Low-temperature-curing high-temperature-resistant wave-absorbing coating and preparation method thereof

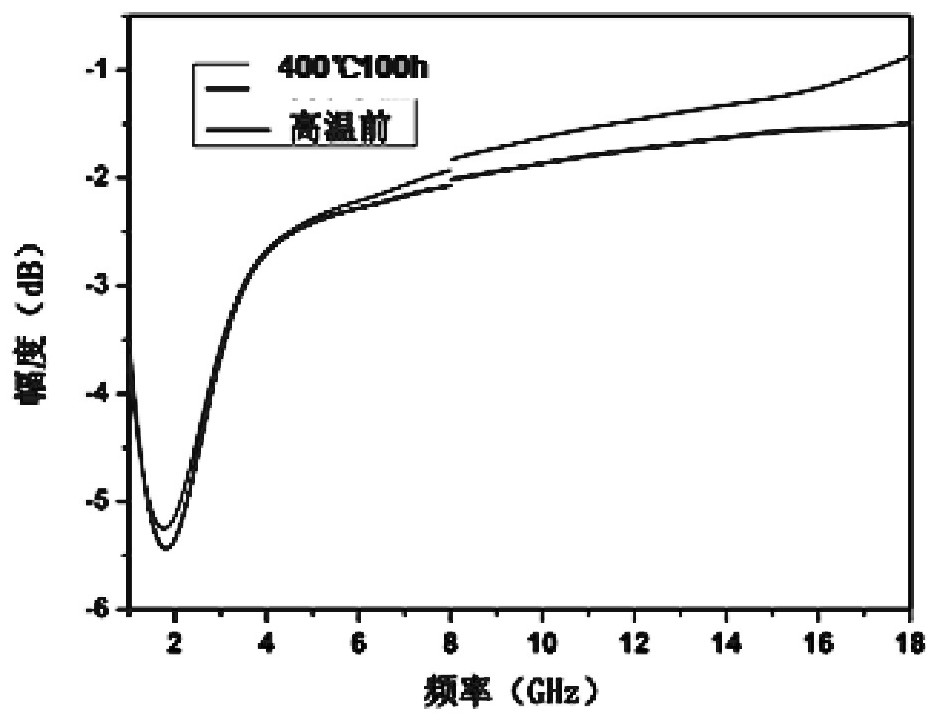

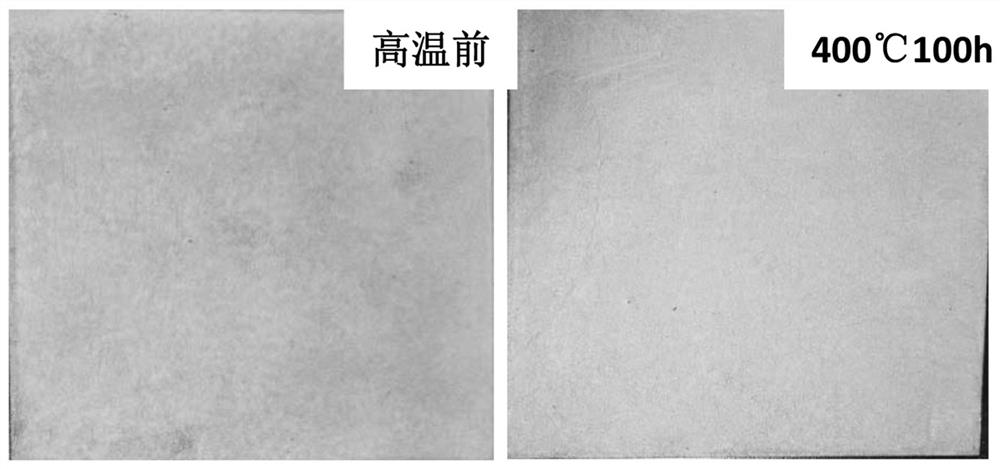

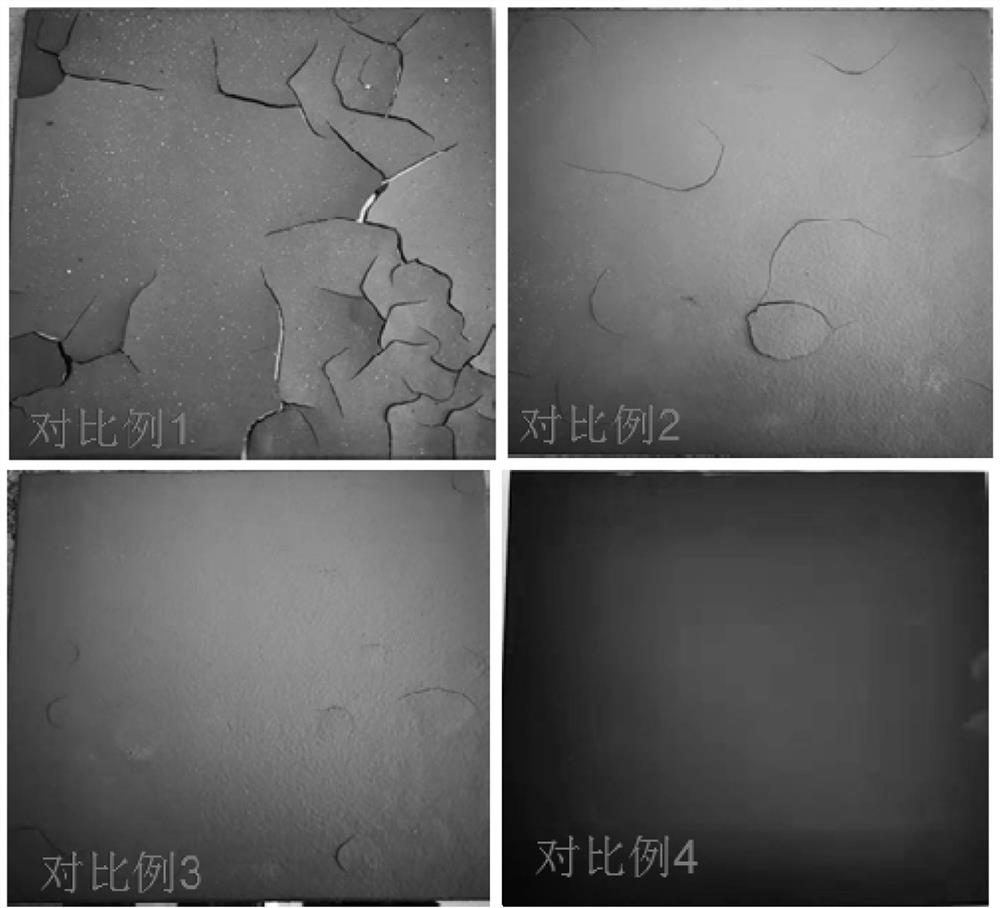

A wave-absorbing coating and high-temperature-resistant technology, which is applied to radiation-absorbing coatings and coatings, can solve the problems of unfavorable large-area construction, high-temperature coating materials do not have long-term high-temperature resistance, and performance degradation, so as to improve thermal matching performance , Increase thermal stability and prevent cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-temperature-resistant radar wave-absorbing coating cured at low temperature, comprising base material A component and auxiliary material B component, base material A component consists of 600g alloy powder absorbent, 250g methylphenyl silicone resin (phenyl / methyl =1.2, purchased from Zhonghao Chenguang Chemical Research Institute Co., Ltd.), 15g xylene, 5g n-butanol, 15g butyl acetate, 15g cyclohexanone, 1g silicon carbide whiskers with a diameter of 0.6 μm and a length of 10 μm to 20 μm, 0.5 g10μm in diameter, 0.5mm in length carbon fiber, 3.0g anti-settling agent, 1.5g leveling agent; curing agent B is 5g polymethylsilazane (n value is 15; purchased from Anhui Aiyota Silicone Oil Co., Ltd.)

[0035] Wherein the used alloy powder absorber utilizes atomic deposition technology to coat one deck ZnO on the alloy powder surface, the ZnO consumption is alloy powder 3%, the complex dielectric constant real part of gained alloy iron powder is 28, the complex dielectric...

Embodiment 2

[0051] A high temperature resistant radar wave-absorbing coating cured at low temperature, comprising base material A component and auxiliary material B component, base material A component consists of 650g alloy powder absorbent, 300g methyl phenyl silicone resin (phenyl / methyl The ratio is 1.3), 25g xylene, 20g cyclohexanone, 1g silicon carbide whiskers with a diameter of 0.6μm and a length of 10μm to 20μm, 0.5g of carbon fibers with a diameter of 10μm and a length of 0.5mm, 2.0g of anti-settling agent, and 1.5g of leveling agent composition; curing agent B is 5g polymethylsilazane (n value is 15; purchased from Anhui Aiyota Silicone Oil Co., Ltd.)

[0052] The alloy powder absorbent used in it uses atomic deposition technology to coat a layer of Al on the surface of the alloy powder. 2 o 3 (Al 2 o 3 The amount is 3wt% of the alloy powder), the real part of the complex permittivity of the obtained alloy iron powder is 26, the imaginary part of the complex permittivity is ...

Embodiment 3

[0055] A high-temperature-resistant radar wave-absorbing coating cured at low temperature, comprising base material A component and auxiliary material B component, base material A component consists of 550g alloy powder absorbent, 300g epoxy-modified methylphenyl silicone resin (benzene The base / methyl ratio is 1.2), 50g xylene, 50g butyl acetate, 45g cyclohexanone, 1g silicon carbide whiskers with a diameter of 0.6μm and a length of 10μm to 20μm, 0.5g of carbon fibers with a diameter of 10μm and a length of 0.5mm, 2.0 g anti-settling agent, 1.5g leveling agent; curing agent B is 5g polysilica nitrogen oligomer (n value is 20; purchased from Anhui Aiyota Silicone Oil Co., Ltd.)

[0056] The alloy powder absorbent used in it uses atomic deposition technology to coat a layer of Al on the surface of the alloy powder. 2 o 3 (Al 2 o 3 Consumption is 3% of the alloy powder), the real part of the complex permittivity of the obtained alloy iron powder is 26, the imaginary part of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com