High-efficiency crystalline silicon cell

A technology of crystalline silicon battery and crystalline silicon, which is applied in the direction of circuits, crystal growth, electrical components, etc., can solve the problems of affecting the effect of current derivation, large ohmic resistance, etc., achieve good passivation, reduce resistance, and improve cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

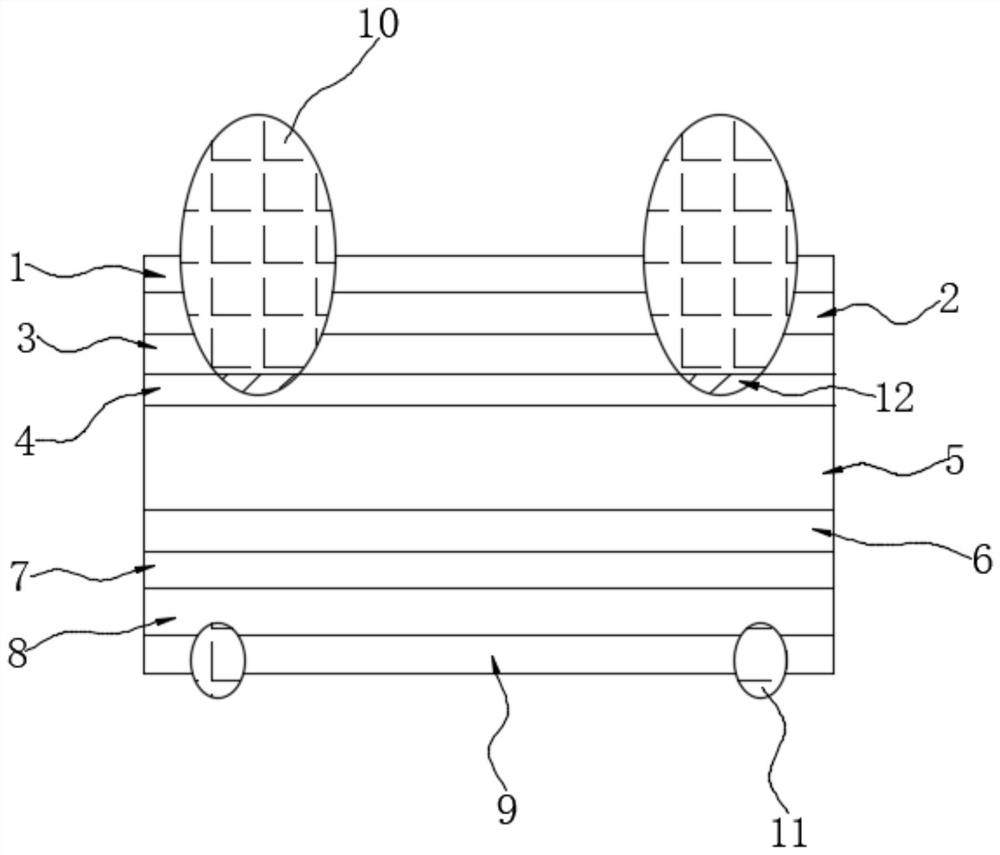

Image

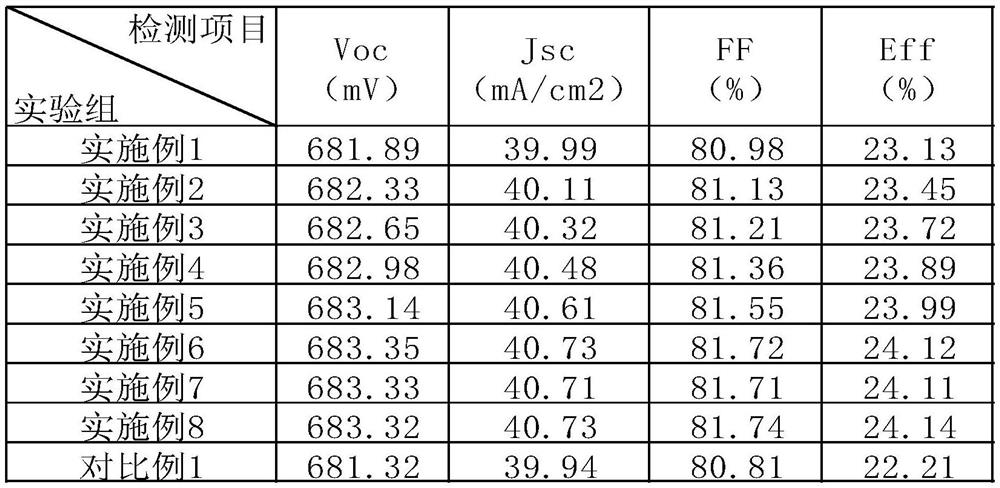

Examples

preparation example 1

[0045] Preparation Example 1: This preparation example provides a cleaning agent for cleaning P-type silicon wafers, which is prepared by stirring and dissolving components in the following mass ratios:

[0046] Potassium hydroxide: sodium silicate: potassium hydrogen phosphate: lauryl polyoxyethylene ether: deionized water = 5:6:1:7:100.

preparation example 2

[0047] Preparation Example 2: A P-type heavily doped emitter 12 provided in this preparation example is prepared by the following steps:

[0048] A1-1 Clean the P-type silicon wafer by RCA cleaning method for 30 minutes, then place the cleaned P-type silicon wafer in the deposition chamber, and then place the heating furnace cover on the deposition chamber, and raise the temperature until the P-type silicon wafer reaches 770°C;

[0049] A1-2 evacuate the deposition chamber to a vacuum through a vacuum pump, then pass nitrogen gas into the vacuum deposition chamber, repeat five times;

[0050] A1-3 performs ion nitriding treatment on the surface of the P-type silicon wafer through a DC pulse power supply with an average current of 3000A and a maximum peak current of 10000A;

[0051] A1-4 feeds phosphorus trioxide and oxygen into the deposition chamber, the flow of phosphorus trioxide is controlled at 600 sccm, and the flow of oxygen is controlled at 400 sccm for 7 minutes until...

preparation example 3

[0057] Preparation example 3: the difference between this preparation example and preparation example 2 is that this preparation example uses the cleaning agent prepared in preparation example 1 to clean the P-type silicon wafer for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com