a cubic phase cu 3 sbs 3 Base thermoelectric material and preparation method thereof

A technology of thermoelectric materials and cubic phase, which is applied in the field of cubic phase Cu3SbS3-based thermoelectric materials and its preparation, can solve the problems of unavoidable monoclinic or orthorhombic stable phase transition, etc., and achieve flexible sintering method selection, stable raw materials, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

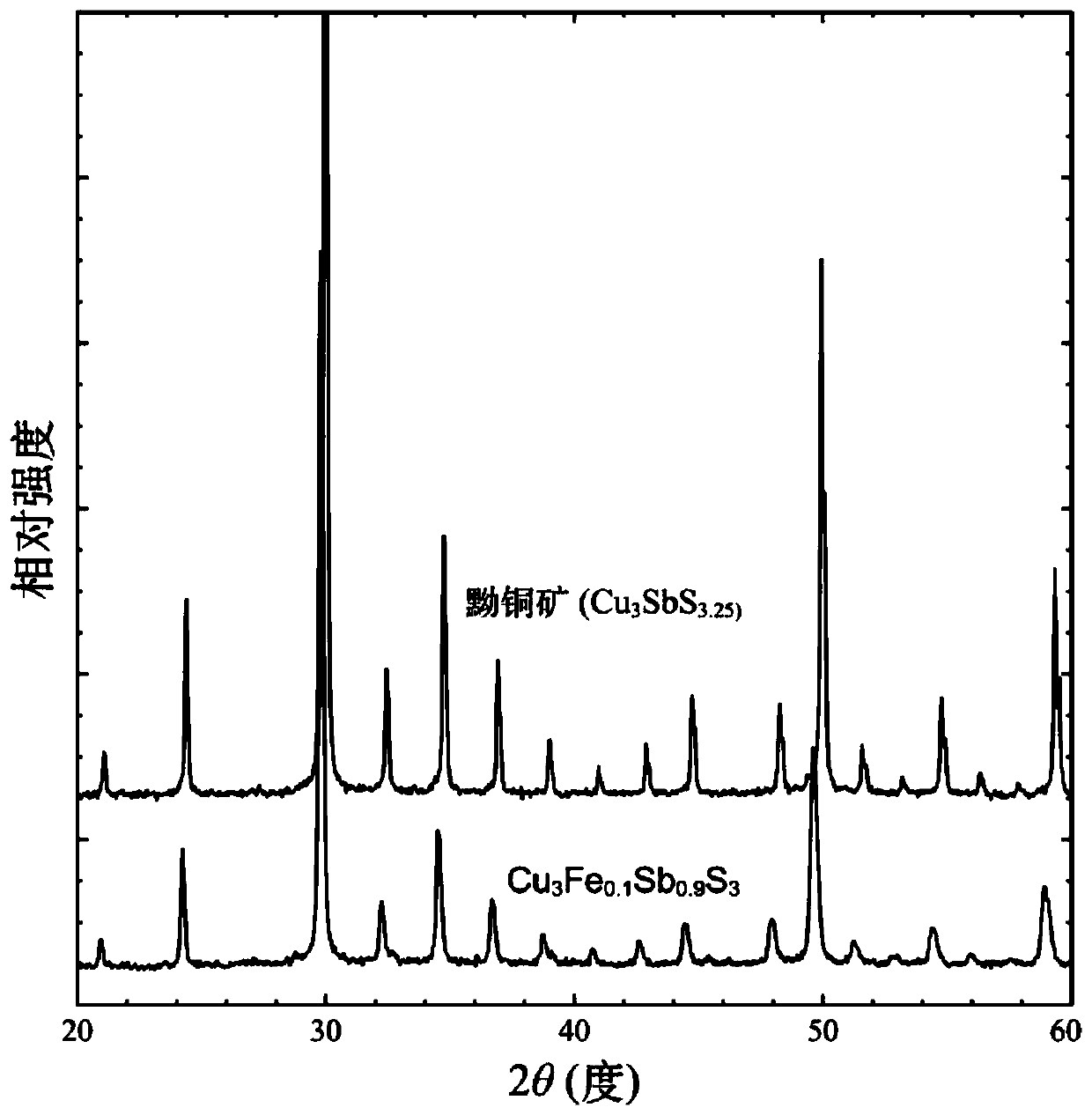

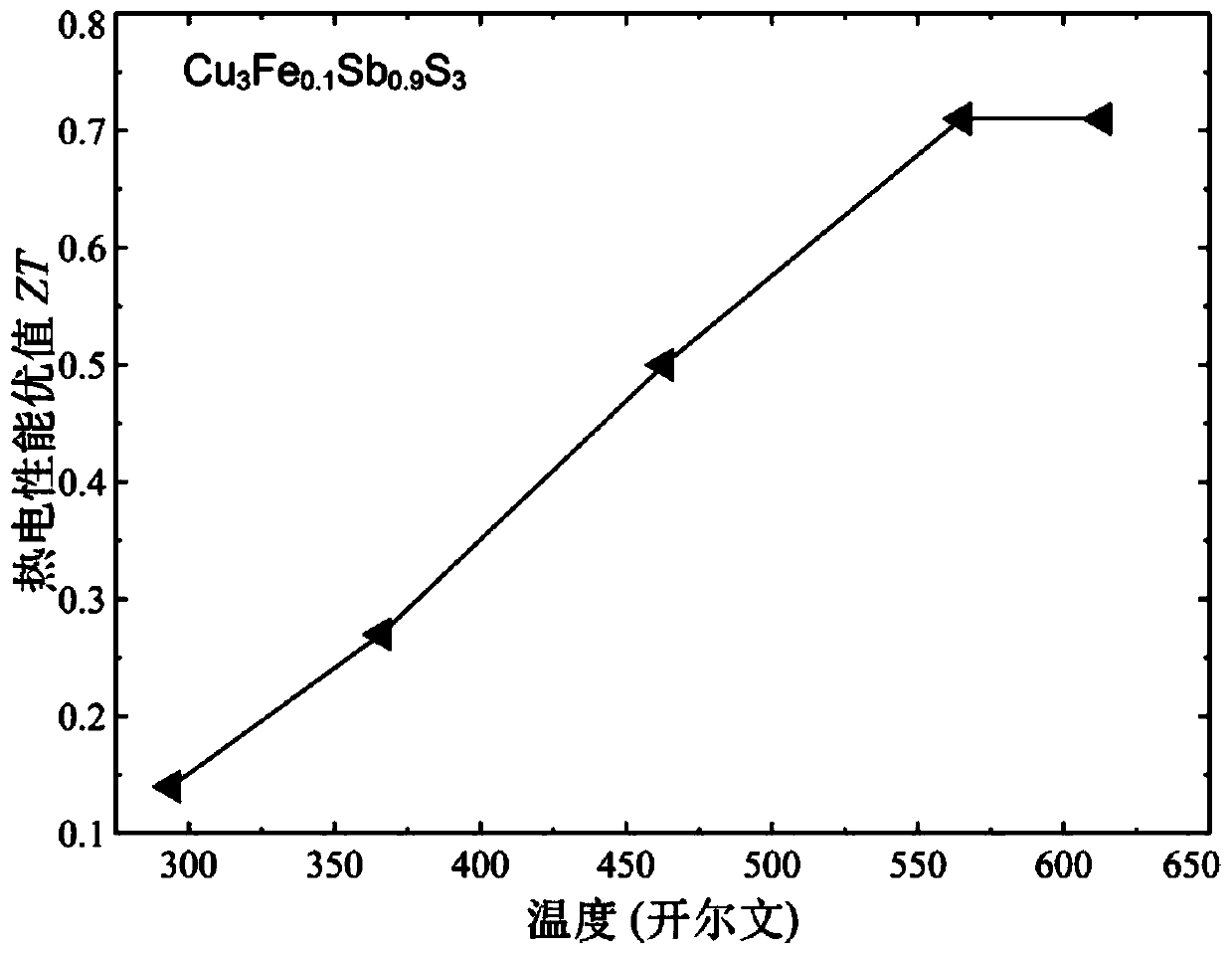

Embodiment 1

[0032] A preparation of cubic phase Cu 3 Sb 3 A method based on thermoelectric materials, comprising the steps of:

[0033] 1) Ingredients: According to the chemical composition Cu 3 Sb 1-x Fe x S 3 The stoichiometric ratio of each element takes copper, antimony, iron, and sulfur as the reaction raw materials, that is, the ratio of the amount of copper, antimony, sulfur, and iron is 3: (1-x): x: 3, where x = 0.10 , the mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, the elemental sulfur is analytically pure, and the elemental iron purity is 99%;

[0034] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 450rpm, the ball-to-material ratio is 20, and the ball milling time is 20h;

[0035] 3) Spark plasma sintering: put the powder obtained in step 2) into a graphit...

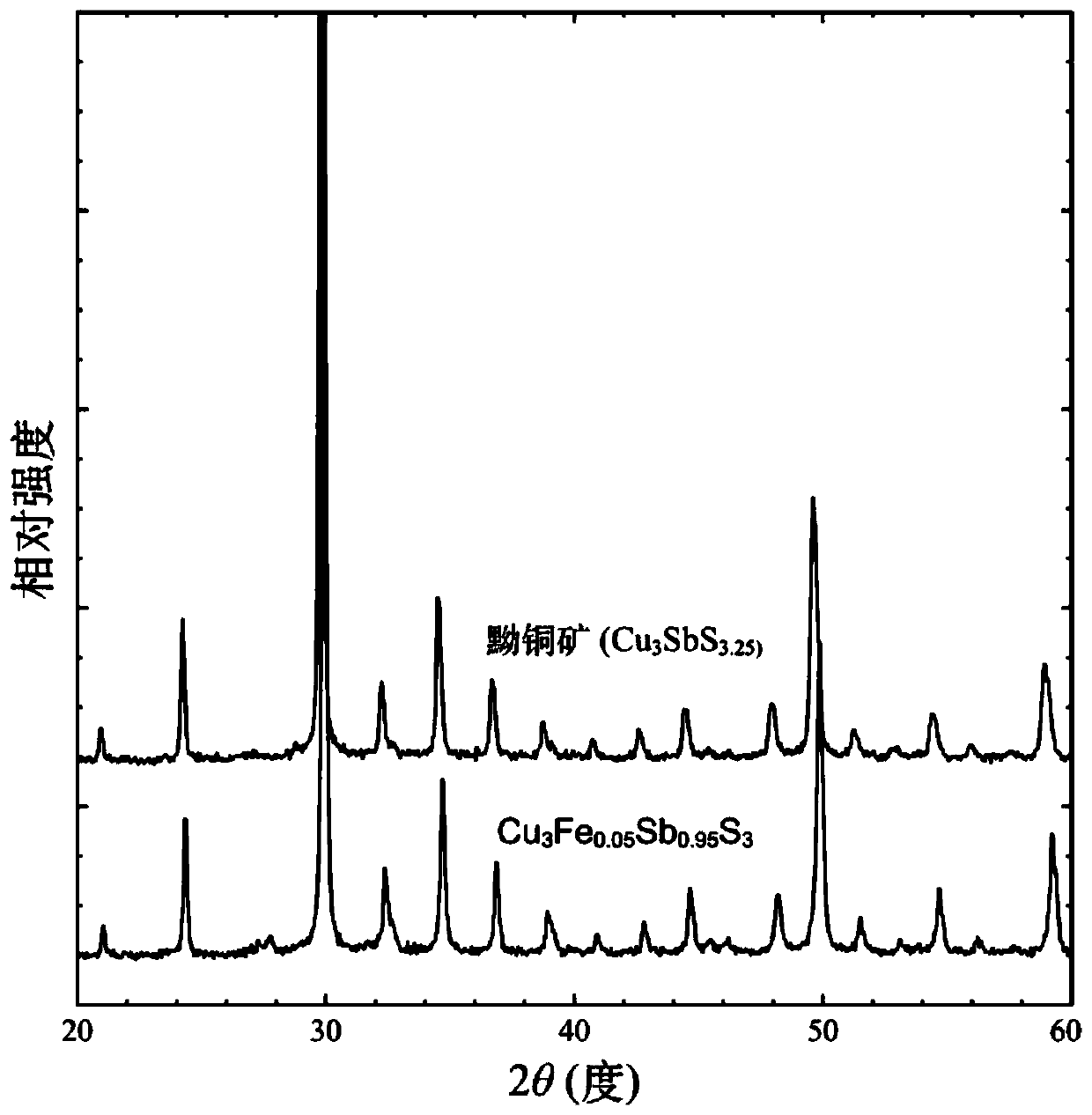

Embodiment 2

[0038] A preparation of cubic phase Cu 3 Sb 3 A method based on thermoelectric materials, comprising the steps of:

[0039] 1) Ingredients: According to the chemical composition Cu 3 Sb 1-x Fe x S 3 The stoichiometric ratio of each element takes copper, antimony, iron, and sulfur as the reaction raw materials, that is, the ratio of the amount of copper, antimony, sulfur, and iron is 3: (1-x): x: 3, where x = 0.05 , the mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, the elemental sulfur is analytically pure, and the elemental iron purity is 99%;

[0040] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 450rpm, the ball-to-material ratio is 20, and the ball milling time is 20h;

[0041] 3) Spark plasma sintering: put the powder obtained in step 2) into a graphit...

Embodiment 3

[0045] A preparation of cubic phase Cu 3 Sb 3 A method based on thermoelectric materials, comprising the steps of:

[0046] 1) Ingredients: According to the chemical composition Cu 3 Sb 1-x Fe x S 3 The stoichiometric ratio of each element takes copper, antimony, iron, and sulfur as the reaction raw materials, that is, the ratio of the amount of copper, antimony, sulfur, and iron is 3: (1-x): x: 3, where x = 0.20 , the mass purity of copper is better than 99.5%, the mass purity of antimony is better than 99.5%, the elemental sulfur is analytically pure, and the elemental iron purity is 99%;

[0047] 2) Mechanical alloying: Pour the reaction materials described in step 1) into a stainless steel ball mill tank, and perform high-energy ball milling under an inert gas protective atmosphere. The ball milling speed is 400 rpm, the ball-to-material ratio is 15, and the ball milling time is 25 hours;

[0048] 3) Spark plasma sintering: put the powder obtained in step 2) into a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com