a cubic phase cu 3 sbs 3 Based thermoelectric material and method for preparing the thermoelectric material by element replacement

A thermoelectric material, cu3sb1-xaxs3 technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve problems such as destroying the good contact between the material and the substrate, restricting the application in the thermoelectric field, etc., and achieving a sintering method Flexible options, easy access and storage, structurally stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

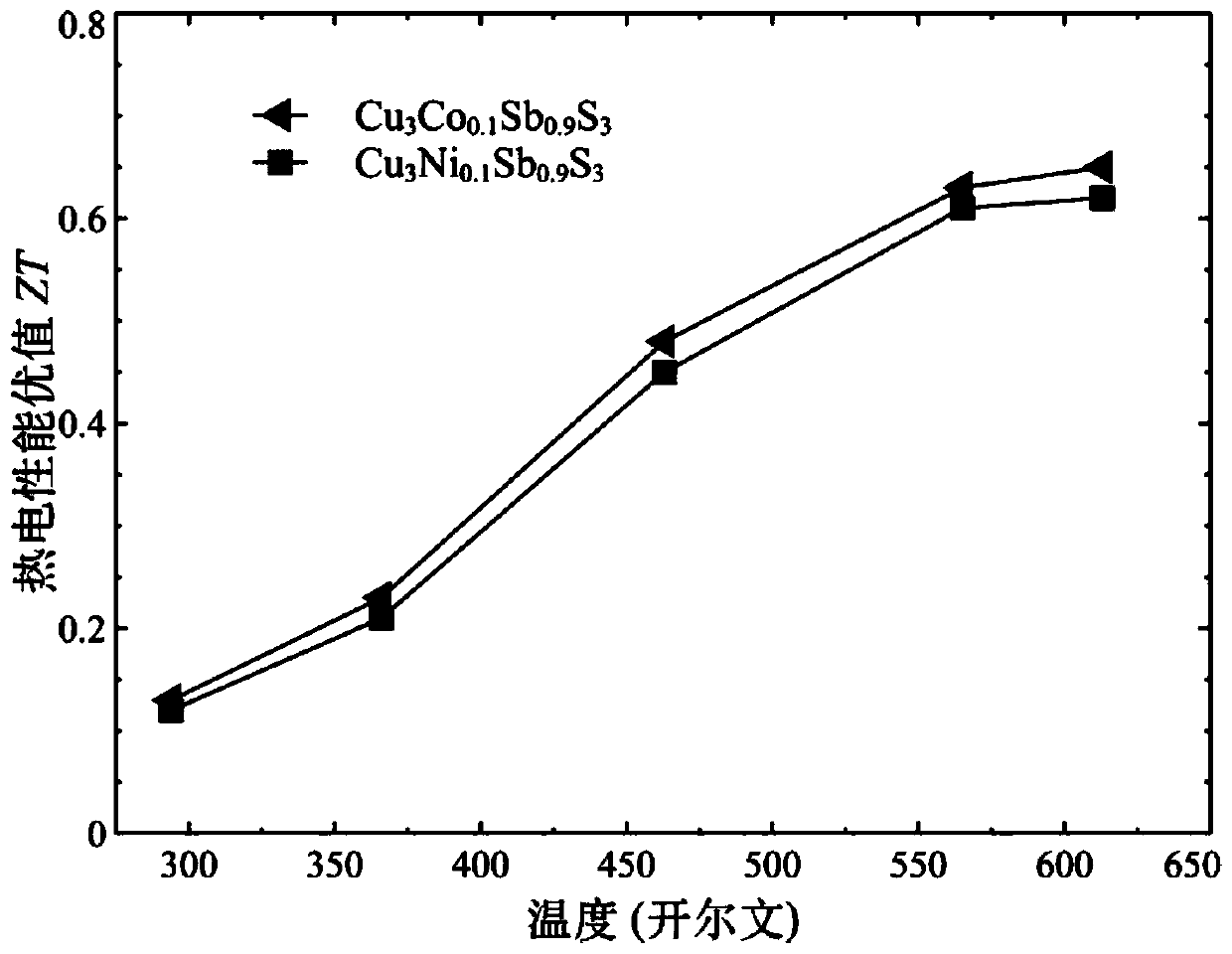

[0032] A cubic phase Cu 3 Sb 3 Based thermoelectric material, its preparation method comprises the steps:

[0033] 1) Ingredients: According to Cu 3 Sb 1-x A x S 3 (A is the ratio of each element in Co or Ni) to calculate the mass of each element, respectively take the required mass of copper, antimony, cobalt or nickel, sulfur as the reaction raw material, that is, the substance of copper, antimony, cobalt or nickel, sulfur The ratio of the amount is 3:(1-x):x:3, wherein x=0.10; The mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, elemental sulfur is analytically pure, elemental cobalt (nickel ) purity of 99%;

[0034] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 450rpm, the ball-to-material ratio is 20, and the ball milling time is 20h;

[0035] 3) Spark ...

Embodiment 2

[0040] A cubic phase Cu 3 Sb 3 Based thermoelectric material, its preparation method comprises the steps:

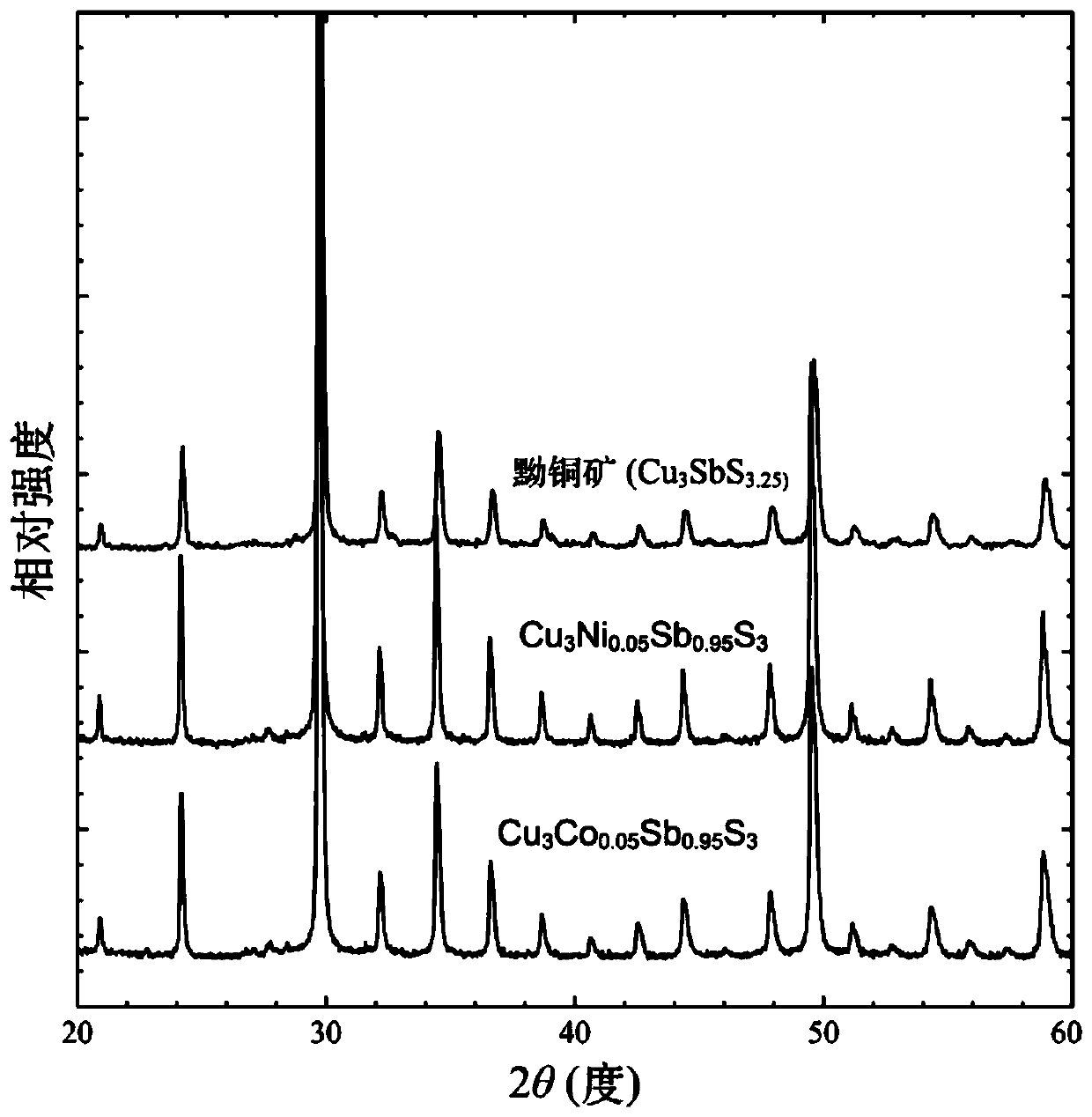

[0041] 1) Ingredients: according to Cu 3 Sb 1-x A x S 3 The ratio of each element in (A=Co or Ni) calculates the quality of each element, takes copper, antimony, cobalt (nickel), sulfur of required quality respectively as reaction raw material, i.e. copper, antimony, cobalt (nickel), sulfur The ratio of the amount of substance is 3:(1-x):x:3, wherein x=0.05, the mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, elemental sulfur is analytically pure, elemental cobalt (Nickel) purity 99%;

[0042] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 450rpm, the ball-to-material ratio is 20, and the ball milling time is 20h;

[0043] 3) Spark plasma sintering: pu...

Embodiment 3

[0047] A preparation of cubic phase Cu 3 Sb 3 A method based on thermoelectric materials, comprising the steps of:

[0048] 1) Ingredients: according to Cu 3 Sb 1-x A x S 3 The ratio of each element in (A=Co or Ni) calculates the quality of each element, takes copper, antimony, cobalt (nickel), sulfur of required quality respectively as reaction raw material, i.e. copper, antimony, cobalt (nickel), sulfur The ratio of the amount of substance is 3:(1-x):x:3, wherein x=0.20, the mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, elemental sulfur is analytically pure, elemental cobalt (Nickel) purity 99%;

[0049] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 350rpm, the ball-to-material ratio is 15, and the ball milling time is 30h;

[0050] 3) Hot-press sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com