Zr1.3Ta0.6Ce0.1O12, wherein in order to avoid volatilization of the lithium source, LiOH is weighed in excess of 10wt%;

[0069] Step 2: One-time ball milling; adopt wet ball milling process, use yttrium stabilized zirconia balls as the ball milling medium, use isopropanol as the ball milling solvent, and carry out according to the mass ratio of mixture: balls: isopropanol is 1:5:1 Grind for 8 hours to obtain a uniformly mixed ball mill;

[0070] Step 3: drying and sieving; drying the ball mill material obtained in step 2 and passing through a 100-mesh sieve to obtain a dry powder;

[0071] Step 4: pre-calcining; the dry powder obtained in step 3 is placed in a magnesia crucible, and pre-calcined at 900°C for 6 hours to obtain a pre-calcined powder;

[0072] Step 5: Secondary ball milling; the calcined powder obtained in step 4 is subjected to a second ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com