A kind of copper-selenium-based thermoelectric material with high structural stability and preparation method thereof

A technology of thermoelectric materials and stability, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, nanotechnology for materials and surface science, etc., can solve material or device cracks, can not accurately test thermoelectric Performance, damage and other issues, to achieve the effect of improving thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specific embodiments of the above scheme.

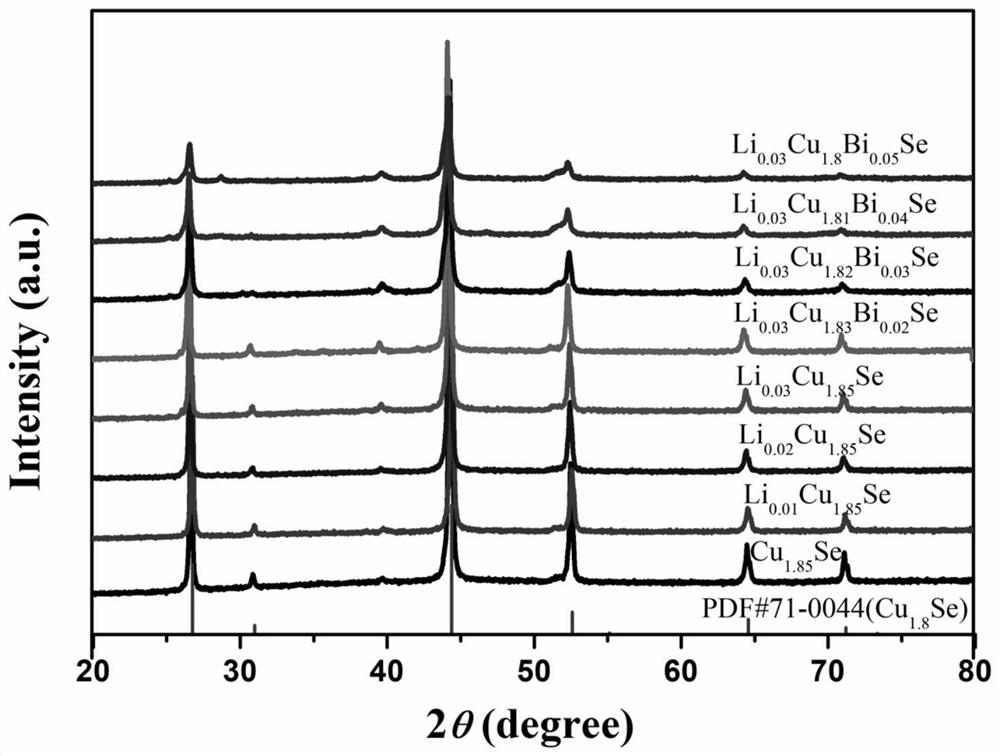

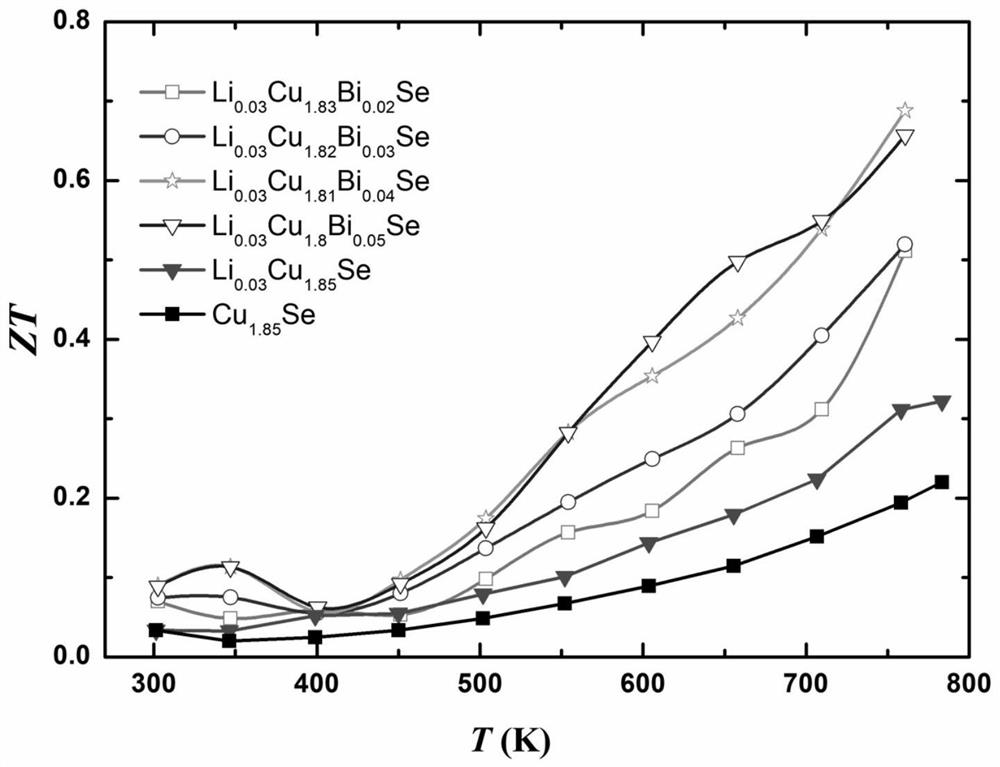

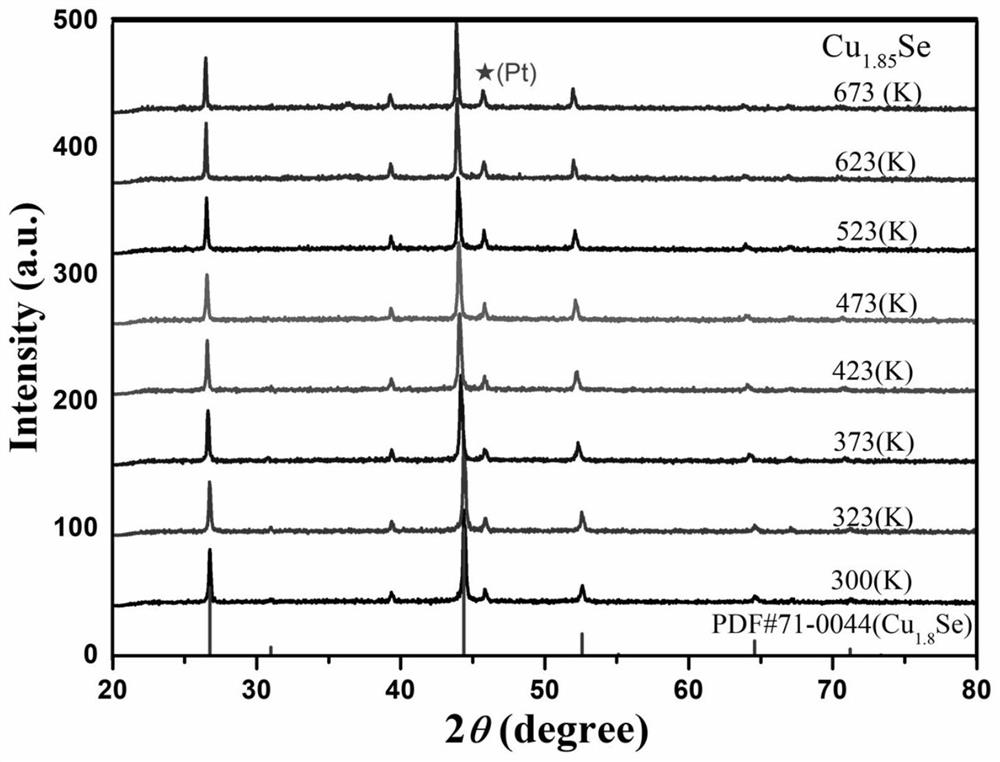

[0025] Step 1: Elemental Cu, Se, Bi, Li are arranged according to Li y Cu 1.85-x Bi x Se (wherein x = 0.02, 0.03, 0.04, 0.05; y = 0.01, 0.02, 0.03) stoichiometric ratio is weighed in an argon atmosphere with a purity greater than 99.999%, the weighing mass is generally in the range of 8g-10g, and then transferred to In the ball mill jar; Li element is the lithium sheet used to encapsulate the battery, and before weighing the Li sheet, it is necessary to lightly sand both surfaces of the Li sheet with 1500 grit sandpaper to eliminate the oxide film and surface impurities.

[0026] Step 2: Put the ball mill jar filled with ingredients in step 1 into a high-energy ball mill for ball milling, and the ball milling time is 10h to obtain uniform Li y Cu 1.85-x Bi x Se, where for x=0.02, 0.03, 0.04, 0.05, y=0.01, 0.02, 0.03 nano-powder respectively; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com