Sulfide solid electrolyte and preparation method and application thereof

A technology of sulfide electrolyte and solid electrolyte, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., and can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

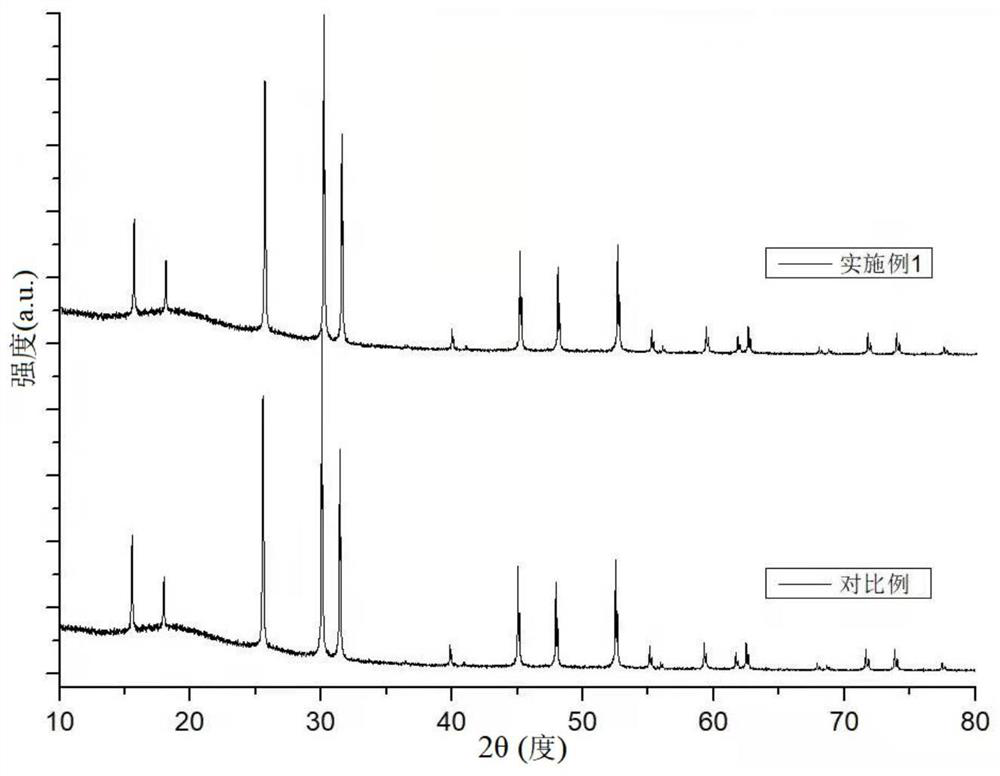

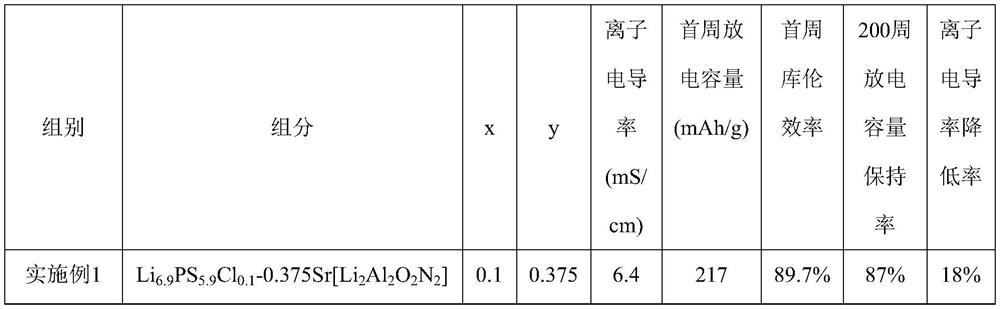

Embodiment 1

[0050] Li 6.9 P.S. 5.9 Cl 0.1 -0.375Sr[Li 2 Al 2 o 2 N 2 ] Electrolyte preparation: take by weighing 3.4mol Li by molar ratio 2 S, 0.5mol P 2 S 5 , 0.1mol LiCl and 0.375mol Sr[Li 2 Al 2 o 2 N2 ] placed in a ball mill jar, sealed and ball milled for mixing, the ball to material ratio was 20:1, the ball mill speed was 660rpm, the ball mill time was 25h, and the precursor was obtained after ball milling. Under the protection of argon atmosphere, the precursor was subjected to high-temperature heat treatment in a muffle furnace. The heat treatment temperature was 500 °C, the temperature rise rate was 2 °C / min, and the holding time was 10 h. After natural cooling, the crude electrolyte product was obtained. After grinding and sieving, a sulfide solid electrolyte is obtained.

[0051] Performance Testing:

[0052] Voltage window test: under the protection of argon atmosphere, the Li 6.9 P.S. 5.9 Cl 0.1 -0.375Sr[Li 2 al 2 o 2 N 2 ] The electrolyte and the conducti...

Embodiment 2

[0058] The difference from Example 1 is that when preparing a sulfide solid electrolyte, 3.3mol Li was weighed in molar ratio 2 S, 0.5mol P 2 S 5 , 0.2mol LiCl and 0.35mol Sr[Li 2 al 2 o 2 N 2 ].

Embodiment 3

[0060] The difference from Example 1 is that when preparing a sulfide solid electrolyte, 3.2mol Li is weighed in molar ratio 2 S, 0.5mol P 2 S 5 , 0.3mol LiCl and 0.325mol Sr[Li 2 al 2 o 2 N 2 ].

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com