Sandwich type solid composite electrolyte membrane as well as preparation method and application thereof

A composite electrolyte membrane and composite electrolyte technology, which is applied in the direction of solid electrolyte, electrolyte storage battery manufacturing, electrolyte, etc., can solve the problems of poor solid-solid contact wettability, low room temperature ionic conductivity, narrow electrochemical window, etc., and achieve good thermal stability and electrochemical stability, solving the effect of low ionic conductivity and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A sandwich-type solid-state composite electrolyte membrane, composed of a composite electrolyte infiltrated into a microporous diaphragm, wherein the composite electrolyte is composed of polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], bis(trifluoromethylsulfonic acid) Lithium amide (LiTFSI), N-methyl-N-butylpyrrolidine bis(trifluoromethylsulfonyl)imide (PYR 14 TFSI), and P(VDF-HFP), LiTFSI, PYR 14 The mass ratio of TFSI is 1:1:1.4.

[0052] In this embodiment, the microporous membrane is a polypropylene (PP) microporous membrane.

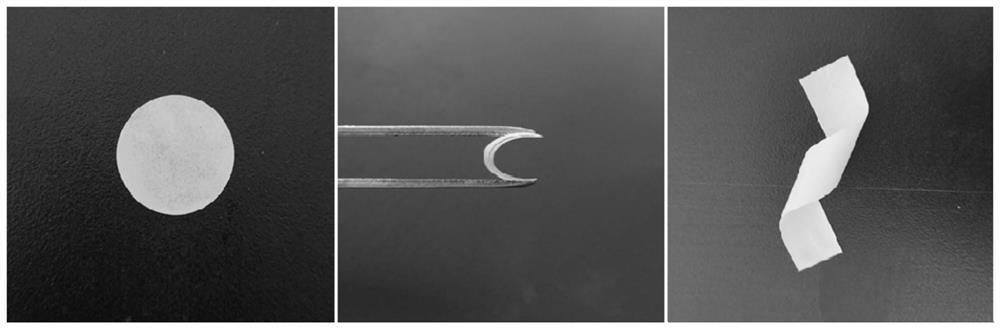

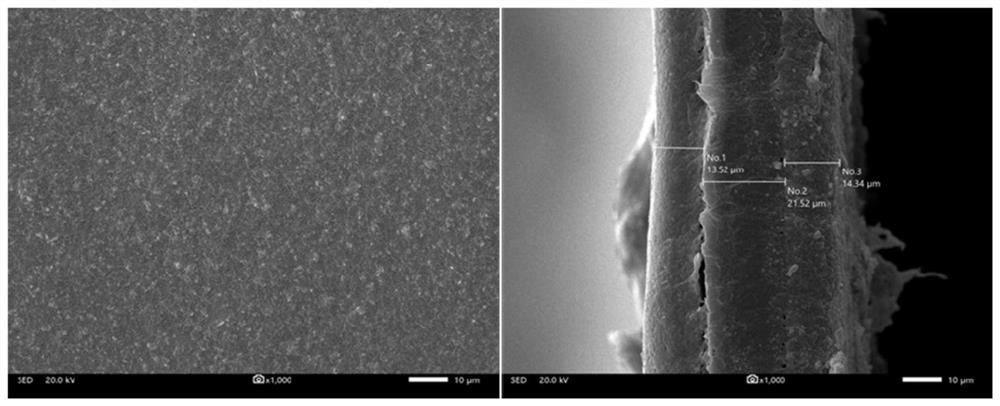

[0053] In this embodiment, the sandwich-type solid composite electrolyte membrane uses a gel-state composite electrolyte layer composed of a gel-state polymer electrolyte and a microporous diaphragm as the middle interlayer, and both sides of the middle interlayer are solid composite electrolyte layers, and the sandwich-type solid composite electrolyte The total thickness of the membrane is 50 μm, the thickness of the gel composit...

Embodiment 2

[0058] A sandwich-type solid composite electrolyte membrane, which is composed of a composite electrolyte infiltrated into a microporous diaphragm, wherein the composite electrolyte is composed of an inorganic ceramic solid electrolyte lithium lanthanum zirconium titanium oxide Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], lithium bis(trifluoromethanesulfonate)imide (LiTFSI), N-methyl-N-butylpyrrolidine bis(tri Fluoromethylsulfonyl)imide (PYR 14 TFSI), and P(VDF-HFP), LiTFSI, PYR 14 The mass ratio of TFSI and LLZTO is 1:1:1.4:0.5.

[0059] In this embodiment, the microporous membrane is a polypropylene (PP) microporous membrane.

[0060] In this embodiment, the sandwich-type solid composite electrolyte membrane uses a gel-state composite electrolyte layer composed of a gel-state polymer electrolyte and a microporous diaphragm as the middle interlayer, and both sides of the middle interlayer are solid composite electroly...

Embodiment 3

[0065] A sandwich-type solid composite electrolyte membrane, which is composed of a composite electrolyte infiltrated into a microporous diaphragm, wherein the composite electrolyte is composed of an inorganic ceramic solid electrolyte lithium lanthanum zirconium titanium oxide Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 (LLZTO), polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], lithium bis(trifluoromethanesulfonate)imide (LiTFSI), N-methyl-N-butylpyrrolidine bis(tri Fluoromethylsulfonyl)imide (PYR 14 TFSI), and P(VDF-HFP), LiTFSI, PYR 14 The mass ratio of TFSI and LLZTO is 1:1:1.4:1.

[0066] In this embodiment, the microporous membrane is a polypropylene (PP) microporous membrane.

[0067] In this embodiment, the sandwich-type solid composite electrolyte membrane uses a gel-state composite electrolyte layer composed of a gel-state polymer electrolyte and a microporous diaphragm as the middle interlayer, and both sides of the middle interlayer are solid composite electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com