Local strengthening device and method for multi-metal melting band-shaped saw blade

A local strengthening, multi-metal technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of reduced welding seam quality, welding dislocation, expensive equipment, etc., to improve welding quality, stable welding, and save welding. material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

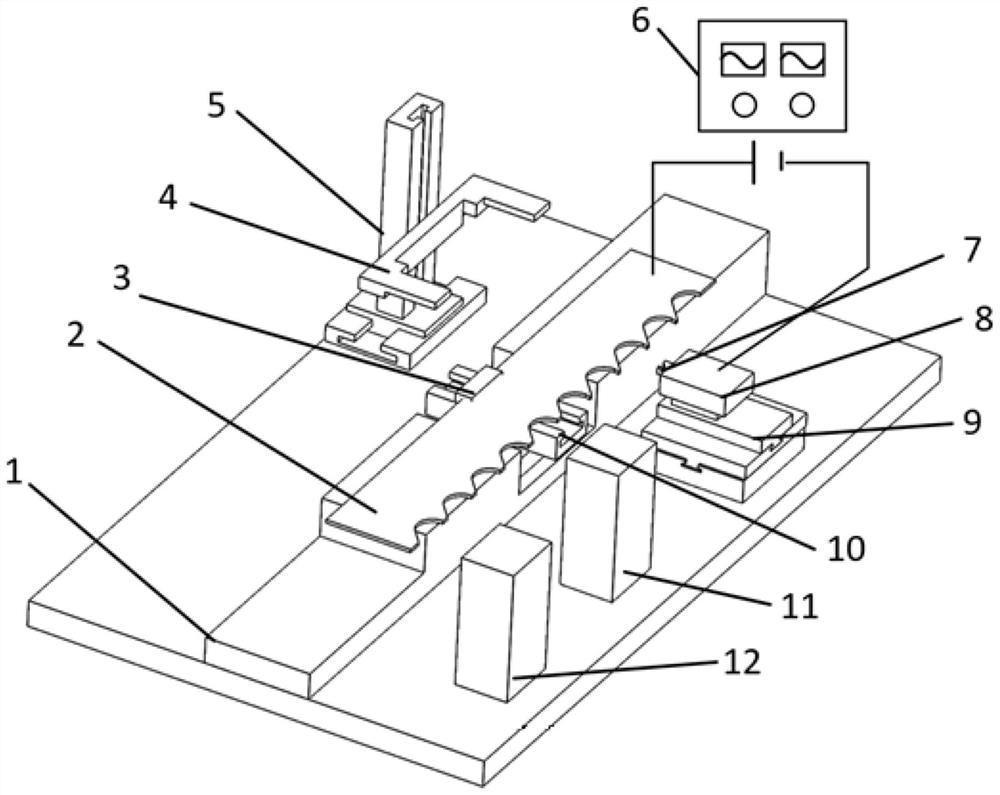

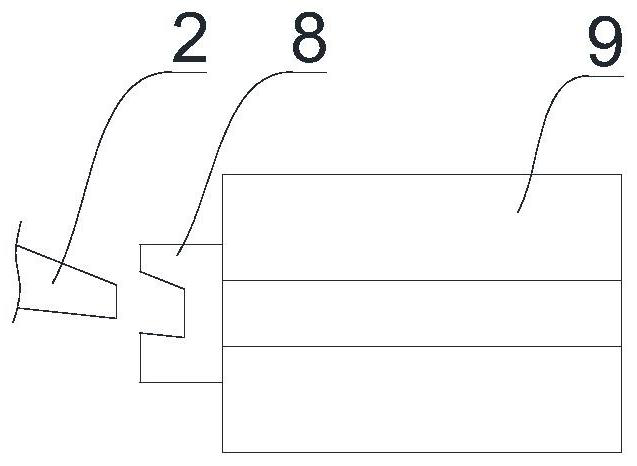

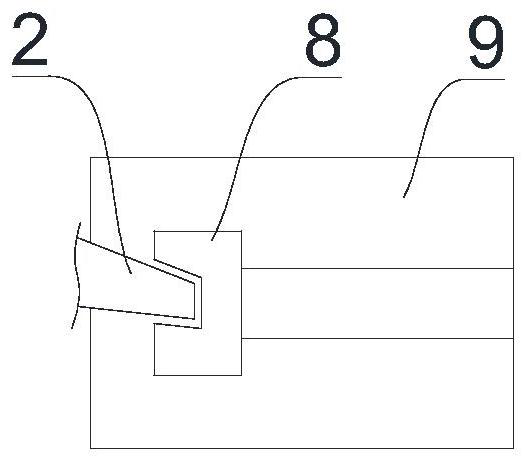

[0040] see figure 1 , the multi-metal fusion band saw blade local strengthening device of this embodiment includes a clamping mechanism for fixing and clamping the saw blade 2, a saw blade feeding mechanism for driving the saw blade 2 to move, and a nano-strengthening material for depositing The nano-electrophoretic strengthening mechanism on the tooth tip of the saw blade 2 and the dissimilar metal melting mechanism 12 for melting deposited nanomaterials from the tooth tip of the saw blade 2 .

[0041] The clamping mechanism includes a support plate 1 for supporting the saw blade 2, an electromagnetic pressing module 4 for pressing the saw blade 2, and a pressing driving mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com