Production process of 23-valent pneumococcal polysaccharide vaccine

A pneumococcal polysaccharide and pneumococcal technology, applied in the direction of bacteria, microorganisms, antibacterial drugs, etc., can solve the problems of increasing operational safety hazards, affecting product safety, polluting the production environment, etc., to prevent environmental and personnel hazards, Good safety and immunogenicity, good polysaccharide stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

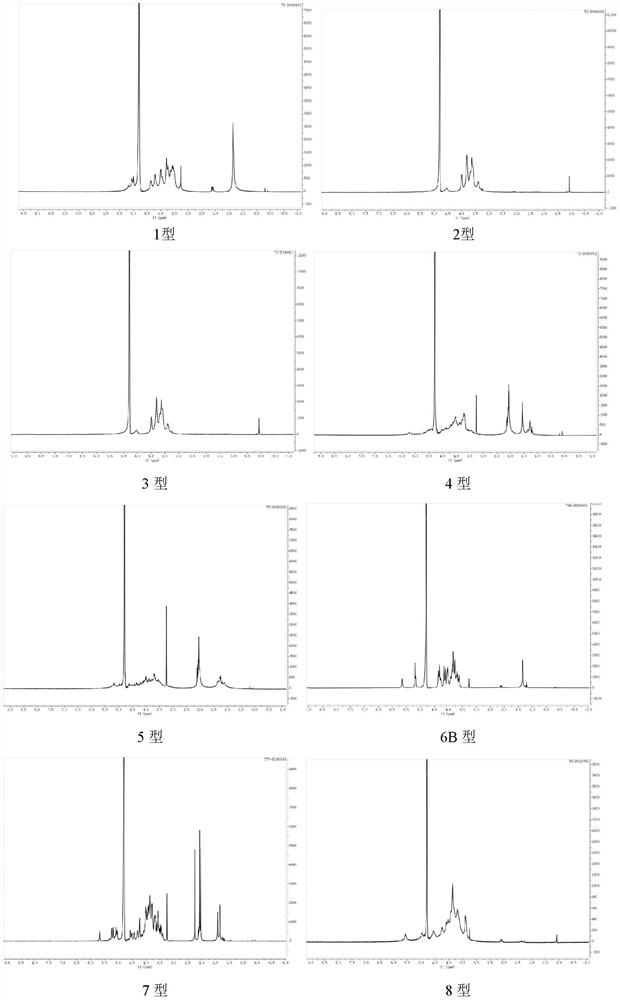

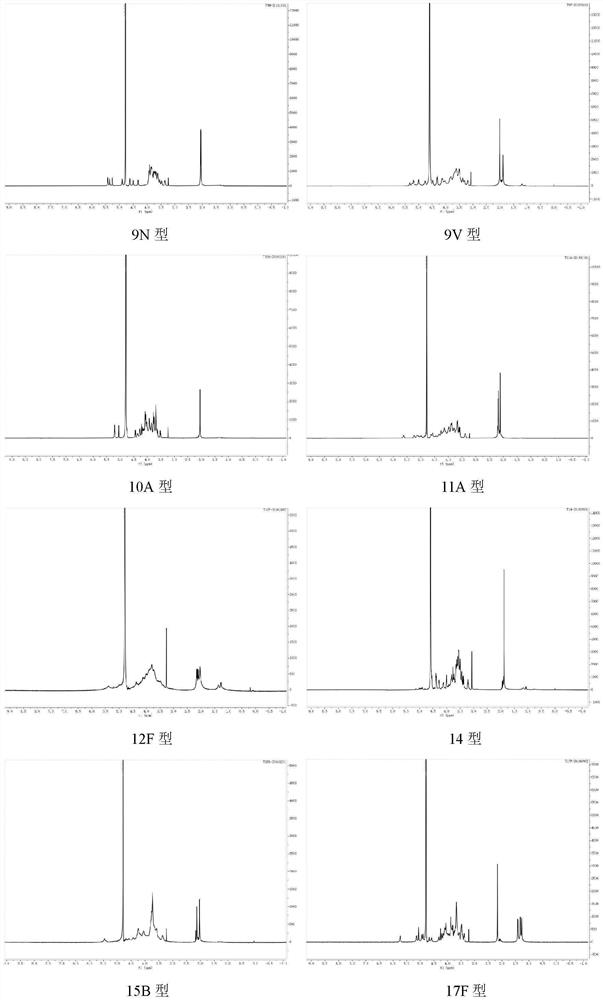

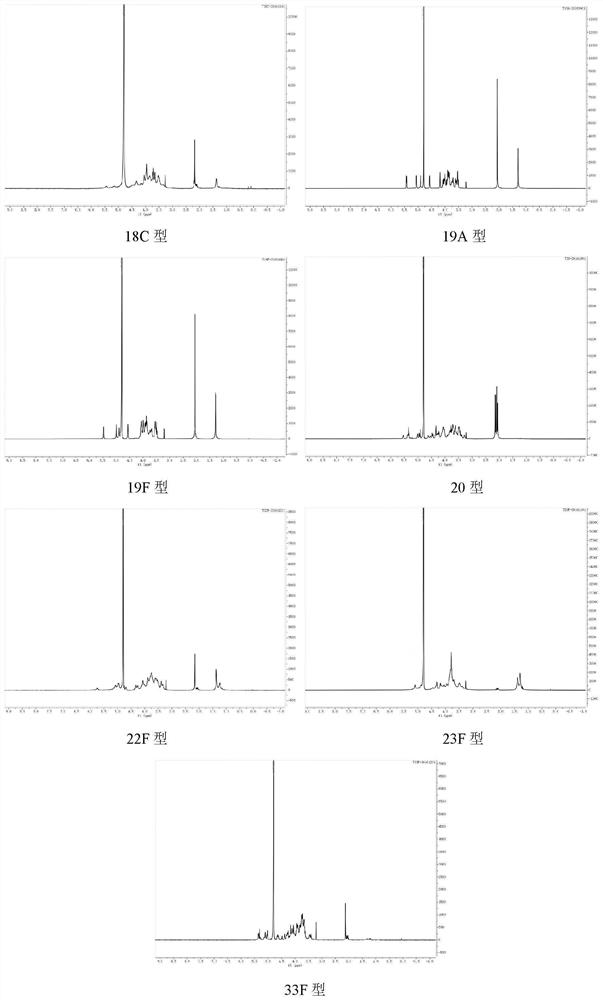

Image

Examples

Embodiment 1

[0069] Example 1: Comparison of fermentation cell concentration and polysaccharide yield under different glucose feed amounts (taking type 8 as an example)

[0070] (1) Use Columbia blood agar plate medium to open type 8 working strains, place at 37±1°C, 10% CO 2 Under the following conditions, a bacterial lawn can basically be formed within 24 hours. The revived strains are stored in liquid medium (about 1L) at 37±1°C, 4%~6%CO 2 Under the conditions of expansion and cultivation, a turbid bacterial liquid gradually formed within 12 hours. Inoculate the cultured bacterial liquid into 9L culture medium and scale up the culture. In 100L fermenter (90L culture medium), 1000L fermenter (400L culture medium) step by step scale-up culture. During the fermentation period, the culture conditions are controlled as follows: temperature 36-38°C, pH value 6.8-7.2, stirring speed 40-100 rpm, ventilation rate 0.1-0.4V / V / M, and fermentation time no more than 10 hours.

[0071] (2) During ...

Embodiment 2

[0074] Example 2: Effects of different lysing agent concentrations on bactericidal effect and polysaccharide antigenicity (taking types 3, 7F, and 18C as examples)

[0075] We chose DOC concentrations of 0.03%, 0.06%, 0.12% and 0.24%, observed the killing of Streptococcus pneumoniae by different concentrations of DOC at different reaction times, and carried out single diffusion experiments on agar plates prepared with corresponding antiserum , by observing the diameter of the diffusion ring to judge the change of polysaccharide antigenicity, the results are shown in the table below. It can be seen from the table: when the lysing agent concentration reaches 0.06% inactivation for 3 hours, the bacteria can be completely inactivated, and the bacteria liquid after the inactivation of the DOC concentration of 0.06%, 0.12% and 0.24%, the diameter of the diffusion ring of the single diffusion experiment is equivalent, It indicated that different concentrations of lysing agents had no...

Embodiment 3

[0079] Example 3: Comparison of the quality of pneumonia polysaccharides obtained by different lysis pH values (taking type 5 as an example)

[0080] Add sodium deoxycholate solution to the harvested type 5 pneumococcal polysaccharide culture solution to sterilize, the final concentration of sodium deoxycholate is 0.12%, and inactivate for more than 4 hours.

[0081] Take 30L of each of the above feed liquids, adjust the pH value to 3.5, 4.0, 4.5, 5.0, and 5.5 with acetic acid solution, and let it settle for 30 minutes; collect the supernatant by centrifugation, adjust the pH value to 6.9±0.2, and use it after clarification and filtration Less than 20 times the volume of 0.001mol / L phosphate buffer was concentrated by ultrafiltration to about 800-1000ml, and samples were taken to determine the polysaccharide content and protein content of the feed liquid. The results are shown in Table 3. As the pH of the lysing agent decreased, the proportion of proteoglycan in the feed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com