Ti2AlNb-based alloy bar and preparation method and application thereof

A base alloy and rod technology, applied in the field of Ti2AlNb base alloy rod and its preparation, can solve the problems of high crack sensitivity, large deformation resistance, insufficient process plasticity, etc. Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

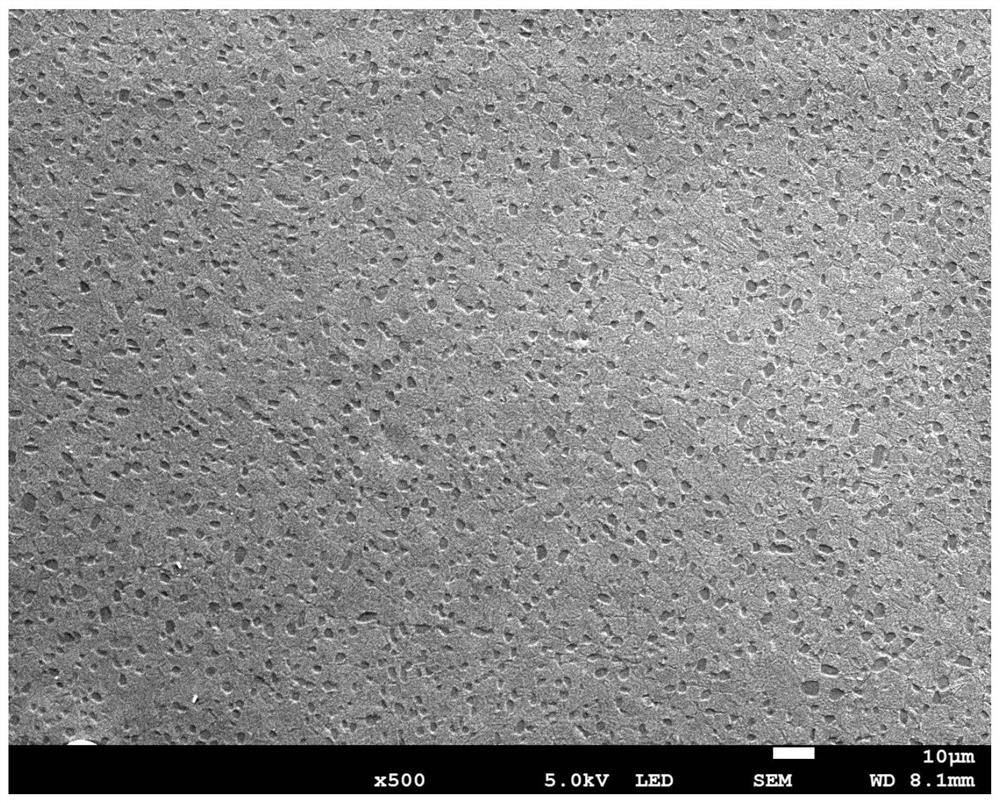

Image

Examples

preparation example Construction

[0028] Some embodiments of the present invention provide a Ti 2 A method for preparing an AlNb-based alloy rod, comprising the steps of:

[0029] (A) put Ti 2 AlNb-based alloy ingots are subjected to homogenization heat treatment at 1160-1200°C to obtain ingot blanks;

[0030] (B) heat-preserve the ingot billet at 1130-1170°C, and then extrude and draw to obtain a billet;

[0031] (C) Insulate the primary billet at 1020-1060°C, and then cool it to below 500°C with the furnace;

[0032] (D) heat-preserve the primary billet processed in step (C) at 960-980° C., and then extrude and elongate to obtain a secondary billet;

[0033] (E) After the secondary rod is subjected to solution heat treatment at 970-1000°C, it is then subjected to aging heat treatment at 780-820°C to obtain Ti 2 AlNb-based alloy rods.

[0034] In some embodiments of the present invention, in step (A), the temperature of homogenization heat treatment, typical but non-limiting, for example, can be 1160°C, ...

Embodiment 1

[0069] This example provides Ti 2 A method for preparing an AlNb-based alloy rod, comprising the steps of:

[0070] (A) will Ti 2 AlNb-based alloy ingots were heat-preserved at 1180°C for 38 hours, then peeled off the surface, removed the riser and the bottom. ingot billet;

[0071] (B) Brush the anti-oxidation coating (TB1200-16) with a thickness of 0.3mm on the surface of the ingot blank in order to resist 1200°C, spray glass powder with a thickness of 0.5mm, heat it at 1150°C for 3 hours, and then place it in an extrusion The press is extruded and drawn to obtain a billet, and the extrusion ratio is 4.5:1;

[0072] (C) Insulate the primary billet at 1040°C for 2 hours, and then cool it to 500°C with the furnace;

[0073] (D) peel off the bar blank after step (C) processing to The surface is coated with 1200°C anti-oxidation coating (TB1200-16) with a thickness of 0.3mm in turn, and after spraying glass powder with a thickness of 0.5mm, it is heat-preserved at 970°C...

Embodiment 2

[0077] This example provides Ti 2 A method for preparing an AlNb-based alloy rod, comprising the steps of:

[0078] (A) put Ti 2 AlNb based alloy After the ingot is heat-preserved at 1200°C for 35 hours, it is obtained by surface peeling, riser removal and bottom treatment in sequence. ingot billet;

[0079] (B) Brush the anti-oxidation coating (TB1200-16) with a thickness of 0.3mm on the surface of the ingot blank in order to resist 1200°C, spray glass powder with a thickness of 0.5mm, heat it at 1170°C for 2 hours, and then place it in an extrusion The press is extruded and drawn to obtain One billet, where the extrusion ratio is 4.5:1;

[0080] (C) Insulate the primary billet at 1060°C for 1 hour, and then cool it to 400°C with the furnace;

[0081] (D) peel off the bar blank after step (C) processing to The surface is coated with 1200°C anti-oxidation coating (TB1200-16) with a thickness of 0.3mm in turn, and after spraying glass powder with a thickness of 0.5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com