Sizing material for improving stripping performance and construction applicability of S-CLF YC type coiled material

An applicability and sizing technology, which is applied in the direction of asphalt material adhesives, adhesives, adhesive types, etc., can solve the problems of unsatisfactory peel strength, etc., to solve the defects of peel strength, improve peel performance, and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

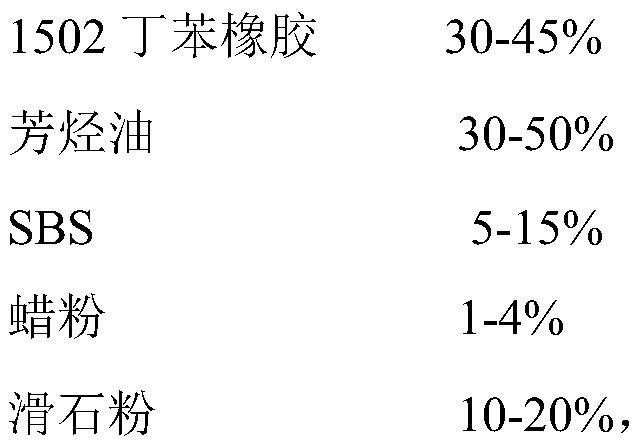

[0069] Preparation of butyl rubber

[0070] Heat 42kg of 150# aromatic hydrocarbon oil to 155°C, add 35kg of 1502 styrene-butadiene rubber and 5kg of SBS, then stir at a speed of 1000rpm for 30min, then increase the temperature of the mixed system to 180°C and stir at a speed of 1500rpm for 3h, then Add 2kg of wax powder and stir at a speed of 1500rpm for 0.5h, then grind until the system has no particles, finally add 16kg of 200 mesh talc powder and stir for 1h to make the system evenly mixed, and cool to room temperature to obtain butyl rubber.

preparation Embodiment 1

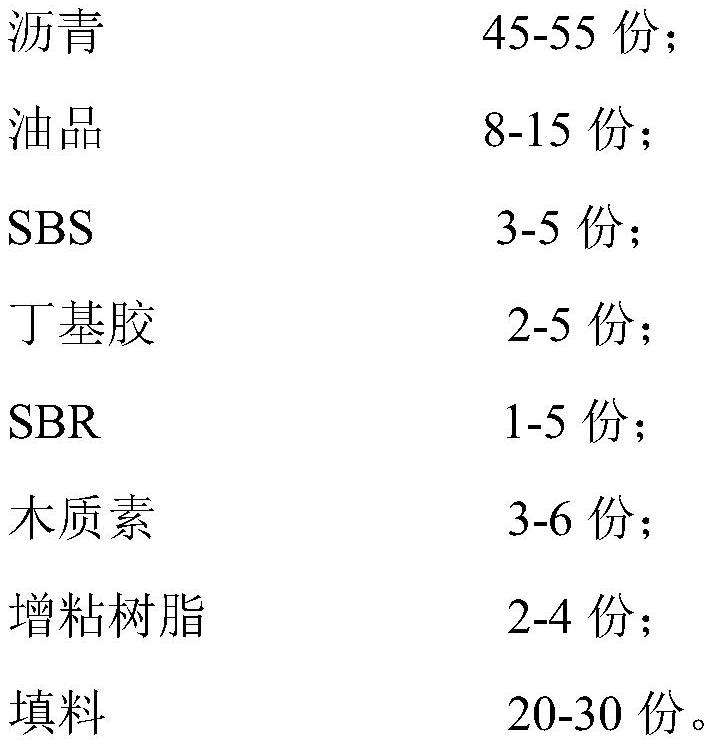

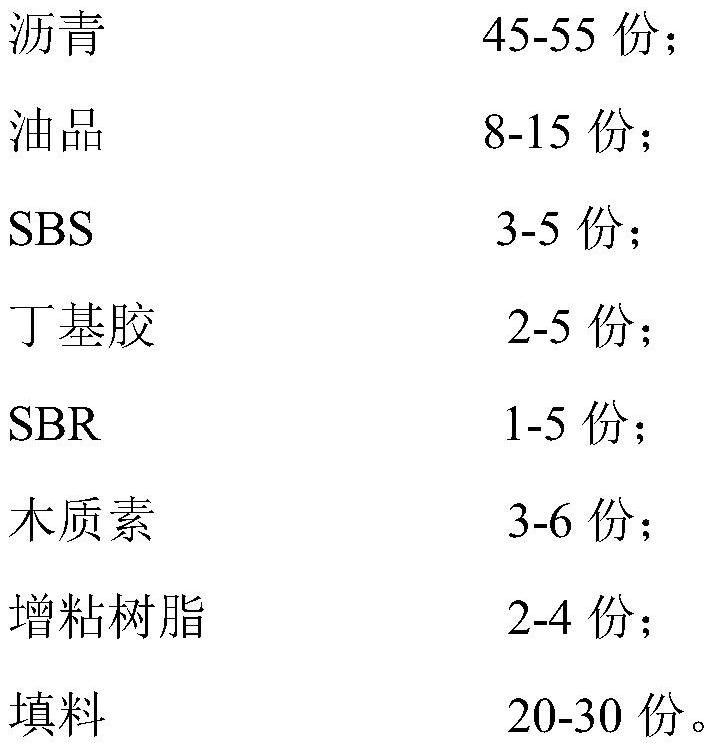

[0074] The specific composition of each raw material of the sizing material is shown in Table 1 below, and its preparation method includes the following steps.

[0075] (1) Mix the oil and asphalt evenly at 120°C;

[0076] (2) Heating the mixture obtained in the step (1) to 160° C., then adding SBS under agitation and mixing uniformly;

[0077] (3) Continue to add butyl rubber, SBR, lignin, tackifying resin and filler and stir for 100 minutes at a temperature of 165°C to make it evenly mixed;

[0078] (4) Grinding the mixed system obtained in the step (3) to a particle size of 0.3mm and continuing to stir for 5min;

[0079] (5) Add talcum powder to the mixed system after grinding in the step (4) and stir for 60 minutes to make the system evenly mixed, then cool down to room temperature and finally discharge to obtain the rubber compound of the present invention, which is recorded as A1.

preparation Embodiment 2

[0081] The specific composition of each raw material of the sizing material is shown in Table 1 below, and its preparation method includes the following steps.

[0082] (1) Mix the oil and asphalt evenly at 120°C;

[0083] (2) Heating the mixture obtained in the step (1) to 165° C., then adding SBS under agitation and mixing uniformly;

[0084] (3) Continue to add butyl rubber, SBR, lignin, tackifying resin and filler and stir for 120min at a temperature of 165°C to make it evenly mixed;

[0085] (4) Grinding the mixed system obtained in the step (3) to a particle size of 0.3 mm and continuing to stir for 10 min;

[0086] (5) Add talcum powder to the mixed system after grinding in the step (4) and stir for 60 minutes to make the system evenly mixed, then cool down to room temperature and finally discharge to obtain the rubber compound of the present invention, which is recorded as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com