High-transmittance high-definition polyester film and preparation method thereof

A technology of polyester film and clarity, applied in the field of polyester film, can solve the problems of poor ultraviolet protection performance, affecting actual use, easy to sunburn drivers, etc., to improve the ignition point and fire resistance effect, improve safety, improve transparency The effect of light performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

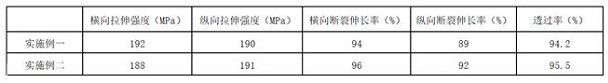

Embodiment 1

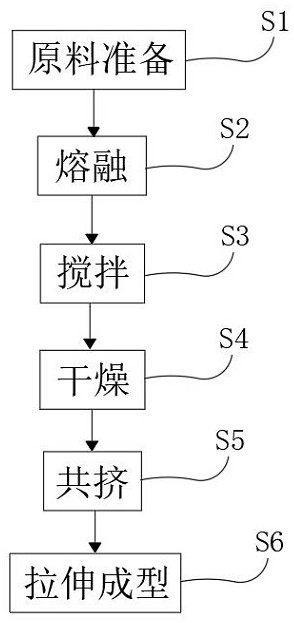

[0036] refer to figure 1 , a polyester film with high light transmission and high definition, the polyester film with high light transmission and high definition includes an outer layer, a core layer and an inner layer, and the core layer includes the following components in parts by weight: polyparaphenylene 95 parts of ethylene glycol diformate, 18 parts of toughening agent, 3 parts of inorganic particles, 7 parts of high light transmittance diffusion masterbatch;

[0037] The outer layer includes the following components in parts by weight: 80 parts of polyethylene terephthalate, 25 parts of ultraviolet absorber, 8 parts of stabilizer, and 6 parts of anti-blocking agent;

[0038] The inner layer includes the following components in parts by weight: 85 parts of polyethylene terephthalate, 8 parts of antistatic agent and 10 parts of flame retardant.

[0039] In this embodiment, the toughening agent is any one of polyvinyl formal, polyvinyl furfural and ethylene-vinyl acetate...

Embodiment 2

[0059] refer to figure 1 , a polyester film with high light transmission and high definition, the polyester film with high light transmission and high definition includes an outer layer, a core layer and an inner layer, and the core layer includes the following components in parts by weight: polyparaphenylene 90 parts of ethylene glycol diformate, 10 parts of toughening agent, 1 part of inorganic particles, 5 parts of high light transmittance diffusion masterbatch;

[0060] The outer layer includes the following components in parts by weight: 75 parts of polyethylene terephthalate, 20 parts of ultraviolet absorber, 5 parts of stabilizer, and 3 parts of anti-blocking agent;

[0061] The inner layer includes the following components in parts by weight: 82 parts of polyethylene terephthalate, 7 parts of antistatic agent and 10 parts of flame retardant.

[0062] In this embodiment, the toughening agent is any one of polyvinyl formal, polyvinyl furfural and ethylene-vinyl acetate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com